Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Crown Equipment in Mexico bought one of the MAE straightening presses from the GMTA booth at IMTS. Crown is a world leader in forklift trucks.

The expansion of the GMTA facility in Ann Arbor, Michigan is underway and targeted for completion in several months. When completed, the new facility will house a new machine demo and training center, plus additional sales and service personnel. GMTA continues to grow steadily, representing numerous high-quality German machine tool builders in North America.

Siemens in Mexico bought a Pittler PV630 ValueLine vertical turning machine for motor manufacturing. Take a look at video of this machine in action!

For more information:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

This Grieve oven has 6” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior and four front access doors with automatic door switches to shut off the heat and blower when a door is opened. Four structural steel slide beds are provided to support the plastic sheets during processing.

Controls on No. 1026 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, SCR power controller and eight auxiliary thermocouples connected to a selector switch and temperature indicator.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingBill Hunter raises company-supported endowment to Foundry Educational Foundation; $25,000 in memory of Al Hunter will provide scholarships to students involved in metalcasting

Bill Hunter, left, president of Hunter Automated Machinery, presented a check to Bill Sorensen, executive director of the Foundry Educational Foundation, on August 9, 2012 at Hunter headquarters in Schaumburg, Illinois, near Chicago. The check raised the amount of money in the FEF Scholarship Fund to $25,000, in honor of Al Hunter, founder of the company.

Schaumburg, Illinois (USA)-Hunter Automated Machinery today announced a donation to the Foundry Educational Foundation (FEF), raising the current endowment to $25,000, in memory of Al Hunter, founder of the company and father of current owner Bill Hunter. Bill made this donation on August 9, presenting a check to the FEF Executive Director, Bill Sorensen.

Hunter Automated has been a contributor to the FEF for many years. Upon the death of Al Hunter in 2011, the family asked that donations be made to the foundation in honor of him. Once the contributions were collected, the Hunter family asked that FEF establish an endowment to honor Al’s memory, with scholarships provided at selected schools. The first school chosen was the University of Alabama. It provides a deserving student a scholarship in Al Hunter’s name.

FEF is a non-profit organization and the foundry industry’s first link to the college campus. The foundation uses funds contributed from the foundry industry to encourage the pursuit of metalcasting as an academic endeavor at schools across the country. Hunter has pledged to donate $500 every year to FEF, going forward.

As Sorensen explained, “Students will benefit not only from the scholarship monies, but also from getting to know the contributions Al Hunter made to the industry and the substantial legacy he left behind.” Al Hunter held over 80 patents in his lifetime and was chiefly responsible for the development and implementation of automatic matchplate molding machine technology in the North American and ultimately the global foundry market.

Bill Hunter presented the check to Bill Sorensen at Hunter headquarters in Schaumburg, Illinois (Chicago) on August 9, 2012. “It is our privilege to help fund this scholarship program that both encourages young people to enter the foundry industry and continues to honor the technological contributions made by Al Hunter,” Bill remarked.

Sorensen further noted that approximately 90% of the students who have received FEF scholarships continue to pursue their careers in metalcasting.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

No. 873 is a 650ºF, electrically-heated inert atmosphere cabinet oven from Grieve, currently used for processing corrosive materials at the customer’s facility. Workspace dimensions of this oven measure 38” W x 50” D x 38” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 2000 CFM, 2-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road, Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com – Attention: Frank Calabrese

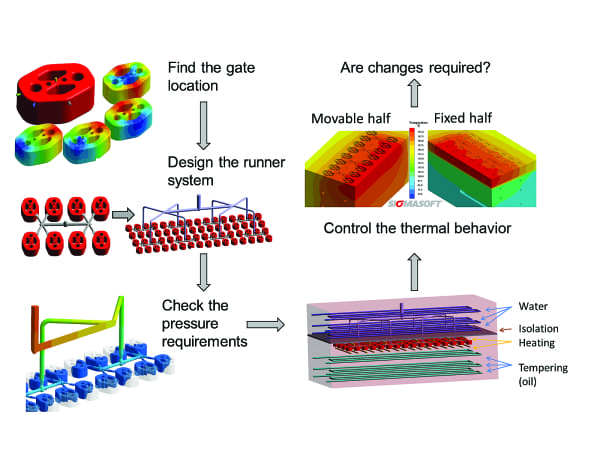

Continue readingBesides predicting the filling process, the process simulation software SIGMASOFT® can also predict the curing reaction of elastomers and the thermal performance of mold tempering systems. A major advantage is that not only the cavity is simulated, but the complete mold including all details is considered in the calculation. Therefore, the interaction between heating elements, elastomer, inserts and mold can be accurately predicted.

Simulation technology can help avoid all these typical processing problems while saving significant time and effort during the development of a new mold. When utilizing the approach of “Process Simulation”, provided by SIGMA® with its software SIGMASOFT®, all the elements of the mold can be included. This allows the molder to run a “virtual production”, including all the process stages (preheating of the mold, injection, curing), not only over one cycle, but over several production cycles. With this process, the performance of a mold design can be evaluated completely before the steel is even cut.

“Historically, elastomer molders have relied on conventional injection molding tools to predict the filling of the cavity. Many processors still think this is all simulation can do for them. However, simulation tools available nowadays are far more powerful. Besides filling, the curing reaction can be accurately predicted, and the thermal behavior can be exactly anticipated”, explains Dr. Marco Thornagel, executive director of SIGMA Engineering GmbH/Germany. “Simulation can make a company achieve its production goals faster, being more profitable”.

Simulation can analyze different variables of the design of a new mold. After determining the desired geometry, the process starts with the selection of the injection point or gate type. Understanding the flow behavior, as well as quality issues related to weld lines, air gaps or jetting, the runner geometry can be defined. In this stage, different aspects including cavity balance or the pressure requirement can be predicted.

Once the part and runner are defined, the tempering of the mold can be designed. In the simulation the tempering elements can be precisely included: it is possible to define their exact location in the mold, as well as the material and the electric power. Even the control system can be defined. Instead of assuming a mold temperature in the simulation, the exact thermal condition of the mold is predicted, including the way it fluctuates over time.

After the effect of the desired tempering system is simulated, factors in the mold which can compromise part quality can be identified. Cold spots in the mold where the material cures too late or irregular temperature distributions, which can produce different curing degrees for parts produced in different cavities, are some examples of the virtual “troubleshooting” that can be achieved with Process Simulation.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

Continue readingThe process-oriented approach of SIGMASOFT® makes it possible to use injection molding simulation of elastomer applications not only for filling or cooling times, but also the non-productive times between each process phase. When the process is simulated considering the influence of operational times occurring between the main process stages, the accuracy of the simulation is dramatically improved.

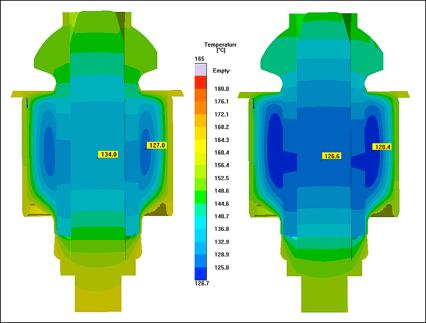

Temperature distribution in a metallic component overmolded with elastomer. Left: without consideration of the mold opening time; right: considering a mold opening time of 60s.

Schaumburg, IL, September 7, 2012 – Even though it is not necessary to include them to complete an injection molding simulation, the non-productive times have a major influence on the process and on part quality. Process Simulation Software SIGMASOFT®, from SIGMA®, can include non-productive times in the simulation enabling substantial improvement in the accuracy of the results to be achieved.

Taking into consideration the times in which the mold opens and closes, the times in which it is heated up or cleaned, as well as handling times when the inserts are placed simulation makes it possible to accurately analyze the process cycle. The interaction between all mold components has to be considered and cycle times have to be predicted accurately. That way even factors that influence the part quality, such as the curing degree, can be predicted by the simulation.

An example is presented in Figure 1. In this case the mold temperature decreases during the time period when the mold stays open. If this time is not considered in the simulation, the prediction of the whole cycle time, as well as the prediction of the cooling time or curing degree, will be erroneous. Besides, the predicted quality of the parts produced can deviate from reality.

In SIGMASOFT®, such non-productive times can be defined and varied separately in the simulation. Therefore, besides calculating the whole cycle, it is also possible to perform trouble-shooting of problems at each of the production stages. Through the utilization of simulation it is possible to decide if changes in the process definition are enough to solve production problems, or if the mold has to be reworked to achieve the desired quality and productivity goals.

—

SIGMA® (www.sigmasoft.de) is 100% owned by MAGMA® (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

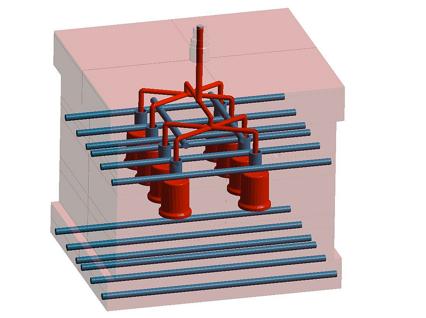

Continue readingWith the process-oriented approach of SIGMASOFT®, the injection molding simulation for elastomers is no longer limited to predicting the cavity filling while designing the part or to answer questions regarding a balanced filling. Based on an accurate simulation of the curing reaction (vulcanization), it can be used for designing the mold, identifying process windows and troubleshooting during production.

The process-oriented approach of the Injection Molding Simulation Software SIGMASOFT® allows for the easy and exact consideration of all relevant information regarding mold and process into the calculation, beyond the part and runner geometry.

Schaumburg, IL, July 25, 2012 – At the recent DKT Conference in Nuremburg, Germany, SIGMA Engineering GmbH, Aachen, presented the latest functionality expansions of its 3D Injection Molding Simulation Software SIGMASOFT®. The focus of the presentation was the software’s ability to reduce development and production costs through new developments in process simulation.

Many factors in elastomer injection molding have an influence on product quality and costs. To ensure a competitive advantage, the whole manufacturing process must be considered. Since the design stage has the largest influence over the total costs of a part, this is where the savings start with SIGMASOFT®.

By using process simulation, feasibility and rough process parameters can be evaluated. Parting line and venting channels can be worked out, as well as the optimal type and positioning of the injection drop point. Where are weld-lines acceptable? Where do they need to be avoided? Do inserts need pre-heating? Which level of vulcanization should be reached and how much time and what temperature are needed to achieve this level? Important factors regarding part quality are optimized in this way, through the algorithms in the software.

A mold, which will be used for producing the part, can now be developed. Decisions must be made at this point, which can incur substantial costs: How many cavities can be designed in the mold (clamping force and required pressure)? How should the runner system be designed to obtain balanced cavity filling and the same compound quality in every cavity? Is there need for a cold runner? What heat-output is needed and how must the heating system be configured? Are the heated clamping plates adequate? Where should control points for the tempering be positioned?

The simulation is able to answer all these questions and allows reaching the desired quality with minimal effort (time and energy). In this way, the process stability is guaranteed before the mold is even built. Costs can be reduced significantly during development and existing processes can continue to be improved. This is all accomplished while substantially reducing rejects and material waste, thereby getting to the first good part much faster.

The latest developments in the software’s thermal solver allows for the exact integration of all mold components. As a result, an accurate reproduction of the real temperature profile in the mold is possible, even over multiple injection molding cycles. The simulation definition is optimized for the requirements of process engineers, so that complex detail questions can be examined from a practical perspective without requiring extensive knowledge of simulation software. For example, it can be determined how heating cartridges influence mold temperature and part quality, simulating them with their respective electric power and control.

—

SIGMA® (www.sigmasoft.de) is 100% owned by MAGMA® (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

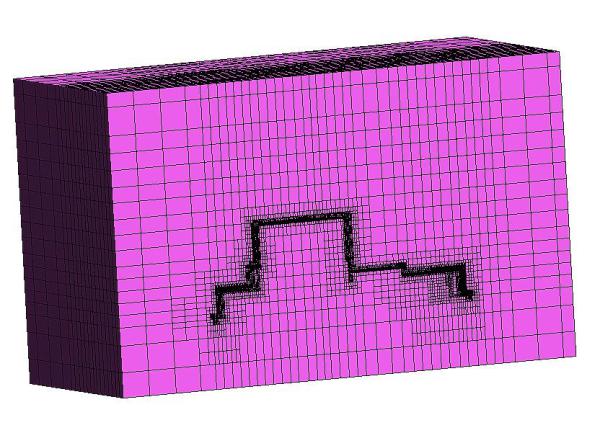

Continue readingThanks to a completely reengineered solver technology and a revolutionary meshing concept, with SIGMASOFT® Version 5.0, the simulation time required in elastomer applications can be reduced by up to 80%. With this dramatic speed-up, simulation can now be integrated in the elastomer processing on a daily-basis, both for part design and process troubleshooting.

Figure 1 –With the new solver technology and the use of “unstructured meshes,” SIGMASOFT® Version 5.0 reduces the calculation time by up to 80% in the simulation of elastomer injection applications.

Schaumburg, IL, July 25, 2012 – At the DKT conference in Nuremberg, Sigma Engineering GmbH, Aachen, presented SIGMASOFT® Version 5.0, the latest release of its process-oriented simulation software. With a completely reengineered solver technology and a new meshing concept, calculation times have been dramatically reduced, while keeping all the advantages of accuracy and user friendliness of a complete 3D-simulation approach.

“With SIGMASOFT® Version 5.0, we have achieved a major breakthrough in injection molding simulation,” explains Dr. Marco Thornagel, Executive Manager at Sigma. “Some years ago, users had to wait sometimes days to get the results of a simulation. It was not viable to use simulation to support every-day production activities, or to quickly optimize products. Now, however, simulation can be part of the daily production tools used in the mold shop or in the production floor, to deliver reliable and profitable answers both to design new products and to optimize existing molds.”

SIGMASOFT® is still the only option available in the market to seamlessly integrate all elements in the mold within the simulation. Thanks to the implementation of “Finite Volume” numerical methods, not only can the cavity be considered in the simulation, but also the complete real mold configuration, including tempering channels, heating elements and inserts. SIGMASOFT® is and has always been based exclusively in 3D technology, developed over a quarter century. The mesh required to conduct the simulation is generated effortlessly by the user in only minutes, without requiring any manual optimization.

The new meshing technique in the latest version of the software uses “unstructured meshes.” These are basically “intelligent meshes,” which can automatically mesh finer regions where complex thermal and flow phenomena take place, such as part boundaries, thin walls or complex runner systems. It also can save mesh elements in regions where fewer interactions take place, such as mold boundaries. The calculation effort is reduced and the productivity of the software increases.

Through parallelization, the new solver architecture makes it possible to exploit the complete potential of multi-core technology in state-of-the-technology computers. Beyond a significant reduction in computational time, the technology now allows users to simulate more complicated injection molding processes. This will be now the focus of further developments in the software, according to Sigma sources.

For further information on this story, please contact:

Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

Continue reading

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

Advanced Machine & Engineering Co. (AME) Rockford, IL announces their return to IMTS 2012. As in the past, they will have two booths to showcase their products and services.

Visit Booth W-2405 to learn about precision machine components, featuring:

Visit Booth E-5714, for additional AME products such

Our sister company, Hennig, Inc., will have their complete line of products in Booth E-5714 and W-2405.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online: