Contact us today:

Author Archives: Bernard and Company

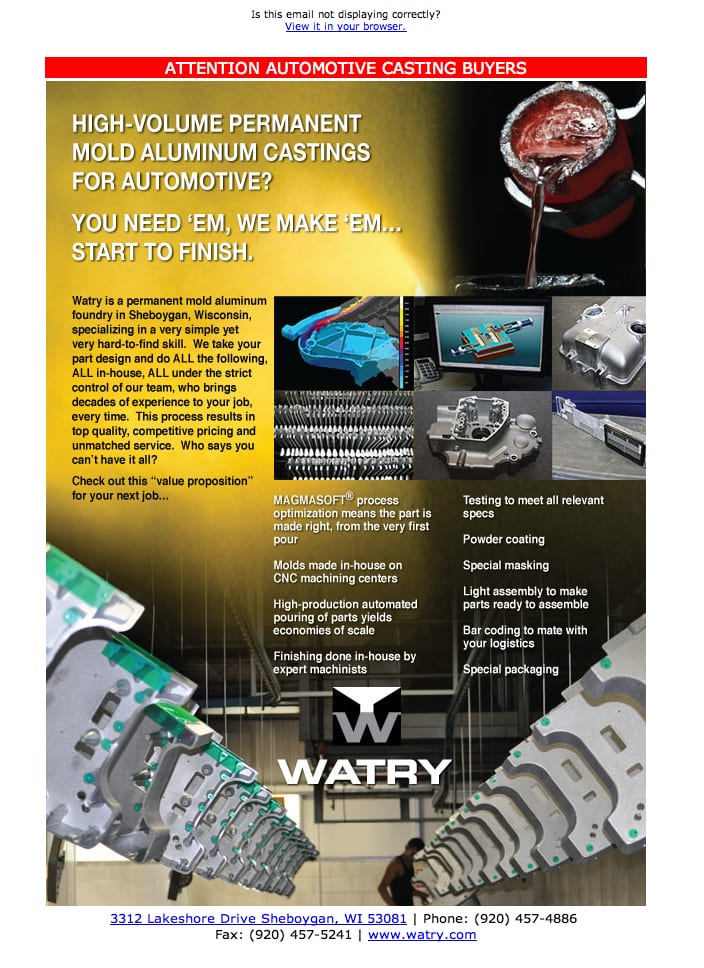

Watry Industries

Siemens at PackExpo 2012

Engineering TV is now featuring Siemens from PackExpo 2012!

Click here to check it out.

Lee Teschler of Machine Design talks to Bill Henderson, Business Development Manager at Siemens about industrial ethernet connectivity solutions and networks used in several manufacturing environments.

Hosted by: Lee Teschler Videography by: Terry Knight Edited by: Terry Knight

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingSiemens Announces New South Carolina Geared Motor Plant

ATLANTA, Oct. 18, 2012 — Siemens Industry, Inc. today announced its plans to open an assembly and manufacturing plant as part of the company’s Drives Technologies Division, Mechanical Drives Business Unit. The 45,600 square-foot facility will be located in the city of Mauldin in Greenville County. Siemens anticipates opening the facility later this year.

“The new South Carolina geared motor facility will place the company and its products manufactured in South Carolina closer to machine builders and manufacturers in the Southeastern United States,” according to Doug Keith, President of Siemens Drive Technologies Division in the U.S.. “The announcement of this plant adds to Siemens ability to be a single-source provider of integrated drive train solutions for industry. Our portfolio of gears, motors, drives and automation is helping to lead a global transformation of the industrial and manufacturing sector, by increasing productivity and energy efficiency to the highest possible levels.”

The facility will assemble Siemens new Simogear family of geared motors, featuring helical, parallel shaft, and helical bevel gear units primarily used in modern conveyor systems often found in warehousing, logistics and distribution, airport baggage handling, automotive manufacturing and food and beverage processing.

Keith added that the site combined all of the necessary elements Siemens was seeking in a location, including proximity to transportation infrastructure, including interstates and ports, a highly skilled workforce with reputable educational institutions nearby, a green-minded community and a dedicated group of business partners.

“It’s a great day in South Carolina when a world-class company like Siemens chooses to locate new operations in our state. We celebrate the company’s decision to invest in South Carolina and create new jobs. Announcements like this show we are doing the right things to attract businesses from around the globe to our state,” said Gov. Nikki Haley.

Throughout the site selection process, Siemens officials worked closely with several entities that were instrumental in the decision to locate in Mauldin, including the State of South Carolina, Greenville County, the City of Mauldin and Laurens Electric Cooperative.

“It’s exciting to see a company like Siemens bring a new manufacturing operation to the Palmetto State. Every one of these jobs will have impact locally. Announcements like this are made possible by a strong team effort from state and local officials,” said Secretary of Commerce Bobby Hitt.

Local Siemens officials are currently working with readySC and Greenville Technical College on workforce development and training needs. Siemens plans to begin hiring in October and individuals interested in learning more may visit the Siemens career web site at www.usa.siemens.com/careers.

Siemens Mechanical Drives Business Unit manufactures mechanical and electrical drive equipment typically used in mechanical designs, including processing, transport and conveying systems, power generation and many off-shore applications. This portfolio particularly concentrates on gear technology, ranging from geared motors to industrial gear units and couplings as well as large gears for power stations and wind turbines. This portfolio of products and solutions are the mechanical foundation to Siemens’ Totally Integrated Automation (TIA) platform.

For more information visit: http://www.usa.siemens.com/answers/en/#683050?stc=usidt100004&sp_source=usidt100004.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingNew and Improved Simotion Scout Improves Usability

New Simotion Scout version 4.2, a visualization tool for parameter configuration of Simotion, the Siemens motion control system for production machines.

CHICAGO, PACK EXPO — The motion control business of Siemens Industry, Inc. has announced that Simotion Scout, the engineering system used for configuring Simotion motion controllers, has been updated with a wide range of usability improvements. As more and more demands are put on modern production machines, this system enables all of the application functions and tasks to be implemented within one uniform user interface.

Simotion is the scalable motion control system that quickly and easily handles increasing machine demands by enabling central machine functions to be implemented with just one controller.

It is available in three variants: drive-based, PC-based and controller-based.

Simotion Scout facilitates the configuration, programming, testing and commissioning of applications. With its graphical-based programming, Scout further facilitates system configuration for new users. Users of Scout 4.2 will also benefit from new features such as automatic drive integration and detailed comparisons for graphics-based programming languages.

The most significant innovation of Scout 4.2 is its simplified interface to the Siemens Sinamics drive system. This feature provides users with an automated means of integrating drives and components into the Simotion system. Using the new symbolic assignment of technology objects (TOs) and I/Os to drive objects, users no longer manually configure communication with message frames and addresses because Simotion Scout now automates this task. Object-to-object assignment takes place via a new inter-connection screen. In this screen, all compatible partners are listed hierarchically and the symbolic connection of the components to be inter-connected takes place by simple selection.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications

or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Siemens Introduces Simotion D Motion Controllers for Enhanced Packaging Machine User Productivity

The new Simotion D motion controllers for production machines cover all levels of performance, from simple positioning tasks to demanding applications with extremely short cycle times or large numbers of axes, up to 128.

CHICAGO, PACK EXPO — Siemens Industry, Inc. announced today the extension of the upper performance range of its popular Simotion D motion controllers. The new generation of Simotion D445-2 multi-axis controllers has new features such as onboard Profinet interfaces, high-speed I/O, and with three times the performance, a single controller can support up to 128 axes of motion.

Simotion D motion controllers are the ideal solution for production machines covering all levels of performance — from simple single-axis positioning tasks to complex synchronous applications — with extremely short cycle times on a large numbers of axes. Thanks to its scalability, Simotion D offers users a high degree of flexibility for the ever-changing demands on machine automation. The Simotion D drive-based multi-axis control not only offers PLC, motion control and advanced technology functions, but also an integrated drive control based upon Siemens Sinamics S120 drives.

Today, with the new Simotion D445-2 DP/PN and D455-2 DP/PN versions, the performance range has been extended even higher. Compared to the previous generation, the maximum quantity has been doubled to 128 axes and the memory capacity significantly expanded. This has increased the PLC and motion control performance by a factor of three. With Simotion D445-2 DP/PN and D455-2 DP/PN, the previously optional Profinet I/O interface has now been integrated on the modules as standard. This frees up the option slot for other expansion cards. The onboard interface is equipped with an integrated three-port switch and facilitates different network topologies such as line, star or tree structures, without the need for additional external switches. The interface not only supports real-time (RT), but also isochronous real-time (IRT) data exchange and can be operated as a controller and / or device of another controller.

In addition to the Profinet interface, Simotion D445-2 DP/PN and D455-2 DP/PN also have two Profibus and two Ethernet interfaces, as well as 28 digital I/Os, of which 16 can be used for technology tasks such as output cams and measuring inputs with micro-second resolution.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

AME Announces A New Line Of Pneumatic Rod Locks

Advanced Machine & Engineering Co., (AME) Rockford, IL announces a new line of pneumatic rod locks. Advanced Machine & Engineering Co., a leading manufacturer of stand-alone and NFPA cylinder mount pneumatic rod locks since 1994, has now introduced the Amlok RLI, its fourth-generation power-off rod lock. This basic lock unit is in addition to the RLN and RCH, expanding the company’s rod lock product line. The RLI Metric (ISO 6431) series will complement the standard NFPA line. This fourth-generation lock is the culmination of 18 years of manufacturing and marketing of pneumatic and hydraulic rod locks.

The rod lock’s standard features include anodized aluminum construction, a heavy-duty clamp system and power-off clamping. The standard seal material is carboxylated nitrile.

The unit uses dry-filtered air, has a release pressure ranging from a minimum of 4 bar/60 PSI to a maximum of 8 bar/120 PSI. The operating temperature ranges from 10 degrees F to 180 degrees F. Maximum rod tolerance is +0.000 in./-0.002 in.

Rod lock options include stainless or electroless nickel-plated housing, viton seals, wiper scraper and sealed versions. The lock mounts to standard ISO 6431 cylinders or can be stand-alone using MXO, MF1, MF2 and MS1 mounting configurations.

The Amlok RLI is available in various sizes for rod diameters of 16mm, 20mm, 25mm, 32mm and 40mm and cylinder and bore diameters from 40mm to 160mm. Holding forces range from 200 lbs/890N to 2,450 lbs/11kN.

The RLI power-off pneumatic rod locks are particularly-well suited for holding applications in industries such as automotive, mobile, food, machine tool and military test, among others.

—

Advanced Machine & Engineering Co., located in Rockford, Ill., is a global manufacturer and distributor of precision machine components, fluid power components, fixturing/workholding, power drawbar and spindle interface components, and saw machines and blades. The company also designs and builds special machines for a variety of industries and provides machine rebuilding, retrofitting and contract manufacturing services. AME has partners and customers around the world and across the U.S.

For more information, visit www.ame.com or contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

AME announces the Fourth-Generation RLI Series Rod Locks

The patented AMLOK® Type RLI is constructed of black anodized aluminum housing with a special piston and wedge locking mechanism actuated by multiple springs that mechanically lock the rod quickly and securely. The clamp is unlocked when air actuates the piston, compresses the spring and releases the locking device.

- No rod displacement on engagement

- Large clamping surface reduces pressure-per-square-inch on the rod, extending service life

- Fast response time

- Low backlash

- 4 bar (60 psi) release pressure

- Precision holding 0.002”-0.003”

- Consistent clamping force in both directions

- High cycle rates and accuracy

- Holds load during power/pressure loss

- Compact unit, easy integration

- Versatile through hole tie rod mounting to ISO 6431 style pneumatic cylinders

- Many NFPA style-mounting attachments available for stand alone applications

The optional sealed RLI Series design is suitable for food and wash down applications as well as pneumatic and hydraulic presses, scissor-lift tables, test and positioning equipment, amusement ride equipment, printing and paper handling equipment, theatrical equipment (platforms), assembly equipment, and machine tool applications.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, Ill., serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems; the Fluid Power – Safety market with cylinder rod locks and safety catcher devices; and the Production Saw market with our AmSaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S.

For more information, visit www.ame.com or contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

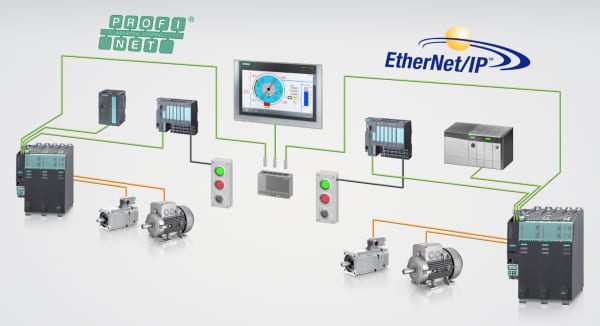

Sinamics S120 Drive Platform with Industrial Ethernet Connectivity

The Sinamics S120 drive platform from Siemens provides users maximum flexibility with industrial Ethernet connectivity.

ATLANTA — Siemens announced today that its versatile Sinamics S120 drive system has been expanded to include Profinet, Ethernet TCP/IP and EtherNet/IP connectivity, thus providing maximum flexibility for industrial Ethernet communication while offering innovative concepts for those wanting a single network for the entire plant.

Whether a greenfield project with multiple vendors or an OEM supporting different platforms on their machines the importance of industrial Ethernet connectivity for drive systems is today’s top requirement.

“In many instances, plant managers have the requirement for a single-plant network, particularly with large automotive, packaging, plastics, metals, food and beverage as well as material handling companies,” says Craig Nelson, Siemens product manager, Sinamics S drives. “Our Sinamics drives platform provides communications without limits to a specific network type.”

Sinamics S120 drives support, as standard, Profibus DP and Profinet to ensure seamless communications between all the components involved in a typical automation solution, including HMI (operator control and visualization) and I/O. Additional higher-level functions including Safety Integrated telegrams and synchronized mechanisms for even the highest-level motion applications are also included in these innovative solutions.

Profinet can transmit operating and diagnostics data simultaneously to enterprise-level systems using standard IT mechanisms (TCP/IP) for an integrated factory environment. The new addition of an EtherNet/IP stack offers another option for Sinamics users. Having the flexibility to communicate with the most common automation systems via Profinet, EtherNet/IP or basic Ethernet TCP/IP makes the Sinamics drive system easily adaptable to the current Industrial Ethernet boom.

Sinamics S120 drives are designed to handle virtually any drive requirement and facilitate vector, servo and variable-frequency drive (V/Hz) applications with the choice of single- or multi-axis offerings. The modular design and system architecture, combined with new communication connectivity features, makes Sinamics S120 a truly advanced drive offering in today’s market.

With a wide power range (0.25 – 1,600 hp), highly scalable solutions, including safety integrated functionality and convenient start-up with automatic configuration of the drive system, through the innovative Drive-CLiQ interface, Sinamics S120 is a powerful solution for a host of applications, including packaging, plastics molding and extrusion, textile, printing and paper machines, handling and assembly systems, machine tools, rolling mills and test stands.

For more information about EtherNet/IP connectivity to Sinamics S120 drives, visit our website: www.usa.siemens.com/eip.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

GMTA News Of Note

Crown Equipment in Mexico bought one of the MAE straightening presses from the GMTA booth at IMTS. Crown is a world leader in forklift trucks.

The expansion of the GMTA facility in Ann Arbor, Michigan is underway and targeted for completion in several months. When completed, the new facility will house a new machine demo and training center, plus additional sales and service personnel. GMTA continues to grow steadily, representing numerous high-quality German machine tool builders in North America.

Siemens in Mexico bought a Pittler PV630 ValueLine vertical turning machine for motor manufacturing. Take a look at video of this machine in action!

For more information:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Universal Style Oven from Grieve

This Grieve oven has 6” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior and four front access doors with automatic door switches to shut off the heat and blower when a door is opened. Four structural steel slide beds are provided to support the plastic sheets during processing.

Controls on No. 1026 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, SCR power controller and eight auxiliary thermocouples connected to a selector switch and temperature indicator.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading