Contact us today:

Author Archives: Bernard and Company

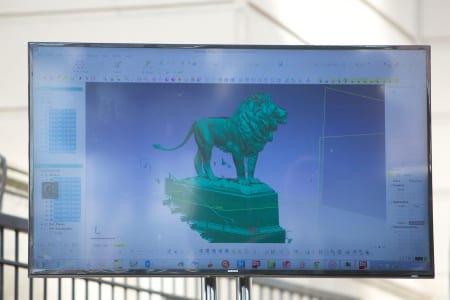

Exact Metrology Does 3D Scans Of South Lion At Chicago Art Institute

Scans to be used by Met-L-Flo to make miniature 3D printed models for FABTECH

The South Lion, named Attitude of Defiance, was

As Dean Solberg remarked, “We’re creating a file with millions of 3D data points that would allow the program to accurately recreate the lion at almost any size, whether on a conventional CNC machine tool or in the new 3D printing method being used by Carl (Dekker) and his team at Met-L-Flo. Dekker noted that 3D printing of one of the seven additive manufacturing techniques his company currently employs to make not only prototypes but also functional short run production parts.

Exact Metrology will be exhibiting its various metrology equipment and services, including robotic articulation and its new CT scanning technology that allows precision examination of internal structures, during FABTECH.

Exact Metrology is an ISO 9001:2008 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Click the link to view a video of the press conference: https://www.youtube.com/watch?v=K0qPVAI5z8Y

For more information on this event or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingGMTA News Of Note (Issue 2015-3)

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders companies, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

-GMTA will exhibit at several shows upcoming, including EMO in Milan and Gear Expo in Detroit. At the latter, the company will show its latest development for gearmaking, namely, the Hard Scudding process. Just a few years ago, the concept of Scudding®, developed by GMTA and its partner company Wera in Germany, left the traditional skiving method in the dust, so to speak, for internal gear production used primarily in the powertrain buildup. This process, 5-10 times faster than gear shaping, formed the surface of the workpiece through several, small enveloping cuts, providing a surface finish and part quality level that was far superior to hobbing, shaping or broaching. Scudding is a continuous generating process, meaning no idle strokes on the machine tool, as when shaping gears. Ring gears, sliding sleeves and annulus gearing, whether internal helical or spur, external helical or spur or blind spline, synchronizer parts with block tooth features and synchronizer hubs remain among the popular products in the market, made with Scudding technology.

Today, this continuous gear cutting process is widely used in production environments for internal, external, helical and spur gears, as well as splines and other components in the powertrain world. The machining can be done without the need for an undercut or groove (clearance) and lead of the gear can be manipulated via axial motions (crown/taper). It is a demonstrably superior technology and automotive suppliers have embraced its advantages for many years now.

Impressive a technology as it is, the industry took another step forward recently with our new process known as Hard Scudding™. The conventional Scudding process provides excellent results on green or soft gears, while this new advancement enables the re-machining of hardened gears with a tooth-to-tooth composite error and total composite error in the AGMA 12, DIN 5 range and a surface finish better than 1.5 Ra.

The capital investment is minimal for shops and production departments already doing Scudding, because the same gear can be run on the same CNC machine, using a solid carbide tool to do the work. Recent testing done on various internal automotive powertrain and agricultural machinery ring gears is showing extremely positive results. Stock division calculations on the tooth position are standard technology for GMTA and Profilator, so re-cutting is quick and easy. Using the latest CNC technology to control the machine kinematics, users are able to transfer this technology to Scudding machinery that is already deployed in the field. Thus, the same part can be cut on different machines at different times, allowing for more flexibility in scheduling. With today’s portable programming, onscreen or offline tool path and cutting condition simulation, plus the immediacy of call-up onscreen for all values and tolerances in real time, the busy machine shop or large production department stays flexible and demand responsive, using this Hard Scudding technology. In some cases, this new technology is applicable on near net, pre-hardened gear blanks, allowing significant step reductions in the manufacturing process.

In operation, cutting 60-100 thousandths per flank on a tooth, the Hard Scudding process can be used on a carburized or through-hardened parts; nitriding generally does not provide enough case depth to ensure sufficient stock for “clean-up”. An automotive ring gear, for example, which requires 40-50 seconds for Scudding can be produced with Hard Scudding in 25-30 seconds. This process development stands as a viable and very cost-effective alternative to conventional grind-and-hone operations, yielding a highly attractive cost per piece and extended tool life scenario. The added benefits of reduced capital outlay and a significantly more consistent end product bode well for the automotive powertrain and other gear market segments.

STOP BY BOOTH 2109 IN DETROIT, OCTOBER 20-22 TO LEARN MORE OR CALL SCOTT KNOY TODAY!

-GMTA management will be attending EMO in Milan with its partners, then exhibiting at Gear Expo, being held this year in Detroit, October 20-22.

-GMTA is running at “light speed” with their new Arnold laser work cells. Available as single or double work cells, the Arnold systems are offered as CO2 or fiber lasers, with full integration into a machining line, either by means of robotic part articulation or other automated transfer mechanisms, most of which are being supplied to customers by GMTA engineering. Leads from the last IMTS and the company’s aggressive ad program are already being developed into serious opportunities for the company, often in tandem with other machine tool lines and auxiliary equipment now offered by GMTA, according to company President Walter Friedrich. The most recent development is laser cladding, a process of simultaneous metal deposition and fusion, with an extremely high degree of control on the geometry. This technology has considerable application in the aerospace, medical, power gen and oil & gas market segments, in addition to the GMTA home base of automotive.

-The new Mexican office of GMTA, located in Queretaro, is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) there is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico from all their partner companies. At the new facility, machines are in place for demo and test runs, plus the facility is fully staffed with application engineering, technical support, after-sale service and parts inventory.

-Sales continue to be brisk on the 9- and 10-speed transmission projects in the automotive market. Scott Knoy, GMTA VP, comments, “We’re seeing a lot of activity here in the States and in Mexico, so we know our timing was right with the opening of our new facility there.”

-As part of the company’s ongoing commitment to education, GMTA Corporate Treasurer Claudia Hambleton volunteers for the Junior Achievement program in Saline, Michigan for educating K-12 students about jobs, entrepreneurship, financial literacy and work readiness in today’s competitive and changing market. She is active in the recruitment of local business people in the area to assist the program.

-The alliance with Star SU, through which GMTA is sourcing tooling locally, continues to prosper and mutually benefit both companies.

– We are proud to announce a business transaction between the Profilator Group and the Dr. Dieter Murmann Beteiligungsgesellschaft, in which Dr. Dieter Murmann Beteiligungsgesellschaft has acquired all shares of the Profilator Group, consisting of Profilator GmbH & Co. KG and the U.S. affiliate company GMTA (German Machine Tools of America Inc.). The Murmann family has long term plans with the Profilator Group to act as an autonomous business, striving for future success and ongoing technical developments. The current management team of the entire Profilator Group will remain the same, including Thomas Buchholz as Managing Director of Profilator in Wuppertal, Germany and Walter Friedrich as President of GMTA.

-GMTA is a corporate sponsor of the Smart Factory Industry Forum, being sponsored by the German American Chamber of Commerce and held at the Digital Manufacturing & Design Innovation Institute in Chicago on October 9.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Jeff Tanner Named Midwest Sales Director For REP

Bartlett, IL (Chicago) – Effective immediately, Jeff Tanner has been appointed the new Midwest Sales Director for REP Corporation, the world leader in rubber and TPE injection molding presses. This announcement was made by Tim Graham, President of REP Corporation, at the company’s headquarters in Bartlett, IL, near Chicago.

Tanner comes to REP with 29 years of experience in the rubber industry, having previously worked at a major OEM supplier to the automotive NVH sector. He has a thorough technical background in rubber injection molding, tooling and adhesion processes, as well as new product development.

Jeff will be based in Cadillac, Michigan and cover the Midwest region for REP. He can be reached at 847-514-8160 or jtanner@repcorp.com.

His interest includes fishing, hunting and camping.

REP is the largest builder of rubber and TPE injection presses in the world, with global affiliates and multi-national manufacturing locations.

For more information, please contact:

Tim Graham, President

REP Corporation

8N470 Tameling Court

Bartlett, IL 60103

Phone: 847-697-7210

Web: www.repinjection.com

1050ºF Cabinet Oven From Grieve

No. 1036 is a 1050ºF (566ºC), electrically-heated cabinet oven from Grieve, currently used for production heating of glass assemblies at the customer’s facility. Workspace dimensions of this oven measure 50” W x 50” D x 50” H. 80 KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 3750 CFM, 3-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 10” thick insulated walls, top-mounted heating chamber, aluminized steel exterior and Type 304 stainless steel, 2B finish interior.

Controls on No. 1036 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

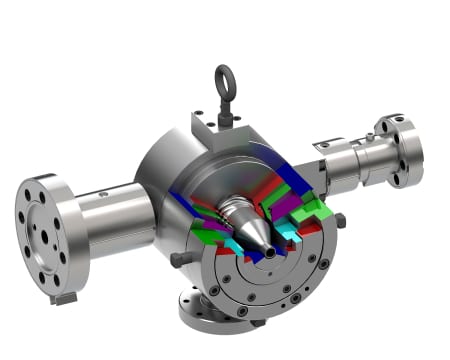

Co-extrusion Crosshead For Irrigation Tubing From Guill Tool

New low-volume spiral flow ABA crosshead with 2-stage clamping for easy concentricity adjustment

Guill Tool introduces Series 824, a co-extrusion crosshead designed for irrigation tubing with an emitter tool. Manufactured from stainless steel, this new crosshead features balanced flow design with spiral technology that improves flow characteristics at all extruder speeds. Dual feed ports provide concentric compound flow, while the splits flow from one extruder to feed the inside and outside layers via a manifold assembly. Series 824 is adaptable to all popular extruders on the market currently.

Capacities include a max. die ID of 1.875”, max. core OD of 1.250”, max. tip OD of 1.500” and max. emitter tool OD of 30mm (1.18”). The Series 824 design allows the emitter insertion tool to pass completely through the crosshead ID. Gum space adjustment is performed with die nut rotation, while the Guill 2-stage clamping mechanism allows easier concentricity adjustment. Quick-change tooling and a tool kit for disassembly and re-assembly are provided with the unit.

Bill Conley, sales manager for Guill, comments, “On this project, the customer challenged us with an application that required precise placement and bonding of preformed emitters within the extruded tubing without melting them in the crosshead. It was also necessary to process either a low-cost ABA layer construction or single-layer construction within the same unit.”

With the Series 824, the customer realized cost reductions, better quality, less scrap and more uptime in their process. The Guill cool-tube design prevented the emitter from melting in the head and the overall unit mechanics allowed more rapid and easier changeover from a co-extrusion to a single layer.

On this project, Guill also supplied the customer the company’s extrusion tool cart, which facilitates easy alignment and tool changes. The removable cart swing gates stay free from accumulated process fluids, while the adjustable height means the cart is compatible with virtually any extruder model. Thermal isolation in the design keeps heat in the head, not the cart.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online:

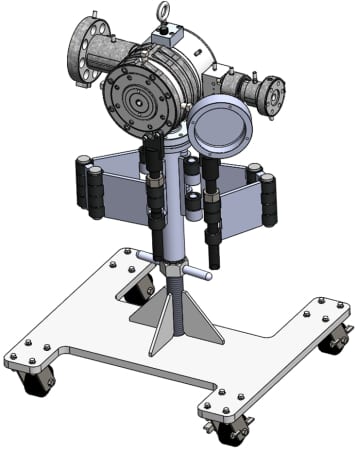

Exact Metrology Partners With FABTECH 2015 and the Art Institute of Chicago for 3D Scanning and Printing of Historic Lions

Event will feature speakers from Exact Metrology, FABTECH and Met-L-Flo to discuss the art of manufacturing and other innovative technology showcased at FABTECH 2015

WHAT: FABTECH 2015, North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry, will bring 3D scanning technology to the steps of the Art Institute of Chicago on Sept. 16. Exact Metrology, a 3D scanning solutions company, will use its Surphaser technology – known for its high accuracy and scan data quality – to 3D scan the museum’s south lion by Edward L. Kemeys (1843-1907). The guardian lions have flanked the Art Institute’s iconic Michigan Avenue entrance for more than 100 years and have become a symbol of the museum and of the city.

Attendees will have the opportunity to witness Exact Metrology’s scanning technology firsthand and hear from industry leaders as they discuss the process and benefits of 3D scanning and printing. Additionally, speakers will provide a look at what other advanced manufacturing technology will be showcased at FABTECH 2015, taking place at Chicago’s McCormick Place, Nov. 9-12.

After the scan data is captured, Met-L-Flo will use it to print approximately 300 small-scale replicas of the lion, which will be on display and used as giveaways at FABTECH.

Following the brief press conference, representatives from FABTECH, the Art Institute, Exact Metrology and Met-L-Flo, Inc., will be available for interviews.

WHO: Dean Solberg, vice president, Exact Metrology

Ed Youdell, president and CEO (FMA), FABTECH

Carl Dekker, president, Met-L-Flo, Inc.

WHEN: Wednesday, Sept. 16

9 a.m. – Press to arrive; photo opportunities

9:20 a.m. – Press conference

WHERE: The Art Institute of Chicago

111 South Michigan Ave.

Chicago, Il 60603-6110

Note: Press conference to take place on steps near the south lion, located in front of the Art Institute.

About Exact Metrology

Exact Metrology is an ISO 9001: 2008 certified company that offers contract measurement & scanning services, metrology equipment solutions, and hardware & software rentals. Its goal is to provide customers with a specifically tailored solution to their measuring needs. To accomplish this, it offers more options, more products and more experience.

About FABTECH

FABTECH is North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry. The event provides a powerfully aligned hands-on, face-to-face business growth experience, attracting more than 1,500 exhibitors and 40,000 attendees. The event is made possible by its five co-sponsors, all of whom representing the varied and diverse makeup of the manufacturing industry. They include SME, the American Welding Society (AWS), the Fabricators & Manufacturers Association, International (FMA), the Precision Metalforming Association (PMA), and the Chemical Coaters Association International (CCAI). Read more about FABTECH’s co-sponsors here.

About the Art Institute of Chicago

The Art Institute of Chicago collects, preserves and interprets works of art of the highest quality, representing the world’s diverse artistic traditions, for the inspiration and education of the public and in accordance with our profession’s highest ethical standards and practices.

About Met-L-Flo Inc.

Met-L-Flo, Inc., is a contract manufacturer specializing in 3D Printing and Additive Manufacturing services since 1991. It strives to partner with clients to implement innovative solutions for their product development and low volume production needs. Advanced applications of its technologies enable it to boost clients’ competitiveness and enhance product success. Its commitment to Quality is solidified in the company’s ITAR, ISO 9000 and AS 9100 Rev C Certifications.

As a leader in the industry, it prides itself on creating innovative, unconventional solutions that utilize both tool and tool-less applications. Products may be produced in metal, plastic, silicone, or wax including fiber reinforcement

For more information on the event, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingMachining Long Aluminum Profiles

Aluminum profiles are produced in all shapes and sizes.

Often, these profiles can be very difficult to machine, because of the various shapes, sizes, number of operations required and cycle times needed. When a profile shape will not allow the holes to be punched and cycle time makes producing the parts on machining centers impractical, Suhner, with its modular design and broad assortment of spindle options, can now offer processors an ideal solution to their machining needs.

Suhner’s line of spindles for Profile Machining includes the popular MONOmaster Electric Driven, Pneumatic Feed Units, ranging in size from the smallest BEM-3 unit, capable of drilling up to a 3mm hole in mild steel, up to the BEM-28 unit, capable of drilling up to 28mm in mild steel and having 200mm of controlled stroke. Many of the units in the MONOmaster line are available with other options, such as inline, direct drive units for the BEM-6 and 12S, as well as 1:4 speed increasers for the BEM-6 &6D units capable of speeds up to 14,400 RPMs @ 60 Hz. With the larger BEM12 & 12D units, the option of 4:1, or 16:1 gear reduction is available, giving RPM speeds as slow as 40 RPMs @ 60 Hz.

Suhner also offers the MULTImaster line of flexible shaft driven units, a feature not currently offered by any other spindle manufacturer. These units are driven by Suhner flexible shafts and are ideal in areas where spacing is a critical concern. The smaller BEW-3 unit allows spacing as close as 48mm center to center. The BEW-6 unit, as close as 55mm center to center and the larger BEW-12 unit, as close as 75mm center to center, are also available. Using these units with Suhner’s VG System, users can drive up to (8) spindles with a single motor.

For high precision, tough applications, Suhner offers the POWERmaster line of spindles. This includes the BEX-15 & BEX-35 machining units, capable of running at speeds up to 23,000 RPM’s. These are block units, capable of milling, drilling and sawing operations. Suhner also offers a complete line of slide products to provide the feed movement for the block spindles. These slides are available in pneumatic or ball screw feed design, for either servo or gear motors.

Also very popular in the machining of aluminum profiles is Suhner’s line of adjustable and fixed spindle multi-heads for drilling special hole patterns or hole spacing where spindles are too large to fit into the required spacing for the center to center distances needed. Suhner’s line of special fixed spindle multi-heads is built in Rome, Georgia and often can be built to spec in less than six weeks.

A typical machine used by a major automotive roof rack manufacturer incorporates many of these Suhner items to produce the long bars for a Ford Escape roof rack.

This machine uses Suhner BEW-6 units to drill 6mm holes from the front and back side of the part, where electric spindles will not fit. BEM-12 motorized units, with special fixed spindle multi-heads are being used to produce 8mm diameter holes that are too close for even the smallest spindles to produce, when mounted side by side. Suhner’s BEX-35 PowerMaster units are used at each end of the part to saw the part to length (Under Yellow Covers). All these operations are ongoing at the same time to produce complete machined parts in seconds, a feat impossible to do on any conventional CNC machining center.

With Suhner’s modular spindle design and machining capabilities, most every need of the aluminum profile industry can be met in every market segment, whether automotive, industrial, solar, aerospace, military or commercial aviation.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

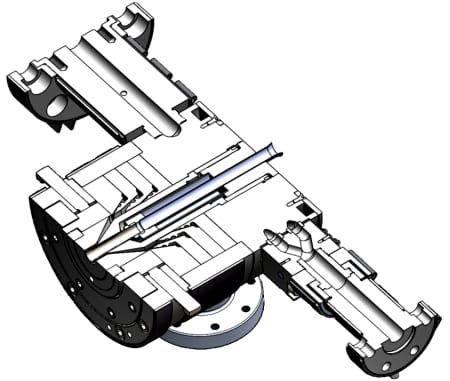

Suhner to Feature Somex® Machining Tools at FabTech Booth 5007

At FABTECH 2015, Suhner will demonstrate its Somex® machining tools, featuring automatic tool clamping and tool release via pneumatic cylinder, designed for heavy-duty sheet and plate cutting to 2“. These tools are typically integrated with laser, plasma and waterjet machines. Thru-tool coolant is standard, along with spindle tapers of ISO/CAT 40. These rugged yet precision tools offer spindle concentricity to 0.01mm (0.0004“).

Adapters for servomotor mounting are onboard these Somex® tools, which also feature a timing belt drive system, max. speeds up to 6000 RPM, max. spindle torque to 400 Nm (275 lbs-ft). The tool without the motor weighs 55 kg (121 lbs).

Options include HSK63 spindle taper, servomotors to 7.5 HP, spindle position sensors and tool release via hydraulic cylinder.

These tools are available with linear ball screw slide assemblies with travel to 480 mm (18.9 in) and thrust of 5500 Nm (1236 lbf).

Many other Suhner drilling units for production and OEM machine integration will be on display, as well.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

850ºF Heat Treating Belt Conveyor Oven from Grieve

The oven travel comprises a 3’ long open belt loading zone, 18’ long insulated heat zone with recirculated airflow, 3’ long open belt unloading zone and a 30” wide, Type 304 stainless steel woven wire conveyor belt with 3” high flex plate edges, driven by a ½-HP motor v-belt drive, variable from 1-19 IPM.

This Grieve belt conveyor oven features 7” thick insulated walls, aluminized steel exterior and interior, exhaust hoods over each end equipped with a 12” diameter tubeaxial fan, driven by a ½-HP motor, plus all safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment, including a 650 CFM, ½-HP powered forced exhauster.

Controls on No. 867 include a digital indicating temperature controller and 10” diameter circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Siemens Sinamics Drive Family Features Integrated Web Server

Siemens announces the enhancement of its popular Sinamics® S120 drive system with an integrated web server to facilitate more efficient diagnostic and maintenance functionality for end-users, integrators and system designers alike.

Sinamics integrated web server allows remote or local area maintenance checks at any time on various drive models in the Siemens drive family.

With this drive improvement, a user may access the Sinamics S120 with any PC with a browser capable of internet connectivity through a standard Ethernet interface to execute a variety of functions. If a wireless LAN (WLAN) router is networked, web pages can be viewed using other web-capable devices such as tablets and smart phones.

Among the functions possible with this integrated web server on Sinamics S120 drive systems are the ability to download a plant configuration, commission a drive from anywhere, perform firmware updates, access an immediate status overview on the drive, check and assess all alarm and fault messages. In addition, users can monitor and adapt all process or line parameter settings, archive machine documentation, including all notes taken, create customized server pages, set-up user administration and access level for operator and service personnel, plus perform virtually all drive diagnostics and remote maintenance actions. This combination of service possibilities results in significant reductions in machine or line downtimes due to faster, more efficient diagnostic and maintenance procedures.

Connectivity of the Siemens Sinamics drive system to the Internet for full web browsing, access and maintenance capability.

This Sinamics S120 drive system enhancement ideally suits applications where no special software or model version dependencies are desired. Series commissioning on a line is possible and the web server is compatible with all system security measures, such as a firewall. An up-to-date internet browser is sufficient for access. This web server capability is integral on Sinamics S120 drive firmware V4.6 or greater.

For more information about the Sinamics S120 web server, please visit: www.usa.siemens.com/sinamics-webserver-pr

—

Siemens Industry, Inc.

John Meyer

(847) 640-1595

john.meyer@siemens.com

Siemens Industry, Inc.

Hollie Davis

(770) 751-4882

hollie.davis@siemens.com

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com

Continue reading