Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

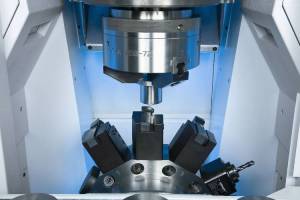

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

In the news…

-DVS, the parent company of Pittler, Praewema and WMZ in Germany, has plans to expand its North American operations, owing to the success achieved with GMTA in this market

-Scudding® technology, pioneered by Profilator, continues to impact the North American gear and spline markets, due to its superior performance compared to other methods of production; several competitors trying to offer it, proving that indeed, “Imitation is the sincerest form of flattery.”

-The renovation of the GMTA facility in Ann Arbor, Michigan is now complete with plans in the works for future expansion of the campus. Additional floorspace, showroom capacity and training facilities, plus more personnel, are planned, according to company VP Scott Knoy.

-Now in final runoff with anticipated start-up in June, GMTA has provided eight machines (16 spindles total) for the advanced cylinder lining program to the Caterpillar operation in Mapleton, Illinois; project for GMTA valued at $15,000,000

-Order received from Chrysler for Phase III transmission line at IPT1 in Indiana

-GMTA and DVS will have joint booth space, considerably expanded, at IMTS 2014

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Workspace dimensions of this oven measure 30” wide x 96” deep x 24” high. A 2’ long open belt loading zone, 8’ long insulated heat zone with recirculated airflow and 2 ½’ long open belt unloading zone constitute the full heat processing system. 48KW installed in Nichrome wire heating elements provide the heat, while a 4200 CFM, 3-HP recirculating blower furnishes vertical downward airflow to the load.

This Grieve oven features 4” insulated walls, a Type 304, 2B finish stainless steel interior, stainless steel exterior with #4 brush finish, as well as a 24” wide, 1” x1” Type 304 stainless steel flat wire conveyor belt with ¼-HP motor drive, variable speed from 0.9 to 17.6 ipm. A side door allows access to the unit’s workspace.

Safety and control equipment on-board No. 853 include PVC electrical conduit, a remote control panel, 325 CFM stainless steel powered forced exhauster, six-point thermocouple jack panel through the oven wall, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

The NOARK value proposition centers on products that improve the profitability and maintain the highest levels of performance for customer end products, through the combination of local support with local inventory, exceptional value and superior product quality, backed by the industry’s first 5-YEAR WARRANTY.

ALL ABOVE NOARK PRODUCTS ARE UL489 LISTED.

NOARK Electric, Inc., the North American headquarters of the company, was previously located in Rockford, IL and, due to its rapid growth and inventory commitments, has recently moved to a larger facility in Oak Creek, WI, just south of Milwaukee.

The company is currently in the process of establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries.

A global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1000 associates. Sales for the company exceed $2 billion worldwide.

For more information, please contact:

NOARK Electric, Inc.

9817 South 13th Street

Oak Creek, WI 53154

Phone: 414-304-8189

Website: www.noark-electric.com

Email: tony.diaz@noark-electric.com

Attention: Tony Diaz

This Grieve cabinet oven features 4” insulated walls, aluminized steel exterior, Type 304, 2B stainless steel interior, a silhouette plate with removable cover inside the door opening and an oven hearth driven by a ¼-HP motor through a gear reducer with a torque limiting device variable from 1 to 27 RPM. This 19” diameter oven hearth is constructed from Type 304 stainless steel with 1” studs on 1” centers to support the paint coupons in process.

All safety equipment required for handling flammable solvents are onboard No. 987, including explosion-venting door hardware.

Controls onboard No. 987 include a digital indicating, time proportioning temperature controller and excess temperature controller with separate heating element control contactors. An auto door switch stops hearth movement when the oven door is opened.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

NOARK ENTERS NORTH AMERICAN MARKET AT AHR 2013, BOOTH 5700

A name you may not yet know, but NOARK Electric provides reliable products and efficient solutions to intelligent power and energy systems worldwide. This global supplier of electrical components and intelligent control systems will be presenting an assortment of UL 489 Listed circuit breakers, relays and contactors at the upcoming AHR Expo in Dallas. This show represents the company’s first trade show in the North American market.

The NOARK value proposition centers on products that improve the profitability and maintain the highest levels of performance for customer end products, through the combination of local support with local inventory, exceptional value and superior product quality, backed by the industry’s first 5-YEAR WARRANTY.

Among the many offerings to be displayed at AHR Booth 5700 will be the following NOARK products:

ALL ABOVE NOARK PRODUCTS ARE UL489 LISTED.

Booth personnel will include Paul Xu, VP of Strategy & Marketing, Ken Hilborn, Sales & Marketing Director, Tony Diaz, Product Marketing Manager and Kirk Wilson, West Region Manager.

NOARK Electric, Inc., the North American headquarters of the company, was previously located in Rockford, IL and, due to its rapid growth and inventory commitments, has recently moved to a larger facility in Oak Creek, WI, just south of Milwaukee.

The company is currently in the process of establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries.

A global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1000 associates. Sales currently exceed $2 billion worldwide.

For more information, please stop by booth 5700 at AHR Expo or contact:

NOARK Electric, Inc.

9817 South 13th Street

Oak Creek, WI 53154

Phone: 414-304-8189

Website: www.noark-electric.com

Tony Diaz

Email: tony.diaz@noark-electric.com

North Carolina job shop seeks to diversify and expand customer base in aerospace and other markets; boasts “large shop ability, small shop agility”

James Tool began as a five-man machine shop in 1987, founded by James “Bud” Toner and has grown steadily, over the years. Today, under the leadership of Bud’s son Jeff Toner, the shop has become a supplier of quality machined components to Fortune 500 companies and prime suppliers to the aerospace, heavy equipment, automotive, oil & gas, nuclear and transportation industries. James Tool currently comprises three manufacturing centers, namely engineer/build hydraulic workholding, CNC production machining and precision short run CNC machining. The shop recently achieved the highly valued AS9100 registration for its manufacturing protocols and processes.

As Jeff Toner explains, “We were driven by a need for market diversification and expansion of our current business, building on the strengths established from our aerospace success. Our goal is to secure more business in market sectors that demand the same precision and production efficiencies as our aerospace customers.” He also explained how the company, already recognized for its in-house engineering of hydraulic workholding systems and its precision CNC machining capabilities, sought to obtain the AS9100 registration as a further value-add to its current and potential customers in the aerospace market, one of the fastest-growing manufacturing sectors in the Southeast.

James Tool produces parts in prototype, one-off, short run and production quantities, using 4- and 5-axis CNC machine tools, from high and low carbon steels, nickel alloys, aluminum, stainless, thermoplastics and engineered aerospace materials alike.

In seeking the AS9100 registration, the company engaged in a rigorous process that included reviewing and understanding all the standard requirements, evaluating all current processes, gap analysis program (GAP) utilization, revision and implementation of all necessary processes, procedures, manuals, documentation and training, as well as the ongoing evaluation and continuous improvements in the processes and protocols used at James Tool.

In assessing the current state of the company, Toner observes, “We use state-of-the-art CNC machine tools of the latest generation, plus highly advance metrology solutions to achieve and maintain consistent part quality. We have 5-axis vertical machining centers, high-speed milling centers and multi-pallet workstations. In addition, we offer wire EDM, thermal deburring, CNC torch cutting, vibratory stress relief and a black oxide coating system in-house.” To enable this expansion of services and in anticipation of future growth, James Tool took a bold step in the current economy and recently completed additions and expansions onto its statewide facilities in North Carolina. One new facility in Morganton is 30,000 square feet, while another facility houses a new training complex for the company’s workforce, currently over 120 employees. Overall, James Tool now occupies in excess of 100,000 square feet of manufacturing and service facilities in Morganton and Columbus, North Carolina.

CAD (SolidWorks®) and CAM (MasterCam®) programming is all done in-house to support the CNC machining at James Tool.

Looking to the future for James Tool, Toner concludes, “We are a very pro-active company. We make a decided effort to acquire the latest machine tools and other technologies, so that we can continue to provide our customers the very highest quality products in the fastest possible turnaround times. Hand in hand with the machining and metrology advancements, however, must be a corresponding program of training for our current and future employees. Highly trained people create a better environment, where high quality work, safety and production efficiencies lead to the very best experience for our customers. This is an ongoing commitment at James Tool.” The new AS9100 registration and substantial investments made by the company in both new machinery and new facilities are further evidence of this fact, according to Jeff Toner.

For more information on this story, please contact:

James Tool Machine & Engineering, Inc.

130 Reep Drive

Morganton, NC 28655

Phone: 828-584-8722

Fax: 828-584-8779

Web: www.jamestool.com

Email: sales@jamestool.com

Attention: Jeff Toner, President

Whether we are talking about North America, Asia or Russia, within the oil and gas industry, there is a spirit of optimism. Geological discoveries have led to a massive increase in the estimated reserves in many countries. Along with these discoveries, the potential for the use of innovative technologies has also increased. According to the expert estimates, oil production in the Gulf of Mexico alone will rise from the present 1.3 million to 1.7 million barrels a day during the next decade, with demands for the highly sophisticated technological equipment required to accomplish it increasing as well. Two examples are delivery pipes and casings. To create the connection safely and in perfect alignment depends on the threads on the pipe ends. With its USC turning machines, the specialists from EMAG Leipzig have not only created a tool that specializes in this application – and one that has perfected the production sequence for these threads – but also developed complete solutions that guarantee component quality and process integrity.

Specially optimized for the thread cutting of delivery pipes and casings: the USC series of machines from EMAG

Economic key performance indicators for suppliers to the oil and natural gas industry change rapidly. An impressive example of this is found in the USA. The USA hopes to reduce its dependence on oil imports and instead invest heavily in new technology. An indicator, for the US, are imports of equipment technology for the American oil and gas industry, which the U.S. Department of Commerce for 2012 show an increase of 33 percent, compared to the previous year. The experts also expect a production boom in South America and Asia. For Brazil, the foreign trade experts at Germany Trade and Invest (GTAI) predict a “high level of growth in new reserves“. And on the other side of the globe, the investment volume in the oil and gas sector of Vietnam alone has reached 40 billion USD, according to GTAI.

Frank Schiffler, Head of Sales at EMAG Leipzig Maschinenfabrik: “We design all-round solutions. In addition to that, we have available a comprehensive service network. The two together guarantee the economic success we enjoy among our clientele.“

The experts at EMAG Leipzig are aware that this extraordinary dynamic has a direct impact on the production of the required technology. For decades, the machine builders at Leipzig have been specializing in the machining of delivery pipes and casings for the oil and gas industry. Many users can no longer do without their special know-how in demanding thread production. Frank Schiffler, Head of Sales, fills us in on the background: “We are talking about a gigantic production output. One steel mill produces up to 2 million metric tons of pipes per annum. Component quality is paramount for these because the pipe threads have to be totally leak-proof and must carry the enormous total weight of pipe and oil during the delivery. The machining centers used must ensure that the quality and efficiency of the threads produced is 100%.”

Flexible solutions for the production of pipes

The flexible loading of the workpieces is designed specifically for the customer and fully automated. The transport system does not need to be reset and adjusts itself to individual tasks and workpiece dimensions

The USC series from EMAG Leipzig Maschinenfabrik represents an extraordinary, sophisticated solution for this particular production requirement. Flexibility is very important in the construction of these turning machines. Not only do the different machine sizes allow for the complete-machining of different sizes of pipes with external and internal threads to API and GOST standards, they can also cut all proprietary threads. “The larger oil field technology producers have their own thread standards. We can adjust our machines perfectly to their demands“, explains Mr. Schiffler. For instance, all workholding and centering equipment is configured to suit individual requirements. The same applies to all automation components. As a result, the customer has an extremely fast production solution that automatically loads and unloads the components in 12 to 20 seconds (depending on pipe size and thread type), then carries out the 3-part threading process – from facing to chamfering and finally threadcutting. The output ratio therefore increases enormously, compared with that of traditional turning machines.

These machines handle an enormous amount of pipe material and are made to perfectly suit manufacturer’s individual requirements. The threading process itself takes just 12 to 20 seconds

However, there are two important factors that must be taken into account when machining threads on delivery pipes and casings: processing quality and process integrity. The quality is guaranteed by a perfectly adjusted machine, with proven EMAG technology and the know-how of the speciality machine builders from Leipzig come together. The whole process benefits from the following important design details:

The USC series offers great rigidity, preloaded linear guideways and dampening clamping systems that together ensure the production of thread profiles as smooth as glass

“This quality is a feature of all our USC series machines,” acknowledges Mr. Schiffler. Depending on the machine used, the max pipe diameter can be any dimension from 2⅜” to 20”.

Complete solutions guarantee process integrity

When faced with high production rates, fast machining processes and expensive pipe blanks, machine downtimes are particularly costly for the manufacturer. For this very reason, the process integrity of these machines is another key development area in Leipzig. “We design complete solutions for our customers, who – in turn – benefit from the quality of the EMAG components“, explains Mr. Schiffler. “In addition to that, we integrate, for instance, measuring stations, crack detection equipment, embossing and plating units and, of course, a monitoring system that covers all components. At the end, what we supply is a production system that guarantees the greatest possible degree of process integrity.“ Of similar importance in this context is the worldwide service presence of the specialists. Not only are both user and maintenance staff trained to perfection, a 24-hour 365-day telephone service is also available. This ensures that possible machine downtimes are reduced to an absolute minimum.

The two compound slides with 4-position table-type turrets of EMAG design accommodate a number of different tooling systems. The various quick-change toolholders hold tools for external and internal turning operations. The compound slides are subject to high rapid traverse speeds in X- and Z-axis and ensure idle times are kept short. The guideway system for the slide unit features pre-loaded linear roller guides for greatest machining accuracy and high dynamics

Projects from A to Z

How do the special machine manufacturers assess their market opportunities over the next few years? Mr. Schiffler’s judgement on the market’s dynamic is a positive one: “We already are the market leader in machines for the threading of oil and gas pipes; and we intend to further extend this position.“ One formula for success in this field is the famous “Made in Germany“ – which is a sign for quality. Over 70 percent of the machine components are made and assembled at EMAG in Germany. Every customer comes to Leipzig for the machine acceptance, where the first test run, using the actual pipe blanks, is carried out. Only then will the machine be installed at the production site. “Our particular quality of service kicks in long before the machine is built, or the central claim made by EMAG Leipzig would not be a valid one. Our name stands for projects that are carried through to perfection from A to Z, and that represent all-round solutions.“

See the USC series in action HERE.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

This Grieve oven has 4” insulated walls, 2” insulated floor, top-mounted heating chamber, Type 304, 2B stainless steel interior, stainless steel exterior with #4 brushed finish, double doors front and rear, plus a special sealing flange to allow the oven to seal into a wall between a cleanroom and the fabrication area in the customer’s facility.

Controls on No. 981 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and a 30-hour shutdown timer.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

VLC 100 G Vertical Pick-up Grinder

Automobile manufacturers all over the world were able to enjoy an increase in their sales figures, this year! The biggest increases were experienced in the USA, China, India and Russia. However, the rapidly increasing number of vehicles built also brought some production challenges – for instance, the sub-contractors must deal with the increasing output levels and also need to ensure that process safety and component quality do not suffer. In fact, even the smallest components with complex geometries must be produced with increasing levels of precision. In the development of the VLC 100 G Vertical Grinding Center from EMAG, our grinding specialists have made sure that the machine concept offers efficient, error-free machining processes for the production of small chucked components.

Small chucked components are typically produced in large quantities. The demand for components, such as gearwheels, planetary gears, chain gears and flanged components for cars, for instance, have necessary quantities that typically go into the millions; and short cycle times in the production of these components have become mandatory. For instance, the internal contour of a gearwheel must be ground in the shortest possible time and the machine’s workholding unit must be loaded with a new workpiece just as quickly. In many production environments, this represents a critical moment, because the idle time is commonly a decisive factor in establishing the economic viability of the whole process.

Automatic loading scores heavily

The VLC 100 G is equipped with three axes (X, Z, C). The machine uses its overhead pick-up spindle to load itself. The machining area features one or two grinding spindles for internal and/or external work.

High output levels – short cycle times. This is exactly why the VLC 100 G Vertical Grinding Center from EMAG, for small chucked components with a maximum diameter of 100 mm, was developed. The machine utilizes its onboard pick-up system to load itself. And while one workpiece is being machined, the operator – or the automation system – is putting the raw-parts on the conveyor belt. This reduces idle time and increases output rates. Another benefit is the vertical machining concept; the design ensures that the grinding sludge falls to the bottom of the machine unhindered, where it is then transported out of the machine. (Click HERE for a video detailing the VLC 100 G Vertical Grinding Center)

Quality control is integrated

Measuring processes can also be integrated into the machine, making quality control an integral part of the whole process. The measuring probe is located between the machining area and pick-up station, where it is protected from contamination.

In use are two different grinding wheels

Dr. Guido Hegener, Managing Director EMAG Salach Maschinenfabrik GmbH

An important feature of the VLC 100 G is that it offers the possibility to use two grinding spindles, which can be used to perform different grinding operations, or to handle both rough- and finish-grinding work. In other words, the first wheel performs the “rough” job of removing excess material from the raw-part at high feedrates (the CBN wheel is specially designed to absorb the necessary forces), while the second wheel (with different specifications) takes over the finishing work to guarantee a perfect surface finish on even the most challenging geometries. With the help of this intelligent tooling combination, EMAG design engineers have succeeded in drastically reducing the grinding time of even very complex components. “For the removal of large amounts, two wheels offer a shorter cycle time than one, with the first wheel designed to do the rough-grinding and the second one in charge of finish-grinding work,” explains Dr. Guido Hegener, Managing Director of EMAG Salach Maschinenfabrik GmbH in Germany.

A convincing machine concept

Very easy access! Generously designed maintenance and service doors make the machine easy to access.

The combination of fast loading and efficient grinding processes leads to a very compelling machine concept. The VLC 100 G works very well with the dynamic developments in automotive production. Now, with the rapid increase in required quantities, the demand is for new machine concepts that can be integrated into existing production without any problem. With the VLC 100 G, two features enable it to be integrated without any problems. “Programming the workpieces with our new EMAG NAVIGATOR software is simple and intuitive, saving valuable setup time. For many production environments, this is an advantage that should not be underrated,“ confirms Dr. Hegener. Furthermore, the exceptionally small footprint for the VLC 100 G should make the work of every production planner easier. The stand-alone machine occupies about 4.5 square meters (48 square feet), making sure that the growth of a production facility of this kind will not be limited by floor space requirements.

The advantages of the VLC 100 G

The dressing unit with diamond roll.

The workpieces are mounted on pallets and taken into the VLC 100 G by the conveyor belt. The pick-up spindle then further automates the whole loading and unloading process

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

The VL 5i Vertical Turning Machine from EMAG has been designed for the quality- and cost-conscious medium-sized business and the sub-contractor: a production aid that can be used universally and that impresses by its small footprint and its highly advantageous price-performance ratio – including automatic workhandling.

Better component quality at a lower price? VL 5i, a vertical turning machine that is custom-made to fully meet the demands of the small and medium size manufacturing company.

With their VL 5i the machine tool specialists at EMAG have developed a comprehensive solution for small and medium size manufacturing companies. It can be used for small and large batch production, and complete-machines workpieces of up to 250 mm in diameter in a single setup. Flanges, gears, gear shafts and steering pinions can be machined with as much efficiency and to the same quality as brake disks or cams. The machine features a powerful 28 kW workspindle with a top torque of 300 Nm, plus a turret that accommodates turning as well as driven tools and has an impressively short indexing time of 2.2 s.

Machining area of the VL 5i: 12 turning or up to 12 driven drilling and milling tools allow you to carry out a great variety of operations in a single set-up.

Drilling and milling operations can be incorporated by equipping some or all of the 12 turret stations with driven tools. The outstanding feature in this is the EMAG turret drive that combines high speeds with outstanding performance and a small space requirement. For instance, the diameter of the turret is only 360 mm but accommodates 12 stations and has a maximum torque rating of 45 Nm.

Flexible automation included

Flexible component loading: workpieces are loaded by inserting them directly into the carrier prisms or, where necessary, into workpiece receptors that can then be inserted into the prisms.

A recirculating conveyor band with carrier prisms that do not need to be reset, takes the components to the pick-up station. As this station lies behind the machining area, the operator is able to remove finished components and insert new raw-parts at the front of the machine.

Proof of the outstanding quality of the VL 5i is, first of all, its integrated automation system. It uses a recirculating chain conveyor equipped with carrier prisms that deliver the raw-parts directly to a pick-up station for machining. This station is located behind the machining area, so the operator can – at any time – insert new raw-parts at the front of the machine. It is hard to imagine a more flexible and, at the same time, more universal solution for the automation of a machine tool.

Short travel times = short idle times

Quickly in and out: the workpieces reach the pick-up station in flexible carrier prisms mounted on the recirculating conveyor belt, with the flexibility of the prisms minimising the resetting effort for different workpiece diameters.

Another advantage of the VL 5i is its short idle times. Changing workpieces is a very fast process, because the distance between the loading position and the machining position is only 550 mm. The importance the EMAG turning specialists attach to the machine’s efficiency can also be seen in the design of the guideways. They are located outside the machining area, where they are protected against chips and dirt. This reduces the maintenance effort and makes the machine less susceptible to breakdowns. The machine can also be equipped with an optional measuring station, located outside the machining area. Here the component is measured on its way from the tooling zone to the unloading station, while still in its original clamping position. The measuring results are not distorted by the entrance of chips, as the vertical turning operation provides for ideal chip flow conditions.

Energy efficiency is very important

The sustainable use of energy and resources completes the picture of an engineering solution that not only offers a small footprint but also eliminates unnecessary design details which is the reason why the machine builders at EMAG can offer this machine at an advantageous price-performance ratio.

Optional measuring: a measuring probe, located outside the machining area, brings quality assurance to the machine. In automated measuring cycles, carried out between machining process and component removal, the VL 5i logs the offset data and provides a record for quality assurance purposes.

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

Continue reading