Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

This Grieve walk-in oven has 6” insulated walls and an aluminized steel exterior with white epoxy paint. Type 304, 2B finish stainless steel interior with continuously backwelded seams and inert atmosphere construction are also onboard, including a pressure regulator, flow meter, pressure gauge, inner oven walls sealing directly against ½” thick silicone rubber door seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. The oven has a 4” insulated floor with truck wheel guide tracks mounted on top of the floor.

Controls on the No. 1038 include a digital programming temperature controller plus a paperless event recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingInformation-packed site features full standard line of polyurethane products plus custom capabilities and unique calculation tools

New Kastalon website features hundreds of standard polyurethane rollers, pads and sleeves for industrial applications plus the company’s custom capabilities.

Kastalon, a longtime leader in polyurethane products, announces the rollout of its new website at www.kastalon.com. The new site offers a look at the company’s extensive lines of standard products, including rollers, pads, bumpers and sleeves for various uses in materials handling, metals producing and processing, as well as myriad other market applications.

Likewise, this new website details the custom material formulation and production capabilities of Kastalon, as the company has built a reputation for problem-solving solutions, since its inception in 1963.

Also included on the website are a number of engineering tools, which allow prospective customers an opportunity to detail their requirements for prompt quotation. Various materials performance calculation tools are provided on the site and these are among the most popular pages. Full company literature downloads are also offered.

Kastalon brings its decades of manufacturing experience and application engineering to each customer task, providing a high degree of material consistency and product performance to the global markets served by the company.

Inside Sales Manager Lyn Thorne comments, “We have worked for over two years to produce this site and believe it will be very useful to our current and prospective customers alike, as it provides a thorough presentation of our company’s successes and capabilities.”

For more information, please contact:

KASTALON, INC.

4100 W. 124th Place

Alsip, IL 60803

Phone: 708-389-2210

Fax: 708-389-0432

Web: www.kastalon.com

Email: sales@kastalon.com

Attention: Lyn Thorne

Announcing an exclusive Distribution Agreement to deliver the Intelligent SILO VLM product line to the North American Market

ICAM and SencorpWhite are proud to announce a new strategic partnership for the exclusive distribution of the SILO VLM product line in the United States and Canada.

Since 1947, SencorpWhite’s White brand automated storage and retrieval systems has been a recognized leader in the North American market. With ICAM’s unique product features, and White’s unmatched network of sales and field service engineers, this powerful partnership provides the North American market with the widest available range of VLM products and services.

Through this partnership, ICAM and White will enable North American companies to simplify day-to-day inventory storage and retrieval, optimize valuable floor space, and increase productivity. ICAM’s highly engineered, tailor-made VLMs are designed and manufactured to satisfy specific customer requirements, unlike standard, pre-configured solutions with limited choice of dimensions and configurations.

“This strategic partnership enables ICAM to bring the unique features of SILO VLMs to White’s extensive customer base in the North American market,” said Roberto Bianco, President and Chief Executive Officer, ICAM. “We are very pleased to partner with SencorpWhite. White is a respected brand throughout the industry, ideally positioning the company for rapid growth. With its technical sales and service capabilities, and multiple locations, SencorpWhite is able to provide customers with the highest level of service, which aligns with our own business philosophy”.

“ICAM and SencorpWhite share the same passion for innovation, quality, and value. This foundation provides a strong strategic and cultural fit for both businesses. We are pleased to partner with an established and innovative industry leader in Europe,” said Chris Lingamfelter, President of SencorpWhite’s White product line. “This strategic partnership leverages the strength of both ICAM and SencorpWhite to rapidly grow our existing footprint in North America, furthering our vision to offer uniquely configured, intelligent VLM solutions that provide value to our customers.”

About SencorpWhite

SencorpWhite, a Connell Limited Partnership portfolio company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services – which range from innovative thermoformers and other packaging technologies to automated storage and retrieval systems and inventory management software – cover the entire supply chain spectrum, from the point-of-manufacture through distribution and to the point-of-use. For more information, call (508) 771-9400 or visit http://sencorpwhite.com/.

About ICAM

For more than 50 years, ICAM has been designing and manufacturing automated-storage-and-retrieval (AS/RS) and filing systems for the European market. Today, ICAM is on the leading edge of Italian and European manufacturing, serving the industrial, retail, public administration and services markets. ICAM’s product range includes state-of-the-art automated vertical lift modules (VLMs); vertical carousels; mobile racking/shelving systems (di- vided into three distinct business lines: industrial, office and healthcare), and innovative, integrated inventory management software. ICAM is certified to ISO 9001 (certificate no. 191886); ISO 14001 (certificate no. 153853-2014 AE-ITA-ACCREDIA); and ISO 3834 (certificate no. IT246224), which assures product and procedure reliability and respect for the environment.

Continue reading

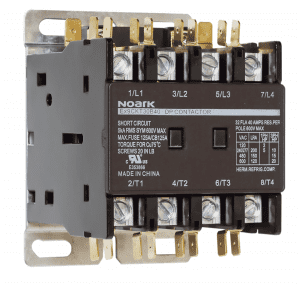

New Ex9CKT series designed for variety of HVACR applications; compliant to UL 508 and UL 60947-4-1 for air resistance heating

The Ex9CKT Series is UL 508 and UL 60947-4-1 Recognized and compliant to CSA C22.2, IEC/EN 60947, CE, RoHS and ARI-780 HVAC standards. It features a Double E magnet assembly for increased performance and reduced power consumption. The newly redesigned body has a high arc-resistant polyester base assembly, allowing for space savings, while the quick-connect spades speed install time. Users can select terminal options, screw or lug connection.

The Ex9CKT Series is designed for a variety of HVACR applications, including air conditioning, resistive heating, refrigeration equipment, motors, welding, pumps, power supplies, foodservice equipment, compressors and various business machines.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative found at www.na.noark-electric.com or email: nasales@noark-electric.com.

Continue readingAcquisition will allow market leader in automated storage and retrieval systems to expand offerings for warehouse, inventory and supply chain management

HYANNIS, MA—SencorpWhite, a global leader in customized, end-to-end solutions for automated packaging and AS/RS systems, announced today that it intends to acquire Intek Integration Technologies Inc., a company specializing in software that helps manufacturers and distributors better manage their warehouses, inventory levels and supply chains. SencorpWhite’s White Systems brand and Intek have been collaborating in the material handling industry for the past 30 years.

Acquisition will allow White Systems customers to benefit from more coordinated product offerings, tighter solution integration and strengthened collaboration

Integrating White brand AS/RS solutions with Intek’s Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) will offer customers:

“Intek and White Systems have been working together for three decades to provide powerful, flexible solutions,” said Chris Lingamfelter, President, White Systems. “The breadth and depth of the Intek Supply Chain Execution platform is a strong addition to the White solution set, and this acquisition will allow us to continue to deliver complete, integrated business solutions for our valued clients.”

“As advanced automation has become the norm in all distribution sectors, we see distinct advantages to more freely integrating White automation systems with Intek supply chain execution software,” says Mac Cutchins, Chairman and CEO at Intek. “The synergy of our two companies will bring formidable and flexible automation solutions to all distribution tiers, creating more robust competitive advantage in the industry. Already a longtime partner to White, we at Intek see this enhanced level of cooperation as an engine for substantive evolution in both distribution automation and supply chain execution at our companies.”

About SencorpWhite:

SencorpWhite, a Connell Limited Partnership portfolio Company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services—which range from Sencorp brand innovative thermoformers and CeraPak and CeraTek brand packaging technologies to White brand automated storage and retrieval systems and inventory management software—cover the entire supply chain, from the point-of-manufacture through distribution and to the point-of-use. For more information, call (508) 771-9400 or visit http://sencorpwhite.com/.

About Connell Limited Partnership:

Connell Limited Partnership is a family-owned business headquartered in Boston, Massachusetts. Connell has a history of owning and operating industry leading manufacturing and service companies that provide superior products, exceptional customer service and operational excellence. The Connell family is dedicated to supporting a wide range of philanthropic endeavors, with a large commitment to the medical field, including the William F. Connell School of Nursing at Boston College, the Connell and O’Reilly Families Cell Manipulation Core at the Dana Farber Cancer Institute, the Connell Nursing Research Scholars Program at Massachusetts General Hospital, and the William F. Connell Emergency Department at St. Elizabeth’s Hospital. More information is available at http://www.connell-lp.com/.

About Intek Integration Technologies, Inc.:

Every day, Intek’s customers collectively scan millions of bar codes, achieve labor efficiency in their operations, utilize space effectively, discover “impossible” inventory accuracy and deliver outrageous customer service to bring goods to homes, offices, people and companies all around the globe using Intek’s software suites. For more information, please visit http://www.intek.com.

Contact: Joseph Kennedy

Telephone: (508) 771-9400

E-mail: jkennedy@whitesystems.com

No. 913 is 500°F (260°C), truck oven from Grieve, currently used for curing rubber parts hanging from the oven’s ceiling at the customer’s facility. Workspace dimensions of this oven measure 48” wide x 52” deep x 96” high. 24 KW are installed in Nichrome wire tubular heating elements, while a 1000 CFM, 1-HP recirculating blower provides combination airflow.

Controls on the No. 913 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch and a 10” diameter circular chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingMarket Leader in 3D and CT Scanning Details a Typical Airfoil Procedure

Exact Metrology, a leading supplier of 3D laser and CT scanning equipment and services details the steps to a successful airfoil evaluation.

The scan can occur at the customer’s facility or at Exact Metrology’s. In many cases, it is most cost effective for the digitizing or scanning to take place at the Exact facility. However, in certain instances, when turnaround time is of great importance or downtime of the scanned component is critical, the scanner is mobile and available for onsite operation.

The airfoils that are typically provided by customers will be received by Exact Metrology for full documentation with photos, measurements and any surface markings or serial numbers recorded prior to any high definition scanning.

Setup

The mobility of the Exact scanner allows a high degree of flexibility in performing onsite scans (Option A) at a customer facility or the more cost efficient in-house scan at the Exact facility (Option B).

Due to the reflective nature of the blades, a thin coating of Magnaflux spray is applied. The SKD-S2 spray is a second phase of the crack checking processes. Phase 1 is a die penetrant that will not be used typically. The spray meets the requirements for AMS 2664, ASTM E165 and is ASME approved. (Health – 1, Flammability – 4, Reactivity -0, No Specific Hazard). See MSDS 0166 for more information on the SKD-S2 product.

When scanning the blade, Exact uses a fixture device. Targets will also be used to constrain data during the alignment phase. Targets will be placed using magnets on either side of the air foil. The fixture itself will also act as an alignment constraint while holding the airfoil in place and allowing Exact technicians to capture maximum data on the part without moving or touching the part. A manual or automatic turntable may be used to allow enhanced scanning and registration access to the part.

Scanning

The part is positioned on the rotating table or on a stationary marble top and scanned from multiple perspectives. This procedure is repeated multiple times to provide complete coverage of the part. Known geometric objects, cubes and spheres are often placed in the scene for quality assurance and validation during the validation stage.

The scanner used on these projects is a Breuckmann Stereo 3D Scanning system. This device uses a unique halogen structured white light projection system with dual 6.6 mega-pixel cameras. The scanner is the highest resolution scanner available on the market and was specially built for Exact Metrology in Germany.

Registration

The registration process can be done with or without targets. Both registration methods have different techniques with similar results. Essentially, the targeting procedure uses an automated fitting of point clouds or scan worlds together, based upon three common positions on the part or scene. This process has been simplified with modern software technology. The software will then analyze every point with overlap and run a best fit algorithm over hundreds of iterations to find the tightest and best alignment. The result of this process will yield a fully registered and organized point cloud.

Validation

It is important to verify the automated method with targeting and adding known geometric shapes to the scan. All scans are documented with notes, computer logging and digital photos accompanying the recorded scan setup within the software. A CD copy of all digital data is recorded prior to returning the part or teardown.

MODELING PROCESS:

Once the data is gathered and the registration process is complete, the point cloud or data set can now be worked. The first step is to triangulate or mesh the points together. As part of this early process, points are “intelligently” removed from the network by algorithms in the software. Essentially, the points of redundancy and overlap are decimated and averaged. This mesh is further manipulated by reducing the triangles and points along flatter areas and retaining more triangles in areas of curvature and complexity. This poly mesh can now be exported as a complete *.STL file or similar format.

Surfacing

The process of fitting NURBs and geometry to the poly mesh or point cloud can be a time-consuming and arduous process. A surface is basically draped over the mesh and smoothed to be reflective of the actual part. Once this task is completed and a complete watertight object is created, the model is ready to be exported to nearly any format via various methods. The end file format is entirely up to the client and the limitations of existing conversion tools available today. A final 3D solid model can be provided as a “dumb solid” with no parametry or history tree as an imported object. The available formats include: Siemens NX, Pro/E Wildfire, AutoCAD, AutoCAD Inventor, SolidWorks, as well as generic formats such as IGES, STEP, ParaSolid (X_T) and others.

Parametric Modeling

The final deliverable is a parametric model. Unlike a solid model, the parametric model possesses relationships of all dimensions within the CAD. With these relationships, the CAD model can be manipulated and fine-tuned without disturbing the overall geometry of the part. For this workpiece, the specific parameters of each cross section within the model can be independently modified without disturbing neighboring cross sections. The end result is a Pro/Engineer CAD model with known geometry that is fully adjustable and possesses a design history.

For more information on this application, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

Continue reading

Effective immediately, Siemens announces the standard 12-month warranty on newly purchased Sinamics DCM DC drive products, including DC converters, base drives, enclosure cabinets and control modules, has been extended by two years, to a total of three years from date of manufacture.

This extended warranty, according to company sources, applies to new orders only and previously placed orders cannot be included in this offer. The extended warranty is exclusive of any other extended warranty program or initiative offered by Siemens or its sales distribution network.

The offer applies to all products in the DCM drive products line and no registration or application is required for compliance.

Siemens has extended the warranty on its Sinamics DCM DC drive products, including DC drives, base drives, enclosure cabinets and control modules, by two years, to a total of three years from date of manufacture, effective immediately.

Contact for journalists:

Siemens

John Meyer

(847) 640-1595

john.meyer@siemens.com

Siemens

Hollie Davis

(770) 751-4882

hollie.davis@siemens.com

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com. Or, go to the website for full details: www.usa.siemens.com/drives.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Seeking to design the next generation multi-layer die to overcome these challenges, the engineers at Guill looked for a way to incorporate this technology into an updated version of the 800 Series. This led to the creation of the 800 Series Hybrid. The inherent benefits of the 800 Series are retained, including compact design, low residence time and a common deflector bore that eliminates tolerance stack up. The challenge was to create a hybrid design that incorporates the benefits of layer overlapping, while reducing unnecessary complexity and making the technology more cost-affordable for customers. This was achieved by overlapping layers in each semi-deflector, using a single cone. The highly efficient design of the 800 Series Hybrid reduces cost and size, as opposed to other methods of overlapping layers.

Essential benefits of the 800 Series Hybrid include eliminating weld lines in materials through patented overlapping technology, producing a more consistent finished product; reduced sensitivity to changes in viscosity; reduced sensitivity to changes in line speed; myriad material and multi-layer application possibilities; works in all tubing and jacketing applications with a wide range of materials; low residence time; compact design and a low tolerance stack-up error factor, all resulting in improved concentricity.

The 800 Series Hybrid extrusion tool greatly reduces stagnation, because overlapping layers are more inherently balanced than single layers and also because each semi-deflector is “tuned to flush.” Conventional deflectors must simultaneously achieve a balance between flushing, balancing and eliminating the weld line. There is less difference between the slowest moving material and the fastest moving material in the deflector channels, thus making the viscosity more consistent in the deflector.

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick , RI 02893

(401) 823-7600

www.guill.com

sales@guill.com

Firm has agents throughout the country, serving the extrusion industry

Guill dies and crossheads for plastic, rubber and other material extrusions are now being sold by Bernal Industrial throughout Mexico. With more than 50 years of experience, Guill is a recognized technology leader in the design and manufacture of extrusion tooling for various applications. These include medical tubing, multi-lumen, multi-layer, profile products, rubber, plastics, wire & cable and fiber optic sheathing.

Bernal Industrial operates as a consultative engineering representative agency, distributor and service provider for its lines. Daniel Bernal is the manager and director of Bernal Industrial. Besides its main office in El Paso, Texas, Bernal Industrial has Mexican offices in Baja California, Chihuahua, Tamaulipas, Nuevo Leon, Mexico City and Queretaro. Bernal also sells products for Nordson PPS (Xaloy, BKG, EDI), American Roller, Scantech, Regloplas, Getcha, Matsui and Pillar Tech, among others.

The company has been in business for 18 years and has 15 employees. During that time, Bernal Industrial has become a major force in Mexico by aligning themselves with industry leaders in the plastics and rubber processing market to provide cutting-edge technology to all the major markets in Mexico, including auto, aero, medical and appliance. Their team comprises industry professionals who have hands-on experience and can provide highly technical application assistance for the products that they bring to the market. Bernal Industrial currently contacts all plastic and elastomer processors in Mexico, including the affiliates of major U.S. and international companies.

Bernal will be promoting the complete line of Guill products. Asked about this partnership, Daniel Bernal commented, “We are looking forward to working with Guill and finding many new business opportunities for them throughout Mexico.”

For more information, please contact:

Thomas Baldock

Guill Tool & Engineering

10 Pike Street

West Warwick , RI 02893

(401) 823-7600

www.guill.com

tbaldock@guill.com