Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

A leading supplier of braiding equipment, Wardwell, has announced the retirement of Steven J. Elderkin and the appointment of Scott A. Hunter. Both announcements were made by company President John Tomaz, at Wardwell’s headquarters in Central Falls, RI.

Elderkin’s retirement, effective December 2017, comes after 44.5 years at Wardwell and several positions. In the last 20 years, his roles included supervisor of assembly and customer service technician. Tomaz said, ”From the beginning, Steven has been a tremendous asset to our company. Every part of business that he’s been involved in, has been improved. We’ll certainly miss having him around.” Now, Elderkin is looking forward to spending time with his grandchildren and enjoying the warm Floridian weather.

Hunter is Wardwell’s new Sales Engineer. In this position, he will be responsible for equipment sales throughout North America. Mentioning this new addition Tomaz commented, “Scott is an experienced professional who brings the necessary skills and knowledge, having previously worked in the wire and cable industry. He will undoubtedly be an asset.” A three-year stint at Amaral Automation Associates is part of Hunter’s experience.

For more information, please contact:

Cynthia Chen

Wardwell Braiding Co.

1211 High Street

Central Falls

Rhode Island, 02863

Phone: 401 724 8800 X 183

Fax: 401 723 2690

Web: www.wardwell.com

Drum handling manufacturer prepares opening of Asian offices

Buffalo Grove, IL, Liftomatic Material Handling, Inc., an industry leading material handling equipment manufacturer, has just announced the opening of their Asian headquarters in the near future.

The move-in date is rapidly approaching for Liftomatic’s headquarters in Wuhan, China. Located in the Jiang-an district, which translates as “River Bank,” the city is conveniently located in central China. With over 10 million residents, Wuhan is the capital of Hubei province and is a banking, production, and transportation hub for much of the country and the region. The new offices will house sales, administration, and engineering, and accounting personnel for the company’s core staff in Asia. Celebrating 30 years in the Asia Pacific region in 2018, Liftomatic serves markets throughout all of Asia, the Indian sub-continent and the Middle East from their China location.

Todd Berg, Liftomatic’s chairman, commented on the expansion saying, “We had a very early start in developing the budding material handling market in China in the late 1980’s. The growth and development in this region has quite honestly been staggering. We are excited to move into our new headquarters before mid-year and continue our mission to develop relationships and provide safe and profitable drum handling solutions to our customers as the region grows and matures further in the next 30 years”.

Liftomatic Material Handling, Inc. is an acknowledged leader in the design and manufacture of drum handling equipment. Headquartered in Buffalo Grove, Illinois, Liftomatic maintains manufacturing, engineering, and sales facilities around the globe. Liftomatic currently sells products in over 40 countries and sells to more than 400 of the Fortune 500 companies.

For more product information, please contact:

George Gambini

Liftomatic Material Handling

700 Dartmouth Lane

Buffalo Grove, IL 60089

sales@liftomatic.com

847-325-2930 ext. 1226

www.liftomatic.com

Siemens offers a new servo package consisting of drive, motor and controller for

a wide variety of motion control applications

“The Sinamics S210 focuses on highly-dynamic motor axis control, while the connected controller, for example the Simatic S7-1500 or S7-1500T with its extended motion control functionality, takes complete charge of positioning functions for the connected drive axes.”, says Craig Nelson, product manager for Sinamics S-series drives.

The Sinamics S210 is commissioned using an integrated web server. One-button tuning functionality allows automatic optimization of control parameters, taking into consideration the behavior of the connected mechanics by different dynamic levels.

Integrated safety functions include STO (Safe Torque Off) and SS1 (Safe Stop 1). Both can be actuated using Profisafe, STO additionally using a terminal. Additional functions are currently in the preparation stage. In conjunction with the rapid sampling and smart control algorithms of the Sinamics S210, a high-grade encoder system on the Simotics 1FK2 motor and the combination of low rotor inertia and high overload capability, allow the servomotors to achieve outstanding dynamic performance and precision.

Simotics 1FK2 motors are connected to the converters using a “One Cable Connection” (OCC), which includes the power conductors, encoder signal and brake — all grouped together in an exceptionally thin cable measuring just 9 millimeters in diameter. Its minimal cross-section makes the OCC cable thinner, lighter and more flexible than previous power cables, considerably simplifying the cabling process. This results in a single motor plug connector and connection at the converter is just as simple with user-friendly plugs with push-in terminals on the front.

To learn more about the Sinamics S210 servo system, please visit: usa.siemens.com/sinamics-s210

The new Sinamics S210 drive system with Simotics S-1FK2 servomotors and Simatic S7-1500 controllers offer users a highly-dynamic servo package with integrated safety functions and quick commissioning.

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

For specific product information and inquiries, send an e-mail to: mc.us@siemens.com

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Major machine tool builder offers their customer an entry-level, compact machine that works a 440-pound steel workpiece into a rock bit with better tool life, higher degree of accuracy and overall production efficiencies through partnership with Siemens

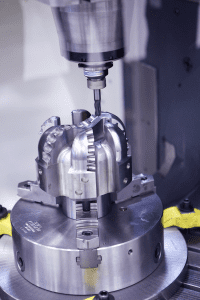

A DMG employee showcasing the DMU 50 with Siemens’ 840D sl CNC. The features of the 840D allow a streamlined simulation of the actual cutting path.

DMG MORI manufactures a wide variety of conventional chip-cutting machining centers for OEMs and production job shops serving the demanding oil-and-gas industry. Inherent in this market are several factors that lobby for great care and planning in the machining process. Typically, components produced for the oil-and-gas field are very large, very heavy and often have complex contours, making the machining time long and the tool life short. The DMU 50, although an entry-level 5-axis machining center from DMG MORI, is a compact unit that features considerable strength, as the following example will detail. “It is a David handles Goliath type of story,” says Matthias Leinberger, the business development director for Siemens PLM (Product Lifecycle Management).

On one recent application, DMG MORI was challenged with a 440-pound, 8” diameter x 8” high workpiece made from 1045 grade steel and being machined into a rock bit for oil field exploration. The customer further presented the builder with the need for fast changeover to produce the part from various metal materials, with all the attendant tool changes and workpiece setup variances present. The customer, a major upstream oil industry supplier, was trying to decide if the better path for this product was a single block of steel or a near net casting being machined. Both high-speed roughing and then very precise 5-axis machining were required in this small footprint machine, which had been selected by the customer due to specific plant capacity utilization concerns, plus their desire for a flexible, reasonably priced and highly cost-effective machine tool.

The machine builder turned to its longtime business partner, Siemens, for assistance. By offering a total package of CAD-CAM-CNC hardware, software and engineering services, Siemens was able to help the machine builder substantially improve every aspect of part production, including reduction of design-to-part protocols, machining time, tool life, surface finish, dimensional accuracies and overall production efficiencies. This scenario was particularly applicable in this case, as the production runs were anticipated to be low with short lead times.

Starting from the CAD file, the Siemens PLM team ran the program through its NX CAM process, eliminating the set-ups through full 5-axis operation. The User Defined Events (UDEs) feature inside the NX program allows simple check boxes for triggering post-processors references for coolant pressure, spindle speed settings and more. This avoids manual programming and, as a result, reduced the program transition time from as long as two days to approximately 30 minutes.

An oil field rock bit being machined on a DMU 50 with Siemens 840D sl CNC. Both high-speed roughing and precise 5-axis machining are possible on this small footprint, entry-level machine.

Once the program was ready for the CNC, the features of that control allowed a more streamlined simulation of the actual cutting path. The 3D quick set compressor feature provides a parametric itemized data file for all path motions, thereby eliminating collision and ensuring the optimum tool path, in conjunction with the NC kernel and PLC on the machine tool. As Siemens technical applications center manager Randy Pearson observes, “This feature is a huge time saver for our customer, as the test ball and probe in the spindle mechanism can be run at any point in the cycle, testing the actual machine kinematics at any time. The procedure can also be automated to run on the table at prescribed time intervals.”

The high-speed machining feature is highlighted here by Cycle 800, which is a static plane transformation that allows a 5-axis machine to define a rotated working plane in space. It is commonly known in the trade as 3+2 programming. The cycle converts the actual workpiece zero and tool offsets to refer to the rotated surface. Of note here, the cycle accommodates particular machine kinematics and positions the physical axes normal to the working plane. This is referenced as TRAORI or transformation orientation.

Meanwhile, Sinumerik Operate, the CNC’s easy-to-use, graphical user interface on the machine allows the operator to perform a variety of integrated tool management and information management functions, all transportable on a USB or network connection.

In the simulation, the loading and fixturing of the workpiece is performed virtually in the NX CAM program, which also calculates a consistent chip load, critical in these large material removal applications. The simulation further verifies the tool length at all cutting sections and the program is finalized for the machine to begin.

In production, this process also yielded a substantial improvement in tool life on this very heavy part over the 3-¾hour cycle time, according to DMG National Product Manager, Luke Ivaska. “With the combination of the NX CAM software, plus the CNC on the machine and all it could do, we had some initial challenges, as most software programs are purpose-built CAM packages that allow quick and easy use by anyone. They have significant limitations; however, as the software drives the tool path and the operator has very little control. With NX and Sinumerik CNC, we have a lot more input on the creation of the tool path. I have yet to find a problem I could not solve with NX.”

In the CNC, the Sinumerik Operate affords the end user’s operator and manufacturing engineering personnel full access to a variety of conditions in production, including all roughing and finishing data in plain text, plus all 5-axis transformation orientation data logged for restart after any interruption and manual restart.

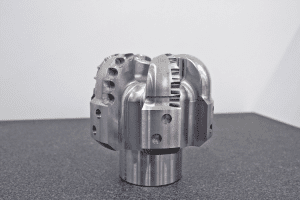

An 8×8″ rock bit machined from 1045 grade steel on the DMU 50. Speedy setup and machining was made possible with Siemens’ total package of CAD-CAM-CNC hardware.

Easy-to-use probing for work offsets is another advantage the builder and their customer enjoy with the CNC used on this machine. The operator is guided graphically for setting the workpiece zero, for example, while the tool length is automatically included in the calculation. With the Operate system, the difference between the position value in the machine coordinate system and workpiece coordinate system is saved in the active zero offset.

The variable streamline operation of the machine tool combines here with an interpolated vector to produce a smoother finish in the machining of the intricate rock bit surfaces in a single tool path. The machine seamlessly transitions from square-to-round machining and then the extreme angle paths needed to accurately machine the internal surfaces. A single bit portion of the program is automatically captured, so a step-and-repeat program can be built-up. The simulation of each bit cutting path was done on both the NX CAM and the CNC programs. It is literally like working with a “Digital Twin” of the machine.

This vectored program, it should be noted, is transportable to any machine with comparable results, according to Randy Pearson and PLM director of business development Matthias Leinberger, who comments, “Precisely because the machine kinematics are knowable, this program, once created, can be transferred onto multiple machines within the same facility or run by shops around the world, all tied together by the control, so there is total continuity between the operations, the data capture protocol and feedback received for production analysis.” Randy Pearson further noted that, in this application, the customer’s desire to change the materials used on successive runs could be easily accommodated by the control, owing to its ability for on-the-fly adjustments, based on the orientation of the tool tip to the workpiece.

This project was accomplished, using CELOS® onboard the DMG MORI machine. CELOS facilitates the total interaction between operator and machine, in this application, as it has numerous apps to enable instant call-up of actual conditions, full data comparison through a link to CAD and CAM products, plus full interface to the customer company’s ERP system for logging and analysis, with in-process remote adjustments achievable. In the case of this oil-and-gas customer, interactive communication to a global production network is also provided, which allow the customer to run parallel production of different rock bits at locations around the world, with seamless data tracking and full production analysis.

For more information on this story, please contact:

Siemens Industry, Inc.

John Meyer

(847) 640-1595

john.meyer@siemens.com

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: cnc.us@siemens.com

To watch a video of this line in operation, please visit https://youtu.be/xA1hyv6A7Hs

Continue readingMyriad ways to boost productivity, enhance shopfloor flexibility and preserve data security…

all on the market today for machine shops of many sizes

by Ramona Schindler, Siemens Industry, Inc.

Ramona Schindler is the business development manager for the digitalization of machine tools at Siemens Industry, Inc.

With the machine tool industry in flux currently, as it seeks to find its way into the digital world, the entire process chain necessitates the integration of suppliers who can respond to the needs of the industry. The situation has very little “history” and so large end-customers and machine shops of all sizes are seeking assistance from their suppliers, while the machine tool builders are likewise seeking to partner with hardware, software, communications and controls suppliers to bring the most needed machine types to market.

Within this scenario, the large manufacturers focus on the “big picture” as they link their production departments, often located in different cities or even countries throughout the supply chain, while the small contract manufacturer with a dozen local customers wonders how this drive to the digital factory will impact their world— and it will. The good news is they can already utilize the IT, apps and communication devices onboard many of today’s advanced machine tools and the rapidly emerging skill sets of new workers in the machine tool industry to develop and implement the three basic levels of machine shop operations.

These levels comprise the communications hardware and protocols at the machine, the integration of inline machine production and the data resident in the cloud, which can be used today in many ways to boost productivity through automated analytics of the shopfloor’s utilization; to enhance shopfloor flexibility through optimized methods of production; and to preserve data security by state-of-the-art software solutions. In essence, the capture and manipulation of such data drives the productivity of a small shop or large production department in quite similar ways. The concept of your manufacturing seen as an eco-system, with information and control capabilities at all levels, can drive that “factory of the future” and, the good news, it can do so today.

From the CNC on your machines, whether they are number three in a mold shop or three hundred at a transmission plant, you can extract the pre-analytics that can be used to feed existing apps or to develop the most beneficial apps to suit your production scheme and workflow. The beauty of the app, whether you create your own, have a third-party integrator develop it or use existing solutions, is that it provides the hierarchy of information to your operator, line supervisor, plant operations personnel or global IT department in a similar manner. This scalability offers immediate benefit to manufacturers of all sizes and it does so, right now. For example, machine tool users can quickly and easily configure a CNC machine’s connections and ascertain its program status and operating mode. This will lead to increased manufacturing productivity, reliability and availability of the machine.

Cloud-based systems always raise the question of security issues, as the data flow in real time at high-speed and can be made accessible to many levels of information managers and operations personnel. It is critical that a thorough assessment of the access to that data precede the development of any communications protocol.

Digitalization is not necessarily a costly undertaking. First steps can be quickly implemented on the shopfloor, for example, through the use of small PCs like Raspberry Pi. Likewise, for the machine tool builder, the development of “digital twin” engineering, where a machine is fully designed, commissioned and test run in a virtual environment, is rapidly changing the playing field in this industry.

The number of connected machines is increasing exponentially and this is not simply engineering adornment, it is a necessary function for any manufacturer. Being able to quickly determine the overall equipment effectiveness (OEE) and conduct practical, beneficial predictive maintenance actions on your machines will contribute greatly to the production and profitability of your operation.

The management of today’s manufacturing shops and production departments have the challenge to become aware of all these available technologies and chart a course for their implementation. This is not a “someday” scenario; it is a vital journey for shops of all sizes, if they want to remain competitive in today’s changing market.

My last advice, look at digitalization as an umbrella for the secure shielding of smart data, not just big data. IIOT is the essential connectivity for all the elements of data on machine performance, materials flow, operations efficiency and ultimately your overall productivity.

It’s an exciting time in our business.

Digitalization, for example from Siemens, can be implemented at every level of machine tool operation today.

Exact’s new scanner provides fast and accurate data for applications such as: reverse engineering, inspection, construction (BIM), product design, forensics, and heritage presentation.

Additionally, Artec Ray is equipped with software solutions. Once scanned, the scan is processed directly into the powerful Artec Studio, then seamlessly exported to Geomagic Design X.

To obtain maximum benefits, Artec Ray can be paired with Eva or Spider handheld Artec scanners to scan hard-to-reach areas such as the interiors of cars or add intricate detail to a large-scale 3D model.

For more product information, please contact:

EXACT METROLOGY, INC.

Steve Young, President

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Telephone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingAdded Manufacturing Quality Systems business unit provides dedicated team for long-term growth.

RedViking’s MQS group provides unique solutions utilizing the latest technology and innovative ideas to effectively validate and test our customer’s product with extreme accuracy and repeatability resulting in indisputable data. The three key product offerings are Dimensional Gaging, Leak Testing, and Component Assembly Validation which are incorporated within our customer’s new or existing production and assembly lines. The formal announcement was made by RedViking President, Randy Brodzik.

As Vice President of MQS, Greg Cameron, explained, “We have been providing part validation, and gaging systems to our customer’s for nearly 25 years working within the Automotive, Off-Highway and Aerospace markets. RedViking started by providing Tier 1 Automotive Exhaust Manufacturers with gaging, leak test, and validation equipment comprising of bar code traceability, pin stamping, torque guns, banding install, shield detection and dimensional measurement. Over the years, RedViking has evolved in providing similar systems to other customers with products such as Drive shafts, Prop shafts and half shafts and today we’re integrating technologies to verify and validate assembly processes.”

Cameron further noted. “All MQS solutions will be MES Ready using our new Argonaut software. In the industry, there is more requirement to store part data and create a traceability profile of every part that is being manufactured by our customers. Working In conjunction with our Argonaut MES group, we can now can integrate all the data into a central location either onsite or externally in a hosted Cloud. ”

As Vice President of Sales and Marketing, Josh McNeely stated, “RedViking customers will benefit from a dedicated team of applications, engineers, service and sales support on these very complex systems.” This new business unit will perform needs assessment, system engineering, system build, install, commissioning and ongoing support services to its customers.

Brodzik summarized, “We see this new business unit as a further enhancement to the relationship with customers as it makes RedViking a true end-to-end partner, offering our engineering and manufacturing capability for production and assembly systems along with our established dynamic test stand, manufacturing solutions and manufacturing execution system (MES) groups.”

Key individuals for management of the new MQS business unit at RedViking are Randy Brodzik, President, Greg Cameron, Vice President for MQS and Josh McNeely, Vice President for Sales and Marketing.

For more information, please contact:

REDVIKING

46247 Five Mile Road

Plymouth, MI 48170

Phone: 734-454-0500

www.redviking.com

Lexi Vargo, Marketing & Communications Manager

lvargo@redvikingeng.com

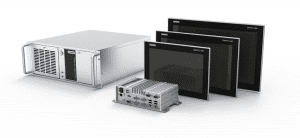

Siemens Factory Automation seeks to open market for its embedded and panel PC products in healthcare segment, including x-ray, analyzer, imaging and diagnostic equipment plus data acquisition to patient and hospital records; domestically sold product now assembled in Lebanon, Ohio

Commenting on the Lebanon, Ohio facility, Thorsten Julich noted the in-house development of Siemens IPC technology for this market segment will include both software and motherboard manufacturing. Complementing the PC product offerings, rugged handheld units with Windows 7 or 10 compatibility, will be offered for technician ease-of-use and connectivity to cloud-based systems.

Single- and multi-touch panel PCs will be offered in 7”-22” displays in the company’s Nanobox/Nanopanel and Microbox/Micropanel designs.

Julich concluded, “Because our IPC range has full interface capabilities with SCADA software plus the medical grade tablets offer full compatibility with networking solutions in the digital world, we believe the company is well positioned to enter this medical equipment market with a very substantial and sustainable suite of products and services.” He also mused the Lebanon, Ohio facility would give Siemens something of a “home field advantage” in the market.

To learn more about the event and products, please visit: usa.siemens.com/ipc or contact Siemens via email at info.ipc.us@siemens.com.

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

Siemens Factory Automation gathers its team, Solution Partners and End User community for four days of learning and fun

From February 19-22, 2018, at the Riverwalk Westin in San Antonio, Texas, approximately 130 people gathered for four days of product presentations, emerging technology discussions and a market trend outlook at the Siemens Factory Automation SCADA/IPC Days 2018. Members of the Siemens management, sales and support team joined their Solution Partners and a diverse assortment of end user companies from various market segments to review new product offerings in the IPC segment of the Siemens portfolio, plus a number of new platforms in the SCADA segment. The event was hosted by the product marketing teams for Factory Automation, based in Norcross, Georgia.

Following a welcome session on the first evening, a series of presentations were made on day two to the entire group by Siemens management and technical thought leaders, covering the digital factory strategy and the company’s forward-thinking move to Digitalization, the current theme for the Siemens marketing message across its entire industrial platform. Key speakers were Kevin Lewis, Russell Barnes, Thorsten Julich, Bernd Raithel, Michael Steigberger, Bernd Staufer and Tom Elswick. The primary message takeaway for the group was that Digitalization will hallmark the factory of the future and SCADA will be the “digital doorway for data” in that rapid evolutionary process, as it impacts all industries, both discrete and process.

There were also presentations on cloud computing and edge computing, the constituent elements of the Digitalization trend, comprising both hardware and software elements. This discussion led directly into the program’s introduction of various new thin client IPC product offerings and the latest version of SIMATIC WinCC SCADA systems.

In addition to the technical presentations and market overviews, a very interesting end user application was detailed by end user Derek Thoma of Hop Valley Brewing, a Miller/Coors company. Thoma spoke on the marked improvements in production and product quality tracking made possible by the advanced IPC and HMI provided by Siemens, in addition to the SCADA software for process monitoring and management.

During that evening, the entire group enjoyed a genuine Texas BBQ and a good time was had by all.

Presenters at the event (starting from left): 1-Russell Barnes, 2-Johann Strobl, 3-Bernd Staufer, 4-Kevin Lewis, 5-Michael Steigberger, 6-Thorsten Julich, 7-Bernd Raithel

Day three began with a review of new IPC products and emerging technologies on the horizon from Siemens, followed by more intense product and software breakout workshops, tagged the Wisdom Series by the event coordinators.

Finally, day four offered direct consultation from the Siemens product specialists gathered at the event, including the Solutions Partners, who represent the system integrator community at Siemens, as they bring the products, application engineering, installation and service, plus related data gathering and process control products to the process industries. In addition, those interested in becoming a WinCC Specialist were offered the opportunity to take their certification test during the event.

Guest instructors were present during the workshop sessions to discuss such topics as Automation for Networks, Using WinCC to Build a Toolbox, Batch Tracking Made Easier with WinCC Archives, Mindsphere and Cybersecurity, and the Industrial PC of tomorrow. Rapidly developing MindApps for performance optimization on all types of industrial manufacturing and process machines were also discussed in detail, as Siemens seeks to assist its customer base and machine builders alike to gather, process, analyze and apply relevant data. Such data allow better process control and KPI development, plus have positive uses for machine liability, insurance, warranty and even energy saving calculations.

To learn more about the event and products, please visit: usa.siemens.com/automation

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

The full Ex9M series line now covers six frame sizes starting from M1 through M6 in a variety of breaking capacity options. Each frame size offers a range of interrupting voltage ratings from 240-690 Vac and 250-600 Vdc and are compliant with global standards that include UL 489, CSA C22.2 No 5.1, IEC 60947- 2. The full Ex9M line is CE and RoHS compliant.

Features of the Ex9M series include high-breaking capacity, a high quality compact modular with an energy saving and environmentally friendly design, fixed and adjustable trip setting units, a patented arc extinguishing design and patented technology that allows for reduced operating force. A wide range of accessories are now available for the full NOARK Electric molded case circuit breaker product line, including alarm switches and auxiliary contacts, shunt and under-voltage trips, interlocks, NEMA type rotary handles, NEMA type flange handles and motor operators.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and low voltage motor control and power distribution supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative or email: nasales@noark-electric.com

Continue reading