Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

FOREST CITY GEAR EXPANDS BLANKING DEPARTMENT

Leading gear manufacturer acquires three new Haas turning centers to produce “donuts” for its gearmaking operations

Forest City Gear’s blanking department now boasts a Haas ST-10 and two ST-20 Turning Centers. These machines were acquired recently to improve the throughput at Forest City Gear, a world leader in fine- and medium-pitch gear and spline work. The machines are used primarily for production of “donuts”, the near net blanks used in the company’s gearmaking operations.

Roscoe, IL-Forest City Gear has acquired three Haas turning centers to improve the throughput at its gearmaking facility. The company has made this investment, according to President Wendy Young, “…because we needed to better control our throughput and reduce the time to start up jobs. We were experiencing some severe delays from outside vendors and we saw problems on the horizon from such bottlenecks. Our company is always on the lookout for such conditions, because both our quality and our delivery protocols are vital to our success with current and potential customers in the world market.” These new machines will be used in the company’s Blanking Department, headed by Tommy Kalt, who detailed the new machines.

“We purchased a Haas ST-10 Turning Center with a magazine bar feeder, 300 PSI high-pressure coolant system and automatic tool presetter. It’s a fast, very flexible and very easy-to-use machine tool.” This machine, as well as two Haas ST-20 Turning Centers with 8” chuck and 20-station hybrid turret, fully programmable tailstock and high-pressure coolant pump, are currently operating in the Forest City Gear facility to produce “donuts” from automatically fed bar stock. These donuts are the near net shape blanks used in the gearmaking operation here. As a custom producer of extremely tight tolerance gears for the most demanding applications, according to company CEO Fred Young, “We need to have optimum control of our operation, at every step. Our company today exports gears to every corner of the world and our rigorous quality standards require a number of intermediate steps, prior to shipment. If the blanks are not available and our production is delayed, the entire operation slows and we simply will not allow that to happen,” Young stated emphatically.

Kalt expands on the ST-10. “It has a manual, programmable tailstock for shaft work, another real advantage in

On the business side, Wendy Young was very satisfied with the cooperation of the Haas sales and delivery team. “We were treated fairly and the support has been first-rate, right from the start. We already see the benefits of this purchase to our company.”

For more information on this story, please contact: FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com

Email: wyoung@forestcitygear.com Attention: Wendy Young, President

PR agency contact for Forest City Gear: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

The oven has 4” insulated walls and a 750 CFM, 3/4-HP recirculating blower provides vertical airflow to the oven. Safety equipment, such as a 325 CFM, 1/3-HP powered force exhauster, is included as required by IRI, FM and the National Fire Protection Association Standard 86 for gas-heated equipment. The oven also features shelf supports on 3” vertical centers that are rated 200 lb. per level for a 1000 lb. maximum oven load.

Controls onboard No. 900 include a recirculating blower airflow safety switch, digital indicating temperature controller and a manual reset excess temperature controller with separate contactors.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Agency Info: Tim Daro 847-934-4500

Continue reading

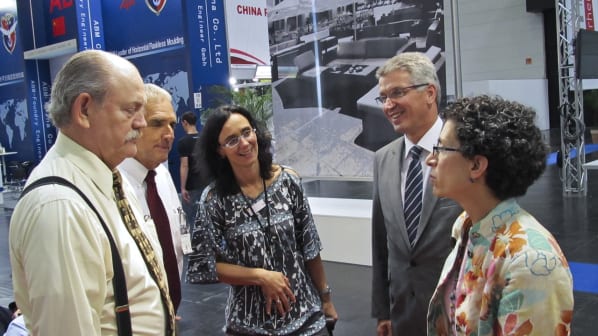

Schaumburg, Illinois (USA)-During the recent GIFA show in Duesseldorf, Germany, both Hunter Automated and its partner Maus reported successful exhibition of their machinery and related equipment.

Sandra Selwan, marketing manager for Maus (Padua, Italy), said the booth traffic was excellent throughout the show and that many current and potential customers visited. At the booth, Maus displayed its SAM multi-axis grinding system for gate and riser removal on metal castings. Owing to the offline programming station and rotating worktable, the SAM system from Maus enables cost-effective and high production rates. Also present at the booth were managing director Roberto Sammartin, sales manager Claudio Cossalter and the new North American sales manager, Carlo Canevese. Maus markets its machinery and related systems through Hunter Automated in North America and other select regions globally.

Meanwhile, at the Hunter (Schaumburg, Illinois-USA) booth, which was immediately adjacent to the Maus booth, activity was brisk throughout the event. Hundreds of metalcasters from dozens of countries around the world visited and, in several cases, consummated deals with Hunter, the global leader in matchplate molding systems and mold handling lines for green sand casting.

Working the booth were company president Bill Hunter, sales vp Kevin Purdy, sales manager Dean Martin and most of the global agent network Hunter, as well as representatives from the other manufacturing locations besides Chicago, namely, Brazil and China. As Purdy noted, “The strategy we’ve employed of manufacturing our machinery around the world, in key market areas for the foundry business, has proven both cost effective and customer-friendly.” Hunter also partners with Space’ and Versatile, all manufacturers of foundry equipment, in addition to Maus.

During the show, Hunter also inked deals for other representatives in the global foundry market. Details of these new arrangements will be forthcoming shortly, according to Hunter management.

Also a show highlight at the Hunter booth, they welcomed Ms. Janice Weiner, U.S. Consul General, along with Klaus Jonas, Communications Specialist for the U.S. Department of Commerce and representatives from the Messe Duesseldorf show management team, Eva Rowe and Ryan Klemm.

For more information, please contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

At this new location, Hennig Enclosure Systems will produce turnkey enclosures and fuel tanks for OEM power generator customers, as well as architects, design/build firms, contractors and consulting/engineering companies who constitute its current customer base. Customers interact with the company by utilizing the network of Hennig field sales engineers and service centers, as well as the recently developed online configurator software at the company’s website.

Local Rockford, IL contractor Cord Construction completed this new facility in less than six months from the date the previous facility was acquired by Hennig in November, 2010.

In addition to its work in the power generator market, Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities are located in the U.S., Germany, France, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico.

To learn more about Hennig Enclosure Systems, visit www.hennig-enclosure-systems.com or contact:

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

—

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the USA, Germany, France, Brazil, India, Japan, Czech Republic, England and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico.

Continue reading

The presentation recapped the history of the company, from its humble beginnings in 1946, when Mike Dudek’s grandfather Joe and his partner Stan Bock started the business with two four-slide machines for springforming and a commitment to vertically integrated manufacturing, product quality and efficient operation of the factory that was and is the envy of the industry. Dudek & Bock today maintains over 500 machines for use at both plants, retrofitting and rebuilding them in their Chicago factory, plus the company produces over 90% of its own tooling to minimize reliance on outside sources and the attendant cost/delivery issues. Currently, the company produces over 1500 products to order.

Complementing the core competencies of spring, wireform and light metal stamping production at Dudek & Bock, the company also maximizes its value to customers by providing a number of secondary operations on products, including all the following: welding, riveting, inline tapping and extrusion plus drilling, swedging, grinding, tapping, deburring, stress relief, shot peening, degreasing, some coating and oven curing, plus specialized packaging to suit customer requirements.

Raquel Chole noted that the employees from the Mexico plant, nearly all young and all well educated, are frequently brought to Chicago for machine cross-training and instruction on the protocols used by the company for production evaluation. “This policy gives the employees a great sense of belonging to our organization and company culture, plus they come away from the experience here with multiple skill sets that can be utilized at the Saltillo facility.”

Puz concluded the presentation with a detailed discussion on the “cost of quality” at Dudek & Bock. “We utilize world-class metrics to keep us a world-class company,” he said with no small amount of pride. “Quality has become part of our culture here and we review everything related to our machines, labor, overtime, earned hour ratio and more.” The result has been an outstanding 25% higher efficiency for man hours worked, over the last eight years, Puz noted.

Dudek & Bock is committed to a “design for manufacturability” strategy and utilizes an Advanced Production Quality Planning (APQP) process to make optimum use of the machinery and secondary operations in-house to produce products to specification and in the most efficient manner possible, Puz concluded.

Eipe Varghese conducted the tour of his quality department, detailing how PPAP and segment checks are performed on all jobs at Dudek & Bock, sometimes in compliance with customer mandate, but more often to the stringent internal protocols established long ago by the company itself. “We perform load testing, full data capture and record keeping on all the work cells in the plant.” He noted the Mexico facility has a mirror image quality lab. “Gaging is often built in-house but we use external calibration services, as well, to be sure we’re on track at all times.”

All in the group agreed this forward-thinking company was a fitting end to the Manufacturing Summit.

For video of this event, please visit: http://www.youtube.com/view_play_list?p=64D854D474995127

Agency contact: Tim Daro Bernard & Company 847-934-4500

Continue reading

The oven has 10” thick insulated walls comprised of 2” of 1900°F block and 8” of 10 lb/cf density rockwool, an aluminized steel exterior and a Type 304, 2B finish stainless steel interior. A 12,500 CFM, 10-HP recirculating blower provides universal front to rear airflow to the unit.

The unit is also equipped with a 7” insulated floor with truck wheel guide tracks and a flatbed loading truck with a 5000 lb capacity. The external frame works with lifting eyes to allow this 18,000 lb oven to be moved by crane. It also features inner and outer gaskets; the inner gasket seals directly against the door plug and the outer gasket seals directly against the front face of the oven.

Controls onboard No. 905 include a digital programming temperature controller, free standing remote control panel, manual reset excess temperature controller with separate contactors, SCR power controller, strip chart recorder and recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Agency Contact: Tim Daro: 847-934-4500

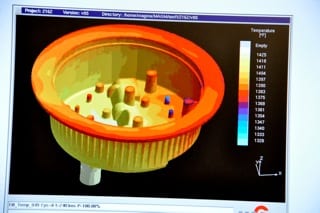

Continue readingWisconsin foundry prospering from its use of technology, including MAGMASOFT® simulation software for metalcasting

Premier has invested in all necessary tools and facilities to enable full collaborative engineering with its customers. Its current goal is to achieve the desired casting quality by further reducing costs and decreasing time to market for its customers. This progressive approach to working with customers by utilizing advanced technical tools in an R&D facility will now be referenced as the Technology Center at Premier Aluminum.

The Technology Center will now be available to any Premier customer or potential customer who wishes to work closely with the Premier Engineering Team to quickly and accurately develop new products or re-engineer already existing ones. Its engineering team boasts 50+ years experience in metalcasting, plus the latest advancements in the aluminum foundry industry. To better serve its customers, Premier employs such advanced software as Solidworks, MAGMASOFT® and other engineering tools to enhance customer confidence in tool life, product quality and efficient manufacturing processes, through a more predictive and trackable engineering protocol.

For more information on this announcement, please contact:

Kevin Kelly – Sales Manager PREMIER ALUMINUM 3633 S. Memorial Dr. Racine, WI 53403 Phone: 262-554-2100, Ext. 130 Email: kevin.kelly@premieraluminum.com Web: www.premieraluminum.com

OR

10 N. Martingale Road, Suite 425 Schaumburg, IL 60173 Phone 847-969-1001, ext. 223

Email: ssikorski@magmasoft.com Web:www.magmasoft.com

Agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

In-depth injection molding simulation software has typically been used by analysts who have the expertise to setup the complex mesh model required for simulation. With advanced simulation technology from SIGMA, injection molding simulation is easier to use and more accurate than ever. This opens the door to product designers, project managers, and engineers in charge of polymer injection molds and processes, as well as analysis groups. Companies no longer need to rely on a “meshing expert” to employ injection molding simulation.

The presentation will highlight the power of injection molding simulation when considering 3D mold components, cooling channels, the complete runner system, and part geometries coupled with multi-cycle analysis. Simulation is a must-have tool for companies wanting to evaluate ‘what if’ scenarios of the entire injection molding process early in the design and tooling stages.

Where: Exponent, Inc. 149 Commonwelath Drive, Menlo Park, CA

When: Thursday, June 30, 2011, 11:30 AM – 1:00 PM (lunch provided to those attending the seminar)

Cost: Lunch: $20 non-members, $15 members, $10 students/unemployed/retired – cash at door or via Paypal

Cost: Webinar: $10 – Paypal only. WebEx invitation will be sent upon receipt of payment

RSVP: Jennifer Hoffman at jhoffman@exponent.com; RSVP by noon, Tuesday, June 28th.

During the upcoming GIFA 2011 show in Dusseldorf, Germany, Magma will present its new software generation for casting process simulation, MAGMA5. At the 300 sq. m stand 12A16, the company will demonstrate how casting process simulation with MAGMA5 can be used for optimization at all stages of casting manufacturing to contribute to foundry profitability. MAGMA will show the newest version MAGMA5 5.2 with extended capabilities for all cast materials and processes, introduce its new software MAGMA C+M for the simulation of the core production processes and provide a view into the future of autonomous optimization of casting processes. Additionally, MAGMA is participating in the initiative “ecoMetals” from the Messe Düsseldorf, which supports companies who develop innovative products and processes leading to a more efficient use of energy. MAGMA will demonstrate, using practical examples, how the application of casting process simulation considerably increases a foundry’s energy and resource efficiency.

MAGMA5 – optimized simulation

Autonomous optimization of casting processes and layouts, shown here for gating optimization in die casting, is the future of casting processsimulation.

MAGMA5 5.2 introduces several new simulation capabilities: new process modes for permanent mold, low pressure sand and low pressure die casting, as well both hot-chamber and cold-chamber die casting, allow for detailed process-specific definitions. The software also supports process design by controlling process parameters during a simulation run. For gravity casters, process modules for DISAMATIC and investment casting are now available.

At GIFA, MAGMA will also present its newest developments for the quantitative prediction of as-cast and heat treated local microstructures and properties in aluminum, iron and steel castings. MAGMA5 simulates sand and reoxidation inclusions during mold filling and predicts defects related to molding materials. MAGMAnonferrous calculates the final microstructure and mechanical properties for aluminum alloys considering the metallurgy, inoculation, and hydrogen content of the melt. MAGMAiron predicts local microstructures for iron materials from graphite growth through to the distribution of phases making up the matrix. MAGMAsteel calculates macrosegregation in steel castings and the local microstructure resulting from heat treatment.

The stress module MAGMAstress for the first time offers casters the option to calculate thermally induced casting stresses in permanent molds for all manufacturing steps, including heat treatment and finishing, in order to predict casting crack problems and distortion. The simulated distortion results can be evaluated just as on a coordinate measuring machine and compared directly with real measurements. For the first time, the new module MAGMAdielife facilitates the evaluation of the effects of tooling design and thermal stresses on the durability of permanent molds.

MAGMA Core+Mold – transparency in core production

With MAGMA C+M, the simulation of the core shooting process is possible for complex tools, shown here for three cores including blow tubes in a single core box.

With MAGMA C+M, MAGMA introduces an integrated tool for the simulation of core production processes. MAGMA C+M simulates core shooting, blowing and hardening of organic and inorganic cores. Processes where binder hardening is driven by a catalyst gas as well

as core production with tempered core boxes are supported. MAGMA C+M considers all aspects of core production starting from the core shooter, in order to calculate the flow of the air-sand mixture based on the real shot parameters. An integrated database provides the ability to specify the characteristics of the sand and the binder system as well as core box vents and blow tubes. The program simulates gassing, purging and the curing reaction of gas-hardened cores. The design and control of core box tempering for heat-cured cores (hotbox, croning, inorganic) is effectively supported by modeling of heating cartridges and oil channels. For inorganic cores, MAGMA C+M calculates the drying of the core in the heated core box as well as due to transport of water vapor by hot air during gassing. MAGMA C+M takes advantage of all the functionality of MAGMA5 and is available as an add-on module to MAGMA5 or asa stand-alone product.

Autonomous optimization is the future

With autonomous optimization, foundrymen can make use of simulation in order to pursue their objectives for quality and cost. Autonomous optimization makes proposals for the right casting layout or the optimum process parameters. The virtual test foundry in the computer enables variation of parameters and systematic examination of influencing variables leading up to the optimum configuration. Based on the fundamental physics embedded in MAGMA5, the program finds the best possible dimensions and positions of ingates, as well as the location of feeders and chills including their optimum size. Using industrial examples, MAGMA will present state-of-the-art capabilities and provide a view into the future of optimization.

MAGMA – very involved

At the accompanying WFO Technical Forum, MAGMA will give presentations on the topics of aluminum casting, core production, and optimization. At the NewCast exhibition, which takes place in parallel with GIFA, simulation specialists will discuss the prediction of residual stresses and distortion in cast iron components.

MAGMA also has a further exhibition stand (12A15) as part of the “Get-In-Form” project “Youth-Technology-Future” (“Jugend-Technik-Zukunft“). Here, the attractiveness of work as a professional or specialist in the metal casting industry will be illustrated to students and apprentices in an entertaining and interactive manner.

About software for casting process simulation

Casting process simulation software considers the complete casting process including mold filling, solidification and cooling, and also provides the quantitative prediction of mechanical properties, thermally induced casting stresses and the distortion of cast components. Simulation accurately describes a cast component’s quality upfront before production starts, thus the casting layout can be designed with respect to the required component properties. This results in a reduction in pre-production sampling, but also the precise layout of the complete casting system leads to energy, material and tooling savings for the foundry.

The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. The software supports the user in component design, the determination of melting practice and casting methodology through to mold making, heat treatment and finishing. This saves costs consequently along the entire casting manufacturing line.

During the last 10 years, the use of casting process simulation has become a valuable business asset for many foundries. MAGMA5 now expands the capabilities of casting process simulation and will further accelerate the acceptance of this technology.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. The MAGMA product and service portfolio includes the powerful modular simulation software MAGMASOFT®,with the newest release MAGMA5, as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.

For more information on this release, please contact:

Christof Heisser President MAGMA Foundry Technologies, Inc. 10 N. Martingale Road, Suite 425 Schaumburg, IL 60173 Phone 847-969-1001 ext. 225

Email: cheisser@magmasoft.com Web: www.magmasoft.com

Agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

The oven has 5” insulated walls and an aluminized steel interior and exterior. It features three zones: 2’ long open belt loading zone, 7’ long insulated heat zone with recirculated airflow and 4’ long open unloading zone. The mandrels holding product move through the oven on two strands of 60 pitch roller chain on 35” centers, powered by a ¼ HP motor drive with fixed speed of 32 inches per minute.

A 4200 CFM, 3-HP recirculating blower provides vertical downward airflow to the workload, while a 325 CFM powered forced exhauster is also onboard. Motor operated vertical lift doors are provided at each end of the oven.

Controls onboard No. 874 include SCR power controller and fused disconnect switch. A PLC controls temperature and conveyor indexing.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP