Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Firm has agents throughout the country, serving the extrusion industry

Guill dies and crossheads for plastic, rubber and other material extrusions are now being sold by Bernal Industrial throughout Mexico. With more than 50 years of experience, Guill is a recognized technology leader in the design and manufacture of extrusion tooling for various applications. These include medical tubing, multi-lumen, multi-layer, profile products, rubber, plastics, wire & cable and fiber optic sheathing.

Bernal Industrial operates as a consultative engineering representative agency, distributor and service provider for its lines. Daniel Bernal is the manager and director of Bernal Industrial. Besides its main office in El Paso, Texas, Bernal Industrial has Mexican offices in Baja California, Chihuahua, Tamaulipas, Nuevo Leon, Mexico City and Queretaro. Bernal also sells products for Nordson PPS (Xaloy, BKG, EDI), American Roller, Scantech, Regloplas, Getcha, Matsui and Pillar Tech, among others.

The company has been in business for 18 years and has 15 employees. During that time, Bernal Industrial has become a major force in Mexico by aligning themselves with industry leaders in the plastics and rubber processing market to provide cutting-edge technology to all the major markets in Mexico, including auto, aero, medical and appliance. Their team comprises industry professionals who have hands-on experience and can provide highly technical application assistance for the products that they bring to the market. Bernal Industrial currently contacts all plastic and elastomer processors in Mexico, including the affiliates of major U.S. and international companies.

Bernal will be promoting the complete line of Guill products. Asked about this partnership, Daniel Bernal commented, “We are looking forward to working with Guill and finding many new business opportunities for them throughout Mexico.”

For more information, please contact:

Thomas Baldock

Guill Tool & Engineering

10 Pike Street

West Warwick , RI 02893

(401) 823-7600

www.guill.com

tbaldock@guill.com

New extrusion head from market leader features Mechanically Assisted Gum Space (MAGS) adjustment

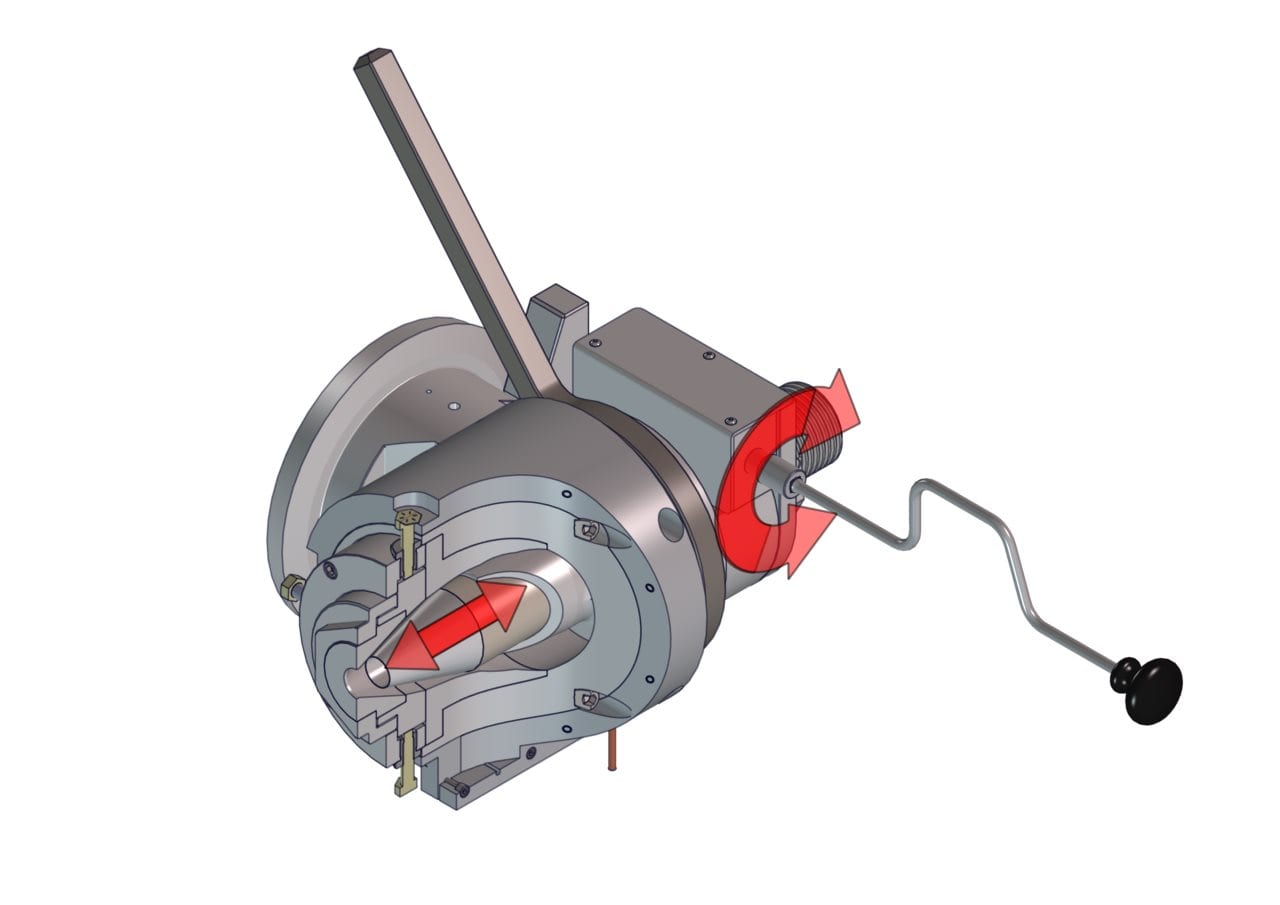

Guill Series 500 crosshead with Mechanically Assisted Gum Space (MAGS) adjustment…specially designed for the flow characteristics of elastomeric compounds

Guill Tool introduces the NEW 500 Series crosshead with MAGS gum space adjustment. The 500 Series is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds. One of the key features engineered by Guill on this new crosshead design is the mechanically assisted gum space (MAGS) adjustment system. This new method of gum space adjustment allows the operator to make an effortless adjustment from a single point using a common socket wrench. No more need to struggle with multiple nuts and bolts in order to adjust gum space, which leads to faster adjustments. The visual indicator on the core tube allows the operator to see how far the gum space has been moved, making those adjustments much more accurate and repeatable.

The hardware-free and patented cam lock design of the NEW 500 Series from Guill means no time is wasted unbolting and re-securing fasteners for disassembly and re-assembly. Only half of a rotation of the cam nut is required to loosen and automatically extract the deflector from the head body, which is another time saver. Also, with no undercuts on the deflector, there are no material hang-ups when extracting the deflector, allowing for faster and easier cleaning and changeover.

The NEW 500 Series also features the latest Center-Stage concentricity adjustment system that significantly reduces pressure on the tooling, allowing easier and more precise concentricity adjustments without loosening the face bolts. Easy-Out inserts for the adjusting bolts also allow simple replacement of locked or damaged adjusting bolts, which further saves on repair and downtime.

Another innovative feature of this new rubber/silicone crosshead is a cast aluminum liquid-fed cooling sleeve that allows the user to switch out the cooling jacket in the event of a line obstruction, again reducing downtime compared to traditional integrated cooling systems.

The NEW 500 Series crosshead with MAGS gum space adjustment is a drop-in replacement on most existing NRM lines, however this crosshead design can also be adapted to fit any extruder design or line layout.

The addition of a newly designed flow inlet channel reduces the shear and heat that is generated as the materials are being processed. This leads to lower head pressures allowing the material to move through the head in a much more balanced and even flow.

All crossheads supplied by Guill are furnished with a tool kit for assembly and disassembly as well as a detailed operator’s instruction manual. The engineering team at Guill will gladly assist users in the implementation and operation of the NEW 500 series crosshead.

For a video of the NEW Guill 500 Series crosshead with MAGS gum space adjustment, please go to:

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

www.guill.com

sales@guill.com

Continue reading

New low-volume spiral flow ABA crosshead with 2-stage clamping for easy concentricity adjustment

Guill Tool introduces Series 824, a co-extrusion crosshead designed for irrigation tubing with an emitter tool. Manufactured from stainless steel, this new crosshead features balanced flow design with spiral technology that improves flow characteristics at all extruder speeds. Dual feed ports provide concentric compound flow, while the splits flow from one extruder to feed the inside and outside layers via a manifold assembly. Series 824 is adaptable to all popular extruders on the market currently.

Capacities include a max. die ID of 1.875”, max. core OD of 1.250”, max. tip OD of 1.500” and max. emitter tool OD of 30mm (1.18”). The Series 824 design allows the emitter insertion tool to pass completely through the crosshead ID. Gum space adjustment is performed with die nut rotation, while the Guill 2-stage clamping mechanism allows easier concentricity adjustment. Quick-change tooling and a tool kit for disassembly and re-assembly are provided with the unit.

Bill Conley, sales manager for Guill, comments, “On this project, the customer challenged us with an application that required precise placement and bonding of preformed emitters within the extruded tubing without melting them in the crosshead. It was also necessary to process either a low-cost ABA layer construction or single-layer construction within the same unit.”

With the Series 824, the customer realized cost reductions, better quality, less scrap and more uptime in their process. The Guill cool-tube design prevented the emitter from melting in the head and the overall unit mechanics allowed more rapid and easier changeover from a co-extrusion to a single layer.

On this project, Guill also supplied the customer the company’s extrusion tool cart, which facilitates easy alignment and tool changes. The removable cart swing gates stay free from accumulated process fluids, while the adjustable height means the cart is compatible with virtually any extruder model. Thermal isolation in the design keeps heat in the head, not the cart.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online: