Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

35”W x 31”D x 42”H. 9.6 kW installed in Nichrome wire heating elements provide heat input, while a 750 CFM, 3/4 HP recirculating blower provides horizontal airflow across the load.

This Grieve cabinet oven features 4” thick insulated walls, a stainless steel exterior with #4 brushed finish Type 430 stainless steel interior, two independently operating doors for access to the workload and two tiers of five shelves, supported on rollers. Swivel casters with swivel locks and wheel brakes are also included for oven portability.

No. 947 has a digital indicating temperature controller, manual reset excess temperature controller with separate control contactors and recirculating blower airflow safety switch.

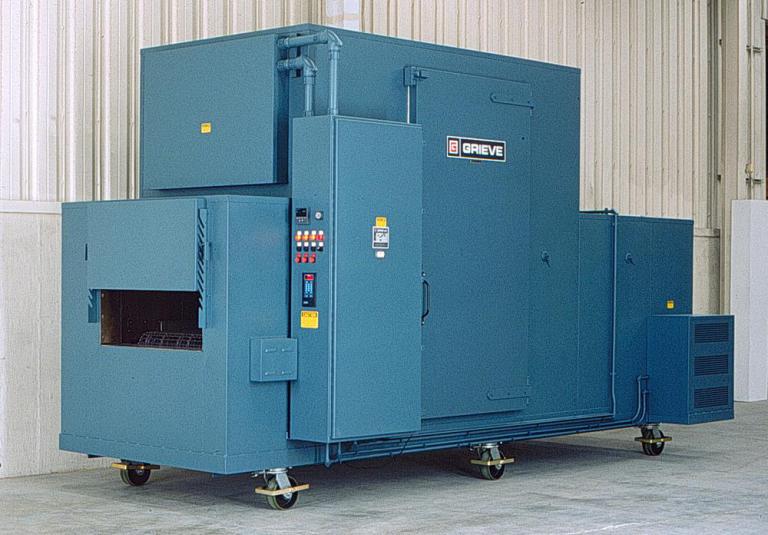

As shown in the photo, this Grieve oven has a top-mounted heat chamber for space efficiency.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve pit furnace feature 7” thick insulated walls, comprising 5” of 2300°F ceramic fiber blanket and 2” of block insulation. A 6-1/2” thick furnace floor is made of castable refractory materials.

No. 943 also includes an air-operated vertical lift door and a reinforced 1/2” steel top plate to protect the unit while loading and unloading occur.

Safety equipment includes an adjustable, thermocouple-actuated, manual reset excess temperature controller, separate heating element control contactors and a door interlock switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This inert atmosphere oven features an aluminized steel exterior, Type 304, 2B finish stainless steel interior and 10” insulated walls, comprising 2” of 1900°F block and 8” of 10 lb./cu. ft. density rockwool insulation. Inner and outer door gaskets are provided, with the inner gasket sealing against the door plug, while the outer gasket seals directly against the front face of the oven body.

No. 938 has all construction features onboard for inert atmosphere operation, including pressure regulator, pressure gauge, internal high temperature gasket, all-welded expansion connection in doorway throat, air jacket on inner oven body for cooling, 1/2” thick silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fitting for maximum integrity.

Additionally, a 975 CFM blower is provided to pull air through the air jacket on inner oven for cooling. The entire unit is built to meet JIC / NEMA 12 electrical standards.

A digital programming temperature controller, manual reset excess temperature controller with separate contactors and SCR power controller are included, as well.

This Grieve inert atmosphere oven is mounted to an integral leg stand.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve walk-in oven features an aluminized steel exterior and interior with 7” thick insulated walls, plus a 4” thick insulated floor with built-in truck wheel guide tracks. Inner and outer door gaskets are provided, with the inner gasket sealing against the door plug, while the outer gasket seals directly against the front face of the oven.

All safety equipment required by NFPA Standard 86 for handling flammable solvents are onboard No. 839, including explosion-venting door hardware, powered forced exhauster air flow safety switch and purge timer, . Also featured on this walk-in oven are a recording and programming temperature controller with separate contactors and a recirculating blower air flow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

50”W x 50”D x 50”H. 60 kW power installed in Incoloy-sheathed tubular heating elements and a 2450 CFM, 1-1/2-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 4” insulated walls, aluminized steel exterior, Type 430 stainless steel interior, brushed stainless steel control panel face, heavy-duty doors and door frame with explosion-venting latches and a 325 CFM powered forced exhauster. The oven is supported by I-beams to allow the loading cart’s front wheels to extend under the oven during loading.

No. 932 also includes a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and 10” diameter circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

No. 919 is a seven-zone, gas-heated belt conveyor oven from Grieve, currently used to cure various coatings onto ceramic parts. Maximum operating temperatures are 350°F in Zones 1-4 and 1000°F in Zones 5-7. Workspace dimensions measure 51”W x 56’D x 15”H, with a 30” long open belt loading zone, four 3’ long insulated heat zones with independent recirculated airflow and temperature control (350°F), 30” long open zone, three 3’ long insulated heat zones with independent recirculated airflow and temperature control (1000°F), 9’ long cooling zone and 3’ long open unloading zone.

400,000 BTU/hr. are installed in modulating natural gas burners in Zones 1-4, with 500,000 BTU/hr. in Zones 5-7

A 1/2” wide, B36-20-12-14, Type 316 stainless steel balanced weave conveyor belt is powered by a 1-HP motor drive, variable from 1.5 to 30 inches per minute.

A 30,000 CFM, 30-HP recirculating blower provides vertical upward airflow to the workload in Zones 1-4, while 25,000 CFM, 20-HP unit in Zone 5 and 12,500 CFM, 10-HP units in Zones 6-7 do likewise.

Two 36” diameter tubeaxial fans, each driven by a 5-HP motor, push / pull air through the oven’s cooling zone.

This Grieve belt conveyor oven features an aluminized steel exterior and Type 316L, 2B finish stainless steel interior with continuously welded seams. There are 4” thick insulated walls in Zones 1-4 and 8” thick insulated walls, comprising 2” of 1900°F block and 6” of 10 lb/cf density rockwool, in Zones 5-7.

The unit has top mounted heating chambers, doors for access to the work space and heat chambers in each zone and is designed to be split into two sections for easier shipment.

No. 919 has onboard all safety devices required by IRI, FM and NFPA Standard 86 for gas-heated equipment, as well as digital indicating temperature controllers.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Two 6,000 CFM, 5 HP recirculating blowers provide a total 12,000 CFM vertical upward airflow to the loads. Four 24” diameter tubeaxial fans are each driven by a 5 HP motor to push/pull air through the cooling zone on this Grieve conveyor oven.

No. 933 features 4” insulated walls, a removable top-mounted heat chamber (shown removed in photo), aluminized steel interior and exterior, plus two independent doors for access to the workspace.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment are onboard this oven, including a 975 CFM, 1 HP powered forced exhauster for combustion venting.

This Grieve vertical conveyor oven is built to all applicable JIC/NEMA 12 electrical standards.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

No. 823 is an electrically-heated, 1000ºF belt conveyor oven from Grieve, currently used for drying water-based glue onto stainless steel mesh. Other features include:

-160 KW installed in Incoloy sheathed tubular heating elements

-30″ wide, 1″ x 1″ 316L stainless steel flat wire conveyor belt with 1/4 HP motor drive, with digital controller; variable from 0.5 to 10 feet per minute

-hot load, unload, and belt return

-7800 CFM, 5 HP recirculating blower providing vertical downward airflow

-8″ thick insulated walls comprised of 2″ of 1900°F block and 6″ of 10 lb/cf density rockwool

-aluminized steel exterior

-16 ga. type 316L stainless steel interior

-650 CFM, type 304 stainless steel, powered forced exhauster

-NEMA 12 electrical standards

-digital indicating temperature controller

-manual reset excess temperature controller with separate contactors

-recirculating blower air flow safety switch

-swivel casters with swivel locks and wheel brakes

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

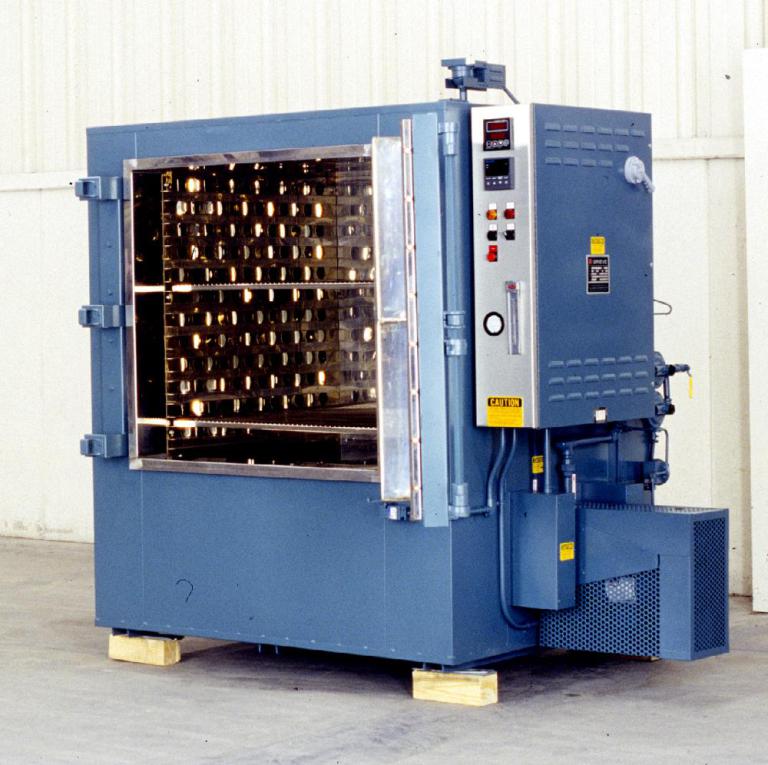

This Grieve inert atmosphere cabinet oven features 4” insulated walls, aluminized steel exterior, Type 430 stainless steel interior and an automatic door switch to shut off heaters and blower when the door is opened.

Special inert atmosphere construction features include a pressure regulator, flowmeter, pressure gauge, inner oven walls sealing directly against a 1/2” thick silicone rubber door seal, air jacket on the inner oven for cooling, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all oven wall penetrations equipped with compression fittings to maintain atmosphere integrity.

No. 930 also includes a digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve universal oven features 10”-thick insulated walls, comprising 2” of 1900°F block and 8” of 10 lb/cf density rockwool insulation, plus an aluminized steel exterior, Type 304 stainless steel interior and a motor-operated vertical lift door controlled by a foot pedal.

No. 931 also includes a digital indicating temperature controller, manual rest excess temperature controller with separate contactors, recirculating blower airflow safety switch, fused disconnect switch and a 10’ power cord.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP