Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Selling your services or products requires an in-depth knowledge of your customer, regardless of industry. This need becomes even more apparent when a company plans to roll out a new product and/or service and wants to find out what the target audience thinks. This is where market research comes in. The process of collecting, analyzing and interpreting data about the target market, consumers, competitors and the industry offers several benefits.

One of these is to help companies understand their customers’ needs and characteristics, such as: age, gender, race, ethnicity, education, income and employment status. By segmenting the audience, businesses can tailor their messaging to appeal to each group. Market research also helps companies understand what their competitors are doing, thus discovering a competitive advantage. Last but not least, market research helps businesses identify opportunities and avoid costly mistakes. For example, there would be no point in introducing a new product if the data showed that such a product wouldn’t be well received in the market.

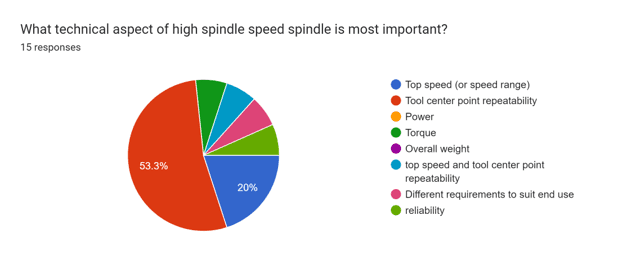

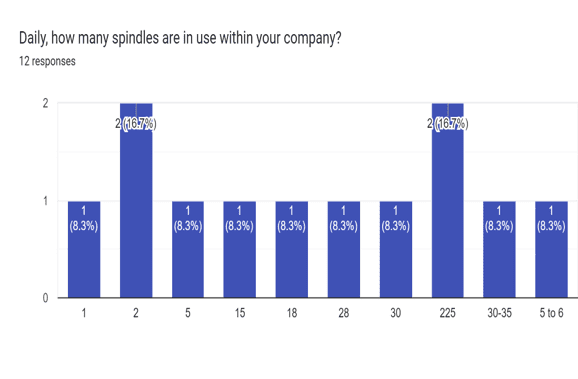

At Bernard & Company, we recently obtained and analyzed market research data on behalf of our German spindle manufacturer and repair client. They wanted to see if there was a potential U.S. market for their line of small, high precision spindles used in industries such as: mold and die, medical, semiconductor, optics, watch/jewelry and aviation/defense. To reach machine builders and end users effectively, our agency distributed a short online survey through two publications, Manufacturing Center and Manufacturing Engineering. Questions included industries served as a high precision spindle manufacturer, technical aspects of the spindles, machine tool brands currently used, number of spindles in use and biggest challenges. Both publications provided a click report, with Manufacturing Center also generating a huge list of leads.

While the survey indicated there was modest market potential for the company, a second survey was sent out to uncover OEMs making machines in the U.S. that could use the German spindle line. The second survey was sent out through Manufacturing Center and contained only five questions, as opposed to nine in the first survey. Furthermore, participants had to list their name, company address and email to qualify for a $10 Amazon gift card. These questions were more specific, with participants asked to name the brands of machines that currently used our client’s spindles, machine manufacturers they’d consider for future purchases, well-known North American machine tool builders, as well as technology leaders in the industry. Results of the second survey still showed a low market potential and confirmed that a majority of the well-known machine tool builders were either Asian or European companies. Thus, the agency confidently recommended that the company focus on increasing exposure to the full line of capabilities offered in North America by their Racine, Wisconsin office.

Market research is just one of the many ways we help our clients get ahead of the game.

Thank you!

Ioana Benea is a Marketing Information Specialist at Bernard & Company, an industrial advertising/marketing agency. Her responsibilities include translating technical press releases (English-Spanish) for magazines in Latin America, interviewing clients for stories, writing product releases, ads and success stories, conducting client research on the market/ competitors and managing and posting to clients’ social media pages.

She has worked at Bernard & Company for 10 years and is based Palatine, Illinois (Chicago). Ioana is a graduate of Benedictine University, holding a Bachelor of Arts in Global Studies and Spanish. She received her Masters in Integrated Marketing Communications from Roosevelt University.

For more information, please contact:

Tim Daro, President

BERNARD AND COMPANY

1540 E. Dundee Road

Suite 250

Palatine, IL 60074

Phone: 847-934-4500

tdaro@bernardandcompany.com

Complete enterprise-grade solution accelerates Industry 4.0 adoption through hands-on technology demonstration center at MxD

CHICAGO, IL – In a milestone for manufacturing innovation, Betacom, a pioneer in private wireless networks, today announced a groundbreaking partnership with Siemens Industries. The companies have deployed a first-of-its-kind private 5G network platform at MxD (Manufacturing x Digital), the National Center for Cybersecurity in Manufacturing in Chicago. The platform is the first complete private wireless network to operate behind a Siemens firewall, demonstrating the future of secure enterprise connectivity.

“Manufacturing enterprises need more than just network connectivity – they need a complete solution that seamlessly enables Industry 4.0 applications while maintaining total control of their data and operations,” said Johan Bjorklund, CEO of Betacom. “By partnering with Siemens at MxD, we’re providing manufacturers with a blueprint for digital transformation, combining our private 5G expertise with Siemens industrial automation leadership to create a truly comprehensive platform for smart manufacturing innovation.”

The platform demonstrates how enterprises can:

Developed specifically for Siemens U.S. manufacturing initiatives, the solution features:

“This deployment represents a significant milestone in manufacturing innovation,” said Joel Green, Wireless Business Development at Siemens Industries. “The platform gives our customers the security and control they need while enabling the full spectrum of Industry 4.0 applications that drive operational excellence.”

Industries benefiting from this complete private 5G solution include manufacturing, logistics, defense contractors and supply chain operations. The MxD facility showcases practical applications including:

About Betacom

Betacom offers the first fully managed private 5G network service in the U.S., building on decades of expertise as a trusted wireless infrastructure provider for major carriers such as AT&T, T-Mobile, and Verizon. Founded in 1991 and headquartered in Bellevue, Washington, Betacom has established a reputation for delivering high-performance connectivity solutions to meet complex enterprise needs. With its secure, high-speed and scalable 5G services, Betacom continues to lead innovation in private wireless networks. For more information, visit http://www.betacom.com.

About Siemens Industries

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. Active around the world, the company focuses on intelligent infrastructure for buildings and distributed energy systems and on automation and digitalization in the process and manufacturing industries. Siemens brings together the digital and physical worlds to benefit customers and society. Through Mobility, a leading supplier of intelligent mobility solutions for rail and road transport, Siemens is helping to shape the world market for passenger and freight services. Via its majority stake in the publicly listed company Siemens Healthineers, Siemens is also a world-leading supplier of medical technology and digital health services. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power that has been listed on the stock exchange since September 28, 2020. In fiscal 2020, Siemens Group USA generated revenue of $17 billion and employs approximately 40,000 people serving customers in all 50 states and Puerto Rico. For more information, visit http://www.siemens.com.

About MxD

MxD (Manufacturing x Digital) is where innovative manufacturers go to forge their futures. In partnership with the Department of Defense, MxD equips U.S. factories with the digital tools, cybersecurity and workforce expertise needed to begin building every part better than the last. As a result, our more than 300 partners increase their productivity, win more business and strengthen U.S. manufacturing.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood has expanded its E-Z Press™ line with stainless steel and brass inserts, while E-Z Sonic™ added stainless steel inserts.

These inserts are designed for post-molding installation in thermoplastic materials such as: acrylic, polypropylene and PVC. Features include tapered or straight designs, installation with a heat drive or ultrasonic horn, superior torque and pull-out resistance, inch or metric threads, tapered design and single vane and straight design in flush or flanged configuration.

E-Z Sonic™ heat staking inserts for thermoplastics work well with 3D printing applications and products made from similar materials. They require heat generation to melt the plastic around the insert for proper installation. Meanwhile, E-Z Press™ threaded inserts for plastic are designed for both thermoset plastics and thermoplastics. Available in flush, flanged and reverse slot, they are created specifically for “cold” installation using anything from a rubber mallet to an arbor press.

Straight E-Z Sonic™ Ultrasonic inserts allow for thinner boss walls. Flush heat stake permits installation even with or below the material surface, while flanged inserts are ideal for electrical connections or for additional pull-out resistance in reverse installations. Furthermore, E-Z Sonic™ straight ultrasonic threaded inserts feature a lead-in pilot to facilitate installation and are available from #2 to 3/8.

Tapered E-Z Sonic™ Ultrasonic inserts are designed to reduce installation time, particularly in production runs, while maintaining outstanding performance characteristics. Internal threads from #2 to 3/8 and M2.5 to M6 are available.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die-cast zinc alloy in hex drives for softwood and brass knife threads for hardwood. A variety of kits are available and feature installation tools, drill bits etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells North American OEM’s, end users and the DIY market through local, regional and national industrial distributors.

By Preben Hansen, President, Platinum Tooling

With today’s machining practices, many applications dictate the use of smaller cutting tools running at high rpm and high feed rates. The increased rpm helps to optimize the results of the cutting tools and final product. Those required rpm’s are not always available in the machine spindle or turret. Additionally, when running the machine at its maximum capacity, premature wear can occur or thermal growth may result causing “out of tolerance” workpieces.

Machine tool builders produce machines for the broadest audience and that does not always take into consideration high-speed applications. In light of this, there is a large variety of speeders available to complement the wide range of machines in the market.

Depending upon your machining center application needs, one can choose from air driven, geared or motor speeders. For the highest rpm requirements, air speeders are available that can run up to 80,000 rpm continuously. They are best suited for very small diameter milling, drilling and engraving, in particular, when long duty cycles are involved. Geared speeders are available in a wide range of sizes from ER 11, with 1:8 gear ratio, that can run at 50,000 rpm. In addition, large 50 taper output tools can achieve 4,000 rpm with 50 hp. These are the extreme cases, but many other tool options exist for mid-range applications.

Turning centers face similar challenges but, in these cases, it is not the main spindle that requires additional rpm but rather the turret tooling. Live tool speeders are available for the most popular machine brands with gear ratios from 1:2 up to 1:4 with a maximum rpm of 48,000. Speeders can be supplied in a variety of styles including straight, 90 degree, and universal adjustable. Live tool speeders are also offered on the market today with internal coolant capabilities when there is a requirement for a coolant-through cutting tool.

Undoubtedly, these invaluable tools for high-speed applications will continue to gain popularity in the manufacturing world, offering increased productivity regardless of the size and shape of the machine tool.

For more information, please contact the author:

Preben Hansen, President

PLATINUM TOOLING

16 East Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

www.platinumtooling.com

Joseph Guigli, the company’s President/Owner, holds a B.S. in Mechanical Engineering from the University of Vermont. After graduation, he started working at Davis Standard in Pawcatuck, Connecticut. For the next 17 years, Guigli held various positions within the company ranging from mechanical engineer, screw designer, product manager, to regional sales manager and then Vice President of sales for the North American aftermarket.

Covering North Carolina, South Carolina, Georgia, Tennessee and Alabama, Guigli’s primary responsibility is to sell the extrusion product portfolio to existing and new customers. This includes “… providing these customers with the best buying experience possible from the time a project is kicked off until the customer is successfully using the equipment.”

When asked what he enjoys the most about working with Guill and his hopes regarding his role, Guigli said, “Guill has a strong name in the market, and they make a good product. I’m happy to be attaching my name and my company to Guill because of these reasons. I hope to bring my almost 20 years of industry experience to the customer base here in the Southeast.”

In addition to the rubber and plastics extruder market, Guigli also serves the construction, infrastructure, medical, food, industrial packaging and home care products markets.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Continue reading

Australian Technology Pioneers Share Their Inspiring Story in a Heartfelt Video Retrospective

ANCA, an Australian advanced manufacturing leader, proudly announces that its co-founders, Patrick Boland and Patrick McCluskey, have been awarded the Medal of the Order of Australia (OAM) in the 2025 Australia Day Honors List. Known as “The Two Pats,” their visionary leadership has propelled ANCA to the forefront of global technology, demonstrating that advanced manufacturing can not only thrive in Australia but also contribute to high-value products, international competitiveness, meaningful careers, and sovereign industrial capabilities.

The dynamic partnership of Boland and McCluskey, combining academic expertise and practical ingenuity, has driven ANCA’s success for over 50 years. Their passion for innovation and engineering excellence has led to the development of world-first technologies that have revolutionized the cutting-tool industry. Notable innovations include groundbreaking in-machine measurement that disrupted and shaped the market, setting new standards in precision manufacturing.

Success didn’t come overnight. By targeting a niche global market, adopting robotics, and applying innovative solutions to the machine world—long before the internet era—they brought their ambitious vision to life. Today, ANCA continues to lead the industry, driven by a culture of innovation, talent investment, and a commitment to “dreaming and having fun.”

Patrick Boland OAM, who holds a Master’s in Electrical Engineering from Melbourne University, is one of a handful of life members of the Australian Manufacturing Technology Institute Limited (AMTIL). He served as AMTIL’s President from 2010 to 2016 and was a founding member of the Future Manufacturing Industry Innovation Council from 2008 to 2014.

Patrick McCluskey OAM, the practical and design-focused counterpart, began his career as an apprentice working on fuses and radios. Today, he leads the mechanical design of ANCA’s advanced machines and mentors the engineering team, fostering the next generation of innovation. He also spearheads ANCA’s apprenticeship program, emphasizing the company’s commitment to skill development. In his spare time Pat wrote and self-published a memoir ‘Trust’* detailing his early beginnings growing up in a Ballarat orphanage to his move to Melbourne with a Diocesan Scholarship through to starting his apprenticeship with Department of Supply.

“This is an incredible honor,” said Patrick Boland. “I see it as recognition of the work ANCA has done over 50 years to sustain an advanced manufacturing business in Australia. By competing on smarts and riding the wave of technology, we’ve achieved an incredible journey filled with immense fun.”

Patrick McCluskey added, “ANCA is my life, and this award validates the countless hours, challenges, and triumphs that have shaped our journey. I’m thrilled to have built a company of over 1,300 people recognized globally for its technology solutions. From apprentices to seasoned professionals, I’m grateful to have them as part of our team.”

The awards coincide with ANCA’s 50th anniversary and the co-founders’ 75th birthdays. With 13 registered patents and three pending, including a recent patent for a Motor Temperature Control algorithm in the U.S. and China, ANCA continues to lead the field in advanced technology. Headquartered in Melbourne, ANCA’s offerings include CNC tool and cutter grinding machines, laser markers, automation solutions, motion controls, and manufacturing services. These technologies are critical to industries such as automotive, aerospace, electronics, medical devices, and cutting-tool manufacturing.

Investing 10% of profits into research and development, ANCA is committed to fostering STEM talent through partnerships with RMIT, Melbourne, and Monash universities. Its robust apprenticeship programs further strengthen Australia’s skilled workforce, ensuring groundbreaking innovations continue to emerge from this “hidden gem” of Australian manufacturing.

Hear directly from Patrick Boland and Patrick McCluskey about their journey and legacy: Watch the video

* Catherine Butterfield ghost wrote the memoir Trust with Patrick McCluskey

ANCA is a world-leading manufacturer of CNC grinding machines, motion controls, and advanced manufacturing solutions, employing over 1,300 staff globally. With a legacy of 50 years of innovation, ANCA designs and manufactures cutting-edge products in Melbourne, Australia, exporting 99% of its products to over 50 countries. The company has offices worldwide, including the UK, Germany, China, Thailand, India, Japan, Brazil, Korea, and the USA, supported by a comprehensive network of representatives and agents.

Two AS/AR systems leaders join forces

The majority shareholder of Fehr Lagerlogistik AG in Winterthur, Switzerland, today announced the acquisition of Matter srl in Italy. Both companies are global leaders in AS/AR systems for intralogistics in a variety of metal and other market segments, from mills to service centers, large production companies to job shops. According to majority shareholder CEO Thomas Lehner of Fehr, “We see this acquisition representing a new day in AS/AR for industry. Together, we can offer a comprehensive range of equipment and services to the market.” The acquisition was finalized between the company management teams on October 31, 2024.

Fehr, founded in Switzerland in 1949 by Hans Fehr, is today owned by the Lehner family. From warehousing logistics, through automation and special handling functions, the Fehr team of experts ensures a smooth movement of materials from stainless steel, tool steel, tube & pipe, aluminum, plastic or wood and other specialty materials handling needs, for its customers. Fehr systems are available in various configurations and offer robotic materials handling, automated sheet and long product picking, robotic saw cells and laser-guided loading/unloading.

Fehr operates numerous production facilities and warehouses worldwide. The company’s honeycomb system is considered one of the fastest AS/AR systems in the market for large quantities. Fehr Warehouse Solutions in Charlotte, North Carolina is the North American base of operations for the company.

Likewise, Matter, founded in Bibbiano, Italy in 1992, specializes in the design and installation of technically advanced, vertical intralogistics solutions for the steel industry, especially for bars, tubes, billets, sheets, dies and components handling with vertical storage. The company is fully integrated in its engineering, software design, industrial automation, full fabrication and system integration. It supplies the industry its MATTER PRO series of customized systems for large quantity handling, as well as its popular MATT BOX modular storage systems for smaller quantities, aimed at eliminating outside materials storage for the job shop and contract manufacturers. As Giuseppe Rotondi, CEO at Matter, notes, “We see the synergy of this relationship as a great opportunity to serve both our markets with a more comprehensive suite of equipment and services.” Matter USA is based in Charlotte, North Carolina. The company counts major U.S. metal service centers, manufacturing operations and numerous job shops among its diverse customer base.

Both companies provide fully integrated and application-specific materials handling solutions with state-of-the-art material management interface, data communications and automatic transport devices. Furthermore, both companies work daily on projects for existing and greenfield locations.

Consummating the acquisition were Marcel and Thomas Lehner, while the Matter management team comprised Raffaele Fiore and CEO Giuseppe Rotondi. The Lehner family obtained full ownership of Matter.

Going forward, plans include the maintenance of both brands in the market, according to company sources.

For more information, please contact:

FEHR WAREHOUSE SOLUTIONS

4801 Chastain Avenue, Suite 140

Charlotte, NC 28217

Phone: 704-666-8448

Attention: David Veldung, President

www.fehr.net

The competition to win ANCA’s annual Tool of the Year contest is fierce. So it’s no surprise that last year’s top contenders were team efforts. You could say the same thing about the entry from ARCH Cutting Tools in Cornish, Maine. It’s a platoon of cutting features they called “The Utilitarian.” Like many of the tools the outfit produces for their demanding client base, The Utilitarian can eliminate a host of what would otherwise be separate cutting tools. It can accomplish both plunge and side milling, plus multi-directional milling. It can cut a groove, thanks to a back trepan feature. It can add a back chamfer. And it’s concave end can create a convex ball. With an eye toward real-world practicality, the tool also features chip breakers to aid chip evacuation, corner radii to prevent chipping, and cylindrical margins to enable the various milling functions.

How do you build such a beast? It started with 30-year veteran, Pete Chapman, in engineering. Chapman has spent most of his career programming WALTER machines, and only recently got involved with ANCA machines. “I’d never seen this version of ANCA’s iGrind software until a year ago,“ he explained, “and I wanted to see what it was capable of. I poked around to find things I hadn’t used before, thinking someday someone is going to want to have a tool that does X, and we are going to have to figure it out. We’re better off learning in advance.” So, Chapman piled on feature after feature, testing each with ANCA’s 3D simulation to confirm that the machine could actually move the wheels through the carbide to grind the desired geometries.

From there, Steve Hutchins, a 28-year vet, used ANCA ToolDraft software to convert Chapman’s simulation into tool prints for the production floor. Hutchins praised the software, saying it’s easy to import multiple views of the tool and then add tolerances to each feature to guide the operators. Ordinarily, he’d also use ToolDraft to add images of the required wheels, along with their specifications. But he didn’t do that in this case because they planned to make just a few tools for the contest.

The tool has a 1” shank diameter and multiple steps ranging down to ¼” in diameter. So they opted to grind the OD on their new ANCA CPX pinch/peel grinder, operated by new team member, Jacob Hart. As Hutchins put it, “Jake’s only been here one year, and he can grind the most complex profiles there are, with tight tolerances and excellent finishes.” Hart modestly credited the CPX, saying it’s “very user friendly, and the repeatability is better than anything else I’ve heard about from more experienced grinders.” It was also the first time the facility used the machine for tools larger than ⅞” in diameter, Hutchins added.

After this prep work, Jake’s younger brother Josh Hart took over. Josh Hart has been with the company for 4 years, and used an ANCA MX7 Linear for the final 5-axis grind, including some spin grinding of the margins and the face of the trepan areas. In fact, with the exception of the major ODs ground on the CPX, all the complex geometries of The Utilitarian were ground on the MX in one shot, said Hart. “I used six different wheel packs to make the tool. Fluting alone was two wheels. A 30 degree for the smaller diameter and a 10 degree for the bigger back-lobe. There were two different profiles in the center section, so I needed a front facing and a back facing 12V9. I used the front facing 12V9 to get into back concave profile. Plus, there’s an 11V9, a chip breaker wheel, a cup wheel, and a gash wheel.”

Hart confesses that he broke the trepan off during the first grind, because he hadn’t yet dialed in the wheel speeds. “But it was perfect from there out.” He ground 4 tools, which Hutchins then inspected on a Zoller Genius using a program written by Seth Tillson, who’s been with the company about 7 years. All tools met the design tolerances of 0.0002” (5 µm) on the diameters and ±0.0005 to 0.001” (12.7-25.4 µm) on the profile sections, reported Hutchins. “The fact that the second tool was nearly perfect shows how good the simulation software is now.” He added that going from a simulation to a real tool accurate within 2 tenths is now routine at ARCH Cutting Tools.

Interestingly, they neither balanced the wheels nor used particularly fine grits to achieve the desired surface finish. Hutchins explained that customers have been demanding ever better surface finishes for about 5 years. “At first we were buying finer finish wheels and slowing programs way down. But ANCA’s new linear motor technology instantly makes it twice as easy to maintain fine finishes, due to the absence of lead screws and ball nuts. I’m not saying it’s easy. But you don’t have to buy polishing wheels and go back through your flutes, and so forth. You get a cherry finish out of the gate with the new machinery.”

The Maine team won the inaugural Tool of the Year competition back in 2018 (when they were Contour360). That tool made a splash in the market, recounted General Manager Chris Karcher. Naturally, they take the amazing 2023 Utilitarian on sales calls as well, he adds. “But it’s not the big wow factor you might expect, because we now make many such special tools, including staggered dovetail cutters and chamber reamers for the firearms industry.” In short, the “village” at ARCH Cutting Tools in Cornish, Maine has learned how to make the extraordinary, ordinary.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood has purchased a LOCTITE® machine.

According to Director of Sales & Marketing, Kyle Lindsly-Roach, “We decided several years ago that bringing LOCTITE® application in-house would allow us to more efficiently and cost effectively apply the coating.” E-Z LOK purchased the machine nine months ago. It applies LOCTITE® to the external threads of the solid wall inserts, which proceed through a curing oven. Afterwards, the inserts are ready to use.

Having the machine at E-Z LOK’s Gardena, California headquarters, brings several benefits. Not only does the company save time by no longer using outside processers but they can apply the LOCTITE® in a semi-automated fashion, thus increasing their throughput.

Discussing its importance, Lindsly-Roach said, “LOCTITE® is an integral part of our company’s hallmark E-Z LOK inserts for metal, as it is this adhesive that holds the insert in place once installed.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die-cast zinc alloy in hex drives for softwood and brass knife threads for hardwood. A variety of kits are available and feature installation tools, drill bits etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells North American OEM’s, end users and the DIY market through local, regional and national industrial distributors.

Guill Tool, the global leader in extrusion tooling, has announced its 10-day program. This program applies to eligible tips and dies that will be shipped within 10 business days of receiving the purchase order from the customer.

The company’s quality precision tips and dies have been manufactured in the U.S. for 62 years. All Guill extrusion tools are produced using certified and documented quality steel material specifically qualified for the polymer to be extruded. Furthermore, Guill designs tips and dies for any application the customer needs. These feature multi-lumen, stripe, multiple stripe, wire and cable, hose, pipe, tube, fiber optic, blown film, corrugated tube and profile. Dies include face seal, shouldered, snap together, floating, die plates, interchangeable die plate and custom dies. Available tips include single and multi-lumen, threaded style, snap together, fixed center shoulder, profile, tapered style and custom.

To find out which tools are eligible for the program, check with any sales representative. For all other parts, company personnel will review the customer’s drawing to determine if it is eligible for the program.

Eligible tips and dies for this program cannot be plated and must have a diameter less than 1.5” and a length less than 4.75.”

Guill proudly manufactures its products in the U.S. under the quality standards of ISO 9001:2015 and AS9100:2016.

For more details, visit www.guill.com/tooling-cell

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com