Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

See it at Pack Expo 2015! Siemens Booth: S-6137

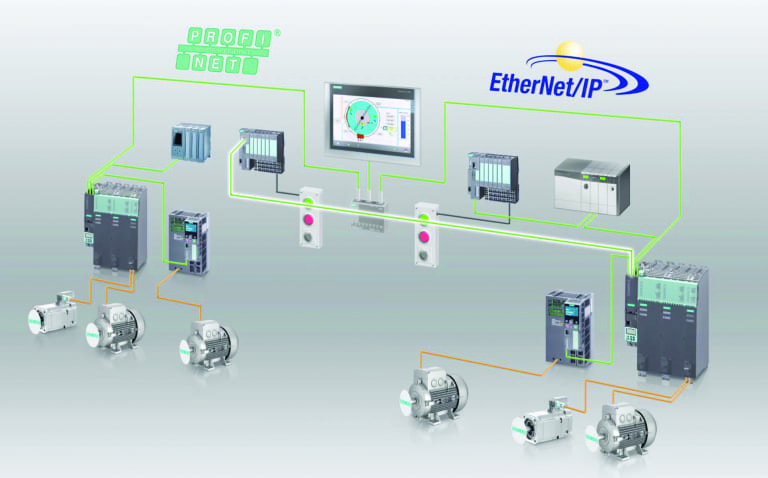

Siemens has announced that its versatile Sinamics G120 drive system has been enhanced to include EtherNet/IP connectivity, thus providing maximum flexibility for industrial Ethernet communication while offering innovative concepts for those wanting a single network for the entire plant.

“In many instances, plant managers have the requirement for a single-plant network, particularly with large automotive, packaging, plastics, metals, food and beverage as well as material handling companies,” says Robert Soré, Siemens product manager, Sinamics G drives. “Our Sinamics G120 drive provides communications without limits to a specific network type.”

Sinamics G120 drives support, as standard, Profibus DP and Profinet to ensure seamless communications between every component involved in a typical automation solution including HMI (operator control and visualization) and I/O. Additional higher-level functions, including Safety Integrated telegrams and synchronized mechanisms for even the highest level control applications are also included.

Profinet can transmit operating and diagnostics data simultaneously to enterprise-level systems using standard IT mechanisms (TCP/IP) for an integrated factory environment. The new addition of an EtherNet/IP stack offers another option for Sinamics G120 users. Having the flexibility to communicate with the most common automation systems via Profinet or EtherNet/IP makes the Sinamics G120 drive system easily adaptable to the current Industrial Ethernet boom.

The Sinamics drive platform from Siemens provides users maximum flexibility

with industrial Ethernet connectivity.

With a wide power range (0.50 – 350 hp), highly scalable solutions, including safety integrated functionality and convenient start-up with Siemens Starter software, the Sinamics G120 drive is a powerful solution for a variety of applications, including packaging, plastics molding and extrusion, textile, printing and paper machines,

handling and assembly systems, rolling mills and test stands.

For more information about Siemens connectivity to EtherNet / IP platforms, visit www.usa.siemens.com/eip-drives.

For more information about the Sinamics G120 drive platform, visit www.usa.siemens.com/sinamics-g120.

—

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingMajor German supplier of finished length tube and solid bar processing equipment greets 100+ at new 30,000 square-foot facility in Grand Rapids area; plans to expand for full machine builds here

Rattunde Corporation, a German-based manufacturer of finished length tube and solid bar production systems, has been operating in the North American market for over eight years. The company’s success was celebrated with a technology open house on May 13-14, during which guests saw a resident machine in action, taking steel tube lengths and producing finished, cut-to-length, chamfered and machined tubing sections, automatically stacked for shipping, all within the work envelope of the machine.

Rattunde Corporation President Richard Stadler proudly opened the doors to the company, a 30,000 square-foot facility in Caledonia Township, near the company’s previous location in Grand Rapids, Michigan.

The plant houses the North American sales and service operations, plus spare parts inventory and manufacturing operations for the production of machine tooling. Areas within the new facility also house a technical center with a machine onsite at all times for demonstration and training. Future plans call for an expansion of the building to over 100,000 square feet, enabling Rattunde to produce their entire finished length tube and solid bar production systems here. This decision was reached, after an analysis of the current and anticipated business needs of the company, according to Stadler. “Our growth in North America has been rapid, though not unexpected, due to the unique nature of our equipment and the reliability and performance characteristics of our machines.” Stadler further noted that solid growth of the company into diverse markets throughout North America made the new facility a logical choice.

In commenting on the new facility, Richard Stadler noted, “There were several reasons why we wanted to remain in the greater Grand Rapids area, but one of the main reasons is the excellent talent base here. Companies are built on people and, whether you are looking for an experienced veteran of industry or a fresh graduate from one of our ranking high schools, colleges or universities, outstanding people can be found here in the Grand Rapids area.”

Concurrent with this development, Rattunde has expanded its workforce with technical service and administrative personnel. As Stadler explains, “Whenever a machinery company grows quickly, there’s an ever-present need for more customer service and technical personnel. Of course, new people must be found and trained.” Stadler went on to explain that rapid growth also means working smarter. Rather than waiting for a customer to reach out to Rattunde in a time of need, Rattunde is proactively sending technicians to the customer and performing comprehensive machine inspections, identifying and correcting small issues before they become large ones.

In the end, Stadler says, “This new facility solidifies our North American presence in the high-volume tube and solid bar production markets, thus benefiting our current and future customers in many ways. It’s a purpose-built building, with a forward-looking eye on all we will need to build our machines and systems from the ground up.”

Over 100 guests joined in this two-day event, watching the machine operate, examining the dedicated tooling Rattunde will produce onsite, participating in the technical sessions, led by Stadler and VP Alec Banish, plus enjoying the outdoor barbeque, as the weather cooperated nicely.

The attendees comprised Rattunde personnel, sales representatives from the North American network, honored guests from the parent company in Germany, plus numerous customers, prospective business partners and suppliers to the company. A good time was had by all!

For more information on this development, please contact:

RATTUNDE CORPORATION

5080 Beltway Drive SE

Caledonia, Michigan 49316 USA

Phone: 616.940.3340

Contacts: Rick Stadler, President or Alec Banish, Director of Business Development

Emails: r.stadler@rattunde-corp.com or a.banish@rattunde-corp.com

Web: www.rattunde-corp.com

This Grieve universal oven features 6” insulated walls, aluminized steel exterior, Type 304 stainless steel interior with 2B finish plus two 24” wide x 24” long shelves supported by rollers and each rated at 300 lb. load capacity. An integral oven leg stand is also provided.

No. 1034 controls include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Product demonstrations and technical presentations from principals impress large crowd

On May 14, 2015, Exact Metrology held an open house at its Brookfield, Wisconsin facility and the event was attended by over 125 local area companies, comprising quality assessment, design engineering and management personnel from many of the leading manufacturers in the region. Hosted by company co-president Dean Solberg, the day included ongoing product demonstrations of the various metrology equipment brands offered for sale, lease and rental by Exact, as well as the testing procedures provided as a service by this unique metrology supplier.

Services on display at the Brookfield open house included 3D scanning, reverse engineering, quality inspection, instant scan-to-CAD comparison and a full suite of PolyWorks software solutions. Equipment shown at the event included Aicon 3D systems, Breuckmann 3D scanners, Leica Geosystems, Romer and Hexagon brands of scanning devices and related hardware, all of which were available for hands-on use by event attendees.

A new product of great interest to attendees was the Breuckmann steroScan, a flexible scanning system for precise 3D digitization and metrology. Applications for this product include quality inspection, reverse engineering, rapid prototyping, deformation analysis and digital documentation. Because of the adjustable focal length of the scanner, products from small components up to large sections of automotive and aircraft parts can be scanned with high resolution and accuracy. Breuckmann is a company of Aicon 3D Systems.

During the event, technical presentations were made by Aicon, PolyWorks by InnovMetric and Exact personnel on the newest advancements in 3D scanning technologies. The presentations were given to a “full house” of interested attendees.

As Dean Solberg commented, “We seek to find the right combination of equipment and services to suit the applications and challenges presented by our customers. In some cases, it’s a matter of matching the right standard equipment to the job, while at other times we bring custom solutions and services to our customers, whether they buy, lease, rent or simply use our services to achieve the desired results on projects.” Solberg credited his staff of metrology engineers, technicians and customer service personnel for their hard work, dedication and adaptability in seeking their correct solution to all customer challenges.

Exact Metrology is an ISO 9001:2008 Certified Company.

For more information on this new system, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Siemens announced today the release of its new single-axis Sinamics V20 AC drive, frame size E, with both Low Overload (LO) and High Overload (HO) ratings. The V20 family features easy setup and operation with excellent cost and energy efficiency. With a power rating ranging from 1/6–40hp at 480V AC, Sinamics V20 drives are available in five frame sizes and are ideal for material handling, conveyor, pump, fan and compressor applications.

This compact drive can be connected and installed the conventional wall-mounting method or, optionally, mounted with heat sinks pushed through the enclosure wall. Since no additional modules or add-on options are required for operation, installation time is minimized.

The integrated Basic Operator Panel (BOP) enables trouble-free commissioning and operation on-site. Besides the universal serial interfaces that allow for easy connection to Simatic programmable logic controllers (PLCs), a Modbus interface is also included for communication with third-party controls. Pre-built connection and application macros are used for facilitating application-specific settings. For units with power ratings higher than 10hp, a braking resistor can be connected directly to the integrated braking chopper.

Operating the Sinamics V20 drive is just as easy as commissioning. Parameters that have been optimized for one application can easily be transferred to other drive units using SD cards via the Basic Operator Panel or the battery-operated Parameter Loader. The built-in display has the ability to list only those parameters changed from the factory default values rather than having to scroll through all of them.

Tailored inter-connectivity and application macros (i.e. for pumps, fans and compressors) provide the correct settings for the particular application. The Keep Running Mode automatically adapts the V20 drive to the power supply to achieve higher availability when operated on unstable networks. In this mode, line fluctuations are compensated for internally and error messages are acknowledged autonomously. Thanks to enhanced cooling and coated PCBs and electronic components, the Sinamics V20 is extremely rugged, making the unit reliable even in harsh environments.

The demand-driven regulation of the motor speed also provides increased energy savings even for many applications. The Sinamics V20 is equipped with an energy-optimized control mode (ECO-mode) for increased energy efficiency. ECO-mode automatically adapts the magnetic flux in the motor to the optimum operating point. The DC link coupling enables efficient energy utilization of drives grouped together. The Sinamics V20 can also be set to hibernation mode, which prolongs the service life of the motor and also reduces system component wear (i.e. pumps). Additionally, by displaying real-time energy consumption on the operator panel display, the operator always has the drive’s energy and cost efficiencies in focus at all times.

For more information about the Sinamics V20 drive, please visit:

www.usa.siemens.com/sinamics-v20-pr

—

For specific product information and inquiries, call (800) 879-8079

ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com

The Customer’s Challenge:

Significant new business, order intake

New customers

Steeply rising monthly production rates

Building/Facility space constraints

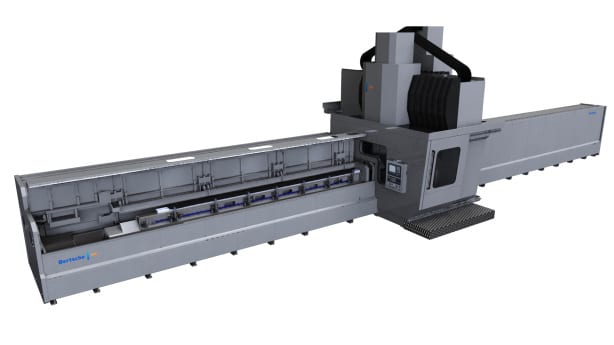

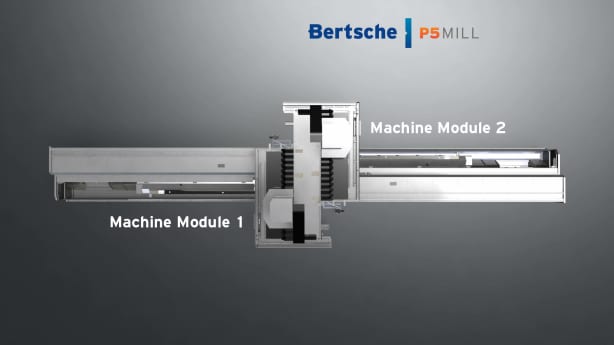

Solution: The Bertsche Two-in-One P5 Mill

Bertsche’s Dual P5 Mill allows dual work chamber manufacturing, independent or simultaneous, thereby saving considerable factory floor space for their aerospace customer.

Our aerospace customer was faced with the choice of either building a new facility to house two new milling machines or splitting their production between two manufacturing sites. Bertsche developed a new machine concept that offered the customer the productivity (throughput) of two machines and the floor space footprint requirements of one machine, thereby saving the customer the cost of building a 2nd facility and moving all production to a larger facility. The Bertsche Dual P5 Mill has all the benefits associated with having two machines, namely independent but linked CNC’s, two 5-axis machining modules ( A-side, B-side) each with separate machining chambers, the ability to machine two different parts at the same time and yet the overall machine is nearly the same size as a previously supplied single 5-axis P5 Mill. Based on the daily production requirements, the machine is operated A-side only, B-side only or A and B side together. Twin integral vacuum fixture tables are designed to accept a variety of different vacuum workholding fixtures that can be quickly changed at a moment’s notice, with a high degree of repeatability. To assist the operator loading parts, each table has retractable datum surfaces that swing into place to edge locate parts and then swing back down, when machining. Thick-walled composite structures (up to 0.625”) are milled, scalloped, edge trimmed and drilled on all sides. High accuracy hole patterns and datum holes are drilled for determinate assembly and then probed for accuracy. Parts are machined complete in a single setup and manufactured one-off to meet user ship-set kitting requirements.

With the growing trend towards cutting composites wet, flood coolant cutting was added and composite debris is flushed into a full bed length flume system. Flood coolant is constantly circulated throughout the machine for greater machine thermal stability. High volume mist collection hoods, integral to the machining compartment, collect and vent mist. A special sealing system is employed on linear ways to protect precision surfaces from very aggressive (detergent type) coolant fluids that must be used with composite materials. Multiple temperature sensors on the bed and X-axis slide accurately capture data for dynamic thermal compensation. To reduce the amount of filtration media, coolant is continuously filtered using a cyclonic filtration system.

Bertsche’s Dual P5 Mill allows dual work chamber manufacturing, independent or simultaneous, thereby saving considerable factory floor space for their aerospace customer.

Benefits:

For more information on this story, please contact:

BERTSCHE ENGINEERING CORPORATION

711 Dartmouth Lane

Buffalo Grove, IL 60089

Phone: 847-537-8757

Fax: 847-537-1113

Web: www.bertsche.com

Email: info@bertsche.com

Attention: Rich Bertsche or Erich Bertsche

High precision 3D mapping supports installation of a new beam transport line for scientific research

Fermi National Accelerator Laboratory (Fermilab), America’s premier high-energy particle accelerator laboratory, in Batavia, Illinois, collaborates with scientists from around the world to perform pioneering research, operate world-leading particle accelerators, plus experiment and develop technologies for science supporting U.S. industry.

In 2014, Fermilab contracted Exact Metrology to work on a project known by its location as “Main Injector Ring Section MI-10.” Horst Friedsam, Head of the Alignment & Metrology Department at Fermilab, led the week-long project with Exact Metrology, which involved 3D mapping of existing equipment in order to yield data to support the placement and installation of an additional beam transport line.

Exact Metrology performed the scanning in section 10 of the Main Injector Accelerator, which is situated in a tunnel about 10 m below ground with a circumference of approximately two miles. The Main Injector accelerates a proton particle beam, arriving from the 8 GeV (Giga-electron-Volts) Booster, to 120 GeV and subsequently blasts it into a stationary target to generate the world’s highest intensity neutrino beams.

Recently, Fermilab has been working on a new Deep Underground Neutrino Project (DUNE) to provide a neutrino beam to the Homestake Mine in South Dakota. This project features access to research facilities 2 miles below ground, which is ideal for neutrino experiments requiring shielding from cosmic ray events. In order to deliver a neutrino beam to the DUNE, a new beam transport line that fits within the existing beam line infrastructure was required. As a result, data scanning, full CAD modeling and photo overlays of a large section of the currently installed Main Injector equipment was needed. The collected data were crucial for the design of new beam elements and visualizing interferences with existing components.

The Alignment & Metrology Department maintained a high precision control network throughout the laboratory complex. For the scanning process, a Leica ScanStation P20 ultra-high speed 3D Scanner was used in conjunction with special laser scanner targets, modified to fit within the existing control network points. Exact Metrology’s Leica ScanStation P20 was chosen for its combination of high accuracy and low scan noise, plus its industry-leading environmental specifications for industrial as-built documentation. The software chosen to aid the process was Leica Cyclone, producing TruView—a web-enabled panoramic point viewer allowing the user to view, pan, zoom, measure and mark up point cloud data over the web. Additionally, RSL300 laser scanner target markers from Berntsen International Inc. were mounted concentric to 1.5” radius steel half spheres interfacing with Exact Metrology’s laser tracker nests. The coordinates of the control network, determined at the millimeter level, were provided to Exact Metrology to globally register all scans relative to Fermilab’s system. Thus, the end product provides information for all scanned objects in the common coordinate system used for the entire Fermilab site.

Fermilab has a long-existing relationship with Exact Metrology, having purchased and rented equipment from their instrument pool plus contracted for metrology services as on-site work, such as this scan.

Exact Metrology is an ISO 9001:2008 Certified Company.

For more information on this new system, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Or

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Or

FERMI NATIONAL ACCELERATOR LABORATORY (FERMILAB)

1117 N Washington Ave

Batavia, IL 60510

Phone: 630-840-2787

Horst Friedsam

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Co-rotating twin-screw compound extruder used in R&D facility to test material batches, recipes; pre-configured extrusion solution on control package monitors entire machine, providing “big data” for customer at attractive price point

KRAIBURG TPE Corporation in Duluth, Ga. is a manufacturer of custom-made thermoplastic elastomer (TPE) compounds for a variety of market applications in the automotive, medical, general industrial and myriad consumer sectors. At the Duluth facility, the product development department routinely evaluates material batches and new custom compounds for performance and customer specification viability. As an integral step in that process, KRAIBURG TPE engineers utilize sophisticated co-rotating, twin-screw extruder technology provided by KraussMaffei Berstorff, from its facility in Florence, Ky.

Owing to the substantial varieties of color, durometer and the wide-ranging performance properties required at KRAIBURG TPE, monitoring every aspect of the machine performance is critical. This includes all temperatures, speeds, pressures and torque on the extruder itself, plus an underwater pelletizer, gear pump and multiple loss-of-weight feeders used on the line.

At a glance, the operator sees the condition of the machine in real time and can make better on-the-fly adjustments

For the latest machine installed at the KRAIBURG TPE facility, as senior application engineer at KraussMaffei Bertstorff, David Frankenberg, explains, “The lab extrusion line is used for both process and product development assessment. A key requirement was the generation of all data in real time, as part of the management system to be used, as well as the condition monitoring system needed for predictive maintenance strategies being employed.” In cooperation with the KRAIBURG TPE team and after evaluating the competitors for the control scheme, KraussMaffei turned to Siemens for assistance, as this supplier was able to bring a pre-configured and highly cost-effective solution to the requirements on this machine.

Siemens temp zone control system monitors all aspects of extruder, providing “big data” to the host network

As Frankenberg and his electrical engineering associate Martin Gonzalez detailed, the Siemens EXT3370 application package represented a blending of the current PLC technology and drives platform with an HMI capable of providing all graphics and multiple data screens on a single display. In addition, the system had the ability to feed the “big data” directly to the KRAIBURG TPE process data archival & analysis system, where it would reside for real-time and long-range performance evaluation by the product development, quality and process teams. All speeds, pressures, temperatures and other parameters can be instantly assessed, using set point and actual value data on the display, either at the machine HMI or a remote monitor within the KRAIBURG TPE network.

On the KraussMaffei Bertstorff machine, the control system comprises the software solution, Siemens drives and motors, the ability to monitor up to 32 separate temperature zones, touch screen technology on a 15” HMI and scalability on the drives to accept the ancillary equipment being monitored at the KRAIBURG TPE facility. In this way, a truly customized solution was devised using an entirely standard and thus highly cost-effective array of components, according to Frankenberg. As an additional benefit, he noted, the training needed was minimal, owing to the plain language on the control with no need for knowledge of high-level programming skills. Finally, all compound recipes can be easily transferred via USB for portability and security.

Allen Donn, product development engineer at KRAIBURG TPE, along with his team of engineers and tech specialists, evaluated the installation and commissioning of the machine at the Duluth facility. “The data transfer from the PLC into the same process data archival & analysis system that we use for our other lines at KRAIBURG TPE. A simple Excel file is generated with any parameters desired for analysis, plus we can easily exchange data between R&D and production here. The result is that our ability to utilize production machinery more efficiently has increased substantially with the use of the new KraussMaffei Bertstorff machine in our test department, as the control system gives us real-time hard data we can use to make adjustments on new recipes and entirely new materials.” KRAIBURG TPE performs extensive new compound property performance testing on its TPE formulae and the time compression realized by using the new extruder line in this “real world” R&D operation is providing substantial advantages for the compounder.

Various compounds are formulated at Kraiburg and test run on the KraussMaffei Berstorff extruder at the Kraiburg lab in Duluth, Georgia

KRAIBURG TPE typically runs materials in the 20-80 Shore A hardness range and, as an example, might test out a variety of adhesion grades for over-molding onto polycarbonate, nylon, or other substrates, Donn explained. “When we can pull the data from any machine in the system, adjust it, run it on the R&D machine, and then feed that data back into production, it makes a huge difference in our efficiencies.” In one instance, shortly after the KraussMaffei machine was installed, KRAIBURG TPE engineers were testing 15 compound varieties on the machine very quickly, compared to using production equipment to do that task. “I could look into the software to compare all set point and actual values, remotely, over the entire test period,” Donn noted. He added that the substantial raw material cost savings of more tests, faster results and less waste all contribute to an improved profitability for the company, as well.

For more information on this story, please contact:

KRAIBURG TPE CORPORATION

2625 North Berkeley Lake Road

Duluth, GA 30096

Phone: 678-584-5020

www.KRAIBURG-tpe.com

info-america@KRAIBURG-tpe.com

Attention: Katherine Olano

Or

KRAUSSMAFFEI GROUP USA

7095 Industrial Road

Florence, KY 41042

Phone : 859-283-0200

www.kraussmaffei.com

david.frankenberg@kraussmaffei.com

Attention : David Frankenberg

Or

SIEMENS

Digital Factory

5300 Triangle Parkway

Norcross, GA 30092

Phone : 770-871-3848

www.usa.siemens.com/plastics

mathias.radziwill@siemens.com

Attention : Mathias Radziwill

Unique below-ground system at Portland Water Bureau utilizes Lucid Energy power generation, Siemens motors and regenerative drives with natural water flow to create energy; will produce 1.1MW of electricity per year, enough to power 150 homes

Recently, the use of regenerative energy has ramped up quickly in American industry due largely to the advancements in drives technology. Through various mechanical components coupled with regenerative drives, energy can be captured or created and used in three ways. Namely, it can be battery-stored for subsequent use, redirected immediately to other electrical power requirements or fed back to the power company in a contract arrangement, all done without loss of host system performance, mechanical component integrity or safety issues.

Typically, regenerative power is produced by, for example, a motor turning during braking or stopping. What if the motor turned as the result of something other than an electrical power supply?

At the City of Portland (Oregon) Water Bureau, they partnered with a local firm, Lucid Energy, who provided a very unique method of power generation. The renewable energy and smart water management solution used is the supplier’s patented LucidPipe™ Power System, which enables industrial, municipal and agricultural water facilities to generate clean, reliable and low-cost energy from gravity-fed water pipeline and stream flow.

The LucidPipe™ Power System uses a unique lift-based, vertical axis spherical turbine technology to smoothly transfer the kinetic energy of the water flow to rotate the motor shaft without impeding the water flow to any great degree. Photo Credit: Sherri Kaven.

For a recent installation under the road at SW 147th Avenue and Powell Boulevard in Portland, Lucid Energy provided their system, which comprises four 42” lift-based turbines spun by the gravity-fed water flow inside the Portland Water Bureau pipeline. These turbines turn four Siemens torque motors as 50kW generators for a 200kW nameplate capacity project. The electricity generated by this system is captured and fed to the Portland General Electric (PGE) grid by four Siemens regenerative drives. In a 20-year power purchase agreement, this project will generate approximately $2 million in renewable energy capacity, to be used for development, installation and operational maintenance costs.

The project investor, Harbourton Alternative Energy, will share the revenue with the City of Portland and Portland Water Bureau to reduce the cost of water operations. Upon completion of the agreement, Portland Water Bureau has the right to purchase the system and the power produced. Since the pipeline is expected to have a lifespan of over 50 years, this project represents a mutually beneficial arrangement for the investor and the city alike.

Known as the Conduit 3 Hydroelectric Project, this system represents the first venture in the U.S. to secure a 20-year Power Purchase Agreement for renewable energy produced by in-pipe hydropower in a municipal water pipeline.

The installation of the system at SW 147th Avenue and Powell in Portland, Oregon. Photo Credit: Sherri Kaven.

“For the execution of this project, we reached out to Siemens, in tandem with their solution partner in our area, Applied Motion Systems, who wrote the software for the regenerative operational protocols, connecting the hardware to the grid,” according to Lucid Energy’s director of operations, Susan Priddy. In addition to the drives and motors on this project, Siemens also provided the motion controller, transformers, circuit breakers and all power supplies. The master control cabinet is installed underground, in close proximity to the pipeline and the four LucidPipe turbines (shown in photo).

Functionally, the water being fed from reservoirs flows downhill to turn the torque motors into generators, which supply power back onto the Siemens Sinamics S120 drive system, which in turn feeds it to the electrical grid of PGE. The electricity is generated by the water flow with no other power source. The pipeline performance is unaffected and there is no environmental impact. The Lucid Energy system has been tested and certified by NSF International to meet the NSF/ANSI Standard 61 for potable water systems. The LucidPipe system extracts very little head pressure, typically 1-5 PSI, so the turbine units can be installed in sequence without disruption of the water flow. The system does not require installation in a pressure-transient zone or where extreme differential pressures are required.

Lucid Energy developed its patented lift-based, vertical axis spherical turbine technology (shown in photo) at the end of the generator’s flange to maximize the use of the water’s gravitational flow to put work back onto the motor. Units can be installed in 24”-96” diameter pipes. For this project, Lucid Energy was able to use standard motor and drive components that would typically require external power supply to control the motion of a machine, as part of its LucidPipe™ power generation system.

Aesthetically, as a collateral benefit, the entire system detailed here is located underground.

The system was final tested in February 2015 and is producing power to full expectations today. Based on subsequent performance metrics analysis, Portland Water Bureau is considering additional installations of the LucidPipe system.

Ryan Misjan and Steve Schoneger from Siemens, plus Susan Priddy from Lucid Energy and Jennifer Allen Newton from Bluehouse Consulting Group contributed to this story.

See the system in action! http://www.lucidenergy.com/how-it-works/

For more information on this story, please contact:

LUCID ENERGY

2420 NE Sandy Boulevard

Suite 203

Portland, OR 97232

Phone: 503-341-0004

www.lucidenergy.com

Attention: Gregg Semler, President & CEO

Or

SIEMENS

Digital Factory

Factory Automation

5300 Triangle Parkway

Norcross, GA 30092

Phone: 770-871-3848

www.usa.siemens.com/drives

Attention: Sandra Tigert

—

How Regenerative Drives Work

Power regeneration is the process of recovering kinetic energy created by a motor turning during stopping or braking or, as in the situation described in this story, by the natural gravitational motion of water flow, and converting that energy to electricity, then feeding it back onto the grid.

Siemens regenerative active infeed drives, as demonstrated in this story, efficiently return the energy created back into the supply system, rather than losing the energy in the form of heat or inertial load losses. The regenerative operation is combined with power quality management, improving the overall operational system efficiency. By virtually eliminating harmonics and optionally providing power factor control to compensate for poor power factor from other loads, active infeed drives provide more stable operation on the load in weak supply systems with voltage and frequency fluctuations and can actually help stabilize the supply system. Motor performance is also improved significantly with active infeed (also called active front end) regenerative drives technology.

No. 1023 is a 550ºF, electrically-heated, Class 100 cleanroom cabinet oven from Grieve, currently used for curing small rubber pieces in rotating drums at the customer’s facility. Workspace dimensions of this oven measure 26” W x 26” D x 60” H. 36 kW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 2000 CFM, 2-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cleanroom cabinet oven features 6” insulated walls, Type 304, 2B stainless steel interior with ½” inside radius corners and all seams welded, ground and polished, top-mounted heat chamber, two motorized stainless steel shafts cantilevered through the rear wall of the oven with a drum coupling device to rotate the loads, four 18” diameter x 18” deep perforated stainless steel drums with internal stirring paddles and access doors on one end. The oven also contains 24” x 24” x 6” thick HEPA fresh air filters with 2” prefilters and two 24” x 24” x 12” thick stainless steel, high-temperature HEPA recirculating filters.

No. 1023 controls include all safety equipment required for handling flammable solvents, solid state heater control relays, circuit breaker disconnect switch, automatic door switch to shut off the heaters and drum drive when the door is opened, plus a minihelic pressure gauge and validation port across each set of filters on the oven.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP