Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Innovative Broaching Solutions for Both CNC Lathes and Machining Centers

Platinum Tooling, the importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, will now carry REV broaching tools exclusively in North America. This announcement was made by Platinum Tooling president, Preben Hansen, at their headquarters in Prospect Heights, Illinois, near Chicago.

R

The REV motorized broaching tool is designed for use on live tool lathes. Single machine set-up eliminates the need for secondary operation or outsourcing. REV tools are ideal for high production runs, offer easy installation and fast processing time. These tools are designed for maximum rigidity, offer long tool life and an excellent finish.

REV broaching tools are a perfect complement to the Heimatec live tools that are sold by the extensive network of Platinum Tooling manufacturers’ representatives and distributors throughout North America.

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts, Hommel + Keller QUICK tools and REV broaching tools in North America. In addition, Platinum Tooling represents Rineck Shrink Fit Tooling in the United States and Mexico.

Save time with continuous production from bar stock to finished tool

By Kaine Mulder, ANCA Product Manager

Recent events have applied extreme pressure to supply chains, with labor and raw material shortages, freight delays and increased energy costs. The need to further adapt has become significantly more important, particularly as these pressures are exacerbated by demand, driven by expectation in our “instantaneous” global culture.

ANCA continually strives to work with its customers to adapt and grow along with these market changes and pressures. One such method assisting customers to adapt is blanket grinding, enabled by ANCA’s unique robot cells offered on each of our platforms.

ANCA’s blanket grinding approach allows for continuous and complete tool production from longer bar stock to finished product using an automated solution, saving time in eliminating extra processes or handling.

Utilizing ANCA’s machine platforms with a robot cell, blanket grinding offers flexibility across a range of tool sizes and applications. Blanket grinding allows for full automation of tools of similar geometries, by consolidating all tool grinding processes into one single machine. A batch of complete finished tools can be produced without interruption directly from lengths of ground bar stock with no operator intervention. Ultimately this gives you the flexibility to respond to customer demands in a dynamic and agile manner. All you need to do is simply load a pallet of ground bar material into the cell, and the machine will take care of the rest.

Blanket grinding is great for:

Beginning with the full 330mm bar stock material loading into the collet; the blank and tool geometry is ground, including any features (such as rear chamfer, for example), before the finished tool is cut off. The tool is then removed by the robot and loaded into the finished pallet. This program continues along the remaining bar stock until all useful raw material is consumed. To complete the automation process, waste is handled by the cell, before new bar stock is loaded into the collet.

ANCA’s machine platforms with the addition of a robot cell, can be utilized to implement the blanket grinding process. Tool size and application will determine which machine is right for you.

The two main features offered by the TX, beneficial in performing the blanket grinding function are the large working envelope and the high torque spindle. These attributes not only allow work on longer bar lengths, but also enable production of a larger range of tool sizes and geometries without limitation, including tools which require a high material removal.

The TX platform also fits any of ANCA’s robot cell solutions, including RoboMate, and the dedicated TXcell offering, which offers large format cell automation, many standard options and the flexibility for automated custom solution.

The nimble RoboMate cell is offered on both TX and MX platforms and offers customers a low barrier to entry for blanket grinding and production automation.

Customers are increasingly demanding products that are more unique and with higher complexity – but more importantly, with immediate response and shorter delivery time; when meeting these expectations, costs take a back seat, while focus is on delivery.

Using ANCA’s robot automation solutions in blanket grinding enables you to realize these demands with minimal disruption to existing production lines, less planning, reduced manual handling and increased utilization and efficiencies. These benefits can compound to deliver an overall value proposition and increased return per tool.

Blanket grinding may also offer a reduction in floor space by removing separate machines and consolidating processes into a single footprint to produce the same tool. The process consolidation allows changes in parts and features to be easily handled. For example, grinding of shank features (Weldon flats or coolant slots) and the handling of very small parts can be made simpler by adding many features in a single setup.

Become more agile

You can provide a quick response to customer requests without the need for re-tooling or disruption to high volume production lines, while also guaranteeing highest quality across the batch.

Reduce costs

Applying blanket grinding will go a long way to improving cost recovery, through increased utilization and efficiencies as well as removal of manual labor and setup times. There is also a benefit in reduced footprint through process consolidation into a single machine.

Blanket grinding can reduce costs through:

Reduce lead times

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

In-Place Machining Company’s new Measurement & Alignment Services Division, comprising Exact Metrology, OASIS Alignment Services and ECM: Global Measurement Solutions, has just released its new brochure and website page, showcasing the benefits of having one source for precision measurement and alignment solutions in plant and process operations.

These new resources highlight the innovative dimensional metrology, machine alignment, measurement tooling calibration, training and certification capabilities of these three highly respected industry suppliers. Providing an integrated approach benefits IPM customers with improved collaboration between a much larger team of experienced metrology engineers and technicians with skills, using a broader range of highly accurate and innovative 3D metrology tools and technologies.

With state-of-the-art measurement technology, cutting edge design and ISO 9100 & AS9100 Rev D certification, the 3D scanning facilities of the IPM Measurement & Alignment Services Division can capture measurements from objects as small as a medical heart stent to areas as large as a football field. Using a fleet of innovative metrology solutions, this new division offers precision machine alignment, resulting in reduced downtime, improved product quality and minimized waste for many in the manufacturing and process industries. Calibrating 3D measurement systems such as laser trackers, portable arms etc. on a schedule will maximize the accuracy and clarity of the data. Highly trained metrology professionals help when clients need to ensure equipment precision and accuracy to boost their bottom line.

Capturing information using 3D scanning methods to find measurements of thickness, accuracy, porosity and more, is achieved with the Data Capture software. It’s compatible with short range, long range, computed tomography (CT) and coordinate measuring machine (CMM) scanners as well as laser trackers. Additionally, post-processing solutions are tailored to fit the needs of myriad IPM client applications.

Proper machine alignment involves more than just data collection. Experienced staff from all the participating companies have the skills, tooling and knowledge not only to provide highly accurate alignment inspection data, but also to make the necessary mechanical adjustments. This saves considerable time and money during planned outages, emergency shutdowns, rebuilds and installations. Using advanced alignment solutions, IPM helps clients increase operating efficiency through alignment inspections and diagnostics, mechanical adjustments, alignment planning and technical reports.

Calibration services can be performed onsite at the client’s facility or at one of the IPM ISO/IEC 17025 Accredited Laboratories. The Measurement & Alignment Services Division provides calibration for a wide array of applications including ISO/IEC 17025 accredited lab, comprehensive reporting, on-site calibration, ASME standards evaluation, cleaning and firmware upgrades, portable instruments and stationary CMMs.

For those who prefer keeping their measurement processes in-house, the company provides training and certification services. These include CMS metrology certification, geometric dimensioning & tolerancing (GD&T), dimensional metrology, equipment and maintenance and measurement software.

Users in a wide variety of manufacturing and process industries will benefit from the collaborative capabilities of the IPM Measurement & Alignment Services Division.

For more information on this development or to request a copy of the new brochure, please contact:

Mr. Brian Hiltunen

Senior VP & General Manager – Measurement & Alignment Services Division

In-Place Machining Company

3811 North Holton Street

Milwaukee, WI 53212

Phone: 414-562-2000

brian.hiltunen@oasisalignment.com

www.inplacemeasureandalign.com

www.inplace.com

To view an online copy of the brochure/flipbook click:

IPM MEASUREMENT & ALIGNMENT SERVICES

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company is the premier provider of high-precision machining, large scale cutting and drilling, dimensional metrology, instrument calibration, and machine alignment services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world. Now with seventeen service locations across the U.S. and Canada, IPM has a breadth of service offerings that is unmatched in the industry.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 3D modeling. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company, a Leader in Precision Measurement, Machine Alignment and Mechanical Services

With a unique combination of tooling and services and a team of knowledgeable and dedicated engineers and field technicians, OASIS partners with customers to develop solutions specific to their precision measurement and machine alignments needs. Using a fleet of precision metrology instruments and mechanical tools, OASIS can provide full turnkey service from a North American network of service centers.

East Coast Metrology: A Division of In-Place Machining Company, a Leader in Precision Measurement, Machine Alignment and Mechanical Services

A globally recognized full-service contract measurement company specializing in 3D scanning and modeling, reverse engineering and design, training and certification, instrument calibrations, equipment rentals, integration & alignment and more. Headquartered in Topsfield, Massachusetts, ECM hosts an ISO/IEC 17025 Accredited Laboratory performing instrument calibrations, repairs and CMM part inspection and programming.

ANCA will showcase the latest products and industry-specific grinding and automation solutions and will announce the Tool of the Year Winner of 2023

CNC grinding technology pioneer ANCA will showcase their latest products and industry-specific grinding and automation solutions at EMO at Booth F52, Hall 6 in Hanover, Germany in September. The eagerly awaited winner of the renowned Tool of the Year competition will be announced live Wednesday, September 20th at 4.30pm (GMT) – and all are welcome to join the celebrations and witness for themselves the ultimate range of cutting tools.

Edmund Boland, ANCA CNC Machines General Manager said, “We are excited to bring not one but several world premieres to EMO, promising premium value, higher productivity and extended capabilities. Visitors can see firsthand ANCA’s latest technology that spans tool precision, integrated manufacturing systems, industry focus applications and optimization across the process chain.”

Martin Winterstein, General Manager of ANCA Europe said, “EMO is the global leading manufacturing technology show, it is where the current market trends and innovations are on display. Our setup in Hanover really shows hands-on opportunities for tool manufacturers, with new application and automation solutions tailored to industries’ needs. I am excited to show visitors our enhanced portfolio to include micro tools with the FX ULTRA, according to the high demand from this growing segment. Experts from ANCA and our partners will be on-site to show and discuss individual requirements at the booth.”

ULTRA value

Never ceasing in their commitment to creating the highest quality product, years of continuous refinements at ANCA have made the ULTRA technology possible. ANCA’s unique vertical integration is key to its success – where machines, controls, drives and precision components are all designed and manufactured in-house. Successfully introduced to the industry last year on the MX machine platform, it boasts the highest accuracy and quality cutting tools in the world. The MX7 ULTRA achieves one nanometre axis resolution, and can maintain better than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius endmills.

At EMO, visitors will find out how ANCA spreads the ULTRA advantages to further fields of application, including smaller batches, regrinding and tools with small diameters.

Launching the FX7 ULTRA, the latest game-changing innovation that revolutionizes precision grinding for small tools down to 0.1mm

The FX7 ULTRA introduces cutting-edge technologies, including ANCA’s unique nanometer control, that revolutionizes precision grinding for small and micro tools down to 0.1mm diameter. This significant technology breakthrough is already redefining the standards for tool and component grinding with the highest levels of accuracy and surface finishes.

New software, hardware and design features significantly improve surface finish, accuracy, and controlled runout, ensuring batch consistency from the first ground tool to the last. These advancements ensure that the FX7 ULTRA is the go-to solution for precision grinding in industries that rely on small tools, including electronics, telecommunications, medical devices, aerospace, automotive, diemold, and general machining.

The ultimate value – ANCA’s premium one stop shop for peel and geometry combined with blanket grinding

From blank to a finished high-quality tool, all on one machine – ANCA’s ultimate single setup solution for complete machining of cutting tools will be demonstrated on the MX7 ULTRA at EMO. Following a legacy of machine efficiency, this latest solution combines peel grinding and tool grinding on the one platform, enhanced with additional power to extend capability. The MX7 ULTRA’s remarkable spindle power of 26kW can handle demanding tools like larger taper ballnose endmills, step drills, and aerospace components ranging from 0.1 to 25.4 mm. This leads to reduced cycle times and increased productivity. Short setup times, optional collet change and proven blanket grinding processes round out the capabilities.

By utilizing the latest innovations in peel grinding technology, ANCA guarantees exceptional stability, accuracy and value, all achieved on a single machine. Manufacturers can now produce high-quality tools with confidence, knowing that the MX7 ULTRA delivers outstanding results.

Smart automation enables unattended cutting tool production

ANCA has further developed its AIMS system for automated tool production. At EMO, visitors can see examples from the field, with systems operating completely unattended over extended period, manufacturing tools.

The AIMS automation package is a modular and growing system, spanning across the tool production process. ANCA is set to include additional operations like blank preparation or laser marking in the automated process. The system’s intelligent design allows for progressive steps of automation, including an automated laser marking station AutoMarkX. The versatile laser marking station is tailored to meet the needs of tool manufacturers. It provides reliable and high-quality marking, ensuring traceability, identification, and branding of tools, while eliminating repetitive tasks to free up time for skilled staff.

The AutoMarkX’s new, retrofittable rotary workholding system allows for unlimited index marking around the tool, with automatic Z-axis focus and compatibility with tool shanks from 3 to 32mm. Moreover, the AIMS Autoline Basic, the standard interface for easy loading at the AutoMarkX enables customers to experience smoother material transfer between machines. By utilizing a manual trolley system, combined with AIMS pallet carriers, Autoline Basic streamlines the transfer of heavy tool pallets between machines, reducing labor-intensive processes.

From blanks with a surface finish better than 0.2Ra, to ANCA’s GCX Linear which has set the new benchmark for skiving cutter grinding

ANCA’s expertise in grinding solutions extends to blank grinding and integrated complete machining of gear tools, including in-process measuring and compensation. The CPX blank preparation machine will feature productivity-enhancing features in Hannover, including automated loading of tools up to 32mm, a flip station for grinding from both ends, tailstock, and extensive probing enabling statistic process control. The machine has been designed to give users high material removal rates and save time and money with unattended production.

The rising demand of gear cutting tools has led ANCA to enhance its product program with the GCX, the turnkey solution for manufacturing and resharpening gear cutting tools. The Integrated Gear Tool Measurement (IGTM) and ANCA’s expertise in grinding wheel dressing gives customers the benefit of full control over the high precision skiving cutter grinding process. First skiving cutter in tolerance, is the motto. ANCA’s widely spread area of grinding applications, can be covered with the versatile GCX and its numerous optional accessories like the LaserUltra for profile tools.

The Premier Cutting Tool Award

One of the most eagerly awaited events at ANCA’s booth will be the winner announcement of the Tool of the Year 2023 competition. This prestigious competition brings together tool manufacturers from around the globe, who compete for the title of the best real and virtual tools. The judging process, overseen by a panel of ANCA and external experts, evaluates precision, surface roughness, creativity, and practical use. The award ceremony promises to be a highlight of the exhibition, recognizing the industry’s most innovative and exceptional tools.

EMO 2023 offers an exclusive opportunity for industry professionals to explore ANCA’s latest advancements in grinding technology, witness revolutionary world premieres, and engage with experts from the field. Visitors will also experience exclusive product launches to be revealed at the show. ANCA invites all attendees to visit their booth in Hall 6, F52, where they can experience firsthand the cutting-edge solutions and industry-specific grinding innovations that are shaping the future of manufacturing.

Strategic Partnerships with Industry leaders

ANCA’s commitment to excellence is further emphasized through strategic partnerships with industry leaders. At EMO 2023, ANCA will collaborate with Mitsubishi, presenting their EDM machine at the booth, and GDS clamping technology, presenting a cohesive ecosystem of solutions that streamline processes across the process chain.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

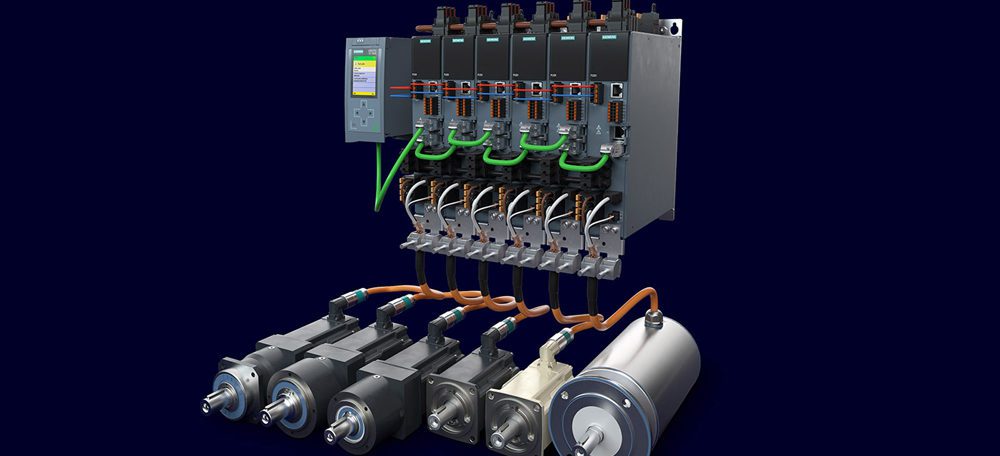

With the SINAMICS S210 next generation servo-drive system, comprising a digitally native drive with wide range of corresponding motors and gearboxes, Siemens brings a new level of high-dynamic, motion control in mid-range operation to stand-alone and multi-axis machines, recently introduced to the North American manufacturing industry.

This next generation servo-drive system introduces a new level of safety and security to discontinuous motion control in the mid-range segment, as well as moving, processing and positioning functions on a wide assortment of packaging, printing, labeling, pick-and-place, stacking, assembly, chip sorting and filling machines, with a special emphasis on food-and-beverage and pharmaceutical applications, owing to the availability of stainless-steel motor and planetary gearbox options.

SINAMICS S210 offers DC link coupling on 3-phase units for increased power efficiency on multi-axis applications. Corresponding SIMOTICS highly efficient synchronous motors feature high-resolution 22- or 26-bit absolute encoders, single or multi-turn. One-cable connectivity is standard and all motors and feature IP64, IP65, IP67 or IP69X protection. Easier setup and selection are assured with the integrated EMC filter and braking resistor.

For the engineering of SINAMICS S210, machine builders and machine users can utilize

the embedded web-server or Startdrive integrated with the Siemens TIA Portal. Easy implementation of the SINAMICS S210 servo-drive system for global use is provided by universal standards and certification compliance.

SINAMICS DriveSim model integrates into simulation software to allow machine builders to create a digital twin of the drive and motor in a project’s planning phase to ensure highest efficiency and performance of the equipment in use. In the field, the S210 is capable of communicating status through Edge or cloud-based data capturing for continuous monitoring and data analytics. Using the Siemens Analyze MyDrives application, machine users can monitor key conditions for advanced anomaly detection. Seamless transfer of data from the drive to the machine controller, Edge device and the cloud are maintained for truly digital native operation from planning through operations.

In the area of cybersecurity, SINAMICS S210 comes standard with integrated security for network connectivity, providing enhanced communication, integrity and authenticity checks

to protect against tampering, plus the drives offer User Management and Access Control (UMAC) within TIA Portal.

These new servo-drives are paired with the popular Siemens SIMATIC S7-1500 PLC or ET200 SP open controller and various SIMOTICS servomotor and planetary gearbox designs. Increased engineering efficiencies are gained with integration into the TIA Portal and TIA Selection Tool for optimized system selection and programming.

With Safety Integrated onboard, the SINAMICS S210 servo-drive system offers machine users up to SIL3 level of protection across an extended range of safety integrated functions including safe stopping and safe limited speed or direction. Integrated into the Startdrive advanced software, the menu-guided safety acceptance testing assures proper operation and safety validation.

The new SINAMICS S210 next generation servo-drive system is ready for digitalization and brings an enhanced level of safety and security to stand-alone or multi-axis machines for use in various manufacturing industries.

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

ANCA, a leading global manufacturer of CNC grinding machines, proudly announces the launch of its first Female Machinist Award. This prestigious accolade aims to recognize and honor the outstanding achievements of female machinists in the tool and cutter grinding industry. By promoting gender diversity and equality, ANCA is dedicated to fostering an industry that excels in every aspect.

Johanna Boland, ANCA Group Strategy & Communications Manager and member of the judging panel, says: “Recognizing and celebrating the contributions of women in the tool and cutter grinding industry is a vital step towards unlocking the industry’s true potential. By embracing and empowering women, we discover a wealth of diverse perspectives, fresh ideas, and extraordinary talent. ANCA is committed to shining a spotlight on these remarkable individuals, because we believe that their success fuels the success of our industry as a whole.”

The Female Machinist Award is open to women of all skill levels who are actively working with ANCA technology in the tool and cutter grinding industry. We are searching for individuals who exhibit unwavering passion for their craft, demonstrate a commitment to excellence, and contribute to the advancement of the industry.

A panel of experienced professionals from the tool and cutter grinding industry will serve as judges for this award. Submissions will be evaluated based on the following criteria:

The winner of the Female Machinist Award will be rewarded with a fully funded ticket to attend a prominent trade show where ANCA is exhibiting. This invaluable opportunity will enable the winner to connect with industry professionals, gain insights into the latest technological advancements, and build valuable relationships.

The winner will have exclusive access to the ANCA team, including top-tier leadership, skilled engineers, and renowned product experts. The prize also comes with opportunities to network with like-minded professionals and participate in educational seminars and workshops.

If you or someone you know embodies the qualities of a talented female machinist deserving of recognition, we strongly encourage you to apply for the Female Machinist Award today!

To learn more and apply, visit www.anca.com. The application deadline is August 31, 2023.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

About ANCA CNC Machines

ANCA CNC Machines is a global leader in the design, manufacture, and service of advanced CNC grinding machines. With an illustrious history spanning over 50 years, ANCA is renowned for its cutting-edge technology, innovative solutions, and exceptional customer support. ANCA’s comprehensive range of products includes tool grinders, CNC grinding machines, software, and automation solutions, catering to diverse industries such as aerospace, automotive, medical, and general manufacturing.

Platinum Tooling, the exclusive importer of Heimatec live tools and angle heads plus other global brands of precision machine tool accessories, is pleased to announce the appointment of Frank Twomey as the company’s Regional Sales Manager. In his new role, he will oversee all activities in eighteen states located in the Northeast, Mid-Atlantic and Southeast Regions of the United States. Company President, Preben Hansen, made the announcement at the company’s headquarters in Prospect Heights, Illinois.

Twomey graduated from Piedmont Technical Institute in 1991. His first job was as a machinist at Ross Industries. He then took on the role of Applications/Service/Quality Engineer at Walter Grinders and SCM Group as an Applications and Service Engineer. Between working as an Applications and Service Engineer, he became the CNC Manager of Euro-Composites Corporation and later Plant Manager at MTEQ. In 2015, Twomey took on the role of District Sales Manager for OSG USA.

Frank brings a vast amount of experience in aerospace, medical, machine tool, cutting tool, metal and composite industries. His technical expertise includes programming CNC machines using Mastercam and Alphacam CAD/CAM software and is well versed in PLC programming. During his career, Frank studied and trained in lean manufacturing, value stream mapping, ISO processes/audits, OSHA compliance, cost reduction, facility/line set-up and operator training. Continuing his education in 2020, Twomey obtained his CPSP (Certified Professional Salesperson) certification and in 2021 obtained his CPSL (Certified Professional Sales Leader) certification through NASP (National Association of Sales Professionals).

Commenting on this new hire Hansen said, “It is great to have Frank on the team as his expertise will benefit clients across industries. I am excited to see all that he will achieve.”

For more information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

New MTC technique offers dramatic improvement in CNC machine tool stability

By Pat Boland, ANCA, Co-Founder & Managing Director

Introduction

Melbourne Australia based machine tool builder ANCA has been granted a U.S. patent for Motor Temperature Control (MTC), a technique that dramatically improves the stability of precision machine tools.

Problem to be solved

A key element of machine tools is the spindle which holds and drives the cutting tool which machines the workpiece. Any dimensional errors in the spindle will be reflected as dimensional errors in the workpiece. A common technique in modern machine tools is to use motorized spindles where the driving motor is an integral part of the spindle. ANCA’s patent is a way of maintaining the motorized spindle at a constant temperature. A significant problem in the use of precision machine tools is the impact of changes of temperature particularly in the temperature of the spindle. Changes in temperature of the machine tool can be caused by changes in ambient temperature, coolant temperature, run time, spindle rpm and spindle load.

Solution

ANCA’s solution is to actively control spindle temperature by varying the electrical losses in the motor element while simultaneously maintaining spindle motor speed and load. This is accomplished by using special firmware in the spindle drive amplifier. Although simple in concept, this in practice is a major step forward in manufacturing technology.

Examples of the application of MTC

Faster Warm Up time

A near universal approach to precision machining is to run the machine in a warmup cycle to bring all the elements of the machine to some level of thermal stability. Typically, this warmup cycle will take approximately half an hour. Using MTC, this time can be reduced to around 5 minutes. Figure 1 shows the impact of MTC on actively heating the spindle to reach working temperature quickly.

Stability in batch grinding of endmills

Figure 2 shows the results in grinding two batches of 6mm diameter endmills, with and without MTC.

Grinding a Skiving Cutter.

Electric vehicles incorporate a high-speed gear box in their drivetrain. The accuracy of the components of this gear box will impact on lifetime, efficiency, and noise of the electric vehicles. Figure 3 shows a typical skiving cutter which is used to manufacture internal and external gears and will determine their accuracy. ANCA manufactures a special machine, the GCX, for grinding this class of tools. MTC is a key enabling technology for this machine to produce cutters to AAA class. Firstly, it is used to control the temperature of a dressing spindle which is used to create a high accuracy profile on the grinding wheel. MTC is also being used to control the main grinding spindle temperature during up to 12 hours of continuous grinding. Figure 4 shows the measurement results for contour accuracy of a tooth and index accuracy for all the teeth.

Summary

Motor Temperature Control (MTC) is a major innovation in machine tool technology. It improves the accuracy and stability by controlling the temperature of motorized elements of the machine by special software in the spindle drive amplifier. It drastically reduces the time required for a machine to reach working temperature.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Consolidation of IPM, Exact Metrology, and OASIS Alignment Services in single location strengthens synergy of divisions for enhanced service to aerospace, power generation, heavy manufacturing and other industries

In-Place Machining Company (IPM) is pleased to announce the addition of Exact Metrology at the company’s newly expanded IPM Ohio industrial facility, located at 6665 Creek Road in Blue Ash, Ohio. Centralizing the Ohio divisions of IPM, OASIS Alignment Services, and Exact Metrology will allow for improved collaboration and a more integrated approach to industrial solutions in this key region.

Speaking from IPM corporate headquarters in Milwaukee, WI, IPM President & CEO Dean Flint said, “We see this move as a classic case of the whole being greater than the sum of the parts.”

Flint went on to explain the synergy of having three prominent suppliers to industry in the Ohio area. “In IPM, we have a leading force in precision industrial machining services plus large-scale wire cutting and drilling. Coupled with the machine alignment expertise of OASIS Alignment Services and the dimensional metrology and onsite scanning capabilities of Exact Metrology, we can now provide faster assessments on potential projects, situation analyses, service execution, and 3D measurement data capture solutions.”

“This unified team will represent a formidable partner to our existing and potential customers in the region,” Flint continued, noting the collaboration of the three companies at one location will enhance customer service, while utilizing shared resources and staff capabilities.

The move is part of a long-term growth strategy at IPM to expand industrial service offerings from single integrated sources and enhance its regional strengths across the U.S. and Canada. To that end, IPM has created two divisions with multiple service locations across North America – the IPM Machining Services group consisting of IPM and newly acquired Western Machine Works, LLC, and the IPM Measurement & Alignment Services group of Exact Metrology, OASIS Alignment Services, and ECM: Global Measurement Solutions. As Flint notes, “Being a ‘local’ company has significant benefits beyond the operational strengths of the partners.”

For more information on this development, please contact:

Mr. Alan Brown

Senior VP & GM – Field Machining

In-Place Machining Company

3811 North Holton Street

Milwaukee, WI 53212

Phone: 414-562-2000

abrown@inplace.com

www.inplace.com

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company is the premier provider of high-precision machining, large scale cutting and drilling, dimensional metrology, instrument calibration, and machine alignment services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world. Now with seventeen service locations across the U.S. and Canada, IPM has a breadth of service offerings that is unmatched in the industry.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 3d modeling. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company, a Leader in Precision Measurement, Machine Alignment and Mechanical Services

With a unique combination of tooling and services and a team of knowledgeable and dedicated engineers and field technicians, OASIS partners with customers to develop solutions specific to their precision measurement and machine alignments needs. Using a fleet of precision metrology instruments and mechanical tools, OASIS can provide full turnkey service from a North American network of service centers.

Beginning with the full 330mm bar stock material loading into the collet; the blank and tool geometry is ground, including any features (such as rear chamfer, for example), before the finished tool is cut off. The tool is then removed by the robot and loaded into the finished pallet. This program continues along the remaining bar stock until all useful raw material is consumed. To complete the automation process, waste is handled by the cell, before new bar stock is loaded into the collet.

ANCA’s machine platforms with the addition of a robot cell, can be utilized to implement the blanket grinding process. Tool size and application will determine which machine is right for you.

The two main features offered by the TX, beneficial in performing the blanket grinding function are the large working envelope and the high torque spindle. These attributes not only allow work on longer bar lengths, but also enable production of a larger range of tool sizes and geometries without limitation, including tools which require a high material removal.

The TX platform also fits any of ANCA’s robot cell solutions, including RoboMate, and the dedicated TXcell offering, which offers large format cell automation, many standard options and the flexibility for automated custom solution.

The nimble RoboMate cell is offered on both TX and MX platforms and offers customers a low barrier to entry for blanket grinding and production automation.

Customers are increasingly demanding products that are more unique and with higher complexity – but more importantly, with immediate response and shorter delivery time; when meeting these expectations, costs take a back seat, while focus is on delivery.

Using ANCA’s robot automation solutions in blanket grinding enables you to realize these demands with minimal disruption to existing production lines, less planning, reduced manual handling and increased utilization and efficiencies. These benefits can compound to deliver an overall value proposition and increased return per tool.

Blanket grinding may also offer a reduction in floor space by removing separate machines and consolidating processes into a single footprint to produce the same tool. The process consolidation allows changes in parts and features to be easily handled. For example, grinding of shank features (Weldon flats or coolant slots) and the handling of very small parts can be made simpler by adding many features in a single setup.

Become more agile

You can provide a quick response to customer requests without the need for re-tooling or disruption to high volume production lines, while also guaranteeing highest quality across the batch.

Reduce costs

Applying blanket grinding will go a long way to improving cost recovery, through increased utilization and efficiencies as well as removal of manual labor and setup times. There is also a benefit in reduced footprint through process consolidation into a single machine.

Blanket grinding can reduce costs through:

Reduce lead times

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.