Contact us today:

Author Archives: Bernard and Company

Han-Kwang Opens New Showroom

Han-Kwang USA announces the opening of its new 13,000 square-foot Chicago-area facility with showroom for laser machine demonstrations, as well as application engineering, parts and service departments. Typically, the new showroom will house multiple plate and tube cutting laser machines for customer use in test cuts and time studies, plus interested parties can see these powerful CO2 lasers in action, when considering a purchase or investigating laser technology for their shops and in-house fabrication processes.

In announcing this opening, Han-Kwang USA VP Robert Won commented, “This showroom is a further step in our company’s long-term commitment to the North American market. We have worked hard over the recent years to develop our business, build relationships with our North American dealer network and especially support our customers with the latest technology and application assistance.”

The parts department is fully stocked with all key consumable and mechanical components for the full range of Han-Kwang lasers currently in the field and offered by the company, including the new PS, PL and TL plate and tube cutters.

Additional key personnel at this new facility include Eric Kim, operations manager, and Jane Lee, administrative assistant.

For more information or to arrange a visit, please contact: HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Release: HAN-KWANG USA INC.

Date: April 1, 2010

Continue readingHunter and Maus Sign Representative Agreement

Hunter to represent Maus in U.S., Canada and Australia for grinding machine sales and service

This announcement was made by Maus CEO, Roberto Sammartin, and Hunter President, Bill Hunter.

Maus is a major supplier to the world foundry market of surface grinding and riser cutoff machinery, as well as automated work cells and complete transfer lines. The U.S. operation of Maus is based in Virginia Beach, Virginia.

Hunter Automated Machinery is likewise a longtime leading supplier to the foundry market, having pioneered automated matchplate molding machinery for sand casters. Today, through various affiliate and representative agreements, Hunter also brings a broad line of automated mold handling, core resetters and sand prep testing equipment to foundries worldwide. Hunter operates facilities in the U.S., Brazil, China and Italy.

According to Sandra Selwan, marketing manager for Maus in Italy, “We see great potential in this agreement, as our machines will now be represented by a name known to foundries worldwide. Coupled with our machine quality and innovative engineering, Maus believes the synergy between our company and Hunter will produce substantial mutual benefit.” Ms. Selwan made these comments from the CastExpo, where both companies were exhibiting their machinery and engineering capabilities to metalcasters from every corner of the world.

For more details, please contact:

MAUS SpA

Via Caltana, 28 35011 Campodarsego Padova, Italy

Phone: +39 0499299311

Email: Sandra_Selwan@maus.it www.maus.it

Attention: Sandra Selwan, Marketing Manager

MAUS USA

2505 International Parkway Virginia Beach, VA 23452

Phone: (757) 689-3725

Fax:(757) 689-2973

Web: www.maus.it

Email: Alberto.fabris@mausna.com

Attention: Alberto Fabris, VP

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Web: www.hunterfoundry.com

Conect with Hunter Foundry online:

FRED YOUNG, CEO OF FOREST CITY GEAR, SPOKE AT THE NCMA SYMPOSIUM 2010 ABOUT “GROWING GLOBAL MARKETS”

Roscoe, IL-Forest City Gear’s CEO Fred Young spoke on “Growing Global Markets” at the National Contract Manufacturers Association (NCMA) Symposium 2010 held at NIU Conference Center in Rockford, IL on Tuesday, March 23, 2010. This year’s symposium focused on “International Contracting: Winning Business In Emerging Global Markets.”

With the use of the internet and social media, we have access to businesses and products without the limitation of boarders and time-zones. More and more companies, even small, family owned businesses like Forest City Gear, find themselves very active in the global market. During his speech. Fred stated that “although the title suggests I deliberately set out to grow global exports, in reality, we fell into it accidentally.” He explained it was his customer’s desire for cheaper production and assembly, along with their unwillingness to lose Forest City Gear’s quality and service, that initially brought FCG into foreign markets. Once recognized in these new markets, Forest City Gear’s unwavering belief in concentrating on high quality, doing what others cannot do expediently and having the most up-to-date gearmaking equipment brought them additional business in these countries. As a result, staying true to these principles has established FCG as a leader in the world market for high-precision gears.

As Fred briefly described the history of Forest City Gear, founded in 1955 by his parents, he stressed that quality and on-time delivery have been essential in proving and maintaining the company’s reputation of excellence since its inception. Fred believes the greatest lesson his father taught him was to reinvest every last dollar. He further believes reinvesting has been a key factor in their success on the global market. Over the past 30 years, FCG has reinvested 25%-40% of gross sales each year into new equipment. FCG’s philosophy is: when you are competing with other gear companies all over the world, it is important to be on the cutting edge. “Others have primarily shot themselves in the foot with the lack of reinvestment. Those who would had been considered leaders 50 years ago didn’t reinvest to update and bring their machines current and, as a result, they cannot compete in today’s global market.”

FCG believes it is a serious error if you don’t know your competition, know what they are delivering and how they do it. In addition to keeping his facility focused on quality and excellence, Fred visits gear companies and machine builders all over the world. Seeing how others run their facilities is “critically important”, as it provides knowledge and insight in offer something better than what the competition is producing.

“The future of exporting manufacturing is critical to the health of our country, we need to educate our youth, keeping that notion going is important to our future.” FCG continues to have a strong presence in the world marketplace by keeping their facility current, educating their employees with top-notch trainers who have global experience and by cultivating a reputation of excellence and helping others, even their competitors.

“Our clients are now all around the world and they found us in Roscoe, IL. Who has ever heard of Roscoe, IL? But we have developed a reputation for gearmaking excellence… Forest City Gear is always seeking, always exploring and always learning.”

Forest City Gear was founded in Rockford, IL in 1955 by Evelyn and Stetler Young, parents of Fred Young.

To watch the full video presentation of Fred’s speech, go to: http://vimeo.com/10460533.

For more information on this announcement, please contact: FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: sales@forestcitygear.com Attention: Fred Young

Agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Release: FOREST CITY GEAR CO., INC.

Date: March 29, 2010

Continue readingWEST-MARK MAKING BIG MARK IN SEVERAL MARKETS

West-Mark is literally a tale of many chapters, especially when it comes to laser fabrication. Started originally in 1967 as a manufacturing and repair facility for dairy transport tankers, it quickly expanded to become a leading West Coast builder of fluid transport vehicles for many industries, including petroleum, firefighting, military, construction, food, liquid sanitation, even arctic equipment, through its branch in Anchorage, Alaska. Today, the company enjoys a diversified customer base and, in addition to the Alaskan location, operates manufacturing, fabrication, assembly and repair facilities in Ceres, Atwater and Bakersfield, California. Over 150 employees provide West-Mark customers a broad range of vehicles for sale or rent, plus the company maintains full service and repair operations.

In the late 1990’s, another market sprung up for the company, namely, the fabrication of display enclosures for entertainment venues, kiosks, elevators, airports, shopping malls and other retail/commercial establishments. Using the engineering and manufacturing skills that had proven successful in the industrial markets, the company opened its “Digital Factory” in Atwater, where today it produces an assortment of enclosures and freestanding kiosks, under the Perfected Protection™ brand name.

West-Mark had long been an integrated design, fabrication and assembly company, according to Fabrication Director, Chris Portmann, “…but we saw one area that needed better control and cost containment, namely, the laser cutting of the various stainless steel, carbon steel and aluminum materials we processed.” The company was utilizing the services of three local laser job shops and occasional bottlenecks would occur, in addition to the cost factors involved. As the company was continuing to grow, these production challenges grew, as well. West-Mark knew a change was in the wind.

At a meeting with one of their trusted machine/equipment dealers, Metal Process Engineering, West-Mark was introduced to the Han-Kwang plate laser with integrated material tower automation. In one of those classic “light bulb” moments, a decision was formulated and the sale proceeded. The company also hired an experienced laser operator from a local shop. The benefits soon became apparent.

As Portmann explains, “Very quickly, we realized we could run a lot faster to save time and money. Beyond that, we could be more responsive to the one-off and short run job requirements we get, all the time, in our operation. Because of the software we use and the products Han-Kwang provided us, we were able to integrate those short runs into the nesting strategies with our longer run jobs.” The tower automation provided West-Mark the flexibility to do several more things in its production. They could stack frequently-used materials on pallets into the tower for quick access and start-up, owing to the powerful CNC onboard the Han-Kwang laser, while the fully automated cycle capability allowed West-Mark to quickly move into a lights-out manufacturing strategy, thereby providing additional cost containment in personnel and power consumption.

West-Mark utilizes Inventor® CAD and Radan® CAM systems, typically, plus the proprietary nesting software provided by Han-Kwang. Since West-Mark launched its 3D software use at approximately the same time as they purchased the laser, the company’s programmers and operators shared a learning curve, but Chris Portmann noted, “It was a ‘law of unintended consequences’ situation, because the market slowed at the same time we were acquiring the new machine and software packages, so our guys were able to learn in the slow times.” He further observed the company has enjoyed an ability to be more responsive to customer needs and that has led directly to more new business for West-Mark, including doing laser processing for other local firms in the area.

A particular benefit of the Han-Kwang laser, according to West-Mark personnel, is its ability to process aluminum tread plate with the diamond side up, so the dross falls onto the back side of the material, compared to the typical laser cutting diamond side down, where the dross falls on the visible side of the material.

A rather direct fellow, Portmann sums up by saying, “When we need another laser, there will be no question about getting another Han-Kwang. Their machine quality, application assistance, operator and programmer training, plus the

West-Mark, in addition to the Digital Factory production of enclosures and kiosks, builds fuel tankers, buffaloes and bowsers, water tenders, firefighting apparatus, grease trap and septic tank vacuum trucks, DOT Code tanks, even aircraft refuelers, working in a variety of industries, as well as for the Department of Defense, National Park Service, Department of Interior, U.S. Army, Navy, Air Force and the civilian supply chain.

In the production of its high-precision metal parts, assemblies and fabrications, the company operates a full complement of laser, shearing, rollforming, head forming and flanging, brake forming, punching, milling, welding and quality inspection equipment.

West-Mark service operations range from leak repair and testing to full retrofit and field replacement.

For more information, please contact: WEST-MARK 2704 Railroad Avenue Ceres, CA 95307 Phone: 209-537-4747 Fax: 209-537-1753 Toll-Free: 800-692-5844 www.west-mark.com www.digitalfactory.com Chris Portmann, Fabrication Director cportmann@west-mark.com

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: mailto:salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Release: HAN-KWANG USA INC.

Date: March 8, 2010

Continue readingSiemens: Industry Leader Speaks About Energy Management with Drive Systems

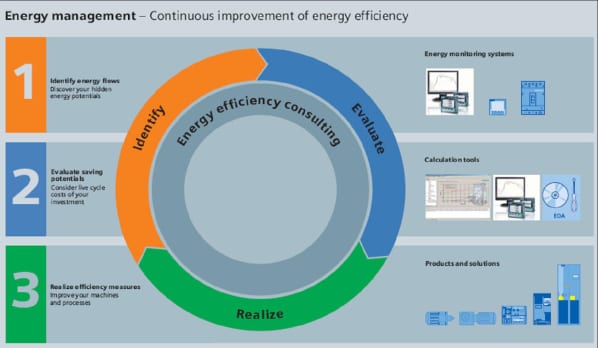

The key is a process, not a product, with many factors contributing to energy efficiency.

What is the key to more energy efficient motion control?

While it is valid to state that energy efficiency is defined as the same level of production being achieved at an overall lower energy cost, it is equally important for today’s machine builders and automation engineers alike to remember than an energy-efficient system can actually translate into higher productivity. This is achievable through a comprehensive approach to energy management. Energy management is a process, rather than a product or series of products installed on a machine, or inline, to achieve a basic energy saving of kW hour consumption.

What are the essential elements and basis of the process?

First, energy monitoring systems must be in place to effectively determine the current consumption. These can include, but are certainly not limited to, energy consumption displays, infeed/supply monitoring devices, power factor meters and more. Next, the proper calculation tools are needed to properly evaluate the life cycle costs of any investment. These tools can be as simple as a motor sizing chart or the software programs used to parameterize drives. However, a more formal mechatronics protocol may be beneficial. In this scenario, a thorough evaluation of both mechanical and electrical/electronic influences on a system, machine or process line is conducted. The results can often open the eyes of machine designers, process engineers and system integrators alike.

What is the general approach to a mechatronics analysis?

This is where a competent supplier can be an effective partner. For example, a solution might involve a vector drive that utilizes an energy optimization function to enhance the efficiency of the motor during partial load operations. In a system with multiple motors, energy savings might be realized to a substantial degree by the use of a drive unit with a common DC bus. The designer can also select the most appropriate infeed solution for the machine, pump or process operation, given the particulars of performance and required output. This may include an appropriately sized infeed unit with regenerative capability, the ability to put unused or braking energy back on the incoming power line.

Some applications may allow the use of high efficiency standard induction motors and, in the process, realize a potential savings of 1-3%. The use of frequency converters (VFD) for speed control might raise this to an 8-10% savings.

Optimizing an entire system through mechatronic analysis of the machine or process design, can result in a potential savings of 15-20% by the avoidance of over dimensioning of motors, plus partial load optimization by means of energy-related flow control. This analysis may also point to the ability to use controlled energy infeed and recovery.

What technologies should be evaluated?

A corollary to this discussion should also include a review of potential hydraulic and pneumatic component change outs in certain applications where replacement with an integrated package of motion control and PLC technology might better resolve closed loop pressure control of axes, for example. Fewer components and their related power consumption can lead to overall system productivity improvements, as well as ongoing enhanced energy efficiencies.

As the emergence of new technologies has impacted many of the products used in energy-efficient systems, it is equally important to take a more holistic look at operational sequences and the overall integration scheme when designing, retrofitting or rebuilding for improved energy utilization.

Michael Perlman is the Marketing Programs Manager for the Motion Control business of Siemens Industry, Inc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingREP CALLS FOR A PITCHOUT! Injection press builder offering molders up to $40,000 credit for scrapping old machines

Graham detailed the offer, saying it would apply to any make or model of rubber or TPE injection press. REP requires the molder to validate the scrapping of their old machine, thereby earning a predetermined credit, based on the old machine’s age and condition. The credit, up to $40,000, can then be applied to the purchase of any new REP injection press in the G9 series.

He further noted the advantages of a new machine. “Besides the higher quality parts a molder can produce, owing to the level of mold mechanics, material flow and control sophistication, a new press consumes less energy, has less downtime and less maintenance requirements, so it stays in production. Even REP presses from our earlier generations cannot match the productivity and resulting profitability of a new G9 machine. That’s not a brag, it’s a fact and it’s one we can document,” he said, noting the new machines offer better molding strategies, improved ergonomics and faster payback for the customer.

“It’s an offer you can’t refuse,” Graham joked.

REP Corporation is responsible for all sales and service in North America. However, this offer is being made to rubber molders worldwide by REP, based in Lyon, France.

For more information, please contact: REP CORPORATION 8N470 Tameling Court Bartlett, IL 60103-8146 Phone: 847-697-7210 Fax: 847-697-6829 Web: www.repinjection.com Email: tgraham@repcorp.com Attention: Tim Graham, President

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading500°F Universal Oven from Grieve

The unit has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. It is also equipped with an integral leg stand with casters and leveling pads.

Controls onboard No. 945 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: FrankCalabrese.

NEWS RELEASE: THE GRIEVE CORPORATION Agency contact: Tim Daro 847-934-4500

DATE: March 22, 2010

Continue reading500°F Walk-in Oven from Grieve

The unit has 4” insulated walls and an aluminized stainless steel interior and exterior. A 3300 CFM, 2-HP recirculating blower provides horizontal airflow to the oven. Safety equipment, such as a 325 CFM 1/3 powered force exhauster, is included as required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-fired equipment. The oven also features a 2” insulated floor with truck wheel guide tracks and a removable top-mounted heat chamber.

Controls onboard No. 813 include a recirculating blower airflow safety switch, circular chart temperature controller and a manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Siemens: Cirque de Soleil Show KA

When the Las Vegas based Cirque de Soleil show, “KA” was looking to maximize motion control and improve the reliability of their stage’s movements, they turned to Siemens. Siemens drives and controls create the automation needed to provide the safety and reliability that is required for a performance of this caliber.

For three years, a Siemens engineering team worked to make this $220 million dollar show and theatre at the Las Vegas MGM Grand spectacular. Visually, the show is like nothing you have ever seen before but reliability, flawless motion and safety was Siemens’ main objective.

The Cirque de Soleil show “KA” requires a 25 x 50 ft section of the floor to rise out of the main portion of the stage. This 6 ft thick, 80 thousand pound

section of the stage provides full motion that rotates 360º and tilts 100º to become a sheer vertical, ultimately lining up perpendicular to the stationary part of the stage… with the performers still on it! I’ll keep my job, thank you. I think Bernard & Company needs to take a field trip to Vegas to see this in person.Check out this video and see how Siemens’ contribution makes this stage show possible.

This article details Siemens’ part in the three year process to get the “KA” stage operating flawlessly.

Converting Toolbox Optimizes Efficiency of Engineering Process for Machine Manufacturers

Complete Set of Application-Ready “Tools” for Converting Applications

ATLANTA — Siemens Industry, Inc. announced today the introduction of the Converting Toolbox, a set of standardized automation tools for the integration of various machine components that previously had to be performed individually. It simplifies web processing applications and offers greater flexibility for machine designers and builders of paper, film, foil and other converting machinery. It is completely scalable and is provided at no cost to qualified machine designers, builders and integrators.

The Converting Toolbox enables machine builders to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation, as much as 80 percent in some cases. It offers modular open functions, for items such as:

- Center winder,

- Flying splice controls,

- Rotary knife with print mark correction,

- Flying saw,

- Traversing control,

- Speed set-point cascade and more.

The Converting Toolbox components take the form of pre-programmed functions. Sample applications demonstrate how each function can be efficiently and effectively implemented into a machine design. Such sample applications are ready-to-use after only minor modifications and include basic HMI functionality. This enables the machine function to be tested and optimized in a very short time frame.

When a functionality module needs to be modified, extended or changed, the Converting Toolbox’s completely open source code provides a wide and solid basis from which even the most specialized functions can be implemented quickly and easily.

Simotion®, the Siemens motion control system, is ideally suited as an operating platform for the Converting Toolbox because applications can be operated directly on an intelligent drive, very compactly and without need of an additional PLC. Simotion offers drive, controller and PC-based topologies. The Converting Toolbox also includes drives-based solutions using Siemens Sinamics® Drive Control Chart (DCC) graphical programming language.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading