Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Supply chain issues are driving more companies to bring manufacturing back in-house. Parallel to this trend in automotive manufacturing is the rise of electric vehicles and increasing automation. Nidec Machine Tool (Wixom, Michigan), responding to the needs of the industry, is debuting the new GE15HS gear hobbing machine at IMTS 2022 in Booth 237036. Emphasizing high speed, precision and efficiency, the new machine produces gears for electric and hybrid cars, as well as for robotic and automation applications.

The GE15HS model is designed for gears with a maximum diameter of 150mm, widely used in automobiles and motorcycles. The high-speed, high-torque direct-drive motor*1 for the main cutting spindle provides a maximum spindle speed of 6,000 min-1*2 – three times faster than previous models. The high efficiency spindle holding the workpiece uses a special table that provides high rigidity and high-speed rotation to handle the necessary thrust load*3 for high efficiency machining. Cutting gears with Nidec super-hard cutting tools yields a surface roughness of less than Ra0.4*4; on par with gear grinding. Scott Knoy, Nidec Machine Tool America VP of Sales says, “The GE15HS provides process efficiency, eliminating the finishing process of shaving prior to heat treatment, thereby improving productivity and reducing processing cost.” A larger machine, the GE25HS, is also available.

Used in combination with Nidec Machine Tool’s new materials and coatings for cutting tools, the GE15HS model provides stable mass production with a maximum cutting speed of 1,500m/min.

More than 2,800 Nidec GE Series hobbing machines have been delivered and installed since the product launch in 2004.

The Nidec booth will also feature the ZI20A-G Generating Internal Gear Grinder. Hard finishing of internal ring gears in mass production is the final frontier for automotive and truck transmission applications. For quiet, smoothly meshing internal ring gears, the ZI20A-G utilizes patented technology for threaded wheel grinding. This breakthrough process delivers fast and very cost-effective production of internal ring gears for planetary gearsets.

Notes

*1: Direct-drive mechanism motors utilize the torque coming from a motor without passing through a gear box or other mechanism in order to control driving loss due to friction and reduce wear on parts.

*2: The “min-1” notation is a unit expressing the number of turns in one minute, synonymous with “revolutions/rotations per minute” (rpm).

*3: Thrust load is the force applied to the shaft in a horizontal (parallel) direction (the axial direction of the rotor).

*4: In-house machining result with GE15S (Workpiece data: Module 1.6mm; No. of teeth 19; helix angle: 24°; face width: 24mm)

| GE15HS | GE25HS | ||

| Max. workpiece diameter | 150㎜ | 250㎜ | |

| Max. cutting module | 4㎜ | 6㎜ | |

| Max. hob diameter | 90㎜ | 130㎜ | |

| Max. hob length | 190㎜ | 230㎜ | |

| Mount of hob shift | 150㎜ | 180㎜ | |

| Max. spindle rotation speed | 6,000 min-1 Direct drive mechanism | 2,300 min-1 | |

| Main motor rated output | 24 kW | 25 kW |

For more information, please contact:

Scott Knoy

Nidec Machine Tool America LLC

46992 Liberty Drive

Wixom, MI 49393

248-669-6136

www.nidec-machinetoolamerica.com

Demand for mass production of high-precision gears is continuing to rise with the shift to electrification of vehicles. With the need for improvements in NVH and fuel efficiency, plus the move toward low-cost manufacturing, Nidec Machine Tool, with its expertise in both gear machine tools and cutting tools, offers a full lineup of gear production machines. By delivering precision cutting tools and processing solutions to achieve high-precision, high-efficiency processing, Nidec Machine Tool provides comprehensive support for manufacturing in a wide variety of industries.

Continue reading

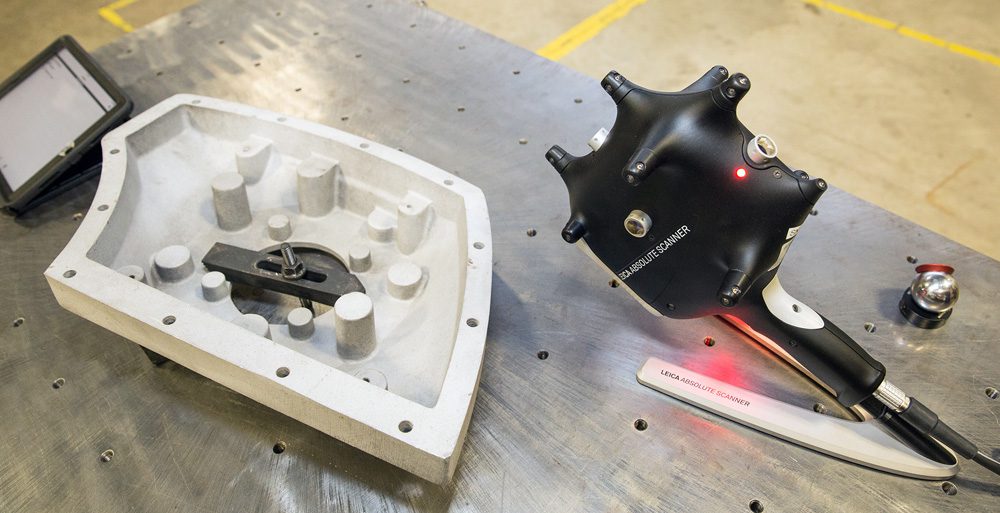

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, was at POWERGEN International with In-Place Machining Company (IPM) and Oasis Alignment Services: A Division of In-Place Machining Company in booth 5508. Representatives from each company were on hand to offer solutions for the thermal, hydro, nuclear, wind and diesel industries.

Located at the Kay Bailey Hutchinson Convention Center in Dallas, Texas, the show ran from May 23 to May 25. POWERGEN is the largest network and business hub for electricity generators and solution providers engaged in power generation. Power producers, utilities, EPCs, consultants, OEMs and large-scale energy users gather to experience unparalleled education, peer-to-peer networking and solutions from top providers.

Exact Metrology displayed the Hexagon 825 and the Leica AT960 Tracker. Also known as the ROMER Absolute Arm 7-axis, it delivers tactile probing and laser scanning in a uniquely ergonomic package. With usability central to its design, the articulating measuring arm offers ease of movement and ease of measurement. Built-in versatility is part of a uniquely modular wrist design that features configurable grip shapes and sizes. Additional features include an on-wrist display that puts control and results in the hands of the user and a wide range of accessories from probe tips to laser scanners to complete measurement systems. This leads to a productive arm delivering high-accuracy measurement results easier and faster than before.

The Leica AT960 is a robust, all-in-one laser tracker that fits in a single flight case. Offering high-speed dynamic measurement as standard, it is a complete solution for six degrees of freedom (6DoF) probing, scanning and automated inspection as well as reflector measurement. Featuring wireless communication and a battery operation option, the integrated-technology design of the AT960 reduces setup time drastically. The Leica Absolute Interferometer (AIFM) enables accurate high-speed measurement of a moving target, while the innovative PowerLock function ensures an interrupted beam is instantly re-established without user intervention, reducing operator workload and training requirements. Intuitive touch-screen controls minimize the potential for user error, thus saving time, effort and money.

Dean Solberg, Vice President of Metrology Sales and Services at Exact Metrology and Karan Singh, Sales Engineer were at the show. In-Place Machining Company personnel in attendance included Noel Brekas, Northeast Regional Sales Manager, Paul Parry, Outside Sales Manager and Bart Rierson, Field Engineer. Bruce Littlefield, Key Account Manager from OASIS Alignment Services was also in the booth.

Dean Solberg expressed his excitement at having IPM and OASIS Alignment Services join Exact at POWERGEN. “With the recent acquisitions of Exact Metrology and OASIS Alignment Services, the IPM Measurement Group now provides expanded 3D scanning solutions, contract metrology services, and precision machine alignment capabilities. With 18 locations across the U.S. and Canada and over 120 field engineers and technicians that travel worldwide, we are truly your one source for on-site excellence.”

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company

OASIS Alignment Services: A Division of In-Place Machining Company, provides 3-Dimensional Metrology Services, Precision Alignment Inspections and Diagnostics and Mechanical Services across a wide range of industries including aerospace, automotive, power generation, shipbuilding, pulp and paper, converting, printing, plastics, textiles and more. OASIS has completed thousands of successful projects since its inception in 1982 and continues to set industry standards in alignment procedures, specialized tooling and reporting techniques. OASIS operates service centers in New Hampshire, North Carolina, Florida, Ohio, Wisconsin, California, Washington, and Ontario and Québec, Canada. For more visit www.oasisalignment.com

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com

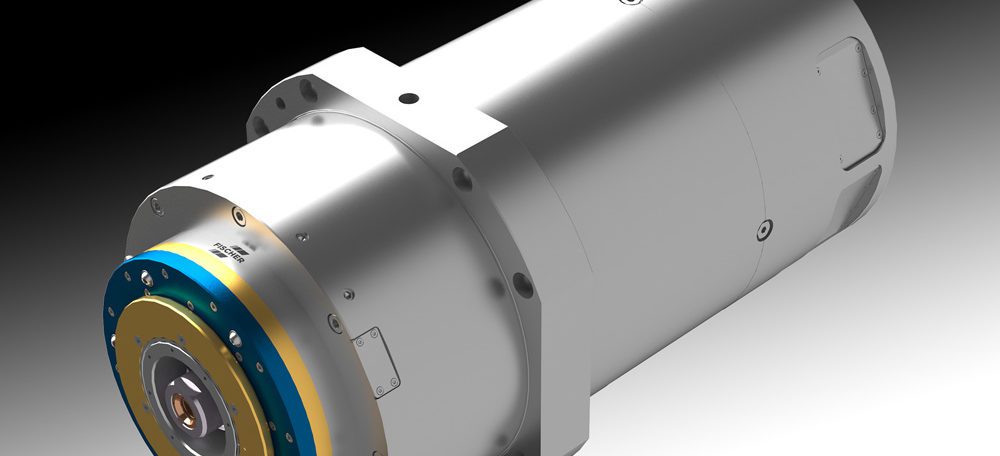

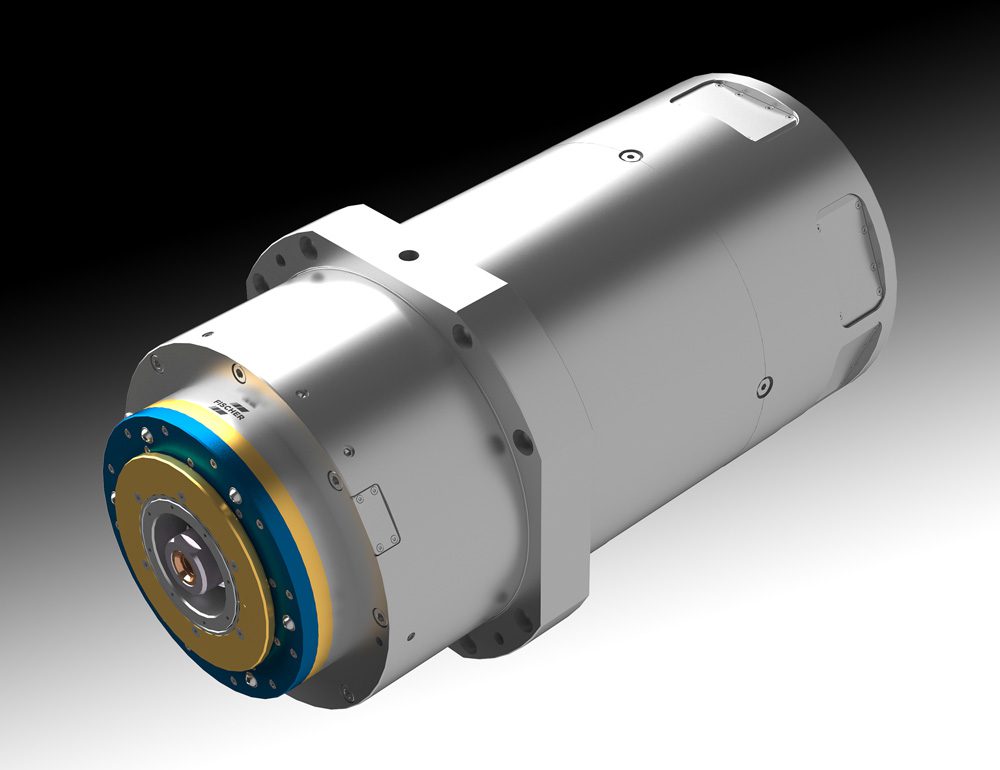

Under the theme of “Technology Leader with Perfect Rotation,” FISCHER will showcase its D27 milling head paired with their newest technology for high-volume material removal in their MFW-2714/20 HSK-100 at IMTS 2022, Booth 237470, in Chicago, September 12-17. With 80 years of experience in high-performance machine tool spindle design, in-house manufacturing and best-in-class repair services, the company will present this new design, a combination milling head-milling spindle that provides maximum stability and precision for aerospace and other 5-axis machining operations.

Features on this advanced milling head and spindle combination include:

Perfect Rotation – Powerful, heavy milling while maintaining accuracy and repeatability requires perfect rotation in not only the spindle but also the milling head. This is achieved by precisely calculated mono-block structures made of high-grade cast iron paired with two cross-roller bearings for A-axis and YRT for C-axis provide the highest load capacity to handle the cutting forces in all directions during power milling.

Technology Leader – Always developing and implementing industry leading technology with customer focus is a FISCHER operating principle. Highest power, highest speed, highest precision to provide our customers with the leading edge.

New Milling Head – The FISCHER D27 milling head is specifically designed for the most powerful, as well as long-tooled, milling applications. With the high power and torque output, the D27 milling head still maintains its sleek symmetric outline while being dynamic and robust. To ensure accuracy and repeatability, the unit incorporates direct optical encoders, dual motors and dual clamps on the A-axis. The D27 milling head is intentionally designed to utilize the maximum power and torque capacity of our FISCHER 275mm spindles for the highest chip removal rate.

New Spindle Design – Paired with the D27 is the spindle type MFW-2714/20 HSK-100. FISCHER is raising the bar for highest volume chip removal. The unit offers machine builders and end users a robust HSK-100 interface, max speed of 20,000 rpm and an S1 continuous power rating of 200kW.

Visit FISCHER at IMTS 2022 in the North building, Level 3, Booth 237470.

For more information, please contact:

FISCHER USA, INC.

3715 Blue River Avenue

Racine, WI 53405

www.fischerspindle.com

Phone: 262-632-6173

Attention: Doug Kranz, Vice President, Sales & Marketing

Email: Doug.Kranz@fischerspindle.com

FISCHER USA, Inc. is the North American operation of FISCHER Spindle Group AG, based in Switzerland. The company builds and markets milling head and spindle combinations, performs spindle analysis, repair and testing at its headquarters in Racine, Wisconsin.

Continue reading

HIWIN Corporation, a leader in motion control and system technology, will feature families of precision motion control components this year at IMTS, with their Torque Motor Rotary Tables, (TMRT), as a highlight of their booth. IMTS will be held September 12-17, 2022, in Chicago.

Designed for machine tool OEM’s and retrofitters, the TMRT series enables 3 axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even 5 axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The TMRT series is compatible with most major CNC brands, making control integration straightforward.

HIWIN Torque Motor Rotary Tables utilize HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Since 1992, HIWIN Corporation has focused on components, systems and expertise in the motion control industry. HIWIN will be celebrating their 30th anniversary in America at IMTS

Visit Hiwin at IMTS 2022 in the East building, Level 3, booth 134514.

For more information, please contact:

Andy Choi, Product Specialist

HIWIN CORPORATION

12455 Jim Dahmer Road

Huntley, IL 60142

224-523-2319

Email: a.choi@hiwin.us

The company offers an expanded line of live and static tools for Swiss-Type CNC Automatic Lathes

Platinum Tooling Technologies, Inc., the exclusive importer of Heimatec live tools, angle heads, and multi-spindle heads, is excited to announce their extended product offering to the current Citizen tool program. In addition to the standard live and static tools, they will offer 1:4 speed increasers for the most current Citizen machine models. Designed to optimize the machine’s parameters, these precision tools are efficient and cost effective.

Originally developed for the manufacture of precision parts in the watch industry, Swiss-type CNC Automatic Lathes are now widely used throughout the industry to produce automotive components, screws and pins for the medical industry, and precision parts for electrical engineering.

Platinum Tooling and Heimatec’s goal during the development of this line was to construct a series of tools that would offer the greatest possible processing quality and longest service life, while additionally enhancing the machine’s capabilities with the use of speed increasers. To achieve this, Heimatec incorporates the highest quality bearings, ground gear components, spindles, and housings to produce superior tools with maximum rigidity.

In addition to Citizen, Platinum Tooling is constantly striving to expand their tooling programs to include superior quality products to enhance machining operations, increase productivity, and create cost savings opportunities.

Visit Platinum Tooling at IMTS 2022 at Booth 432245

For more information and literature, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs worldwide, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts, and AMF Tooling for North America.

Continue reading

All the features and reliability of Suhner technology at an affordable price,

For the OEM or end user…MADE IN AMERICA

Suhner introduces the ECONOmaster® line of drilling units, affordably priced at under $3500 for the basic unit, in stock for immediate delivery or customizable to suit the particular operation. This economical solution is ideal for multiple materials such as light metal, wood, composite, plastic and foam. Because these units are entirely produced at the Suhner factory in Rome, Georgia, response times for delivery and customized construction are minimal, according to Division Manager Lee Coleman. “We recognized the need to bring our global technology to a local level, here in America, and the ECONOmaster® is a key step in that process.” Suhner is based in Brugg, Switzerland, with plants and distribution centers worldwide.

The ECONOmaster® drilling unit features low power and air consumption, adjustable motor housing, adjustable total stroke up to 4”, hydraulic feed control cylinder, J33 taper spindle end, 0-1/2” drill chuck, electric front & rear position limit switches, belt tensioner and chrome-plated quill. Basic unit weight is 45 lbs.

Other key features include adjustable feed stroke of ½-3”, 400 lb. thrust at 85 psi, operating pressures to 110 psi, TEFC/IP56 protection, standard 230V/460V, concentricity of .003” TIR, speed ranges to 9600 RPM and an air connection retract/advance of 1/8”-27 NPT.

ECONOmaster® drilling units can be supplied with an adjustable stand, inline vertical configuration and multiple spindle heads for medium-duty production drilling, with many other spindle options and toolholders available. Please consult the factory in Rome, Georgia.

For more information, please contact:

Suhner Manufacturing, Inc.

Machining Division

25 Anderson Road SE

Rome, GA 30161 USA

Phone: 706-235-8046

Machining.us@suhner.com

ECONOmaster® value-priced drilling units from Suhner are suitable for medium-duty production cutting of light metal, wood, composite, foam and plastic materials. Standard and custom models available to suit all applications and mounting requirements.

Continue reading

As a strictly industrial agency with 30 clients who develop and manufacture all types of machines, equipment, software, communications and other stuff to run industry worldwide, we participate in several dozen trade shows each year. Well, we did until Mr. Covid came to town. That two-year hiatus was not only costly, it also created a silo mentality for both our clients and us, something that’s counter-productive in many ways, especially to the creative process. Human interaction…and NOT on zoom…is most necessary to drive creativity, whether you’re working on a machine tool, a motor or a full-page ad message.

(more…) Continue reading

Embarking on the digital journey with SINUMERIK ONE reduces product development cost and time-to-market, plus the company will display an expanded hardware, software and service portfolio to help pave the way towards digitalization

During IMTS 2022, Siemens will present its hardware automation and software technology portfolio, highlighted by the first-ever, digital-native CNC platform, SINUMERIK ONE, for machine tool applications. In addition, Siemens will present its solutions and services for the industrialization of additive manufacturing. In booths 133346 and 433028, the company will highlight how machine users can quickly and easily embark on their digitalization journeys — from part concept to design, digital twin to simulation, part and machine production, as well as total integration of these processes into the digital enterprise for job shops and production departments alike.

In the Controls and CAD-CAM pavilion (East Hall) in booth 133346, Siemens will demonstrate the end-to-end production and installation of a transmission housing and bracket for the eRod, an autonomous electric vehicle that will be in the booth for visitor inspection. The parts are made by additive and subtractive machining processes. At every stage of the part’s development, including machining, display kiosks will take visitors through the digital process. From the popular Siemens NX CAM design software, which enables the use of 3D models, data and processes to seamlessly connect planning and shopfloor operations on a digital thread to the powerful SINUMERIK ONE, the digital-native CNC that permits a digital twin of the machine and its full operation in production, Siemens has streamlined machine shop operations as well as leading automotive, aerospace, off-highway and medical part production facilities worldwide.

In the Additive pavilion (West Hall) in booth 433028, Siemens will demonstrate its CNC implementation into the additive and additive / subtractive production worlds, displaying part production processes from design to the finished part. Visitors can discuss their manufacturing challenges with Siemens to determine the optimum method of part design and manufacturing, whether one-off or full production runs, all performed with digitalization methods for validation and time / cost containment.

Additional highlights of the Siemens booths will include:

For specific product information and inquiries, send an e-mail to: cnc.marketing.us@siemens.com

Follow us on Social Media:

www.twitter.com/siemens_cnc_us www.facebook.com/Siemens.CNC.US

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

Exact Metrology: A Division of In-Place Machining Company, a comprehensive 3D metrology service provider and hardware sales company, is excited to announce their upcoming Technology Fair in Moline, Illinois and Brookfield, Wisconsin. Both events give visitors the opportunity to witness 3D scanning demonstrations, discuss industry improvements and much more.

Topics covered will include methods of data capture, the latest advancements in articulated arm technology, new developments in Polyworks2022® and Design X™ 2022, as well as reverse engineering. Attendees will also have the opportunity to chat with representatives from Exact Metrology’s parent company, In-Place Machining Company and its sister division, OASIS Alignment Services.

The Absolute Arm from Hexagon Metrology, which will be displayed at both fairs, has an IP54 protection rating. This is a market first for portable measuring arms and it comes with an environment-related improvement that sees the system’s maximum operating temperature increased to 45°C. There are also improvements to the functionality of the Absolute Arm wrist display, now upgraded to a touchscreen, and the RDS software that drives it. With the CP-W Wireless Pack, also IP54 rated, every Absolute Arm boasts full-speed performance all of the time, even when high-speed scanning over a wireless connection.

Polyworks2022® digital platform now facilitates multipiece inspection when CAD data isn’t available and introduces a universal data hub. Digital connectivity is improved with the deployment of global metadata management strategies and the programming of alerts that automatically detect failing dimensions. The collaboration between probing operators and measurement hardware has reached a higher level with mixed reality display technology that enhances the operators’ perception of 3D metrology. Lastly, the software released an API to query data from its data management solution and inject it into third-party software applications

Geomagic® Design X™ combines robust 3D scan processing with complete CAD design functionality. New and enhanced features are Selective Surfacing, separate meshes, updated files I/O, etc. Selective Surfacing features simplify the hybrid modeling process, providing easy workflows for traditionally difficult parts. Separate meshes is a new function that easily separates a multibody mesh object into independent entities for improved handling of additive files and assemblies. File import capabilities have been updated, providing the latest connectivity to scanning devices and updated LiveTransfer to CAD compatibility.

A breakout session will be hosted by Tec-Ease. Based in Fredonia, New York, the company provides high quality products and training for the manufacturing industry in the areas of Geometric Dimensioning and Tolerencing (GD&T), Print Reading and Tolerance Stack-Ups. Their session will cover the foundations of GD&T, why it’s important and use of envelopes in GD&T. There will also be a breakout session from Innovmetric to discuss updates in Polyworks2022® and one from 3D Systems, concerning updates for Geomagic® Design X™.

Brookfield’s Technology Fair is scheduled on June 15, between 9 am and 3 pm CST. The Moline Technology Fair will take place the following week, June 23 at the same time.

Free admission and refreshments/lunch are included for both.

Sign up for either or both of these by clicking:

Brookfield: https://www.eventbrite.com/e/exact-metrology-brookfield-wi-open-house-2022-tickets-318851612757

Moline: https://www.eventbrite.com/e/exact-metrology-moline-il-open-house-2022-tickets-319868213437

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company

OASIS Alignment Services: A Division of In-Place Machining Company, provides 3-Dimensional Metrology Services, Precision Alignment Inspections and Diagnostics and Mechanical Services across a wide range of industries including aerospace, automotive, power generation, shipbuilding, pulp and paper, converting, printing, plastics, textiles and more. OASIS has completed thousands of successful projects since its inception in 1982 and continues to set industry standards in alignment procedures, specialized tooling and reporting techniques. OASIS operates service centers in New Hampshire, North Carolina, Florida, Ohio, Wisconsin, California, Washington, and Ontario and Québec, Canada. For more visit www.oasisalignment.com

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com

In an industry moving at lightning speed, ANCA Tool of the Year (TOTY) celebrates the deep experience and creativity of the craftspeople who create the next generation of cutting tools

Now in its fifth year, ANCA’s industry-first competition launched for 2022 at the first-ever GrindingHub – the new industry meeting place for grinding technology in Stuttgart, Germany. The “Oscars” of the Cutting Tool industry, participants and winners in this prestigious contest achieve important brand recognition as well as cash and other prizes. Last year, the awards achieved a total digital audience reach of 8.1 million readers via the media with 37 global entries seen by over 202,480 fans generating over 200,000 engagements on social media.

Patrick Boland, Co-Founder at ANCA comments, “Every year brings yet another step change in technology that enables cutting tool makers to increase their sophistication in designing and manufacturing products. This year, we brought our ANCA Integrated Manufacturing System (AIMS) to GrindingHub, a huge leap in technology to create the factory of the future. Efficient, automated and operating 24/7, the AIMS factory uses modular program scripts, remote access and cutting-edge machines to operate at maximum efficiency.”

“During my 40-plus years, ANCA has consistently led the industry in designing advanced technology. For example, in 1986, we launched the TG4 – the first machine ever to automate the measurement of tool geometry, thereby making regrinding possible. Reviewing Tool of the Year entries, I am always in awe of the passion and talent of customers who push our machines to their limits and create tooling masterpieces.”

John Saunders from Saunders Machine Works and founder of YouTube channel NYC CNC

and first time TOTY judge said, “Seeing the creative use of custom tooling is amazing. Being able to reduce setups, improve cycle time or even eliminate tools with the use of modern, custom carbide is something all shops should consider. It’s an honor to be part of this competition and I hope it can help raise awareness about the benefits of a well-designed and executed cutting tool.”

ANCA Tool of the Year 2022

ANCA’s Tool of the Year customers can submit their favorite tool, with the winners being judged and announced live at IMTS. There will be two competition categories to recognize both the functionality and creativity of cutting tool manufacturers.

The winner of #MadeonANCA receives $10,000 AUD worth of ANCA innovations for parts, accessories or software that fit the winner’s grinding needs or a trip to ANCA’s headquarters in Melbourne, Australia. This amazing prize further includes access as an ANCA VIP to exclusive opportunities with our ANCA tool experts. The winner of the most innovative virtual tool will receive a full CIM software package.

Submissions are open from May 17th to August 8th, 2022.

The competition will be based on the passion and the craft of tool making and celebrate our highly skilled tool grinding community.

Judging panel

At IMTS, the top five finalist tools will be judged on the following criteria:

For further information, please contact:

Johanna Boland

Group Corporate Communications Manager

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia, where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA, as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading