Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

This innovative feature enables the production of consistently high-quality taps by addressing a key challenge – thermal growth.

Introducing a breakthrough in tap manufacturing: ANCA’s patented Motor Temperature Control (MTC) technology. This innovative feature enables the production of consistently high-quality taps by addressing a key challenge – thermal growth.

True to ANCA’s commitment to solving real-world manufacturing issues, MTC tackles the problem of inaccuracy and variation caused by thermal expansion. Traditionally, manufacturers rely on measurement and compensation to control these variations, adjusting for thermal and mechanical changes during grinding. But what if there was a way to eliminate a major source of inaccuracy altogether?

ANCA’s MTC does exactly that. This patented technology allows operators to set the spindle temperature for production, and the machine automatically monitors and maintains that temperature. By stabilizing the spindle’s thermal environment, MTC removes fluctuations caused by thermal growth, ensuring greater precision and consistency in tap production.

Let’s apply this unique and innovative solution to the TapX, using the cresting operation as an example.

Thread cresting is one of the most important tap features to get right. The relief of the thread typically involves a drop of 10-20 microns over the thread. The quality and shape of the thread crest are critical to the performance of the final (cut or formed) thread.

Threading is often the final operation in the manufacturing of parts, so taps play a crucial role. We do not want to scrap parts due to a tapped thread when all other value has already been added to the part. For example, the cresting affects:

Load Distribution and Thread Strength: Different crest types offer varying load distributions. High-load applications rely on high surface contact from a particular crest shape, such as a flat crest. The tap needs to form this large area without jamming or breaking.

Leak Tightness: Certain crest shapes, like rounded crests, can be more challenging to manufacture but are essential for creating effective seals in gas or fluid environments.

Thread Engagement: V-shaped threads provide high precision with increased thread engagement, while a tapered crest offers a more forgiving environment for quick or easy assembly, as well as being more durable with reduced wear.

Many tap manufacturers also have their own unique or specialized crest designs to achieve specific characteristics for a particular customer or industry. This is where ANCA’s TapX shines.

As mentioned in our previous article, reducing coolant pressure is one key to creating conditions for a more controlled operation. However, MTC takes a leap forward by regulating and maintaining a controlled manufacturing environment.

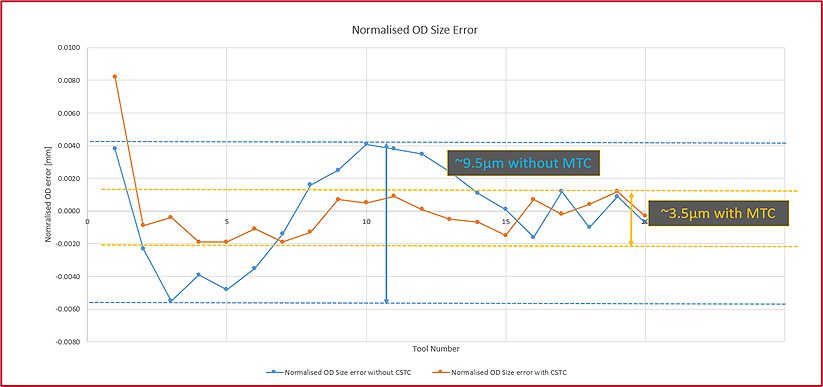

ANCA’s extensive experience has shown that thermal variation in the spindle contributes to variation in tool dimensional accuracy. OD finish operations are particularly sensitive to this. Using MTC significantly improves OD consistency over a batch.

Controlling the production environment with MTC enhances the accuracy, quality, and finish of the tap, leading to several benefits:

For more information, visit www.anca.com or contact your local ANCA representative.

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

ANCA‘s advanced grinding solutions offer seamless finished tool grinding in a single setup, including blank preparation. This setup features the P-axis Arobotech, which supports blanks at the grind point, enabling the efficient production of various tools with a surface finish below 0.2 Ra. This process significantly reduces cycle time while boosting productivity. The 3000 RPM headstock on the MX7 platform further enhances performance, allowing the tool to spin at optimal speeds for this application.

The MX7 platform, equipped with six wheel packs as recommended by ANCA’s application team, supports the grinding of various tool shapes in a single setup, eliminating the need for wheel changes. Depending on the tool’s shape and geometry, grinding can be performed at either the 3 or 12 o’clock position. Additionally, a specially designed hydraulic pump controls the clamping pressure based on diameter, including up/down pressure, to achieve faster cycle times.

Key benefits include:

This application is versatile, working not only with sized blanks but also with bar stock loading.

Bar stock loading, commonly known as “blanket grinding,” involves the automatic loading and grinding of multiple tools from a single blank. This process is ideal for batch production of endmills, drill heads, and similar tools. Its uniqueness lies in the ability to part off completed tools from the blank and then extend the blank from the collet to grind subsequent tools.

ANCA’s LoaderMate software is designed to manage the number, location, and length of blanks in the pickup pallet, allowing for varying blank diameters per row. It also features a used bar report, detailing the number of tools ground and the total length of bar to be scrapped for each blank.

For more information, visit www.anca.com or contact your local ANCA representative.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, just announced it will begin to build out a portfolio of both pull-out and torque out test data for the inserts it offers. The announcement was made by Kyle Lindsly-Roach, Director of Sales & Marketing at the company’s Gardena, California headquarters.

The company’s initial plan was to use a third-party lab to test the performance of E-Z LOK inserts in various materials. However, E-Z LOK ultimately decided it would be more cost effective and beneficial if they brought the testing equipment in-house because it allows them to complete testing at their own pace, as well as perform testing on future products. This decision was made in the first quarter of 2024 as a way for the company to build a more complete library of test data for their users. Carver Engineering/Labs in El Cajon, California is building the machines, which are up and running at E-Z LOK as of early October 2024.

Insert pull-out strength is tested by installation in various test blocks of materials (plastic, wood or metal) and threading a bolt into the insert. Then, the bolt is pulled upwards until the insert is pulled out of the material. The insert testing machine records the value. The torque out machine measures the torque the insert can withstand before spinning out of the material, breaking the fastener or stripping the threads of the insert.

Available on the E-Z LOK website, the data will be housed under the “Resources” section with links for specific product groups. Additionally, the company will create PDFs of the testing data on a product group basis.

Commenting on its significance, Kyle Lindsly-Roach, Director of Sales & Marketing said, “It is a great resource that helps engineers and customers who are designing bolted joints, and want to know the approximate pull-out and torque values they could expect to see in their applications.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

It began with an accident. Dr. Salah Huwais, a renowned periodontist with several offices in Michigan, USA, started to drill a hole in a patient’s jaw, but an assistant had mistakenly set the hand tool to rotate counterclockwise. Although Dr. Huwais found it hard to push the burr into the bone, he also noticed that trying to do so had the effect of hardening the bone a bit. This gave him the idea that the right tool geometry might be able to both make the required hole and compact the cut bone back into the jaw. If so, this would revolutionize dental implant procedures by greatly reducing the required time to heal.

That was back in early 2014. By April of that year, Dr. Huwais, who had no manufacturing experience, formed the company Versah, LLC, in Jackson, Michigan, and partnered with engineers to turn his idea into reality. It wasn’t easy. Aaron Beach, director of manufacturing and product development, recounted that they went through more than 60 prototypes over 6 months before settling on a design. The resulting dental burr, which is protected by numerous patents, returns all the bone back into the jaw as the periodontist cuts the hole needed for the planned implant. According to Beach, this usually enables the surgeon to immediately place the permanent implant, versus waiting 6 to 12 months for the bone to heal, as is required when using a traditional burr.

ANCA machines are key

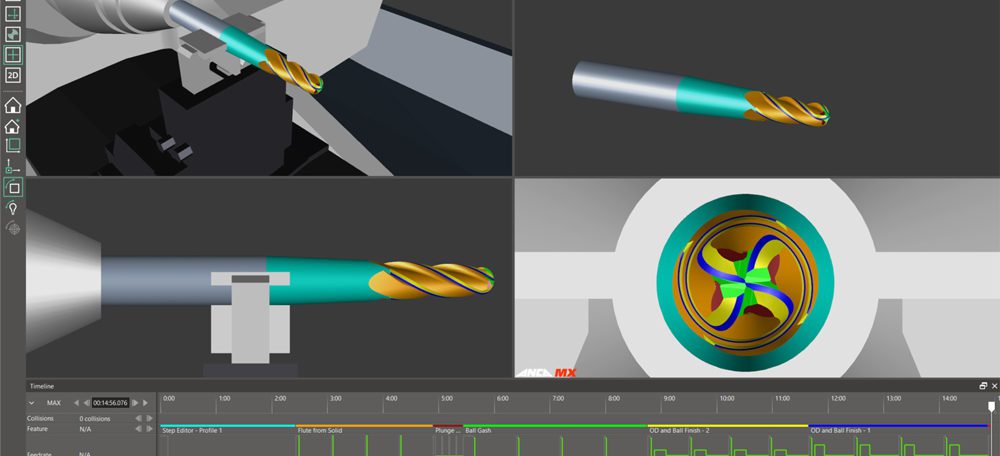

Naturally, Versah does not want to publicize all the secrets that go into making these stainless-steel tools, except to say that they are ground to “extremely tight tolerances” on ANCA MX and FX machines, where the biggest challenge is accounting for wear in the steadyrest and the grinding wheels, said Beach. But the CBN wheels hold up well enough that they don’t require in-process dressing, he reported. In terms of workholding and part handling, all jobs are fully automated, with a typical batch size of 1,000 burrs.

Beach did reveal that the tools have “multiple geometries” that change throughout the flute, which the ANCA software and machines handle well. Likewise, measuring the geometry is a challenge, the details of which can’t be shared. But Beach said they “inspect parts with a vision system every 30 minutes, and document the inspections every 2 hours, to maintain quality.”

Another important point Beach made is that although he had manufacturing knowledge when starting this project in 2014, he had no grinding experience. Versah jumped in with a fully equipped ANCA MX5 and then a number of FX machines. As Beach recalled, “I did some Solidworks programming in the past that helped. But I didn’t know anything about ANCA’s iGrind software or anything related to grinding. The fact that you’re able to watch the part unfold in the software, to watch the changes happen right in front of you on the machine, makes it very, very user friendly.

“The software is also educational. New people coming in, or even our team in the offices with no manufacturing background, can click on different items, leave some highlighted, and it walks them through how that part’s being ground, and shows how each part of the program is connected with each tool feature. It’s really simple. I have hired a few people on these grinders that had zero experience with them, and they’ve picked it up quickly.” Beach also lauded ANCA’s customer service and reliability. “We run these machines around the clock, six to seven days a week. So, they’ve gotten a lot of use, which obviously calls for maintenance and support. But we find them to be very low maintenance.”

Production details

Versah makes their burrs in two lengths and a variety of cutting diameters, but with a single shank diameter that meets the relevant ISO standard. This simplifies their setups, said Beach, such that they use only two collet types. For the longer burrs, the collet swallows more of the shank, providing more rigidity for the grind. They also use a fixed steadyrest on each tool, changing its position based on the tool length. But given Versah’s lot sizes, these adjustments are infrequent.

Versah electro-polishes the tools coming off the ANCA grinder, added Beach, “to remove any free iron. Then they are coated with titanium nitride.” Beach explained that heat reduction is the main coating benefit, since heating the bone typically damages it. “We found that adding this coating, along with the appropriate irrigation, keeps our burrs a little cooler than they otherwise would be. We think the coating also helps prevent the bone from sticking to the burr, and therefore helps transfer the bone back to the jaw.”

On the other hand, the unique geometry is clearly the critical factor, because Versah only added the coating in 2019. By then, the burrs had become a worldwide success. A gratifying success story in improving thousands of lives.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Guill Extrusion Division Enters Pultrusion Market with Advanced, Custom-Engineered Tooling Solutions

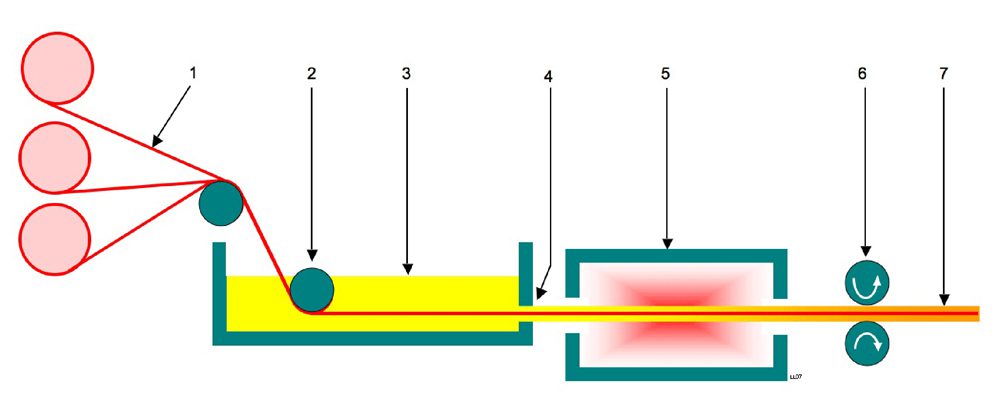

Guill, a global manufacturer and designer of extrusion dies, proudly announces the expansion of its product portfolio to include custom-engineered pultrusion dies. This strategic move marks a significant advancement in providing comprehensive, high-quality tooling solutions for industries such as automotive, aerospace, construction, energy, marine, sporting goods and telecommunications.

As the demand for pultruded composites grows due to their strength, durability and lightweight properties, Guill is well-positioned to meet this need. Leveraging its expertise in extrusion tooling, Guill is now applying its precision engineering capabilities to develop innovative pultrusion dies tailored to the specific requirements of each target industry.

“We are excited to enter the pultrusion market with our advanced tooling solutions,” said Peter Leary, Technical Sales Engineer at Guill. “Our extensive knowledge of extrusion processes and commitment to custom engineering enable us to design dies that not only meet but exceed our clients’ expectations in terms of performance, efficiency and quality.”

The Guill Tool Extrusion Division has a long history of designing and manufacturing tooling for various applications, including medical tubing, wire and cable coating, hose production and multi-layer extrusions. Its capabilities include creating multi-layer crossheads, in-line, reciprocating, rotary dies and a variety of other custom solutions supporting materials such as plastics, rubber and silicone.

New Pultrusion Tooling for Advanced Composite Applications

Guill’s new line of pultrusion dies is engineered for industries utilizing fiber-reinforced polymers (FRP), such as:

* Fiberglass Reinforced Polymers (FRP)

* Carbon Fiber Reinforced Polymers (CFRP)

* Aramid Fiber Reinforced Polymers (e.g., Kevlar)

These dies are compatible with a range of polymer matrices, ensuring versatility and high performance across different applications.

Tom Baldock, Guill sales manager, is looking forward to introducing a whole new set of customers to the company’s dies. He notes, “Pultrusion is a cost-effective process for producing parts with a constant cross section in high volumes, requiring relatively little labor. Fiber-reinforced polymer (FRP) pultruded composites are durable, corrosion-resistant and eco-friendly.”

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: +1 401-828-7600

tbaldock@guill.com

About Guill

Guill is a global manufacturer specializing in custom extrusion tooling and industrial equipment. With a focus on precision engineering and computational fluid dynamics, Guill provides tailored solutions that address industry-specific challenges. The company’s mission is to deliver innovative, high-quality equipment that supports efficient, reliable production processes for customers worldwide. Based in West Warwick, Rhode Island, the company also operates Guill Tool Europe to serve its ever-expanding customer base there.

ANCA’s innovative job management and production control software improves quality and reduces cost for tool manufacturers

ANCA CNC Machines, a world leader in CNC grinding technology, announces the launch of AIMS Connect, a job management and production control software designed to benefit tool manufacturing by optimizing processes, enhancing quality, and reducing costs.

In a highly competitive industry where efficiency is key, AIMS Connect addresses the growing demand for smarter, more streamlined operations. As a smart solution to integrated manufacturing, AIMS Connect has the potential to boost productivity by 20% or more, setting a new standard for excellence in the sector.

“AIMS Connect offers a flexible and customizable solution for tool manufacturers looking to increase efficiency, improve quality, and reduce costs,” said Steffen Kluth, ANCA Product Manager.

“Our goal is to make digital manufacturing accessible to everyone, and with AIMS Connect, we are helping our customers embark on a journey toward a fully integrated smart factory, step by step.”

Key features and benefits of AIMS Connect:

AIMS Connect is an accessible entry point into digital manufacturing, emphasizing the logical connection of machines and systems. It delivers transparent and verifiable processes, featuring a worker guidance system that informs employees about production stages and task schedules. This system frees skilled workers from repetitive tasks, allowing them to focus on areas where their expertise is most valuable. Each tool is meticulously described in a job order process, ensuring consistent quality through defined compensation strategies and logical frameworks.

Building on the foundation laid by AIMS Connect, ANCA’s AIMS Automate transforms tool manufacturing into a fully integrated smart factory. AIMS Automate autonomously adapts to production changes, ensuring smooth operations even during disruptions. With the mobile robot, AutoFetch, it effortlessly manages tool pallet transfers, from raw materials to finished products, maximizing efficiency and minimizing downtime.

To learn more about AIMS Connect, visit www.anca.com/AIMS-Connect

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA CNC Machines is a global leader in the design, manufacture, and service of advanced CNC grinding machines. With an illustrious history spanning over 50 years, ANCA is renowned for its cutting-edge technology, innovative solutions, and exceptional customer support. ANCA’s comprehensive range of products includes tool grinders, CNC grinding machines, software, and automation solutions, catering to diverse industries such as aerospace, automotive, medical, and general manufacturing.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood has a wide range of installation tools available regardless of the type of threaded insert being used. These include drive tools for E-Z LOK™ (Solid Wall) inserts, Knife Thread, Coil and Hex Drive.

E-Z LOK™ tools install Solid Wall inserts for metal without engaging the insert internal threads. This speeds up the installation process and eliminates the possibility of cross-threading or stripping. Furthermore, drive tools fit standard power drills and drill presses for an easy and efficient installation process. They are versatile and adaptable to various metalworking applications ranging from industrial projects to automotive repairs. Drive tools are designed for threaded insert installation in metal as well as woodworking.

Installation tools for E-Z™ Knife threaded inserts are engineered to improved accuracy, reduce effort, prevent insert damage, enhance strength of connections and increase project efficiency. It ensures that threaded inserts are installed correctly and securely. Optionally, power drive wood insert tools provide efficiency and consistency, making them ideal for high-volume projects.

The E-Z Coil™ tools can quickly fortify, or repair tapped holes in soft metal materials. Each mandrel-style insert tool and manual tang break tool offer a low-cost solution for efficiently installing the company’s premium inserts. Installation tools are available for every insert size E-Z LOK offers.

Hex drive installation tools are high-grade and ideal for softwood installation applications. These tools provide the needed control to achieve precise and snug threaded insert installations each time. Versatility is at the core of the tool collection. Threaded insert tools are constructed using top-quality materials, ensuring they are durable, dependable and ready to tackle numerous installations without faltering.

FREE SAMPLE ON REQUEST

CAD files on this product can be downloaded in over 100 file formats from the E-Z LOK website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Guill Tool, the global leader in extrusion tooling, now offers a wide variety of extrusion equipment specifically for food processing.

Extrusion is increasingly becoming one of the primary methods of producing a variety of traditional and innovative food products, and the company’s extrusion tooling is designed to accommodate producing all of them. This includes breakfast cereals, sausages, snacks, pasta, baby food, confectionaries and pet food. Guill’s balanced flow designs control dimensional tolerances in order to increase product quality while reducing waste.

Custom made extrusion tooling and dies make it easy to efficiently and consistently manufacture a variety of food products. More precise tooling allows for considerably reduced wasted extrudate. Furthermore, Guill’s extrusion tooling enables precise temperature control, allowing food to be manufactured under both high and low temperatures.

The company has extensive experience in food, pharmaceutical and medical applications involving stainless steel. As a result, Guill is highly skilled in the machining, welding and assembly of stainless steel dies, the standard in the food industry. Furthermore, they comply with the all the necessary standards to produce equipment for this market.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Stephanie Chrystal from Sandvik Coromant USA takes first place in the ANCA Female Machinist of the Year award

The 2024 ANCA Tool of the Year Awards, now in its seventh year, celebrated excellence in the cutting tool industry at an awards ceremony during IMTS in Chicago. This year’s event, coinciding with ANCA’s 50th anniversary, highlighted the continued creative design and manufacturing prowess that continues to wow judges in ANCA’s prestigious awards.

Werkzeugschleiferei Krämer GmbH earned the top honor in the “Made on ANCA” category with their groundbreaking tool. Their innovative design makes exceptional use of iGrind operations and advanced profile software features, such as layers, pivot editor, and 3D hook compensation. This results in outstanding accuracy, with the tool closely aligning with its intended specifications and delivering exceptional profile precision. The contest has highlighted the ability for a smaller company to gain recognition on a global stage and experience a dream come true moment.

In the Virtual Tool Category, XGE impressed the judges with a creative and technically sophisticated entry inspired by the renowned attractions of the Garden Expo Park in Xiamen, China, including the Moonlight Ring and Xinglin Pavilion. Their design integrates iGrind software with profile and end-face operations, and is brought to life by importing 3D models into CIM3D software.

This year also saw Stephanie Chrystal from Sandvik Coromant USA honored with the Female Machinist of the Year award. Launched in 2023 to promote diversity and provide role models for women in the cutting tool industry, this award reflects ANCA’s commitment to fostering an inclusive and supportive environment. Stephanie was recognized for her exceptional problem-solving, leadership in expanding and training her team, and her ability to deliver outstanding results under pressure.

Pat Boland, ANCA Co-Founder, remarked, “For 50 years, ANCA’s software has set industry standards, enabling Tool of the Year entrants to push the boundaries of what’s possible. Our technology not only meets the highest precision demands but also showcases the creativity and capability of our customers, highlighting truly innovative designs.”

Torsten Mende, Managing Director at Werkzeugschleiferei Krämer GmbH said, “This tool is used by one of our customers to create a profile in a gripper for molded parts. Previously, this contour was produced using a 3D milling process. The customer’s tolerance specification is +- 0.01mm. The program was created in ToolRoom RN32/33 and ground using RN34.1 on an FX7.”

“As a smaller company, it is a great honor to participate in this competition. We have been grinding tools on ANCA machines since 1999. The sophisticated software enables us to grind complex geometries and to monitor them during the process, giving our customers a competitive advantage. For this reason, we extend our heartfelt thanks to ANCA for the excellent symbiosis of software and machines.”

Chen Jianming, R&D Engineer at XGE expressed his gratitude for winning the Most Innovative Award, saying, “This award is a high recognition of our team’s innovative capabilities. Our design was inspired by the ‘Moonlight Ring’ and ‘Xinglin Pavilion’ of Xiamen Yuanboyuan, symbolizing the harmony of nature and humanity. The egret in the design, replaced by our company logo, represents both a tribute to our brand and a leap in tool innovation.”

“Competing with industry elites worldwide has been an honor. This recognition reflects XGE’s innovative strength in the global tool industry, and we will continue to deepen R&D efforts, driving progress alongside our global peers for a brighter future.”

ANCA Female Machinist Award winner Stephanie Chrystal said: “It is a privilege to be a part of Sandvik Coromant who is paving the way for women to be recognized for their contributions to the industry. I am honored to have been chosen out of all of the extraordinary women in this field as the Female Machinist of the year for ANCA. I hope to be an encouragement to women looking for guidance on their journey for meaningful careers. I am excited to see ANCA continue to honor women in this industry and inspire other companies with this award.”

The ANCA Tool of the Year Awards 2024 celebrate the passion, creativity, and expertise driving the cutting tool industry forward. ANCA remains dedicated to supporting innovation, excellence, and diversity, ensuring a bright future for precision tool manufacturing.

Made on ANCA

Winner: Werkzeugschleiferei Krämer GmbH

Their tool demonstrates the innovative use of iGrind operations, advanced profile software features, and achieves exceptional accuracy.

Second Place: ARCH Cutting Tools

Their “Master Mill Combo Tool” continues to lead in multifunction cutting tools with exceptional accuracy, utilizing iGrind software’s advanced profile operation features.

Third Place: Precision Tool Company

A versatile tool combining a drill, reamer, and chamfer, optimized using iGrind software for performance and functionality.

Virtual Tool Category

Winner: XGE

Their simulation, inspired by the Garden Expo Park attractions, creatively uses iGrind software and 3D modelling for a striking design.

Second Place: Zakłady Mechaniczne Kazimieruk

Their simulation of the Olympic flame represents the enduring spirit of the Olympic movement, created with extensive iGrind software use.

Third Place: SST Cutting Tools

Their “LINGAM” simulation symbolizes the Hindu God Shiva, showcasing creative use of iGrind software for profile, cross-section profile, and ripper form relief operations.

ANCA Female Machinist of the Year – 2024

Stephanie Chrystal – Sandvik Coromant, USA

ANCA Female Machinist of the Year Finalists

Roksana Grodowska – CNC Progresja Sp. z o.o., Poland

Jessica Sennott – Gorilla Mill, USA

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

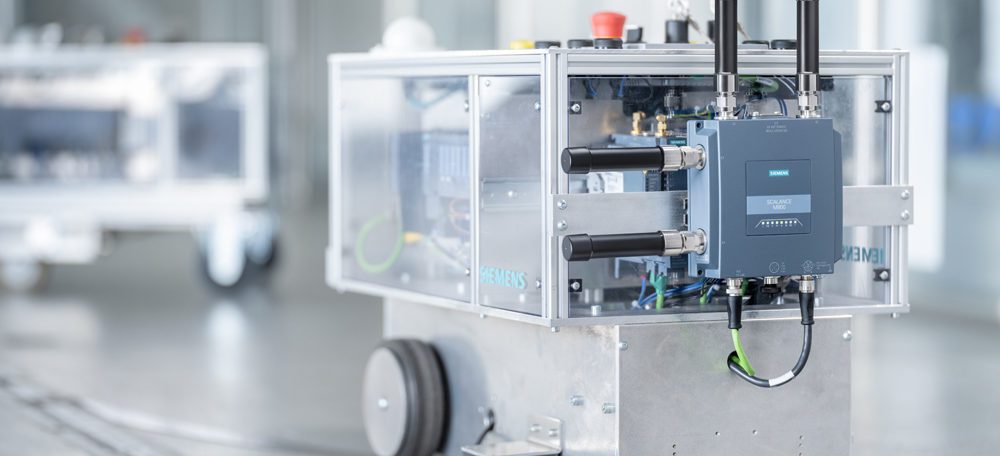

The Scalance MUM856-1 – the first industrial 5G router from Siemens – is now available for the U.S. market. The device connects local industrial applications to public 5G and 4G (LTE) mobile wireless networks. The router can be used to remotely monitor and service plants, machines, control elements and other industrial devices via a public 5G network flexibly and with high data transmission rates. Demand for this type of solution is growing in all industries. The device also integrates into private 5G networks. The Scalance MUM856-1 supports future-oriented applications such as mobile robots in manufacturing, autonomous vehicles in logistics or augmented reality applications for service technicians. Featuring a robust IP65 housing, this Siemens router can also be used outside the control cabinet, for example, under harsh conditions in production or in outdoor facilities in the water industry.

To ensure the powerful connection of Ethernet-based subnetworks and automation devices, the Scalance MUM856-1 supports Release 16 of the 5G standard. This device offers high bandwidths of up to 1000 Mbps for the downlink and up to 500 Mbps for the uplink providing high throughput for data-intensive applications such as remote implementation of firmware updates. Thanks to IPv6 support, the device can also be implemented in modern communication networks. Best-in-class security functions are included to monitor data traffic and protect against unauthorized access in, for example, an integrated firewall as well as authentication of communication devices and encryption of data transmission via VPN.

Where there is no available 5G network, the device switches automatically to 4G networks. The first release version of this new Siemens router has support for U.S. Mobile Network operators as well as the CBRS spectrum; other versions with different licenses are currently in development. With the SINEMA Remote Connect management platform for VPN connections, users can securely access remote plants or machines easily – even if they are integrated in other networks. The software also offers easy management and auto-configuration of the devices.

Successful use of prototypes for private 5G networks

Along with connectivity to public networks, Scalance MUM856-1 also supports integration into private 5G campus networks. Siemens is testing this use case in its own Automotive Showroom and Test Center in a prototype of a standalone 5G test network, which is based on Siemens components. The 5G infrastructure used here comprises a 5G core, a distributed unit and several radio units. Siemens has also built another prototype of a private 5G infrastructure in its plants in Amberg and Karlsruhe, Germany. In these systems, Siemens is relying exclusively on its own independently developed products and solutions, which will be available in the U.S. market in the future. Today, Siemens has private 5G systems running in a customer digital experience center known as MxD in Chicago.

Background info

In today’s industrial landscape in addition to the need for local wireless connectivity, there is an increasing demand for secure remote access to machines and plants. In these cases, communication is usually over long distances. Public mobile networks can be used to access devices that are located at a considerable distance.

Service technicians can connect to the machines they need to service via the mobile network while traveling, making public 5G networks an important element of remote access and remote servicing solutions. The public networks can be used to provide users with very high bandwidths in urban areas with small radio cells and high frequencies.

In rural areas, radio cells need to cover a large area, which is why lower frequencies are used. Particularly at the edges of radio cells such as LTE, there are often significant losses in terms of both the bandwidth and stability of the communication connection. “For companies requiring reliable service in remote areas, such as in water stations or electric power sub-stations, there is a need for solutions with stable bandwidth transmission for remote servicing or video transmission,” explains Joel Green, Business Development Manager for Wireless and Remote Networks at Siemens Digital Industries. “With innovative 5G communications technologies, considerably more bandwidth with greater reliability is available at the edges of radio cells, while the average data rate for users within a radio cell increases.”

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.