Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

American company ARCH Cutting Tools takes out top place in ANCA’s third Tool of the Year competition

A complex multi-functional tool measuring an inch in diameter with a long functional cutting length, the ARCH tool ticked every box to win the prestigious ANCA Tool of the Year 2020

With 28 entries, 1.2 million social impressions and almost 4500 votes, ANCA’s Tool of the Year loudly celebrates the contribution modern cutting tools make to manufacturing, surgery, woodworking and other diverse industries. For example, finalist Ocmandy’s tool makes the outside profile of the windows for the Louvre Museum in Paris. The competition shines a light on and celebrates these tools that shape our world.

Watch the #ANCATooloftheYear2020 live winner announcement:

The overall winner, ARCH Cutting Tool’s entry demonstrated excellent use of multiple iGrind operations with several complex profiles. The tool came out in front of others when compared to the DXF and measured on the Zoller for Profile OD and Runout. The surface finish measurement on the Alicona produced a superb result. The tool also stood out in terms of complexity of grinding and was a large diameter (1”) multi-functional cutting tool with many features. Overall the tool was complete – ticking every box to be the Tool of the Year winner and was an exceptional effort from the team at ARCH.

ARCH Cutting Tools is the third American company in as many years to take out the accolade, highlighting that the skill and craftmanship of the USA cutting tool industry is alive and well.

“We entered to present and showcase our capabilities as a cutting tool manufacturer and to demonstrate the complex capabilities of the ANCA Tool and Cutter Grinder,” said Jim Gray, President and General Manager, ARCH Cutting Tools – Latrobe. “Additionally, we entered to share with customers our own custom capabilities with solid carbide tools.

“Our entry was based on what we provide for our customers,” he added, “it’s multi-functional, providing the customer a single high-performance tool that’s multiple tools in one. A solution-driven tool, that reduces the need for tool changes and increases productivity,” Jim concluded.

ZMK received the runner up award in this category for another outstanding effort with their contribution.

Pat Boland, ANCA Co-Founder commented: “The cutting tool sector has faced a significant challenge with the onset of COVID-19. In these conditions it is even more important to promote and recognise our contributions as an industry. This year we saw the most complex and sophisticated entries to date. Having been part of the industry for over 40 years, the technical advancements demonstrated by cutting tool manufactures continue to amaze.”

“I think of ANCA’s Tool of the Year as the Oscars for cutting tools and am proud to take the time to recognise and reward the creativity and skill of manufacturers globally,” Pat concluded.

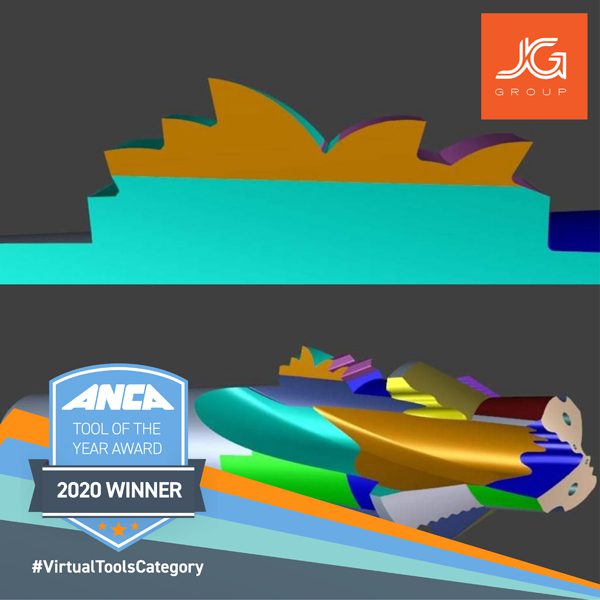

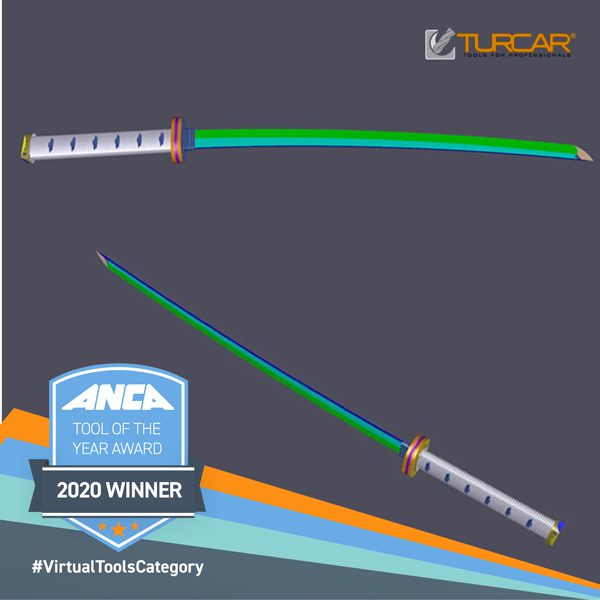

Winners of Virtual Tool Category – JG Group and Turcar

The entries for the Virtual Tool category were so impressive that the Judges found it impossible to split JG Group and Turcar’s submissions. They agreed that both virtual tools were complex and demonstrated great use of different cycles and operations.

Pat Boland continued: “JG Group from Poland took a creative approach using an Australian theme of the Sydney Opera House reproduced in a profile tool, looking as impressive as a tool as it does in real life.”

“Turcar’s tool amazed me in how they achieved their tool design. I had no idea our software could produce something as beautiful and as well executed as their entry.”

“Both tools showed a high level of effort, artistry and creativity. When creating the Virtual Tools, both Turcar and JG Group used their imagination along with the power and flexibility of ToolRoom RN34 and CIM3D V9 to produce works of art,” Pat concluded.

Grzegorz Reszka CEO, JG Group said: “Achieving the Winner status, among the world class tool grinding companies makes us more marketable and gives us exposure on new global markets. It was an amazing opportunity and evidence of what JG Group Experts can provide for our customers. Congratulations to all Participants and the Winners!”

Tarık Öztürk, Chief Technology Officer at Turcar said: “This year we wanted to come up with something different and that is why we named our entry Katana, meaning the best work of the world – a value we brought to this competition.”

The Tool of the Year must be a ground tool that is functional, high quality and complex. A panel of expert judges consider the surface finish, tolerance and functionality. This year the industry-first competition had two categories.

Winner of ANCA Tool of the Year

Runner Up – ZMK

Winners of Virtual Tool Category

#MadeonANCA Finalists

| JG Group | Poland |

| ARCH Cutting Tools | USA |

| Aayudh Tools | India |

| OCMANDY | France |

| Mastermet | Poland |

| ZMK | Poland |

| GUIDOLIN Affilatura Utensili (Pat’s Pick) | Italy |

Virtual Tool Finalists

| JG Group | Poland |

| Aayudh Tools | India |

| Turcar | Turkey |

| Miltas (Pat’s Pick) | Turkey |

Tools made on an ANCA mean quality and endurance

ANCA’s annual competition gives cutting tool manufacturers a chance to not only build brand recognition within the industry, but to also push the boundaries and showcase the beauty of performance expected from ANCA machines in the cutting tools industry. The main winner receives $10,000 AUD worth of ANCA parts, accessories or software and the winner of the most innovative virtual tool receives the full CIM software package.

Judging panel

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Full line of fiber and diode laser machines for cutting and hardening

Ann Arbor, Michigan– German Machine Tools of America (GMTA) proudly announces the signing of an agreement with Stiefelmayer GmbH (Denkendorf, Germany) to represent that company’s line of laser machines in North America. Stiefelmayer offers lasers for various cutting applications, including motor laminations, plus laser hardening.

The agreement is effective immediately and was announced by GMTA President Walter Friedrich from the headquarters in Ann Arbor, Michigan. Friedrich commented, “The Stiefelmayer line is a highly regarded brand in Germany. Coupled with our Arnold line of laser systems, the new lasers will give us a formidable offering to the North American market, especially in automotive and the burgeoning EV market.”

Stiefelmayer further prides itself on their blue effective® program of energy saving technology and sustainability, designed to create both environmental and economic benefits to the user.

The Stiefelmayer laser is particularly well adapted to cutting precision shapes in thin substrates, including mild steel, stainless, copper and brass. Motor laminations are a particular specialty and this fact matches the drive to EV in the American auto industry.

For full specifications on the Stiefelmayer machines, please visit:

https://stiefelmayer-lasertechnik.de/en/laser-technology/home.html

For a video of the Stiefelmayer laser used to produce motor laminations, please watch:

For more information on this announcement, please contact:

GERMAN MACHINE TOOLS OF AMERICA (GMTA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Walter Friedrich, President

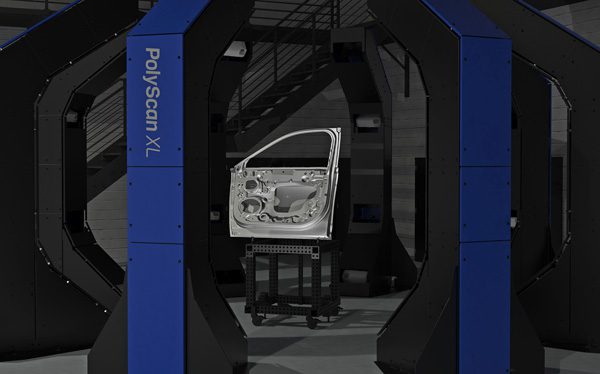

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, proudly represents PolyScan XL. Part of the Polyrix PolyScan™ Surround 3D Scanner family, these scanners are motionless by design during the inspection. Their unique calibration avoids the need for data alignment or sticker targets, and multiple baselines increase accuracy when measuring points.

The PolyScan XL6 is designed to measure parts up to 1600 mm, combining 12 cameras and 12 projectors to provide 210 effective scanning units. It is ideal for medium-to-large aerospace castings, or automotive sheet metal components. Complete inspection of parts is achieved in only 6 minutes. Surround design and simplicity of automation means it can be easily integrated into a production line, while being 100% safe for operators.

PolyScan XL8, the larger version of XL, is designed to measure parts up to 2000mm. It combines 16 cameras and 16 projectors to provide 376 effective scanning units.

Surround Scanning is made possible by the huge amount of R&D that Polyrix placed on software development since 2005. The PolyScan Control Center (PCC) manages data acquisition from all scanning units, thus generating 3D models. Furthermore, PolyScan operation is made easier by the simple interface of the Automation Manager, or by 3rd party plug-ins (e.g. Polyworks Inspector™ Plug-in).

All PolyScan scanners are simple, fast and safe. There is no need to program inspection trajectory, unlike CMM and robotic scanning solutions. Data is quickly captured from every angle. With PolyScan, there is no risk of collision with an operator. No costly enclosure and safety systems are needed. Furthermore, the scanners offer high-inspection throughput, generating higher returns on investment. Process control is fast to obtain, since scanning is easier. Users also benefit from a quick check of their part in a matter of minutes.

Exact Metrology is ISO9001, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

To see Polyscan XL in action, please visit: https://www.youtube.com/watch?v=CXzQQ1JzUqk&feature=youtu.be

Continue reading

No. 1019 is a 500ºF electrically heated walk-in batch oven from Grieve, currently used for curing coatings onto large discs at the customer’s facility. Workspace dimensions on this oven measure 18’ W x 18’ D x 10’ H. 260KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a total of 66,000 CFM generated by two 30-HP recirculating blowers provides combination airflow to the workload.

This Grieve walk-in oven features 6” insulated walls, aluminized steel exterior and interior, 2” thick insulated flooring with built-in oven truck wheel guide tracks and motorized dampers on the intake and exhaust for accelerated cooling of the oven chamber. The oven was sectioned into four pieces for shipping convenience.

All safety equipment required for handling flammable solvents, including explosion-venting door hardware, is provided on No. 1019.

Controls on this jumbo walk-in oven include an SCR power controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Below is a whitepaper by Nikunj Shah, Siemens Industry, on the UL 61800-5-1, a new UL standard for drives. It includes information on what you need to know if you are a user, a panel builder, a manufacturer of motor control centers (MCC) or an OEM.

Continue reading

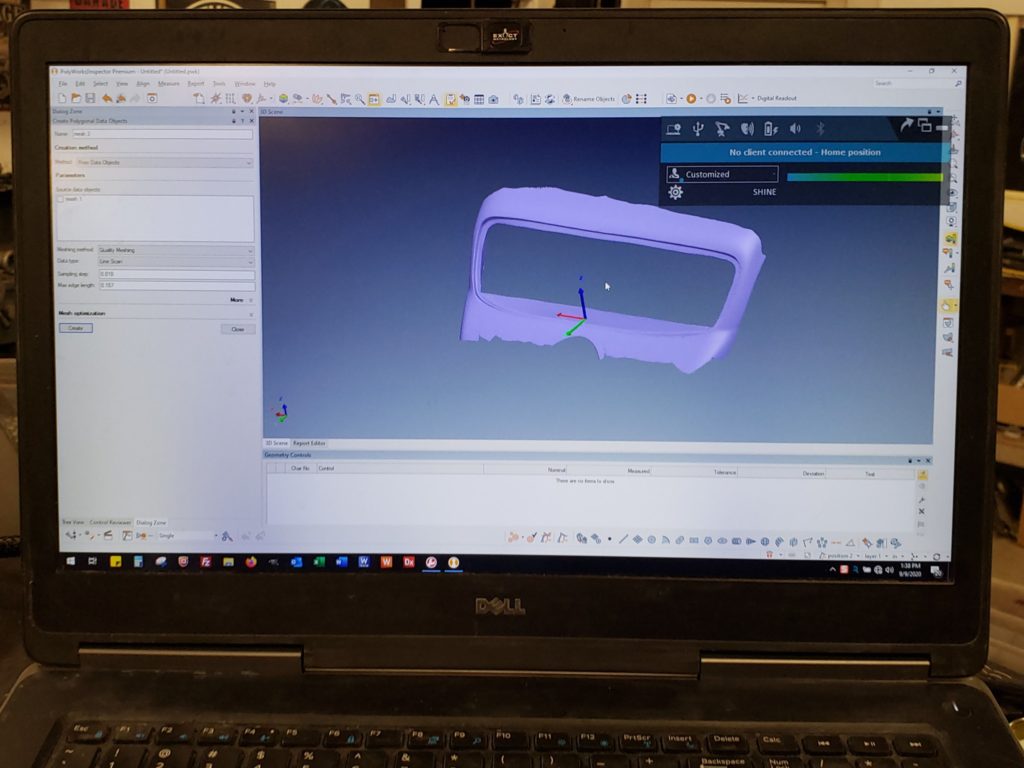

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, recently scanned a unique car model. Exact personnel from the Brookfield, Wisconsin office used reverse engineering to help its owner design the car’s windshield.

Robert Smith is the owner of a one-off design car — a 1933 Speedster Coupe. The car needed a special sized windshield which is no longer produced by any glass manufacturers. Smith contacted Curved Glass Creations, in Pompano Beach, Florida, to find out if they could supply him with the windshield. While the company wasn’t able to help, they did reach out to Exact Metrology with this special request.

Joe van der Sanden from Exact Metrology completed the scan at the client’s location using a Hexagon Absolute Arm 8525 with an RS6 scanner. The Hexagon Absolute Arm 7-axis delivers tactile probing and laser scanning in a uniquely ergonomic package. It is ideal for high-end portable measurement applications. The articulating arm offers ease of movement and ease of measurement. The Hexagon RS6 laser scanner is designed for high-speed and accuracy scanning. It scans up to 1.2 million points/sec with a scan rate of 300 Hz. The RS6 also has a wider laser stripe of 150 mm at mid-range and a visual guide that provides real time feedback for stand-off distance. Built using SHINE technology (Systematic High-Intelligence Noise Elimination), it allows users to easily scan 99% of parts without touching the scanner exposure. With the Hexagon Absolute Arm 7-axis, the scanner can be removed if necessary and replaced without need for calibration. Furthermore, with the arm mounted scanner, it is easier to measure due to less preparation, less set up, less settings and scans with full frame, with full line width, all the time.

Once the scan was completed, the file format was agreed to and delivered to Curved Glass Creations. They were able to make the custom windshield. Robert Smith commented that he had a unique experience reaching out to the 3D image industry to ensure the accuracy of the glass created for his Alloway Speedstar. He was pleased that the scan was completed on-site and that Exact Metrology explained the process well to both him and the glass manufacturer. Smith concluded,” I never suspected my car built at “Speedy’s Rod and Kustom’s” would require such high technology! I can’t thank Exact Metrology enough for their involvement and making it look easy.”

Exact Metrology is ISO9001, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Designing tools online, varied batch sizes, six wheel packs and 38 kw peak spindle power of ANCA’s MX7 tool grinder offers new capabilities that are helping Taylor Toolworks beat competition in the woodworking and metal industry. Capital investment can be a daunting project but Taylor Toolworks have found that with the right research and understanding of your business needs, the benefits offered by new technology can be a game changer.

Located in Alberta, Canada, Taylor Toolworks Ltd. is one of North America’s technological leaders in the manufacturing and service of cutting tools for the woodworking and metal industries. This remains the biggest part of their business. The company is run by President Jesse Taylor and his sister Kristyn, who has worked there for more than 15 years. With state-of-the-art 5-axis CNC grinding, combined with the use of the finest micro grain carbide products, Taylor Toolworks maintains the highest tooling tolerances and mirror finishes needed for high performance tooling. Services offered include reconditioning, end mills and custom tooling. Reconditioning involves tool regrinding, tool re-cutting and tool re-coating. End mills include super polished flutes, special grade carbides and special coating for maximum performance. Custom tooling is made to specifications for both the woodworking and metal industry. These can be micro grain carbide inserts, custom profile tools, step drills, etc.

Jesse Taylor said that ANCA’s MX7 Linear machine allowed them to have greater versatility in their manufacturing. Another factor that influenced the purchasing decision was ANCA’s tool simulation software. According to Taylor, “This allows us to program tools [virtually] on a desktop before they are processed on the actual machine. This saves valuable machine time.” This machine helped Taylor Toolworks produce complex tools better compared to competing companies that offer 2 wheel packs.

The company purchased an MX7 Linear machine because it is a powerful, versatile CNC tool grinder used for production grinding. It meets the demand of high output, high precision manufacturing. Key features include 38 kw (51 HP) peak spindle power, linear scales as standard on the X and Y axes, standard 6-station wheel changer that stores and changes up to 6 wheel packs. In addition, the machine uses ANCA LinX Linear Motors for axis motion (X and Y axis), has an integrated wheel dresser and its automation options include RoboMate or FastLoad-MX Compact Loader. The MX7 Linear is a hard-working, high productivity system with unique features that enable it to handle varied batch sizes with minimum set-up time. It is ideal for high volume production for tools up to 25 mm (1”) diameter. The new cylindrical linear motor design increases reliability and ensures a superior surface finish.

Taylor also highlighted the reasonable lead times at ANCA for purchases of what are sophisticated and highly technical machinery. This made a big difference for Taylor, who commented, “A lot of times in our industry when you’re buying a machine you may be six months to a year out for receiving your machine. When I got to work with ANCA and found out that they had machines readily available that really allowed us to jump on this and get a good start versus waiting for a machine.”

According to Taylor, the tools produced on ANCA machines are complex profile tools as well as step drills, thru-coolant drills and form tools. Applications for these tools range from aerospace, to woodworking, to general machining and cutting of plastics. On ANCA machines, the company uses ANCA’s Tool Room software. The software provides specific applications for each tool produced at Taylor Toolworks such as a step tool editor or a profile tool editor.

Being in the industry for over 20 years, Taylor saw ANCA machines at various trade shows. He talked to several people at the shows, including ANCA application specialists. This made him take a closer look at the machines and he saw that they were suitable for his needs.

In terms of service issues, Taylor commented that ANCA was good at solving any issues that come up, whether it was by calling or sending someone on-site. Besides using the MX7 Linear machine, the company has three other ANCA machines. One is the ANCA Fastgrind for resharpening tools. Taylor said, “ANCA is a big part of our operation.”

To sum up his experience, Taylor was satisfied with the quality and service he received from the company. He remarked, “Buying more ANCA [machines] is definitely in our future.”

######

For further information, please contact:

Sepideh Zandieh

PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

This Grieve oven is a 500°F (260°C) top-loading, electrically heated oven, currently used for heat treating parts at the customer’s facility. Workspace dimensions of this oven measure 96” W x 20” D x 20” H. 18 KW are installed in Incoloy heating elements, while a 2 HP blower provides back to front airflow to the workload.

This Grieve top-loading oven features 6” insulated walls, 16-gauge aluminized steel interior and a bottom reinforced for 800 lb. capacity. Additional features include a heat chamber mounted below the workspace and a pneumatic “L” shaped door.

Controls on this Grieve oven include a programmable temperature controller, separate heating element control contactors, a disconnect switch and a power controller to ensure precision proportioning of electric power to heating elements.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

The Foundry Educational Foundation (FEF) is proud to announce its partnership with the Blue Ocean Student Pitch Competition. This alliance will provide an opportunity for high school students who are interested in entrepreneurship to learn more about metalcasting by creating a pitch that focuses on foundry challenges in the 21st century.

High school students will create a video pitch (up to five minutes) that defines a unique solution to a problem facing the metalcasting industry or describes a new idea to improve productivity, quality or the safety of a foundry. Participation in this competition is a great way for students to showcase their entrepreneurial spirit, develop relationships with leaders in the manufacturing industry, and add to their college applications.

Brian Lewis, Executive Director of FEF stated “this effort by FEF to promote the industry at the high school level will encourage more students to consider educational opportunities that culminate in a career in metalcasting.” Pitches will be judged by professionals in the metalcasting industry and the winner will receive a $1000 prize from FEF.

Ted Dacko, CEO, Arbor Dakota and Executive Director of the competition said “We are pleased to partner with FEF. Having high school students pitch ideas in metalcasting will create new, exciting and Blue Ocean ideas that can trigger critical improvements in the industry.”

The competition will begin accepting video pitches in the first week of December. Individual pitches can be submitted, or students can form teams of five or less. Resources are available from the Blue Ocean Competition about Blue Ocean concepts and how to pitch. Additional details about the competition, including free registration, can be found at https://blueoceancompetition.org . The winner will be announced on April 21, 2021.

For more information, please contact:

Brian Lewis

Executive Director

Foundry Educational Foundation

Office: (847) 490-9200

brian@fefinc.com

www.fefinc.org

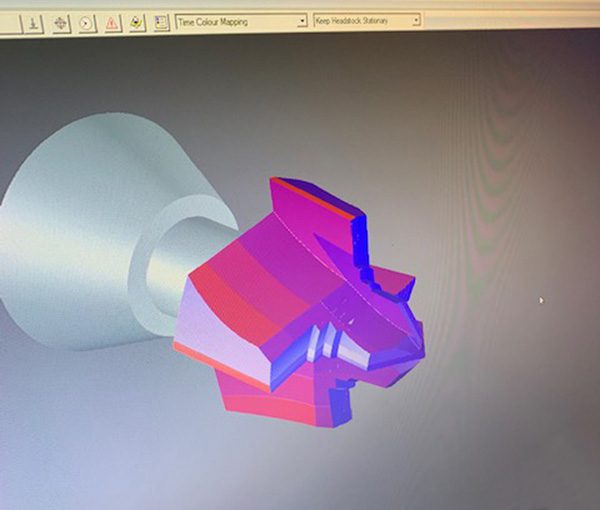

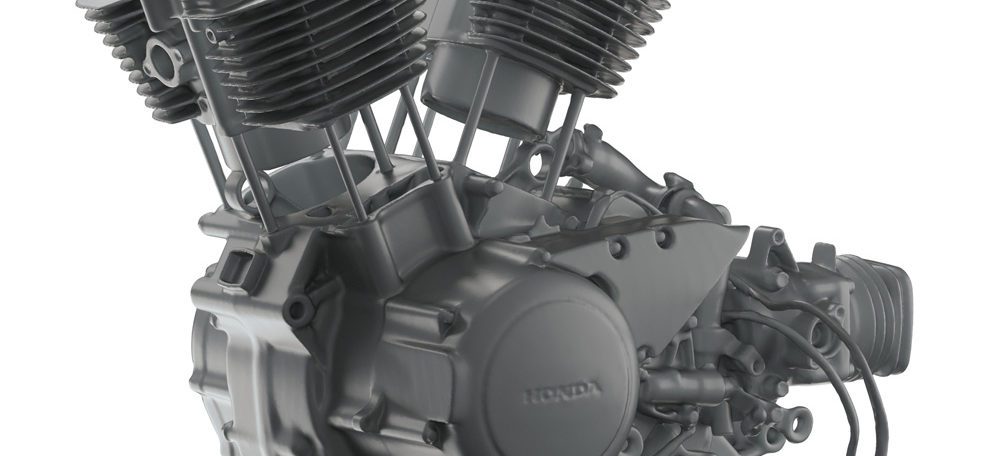

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, has increased the capability of their Artec 3D handheld scanners with the new HD mode. This Artificial Intelligence-powered scanning technology provides ultra-sharp, clean and detail-rich scans for Artec Leo and Artec Eva.

Powered by Artec 3D‘s AI neural engine, users can obtain sharp 3D scans with a resolution of up to 0.2 mm. Trained on hundreds of thousands of carefully selected samples, the engine’s neural network detects familiar patterns, surface details and shapes. This allows the 3D scanner to reconstruct a higher number of polygons per frame, resulting in 3D data that’s both denser and higher quality. Now, the desired HD density can be selected from a standard 1X density up to 36X for Eva (~3 mln polygons per frame) and 64X for Leo (~5 mln polygons per frame). HD mode makes it possible to capture smaller, thinner elements with the 3D scanner while also considerably reducing noise. With these Artec scanners, fine edges can be captured in high definition, faithful to their original shape. It’s easy to capture hard-to-reach areas as the scans are reconstructed with every detail, giving users complete surface geometry.

Handheld Eva and Leo scanners can easily scan dark or shiny surfaces in high resolution and capture the full range of their geometries, without additional steps. Using the Artec AI engine, little to no noise in the raw scan data results in cleaner processed data and also saves time when producing the final 3D model. Once difficult to capture, now short hair, even separate strands, are fully within reach when scanning with HD mode. Furthermore, these scanners can capture a broad range of objects flawlessly and in high detail: from smaller, intricate parts such as thin pipes or valve handles, to larger objects with multiple high-detail sections, including car engines and skeletons. A perfect fit for reverse engineering and quality control due to clean, comprehensive data, scans can be easily fitted with primitive shapes and exported to the most popular CAD solutions for development.

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com