Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Platinum Tooling, the importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, just announced the release of their new product catalog.

The company’s premium lines include live tools and angle heads from Heimatec, Swiss-type collets/guide bushings from Tecnicrafts, mechanical, air and motor spindles from Henninger and QUICK® knurling and marking tools from Hommel + Keller. Additional products are shrink fit tool holders and machines from Rineck, specialty and adaptive guide bushings from Dunner and broaching tools from REV.

Manufacturing tools for the most popular machine tool builders, Heimatec supplies precision live and static tools in all sizes, ranging from the smallest Swiss-type CNC lathes to the largest live tool lathes. Their angle heads are manufactured to handle the most difficult applications; hence they are ideal for drilling, tapping and milling operations.

Tecnicrafts Swiss-type collets and guide bushings are available in standard and ultra-precision grades with a runout accuracy of 5 microns or less. Bore profiles include round, square, hexagon, rectangle and custom. Guide bushings are chamfered in the back bore and slit to provide smooth guiding and unwanted marks.

Available as air, mechanical spindle and high frequency motor, Henninger speed increasers help maximize productivity by achieving a higher cutting tool rpm that is required for certain applications in today’s marketplace.

The Hommel + Keller QUICK® line offers premium quality knurling and marking tools with special consideration for customer requirements. For both form knurling and cut knurling, QUICK® fulfills the most stringent quality standards and masters difficult tasks, while marking tools make it possible to mark workpieces in seconds on a variety of surfaces and part geometries.

Rineck offers standard and custom shrink fit tool holders with various connections including CAT, HSK, BT, SK, PSC and straight shank extensions. Rineck shrink fit machines are equipped with an elevation cooling system. Heated tools can be moved to a cooling tank with the push of a button. The machine’s smart design keeps accessories stored but close at hand during operation.

A manufacturer of guide bushings for Swiss-type CNC lathes, Dunner manufacturers bronze, ceramic and titane (Meehanite®) guide bushings for customer machining needs. All guide bushings are ready for machine use with finished internal surfaces and geometries designed to offer the best result with nominal size material.

REV broaching tools are ideal for machining simple keyways or internal and external profiles, both teeth and splines. Common profiles, including square and hexagon, are easily achieved and custom profiles are available.

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec live tools and angle heads, Henninger speeders, Tecnicrafts Swiss-type collets and guide bushings, Hommel + Keller QUICK knurling and marking tools, REV broaching tools and Dunner specialty and adaptive guide bushing systems in North America. In addition, Platinum Tooling represents Rineck Shrink Fit Tooling in the United States and Mexico.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, has hired a new sales representative firm in the Southwest area.

Located in Scottsdale, Arizona, Desert Distribution covers Arizona, California, Colorado, New Mexico, Nevada and Utah. The entire line of E-Z LOK products will be sold by the Desert team comprising Jo Ann Morris, David Palmquist and John Wachman. Desert currently handles a wide assortment of fastener lines.

Jo Ann Morris, the company’s Managing Partner, studied Business at Arizona State University. She has 32 years of experience in the fastener industry, working with fastener distributors, manufacturers and OEMs. Morris’ first job was at Copper State Bolt & Nut Company, as their Regional Sales Manager. She started working at Desert Distribution in 2014 as a Sales Business Development representative. Morris also serves as Marketing Director for the Fastener Training Institute.

David Palmquist is the Sales Manager in California. He has 27 years of fastener experience in manufacturing, outside processing and application engineering. Palmquist previously worked at ND Industries, serving as Manager and General Manager.

John Wachman is the Founding Partner, having started the company in 2001 to provide professional sales representation for engineered fastener and component suppliers.

Discussing what led Desert Distribution to partner with E-Z LOK, Morris said, “Our core strength is selling proprietary, engineered components and fasteners to all markets. E-Z LOK’s unique designs on inserts to repair threads supplement and complement our other products.” Palmquist added that E-Z LOK offers a quality product that fills a void in the market. Wachman was attracted to E-Z LOK quality and service. He added, “We are impressed with their management team’s honest approach to addressing customer needs.”

Desert Distribution offers sales support, product training and OEM development to distributors, manufacturers and end users, including DIY businesses.

The responsibilities of these sales representatives include generating new business, product training and sales support, marketing and application support on behalf of the manufacturers the company represents.

Morris and Palmquist enjoy working with the team at E-Z LOK and anticipate bringing growth, new brand awareness and business opportunities to their new principal.

Wachman wants to increase E-Z LOK’s business by bringing in new customers to provide sustainable growth.

Regarding his thoughts on this new partnership, E-Z LOK Director of Sales & Marketing, Kyle Lindsly-Roach said, “We are excited to partner with Desert Distribution for the Southwest territory. John, Jo, and David have long been involved in the fastener industry and bring a wealth of knowledge and connections in the growing Southwest market. We look forward to the opportunity to work together and continue to grow the territory.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die-cast zinc alloy in hex drives for softwood and

brass knife threads for hardwood. A variety of kits are available and feature installation tools, drill bits etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells North American OEM’s, end users and the DIY market through local, regional and national industrial distributors.

Substantial increase of 30% in production resulting from large workspace, cutting capabilities and new generation Heidenhain CNC onboard

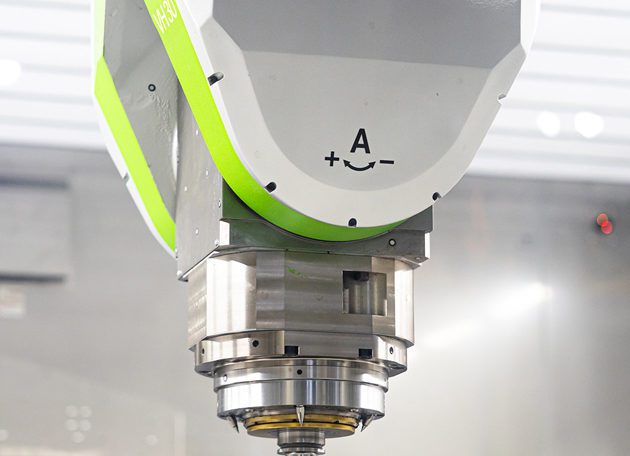

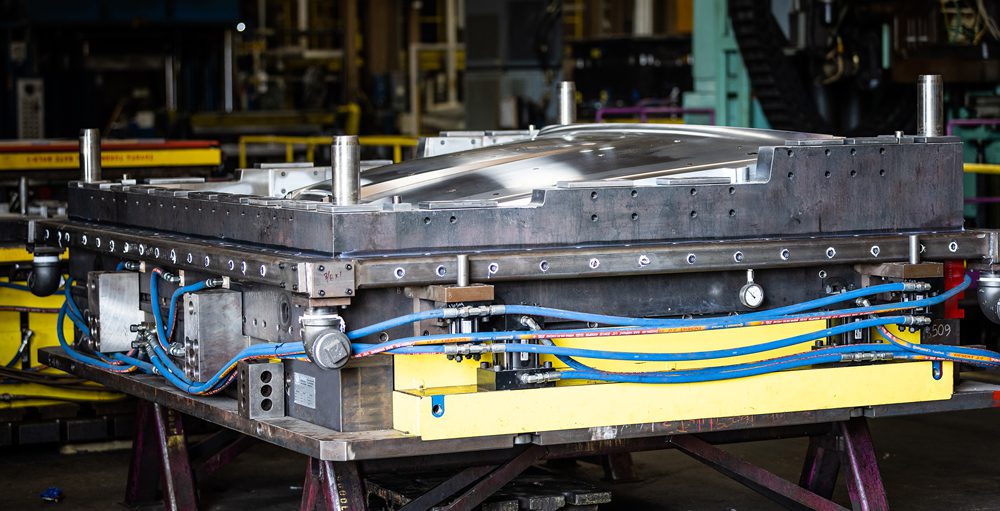

Wixom, Michigan- Zimmermann, Inc. has installed and commissioned its FZU37 portal milling machine, with a 5m x 4m x 1.5m workpiece capacity, at Century Tool, a major tool and die manufacturer in Fenton, Michigan and part of the Tooling Tech Group. The machine has already proven its worth, according to the customer’s Director of Manufacturing, Tom Bradford, who notes, “The table size, speed and accuracy of this Zimmermann machine have already increased our capabilities by 30% or more.” Bradford and the operator on the machine, David Hawes, further note the benefits of the Heidenhain TNC7 control, one of the first machine tool installations in America for this advanced CNC, as a key factor in production planning, CAD/CAM integration, cycle performance and data logging. The CNC also features a visual simulator of the cutting path for cycle validation and in-process monitoring.

According to Cornelius Kiesel, President of Zimmermann, Inc., his company was approached for the discussion of a new machine, which would be replacing an existing, smaller machine that was no longer in operation, plus expand the capabilities of other machines on the floor at Century. “We determined the spec of the new machine and its tasks for Finishing and Semi-Finishing. The primary goal was to cut down the immense number of hours for such processes on the very large workpieces at Century, while enabling them to run the roughing process on their existing equipment.”

Kiesel continues, “To keep things simple, we selected the FZU37 machine, so the foundation of the replacement machine could be filled up to make it flush without a major foundation rework. After several conversations and a few adjustments on the accessories, we were able to lock in the layout. These layout improvements allowed us to go even wider for a total of 5000mm x 4000mm x 1500mm (197” x 157” x 59”) of travel, which was 79% more travel in the same amount of floor space. The FZU37 was subsequently ordered with the state-of-the-art spec for an advanced machine shop such as Century, including our Tool Changer, Top Cover, mist extraction, high-pressure coolant, Tool Laser, Touch Probe and more. Century Tool also wanted to step up their control to the new generation Heidenhain TNC7.”

Lastly, Kiesel notes, “Zimmermann also integrated an extended Spindle housing for deeper cavities plus the side walls were raised to create enough clearance and the machine table reinforced for the challenging molds our customer expected to be produced on this machine. When all these machine parameters got worked out and finalized, we completed the machine rather quickly, commissioned it, did the training onsite and helped Tom and his team start up.” Tom Bradford cited Alfio Campagna, project manager for Zimmermann, for his critical help in getting the machine into production at Century, as this was the first Zimmermann portal mill purchased by the moldmaker.

Bradford also commended the Heidenhain team, who provided three days of training on the CNC at their Chicago location and two more onsite at Century. Operator Hawes commented that he had substantial experience on Heidenhain controls, so the training went quickly for him, though the new control has numerous new features, including its Smart Programming, a graphical programming feature that allows the user to draw contours directly onto the touchscreen, after which the CNC converts the result into a Klartext (German for clear text) program. Century uses Visi as its main CAD program and Tebis as its CAM software and Bradford noted the seamless matching of these programs with the onboard CNC software to configure programs and posts made startup and run a smoother process.

In addition, the new CNC offers the user its Component Monitoring feature, which can protect the spindle bearing from overloading, while also detecting increased component wear in the drive train, all while the machine is running. This feature provides valuable data for predictive maintenance and evaluation of the process capability of the machine. This is vital at Century, who uses the Zimmermann machine exclusively for large, one-off mold prep, often removing over 90% of the material from a workpiece, over multiple days of machining.

Also, the ergonomics of the CNC are extremely user-friendly. Screen layouts and touchpad controls can be adapted to suit user preferences.

Finally, the intuitive contour programming is enabled by symbolic gestures on the touchscreen. Since Klartext remains the main format for files and exporting from the Heidenhain control, existing NC programs can continue in use.

Currently, the Zimmermann machine at Century is running on two shifts, often remotely tended in a low-light or lights-out mode.

Tom Bradford comments on the Zimmermann machine performance. “We do a lot of large tools for compression molding of composites and other substrates. We work for a variety of industries, from automotive to heavy truck, off-highway to agriculture, power sports to infrastructure such as water tanks. Century specializes in Class-A exterior body panels, so the surface finish is critical. During the very long runs we do on the Zimmermann, maintaining tight tolerances is key and the machine plus its onboard control technology make that happen for us.”

Brian Czapla, Director of Sales at Century, adds, “The trend toward high-strength, lightweight composites and large dimensioned, unitized parts for auto and heavy truck make this machine a real asset in our operation.”

In use, the typical workpiece on the Zimmermann is P20 steel, the industry standard for molds, as well as various aluminum materials. HSK 63 and HSK 80 are the primary toolholder types, used for cutting and laser touch probing here. Standard carbide cutting tools and inserts are typical, as well.

Bradford further notes, “As a tooling source, we serve the Tier One and OEMs in the manufacturing space. We have a strong reputation in automotive and heavy truck and we’re looking to expand into aerospace and other consumer products as well. As Brian noted, our core strength in composite molds gives us a real advantage in entering these other markets. The Zimmermann machine helps us achieve superior RA finishes with consistent quality, even on much larger structures.”

Century Tool is part of the Tooling Tech Group. With roots that go back over 40 years, Tooling Tech Group (TTG) has grown to be a leading manufacturer of tooling in the United States. They provide solutions for thermoform molding, high compression composite molding, blow molding, rotational molding, die casting and stamping, as well as custom automation systems for assembly, joining and inspection applications in a variety of industrial sectors. TTG comprises Century Tool, Century Automation for post-molding materials handling and assembly strategies, Die Cad for tooling design & simulation, Majestic for production of stamping dies, Tooling Technology for turnkey cast & billet aluminum tooling solutions, Alpha Integration for assembly automation and G&H Tool & Mold for high-pressure die cast molds.

About Zimmermann

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

Zimmermann, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors.

About Century Tool

Our skill in machining complex geometries and exacting tolerances has positioned Century Tool as a premier composites mold supplier capable of meeting the exceptional surface quality required by manufacturers in the automotive, marine, agriculture, and other industries.

Our Team has mastered the production of molds capable of delivering excellent surface finishes required by Class-A exterior body panels. We have provided the tools used for high-visibility, high-demand vehicles like the Corvette, Jeep, and the Ford Bronco.

About Tooling Tech Group (parent company of Century Tool)

Tooling Tech Group has combined a growing number of industry-leading automation and tooling brands, pooling their collective knowledge and experience to support our efforts to design and build the most innovative automation and tooling solutions for our customers’ greatest manufacturing and product challenges.

Tooling Tech Group is the largest provider of tooling in the United States with 600+ employees, 12 modern facilities and over 1-million square feet of manufacturing space across five states.

We build custom tooling for a variety of applications including thermoforming, compression molding, blow molding, die casting, and stamping, as well as secondary equipment and automated solutions for these applications. We have experience in many industries including automotive, appliance, lawn and garden, agricultural, aerospace, marine, and off-road vehicle industries, among others.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Or

CENTURY TOOL

200 South Alloy Drive

Fenton, MI 48430

Phone: 810-629-0784

www.toolingtechgroup.com

Ms. Amy Stegmuller, Chief Commercial Officer

astegmuller@toolingtechgroup.com

At this year’s AUTOMATE, Siemens is announcing the launch of its enhanced motion control portfolio, featuring SINAMICS servo-drive systems and the new SIMATIC S7-1200 G2 controller, delivering unprecedented performance and flexibility for basic automation applications including handling, moving, positioning and processing.

The new solution combines three key innovations:

“This holistic system approach represents a significant leap forward in basic automation capabilities,” said Craig Nelson, Product Manager, Motion Control, Siemens Industry, Inc.

Key features and benefits include:

The new portfolio offers scalable solutions with various power options:

This cost-optimized solution includes comprehensive safety features, wireless diagnostics capabilities, and seamless integration with the Siemens TIA Portal, making it ideal for manufacturers seeking to modernize their automation systems.

For more information about this new motion control system for basic applications, visit usa.siemens.com/servo-drives and usa.siemens.com/efficient-motion-control.

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

Siemens expands its Run MyRobot platform to allow cost-effective part handling and articulation functions of a KUKA robot directly on the control of the machine tool

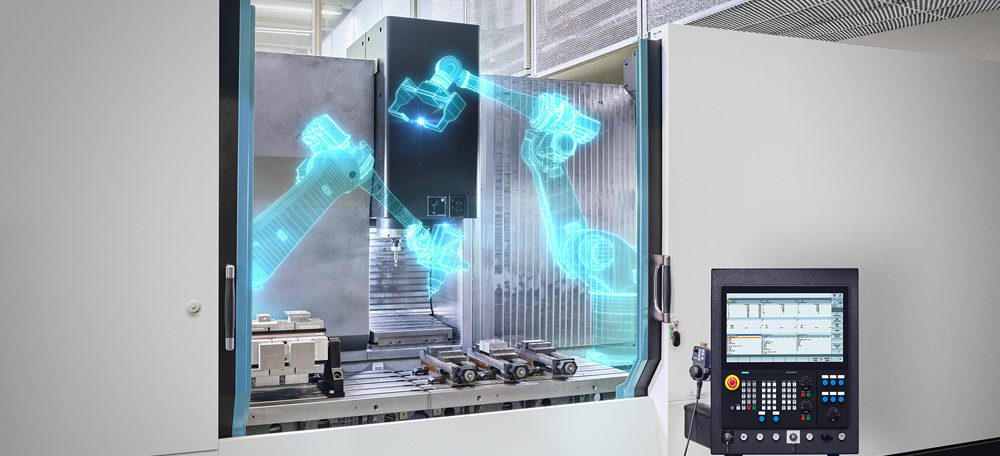

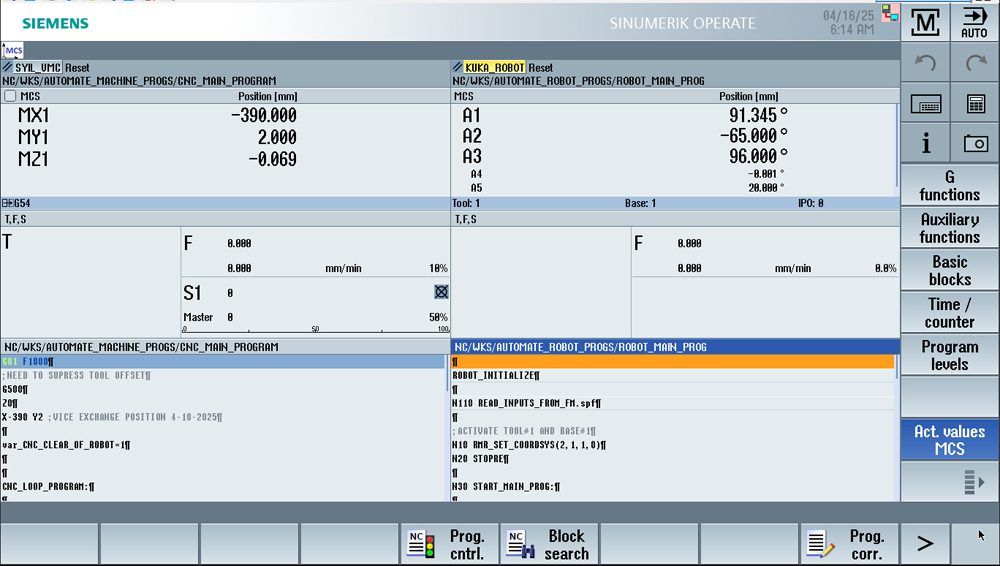

In Booth 3232 at this year’s AUTOMATE show in Detroit, Siemens is presenting an automation solution for the busy, multi-tasking job shop, as it demonstrates a digital twin of the software and programming of its popular SINUMERIK 828 CNC, working in tandem with a KUKA robot, to simplify the operation and programming in part handling for the operator. Meanwhile, in nearby booth 4032, KUKA Robotics Corporation will demonstrate the same control and its robot working in tandem on a SYIL vertical milling machine.

Advantages of this development include:

As automation continues to impact the machine tool industry, robots and CNC machines are collaborating even more closely. The number of handling and machining robots (machine tools with robotic kinematics) is continually on the rise and Siemens is leading this movement, as the only automation manufacturer in the world that equips its CNC with the necessary interfaces for robotic integration.

Increasingly more machine shops and operators are seeing that automation is an important asset when striving to achieve consistent workpiece quality and more flexibility on the shopfloor. Digitalization facilitates the higher level of automation needed and the networking

of the components involved. With this new development, Siemens is offering a cost-effective solution that incorporates the KUKA robot functionality with a line of affordable machine tools, in this case, the SYIL brand of machining centers and lathes for small to medium job shops.

As Tiansu Jing, Product Manager, SINUMERIK CNC systems, explains, “The benefits of this development for the busy job shop are many. Setup, programming, operator interface and diagnostics are all improved with this system, as it easily incorporates the KUKA robot with

the machine tool.” The teach-in functions are implemented through the SINUMERIK Operate system on the control, while the proprietary SINUMERIK Run MyRobot capability of the CNC seamlessly integrates with the KUKA robot control. He further noted that, since there is no need to learn robotic programming, start-up time is reduced and the robot’s separate control pendant is eliminated, making the operator’s task simplified. The SINUMERIK CNC’s HMI is used to operate both the machine tool and the robot.

From the KUKA perspective, Ron Bergamin, Key Technology Manager, Machine Tool Automation, comments, “KUKA offers machine tool builders and end-users alike the ability to incorporate advanced robotics into their equipment and onto their shopfloors, with the goal of optimizing productivity and reducing operator workload. Our partnership with Siemens has resulted in the synergy that brought this development to life. It substantially expands the ability of the small and medium-sized shops to utilize robotics in their work environment.”

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

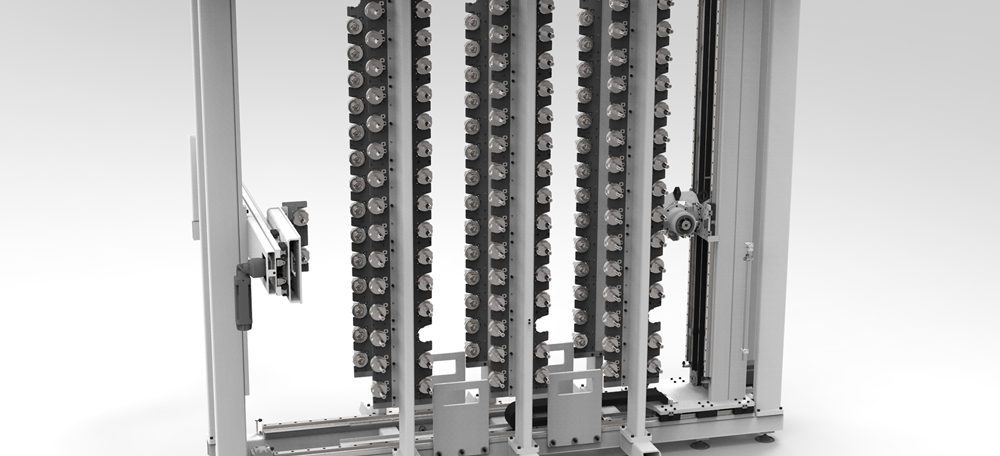

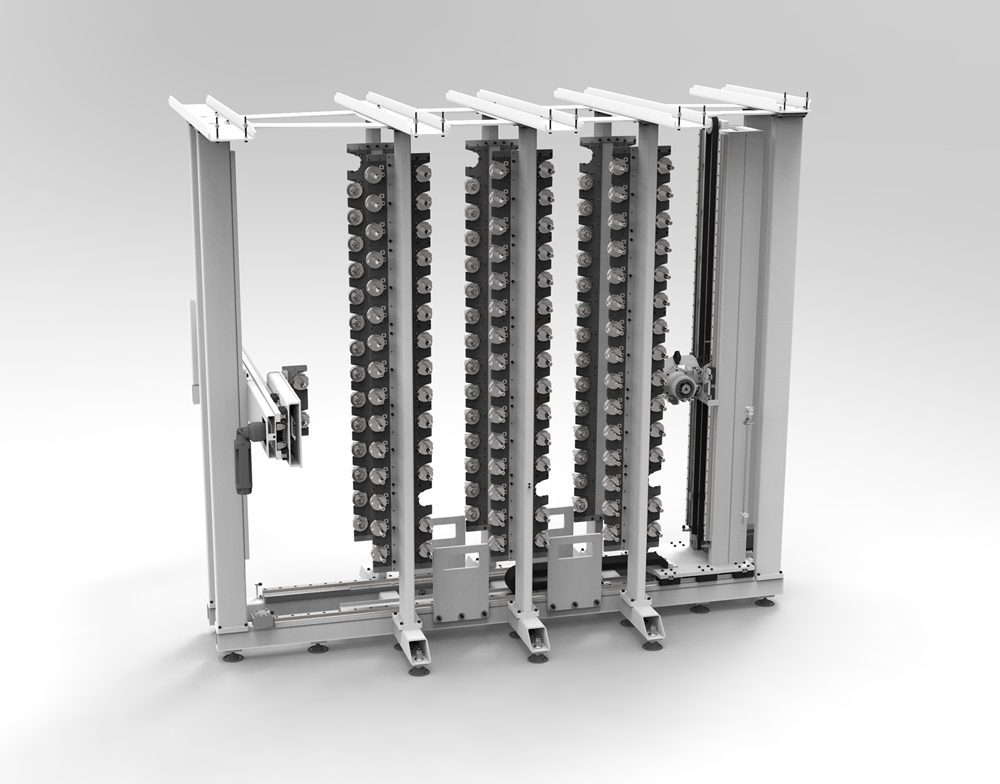

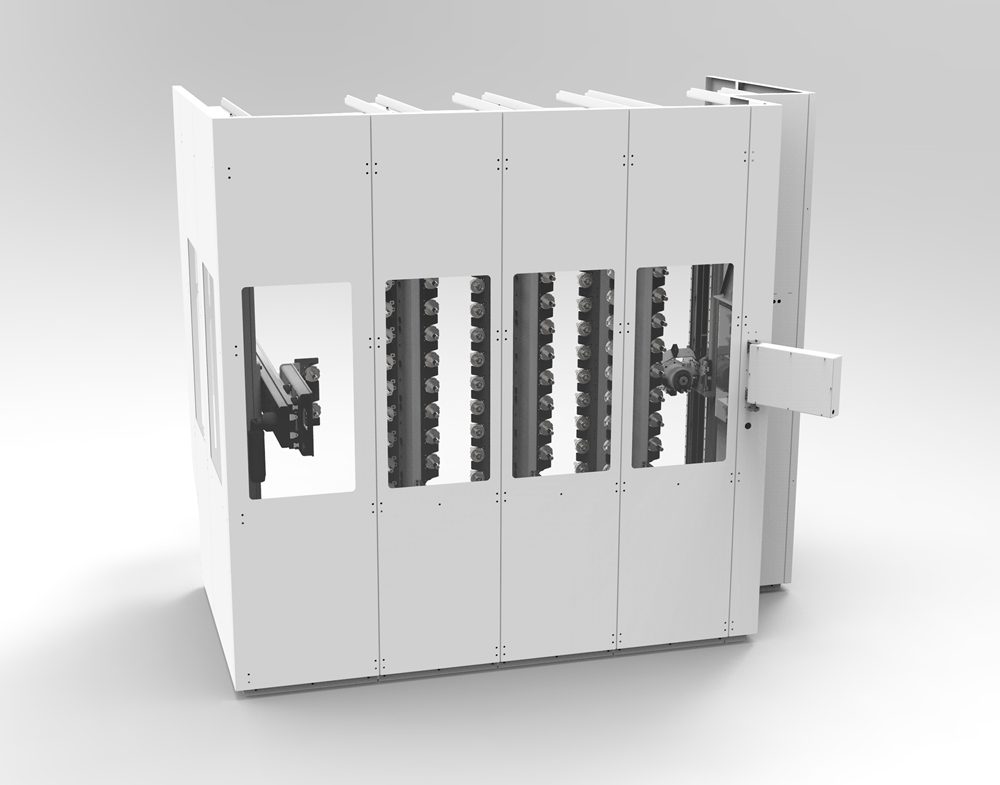

With the FZ rack magazine ZIM Rack, Zimmermann has developed a compact tool changer for its portal milling machines which can be expanded to accommodate several thousand tools. This modularity allows clients to tailor the system precisely to their production without requiring additional storage space.

Tool availability plays a major role in ensuring uninterrupted production for customers. Whether it’s a machine demanding challenging materials or very different components, the right tools must be available quickly and easily due to the high level of wear or diversity. To solve this need, Zimmermann created its own tool changer.

The basic version offers 60 positions and can be expanded in increments of 30 up to several thousand. The operating principle is independent of the number of tools. Thus, the operating personnel have enough space to change all the tools before starting work and to work with them uninterrupted until the next shift. This eliminates the need for a separate storage area.

The tools are stored horizontally in the holders and can be removed via a manipulator. Unlike a conventional chain system, not all tools are moved, but only the necessary ones. Customers can adapt the ZIM Rack to their production. Since both the machine and the changer are from the same source, Zimmermann provides better and faster support when needed.

To see short video of the ZIM Rack, visit: https://www.youtube.com/watch?v=F0a4ygvGqEY

About the company

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood has created a drive tool assortment kit containing a variety of sizes.

While these drive tools were already offered individually, as well as in insert kits, this new offering brings everything together in one kit. According to Kyle Lindsly-Roach, Director of Sales & Marketing, “We decided to offer this assortment kit based on customer feedback indicating that having all of the sizes in one package would be highly beneficial.”

Made from steel, these tools are used to install slotted E-Z LOK threaded inserts like Solid Wall inserts for metal and Knife Thread inserts for wood. Furthermore, all drive tools in the assortment kit fit in standard power tools. Kit drivers can be used to install inserts with internal threads from #6 to 3/4 and M3 to M16. They’re ideal for maintenance departments, machine shops and manufacturing facilities.

Regarding the importance of this product launch, Lindsly-Roach said, “We hope that it will offer an easier way for our customers to access all of the tools needed to install our Solid Wall and Knife Thread inserts in one place.”

The drive tool assortment kit will be available for sale early next year through E-Z LOK’s distribution partners.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

Platinum Tooling, the importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, will exhibit its extensive inventory of machine tool accessories at EASTEC.

The Manufacturing Technology Series EAST features EASTEC in West Springfield, Massachusetts, between May 13-15. The three-day event has over 500 exhibitors and 10,000 attendees who work in a variety of industries, including aerospace, automotive, medical, defense, industrial, commercial machinery, and more.

Premium lines include live tools and angle heads from Heimatec, Swiss-type collets and guide bushings from Tecnicrafts, mechanical, air, and motor speeders from Henninger, QUICK knurling and Marking tools from Hommel + Keller, shrink fit tool holders and machines from Rineck (distributed in the U.S. and Mexico).

Highlighted products are our specialty and adaptive guide bushing systems from Dunner, as well as our broaching tools from REV.

Available for milling and turning machines, the company offers an assortment of standard and custom solutions. Our extensive network of sales representatives supply OEMs, machine tool dealers and industrial supply companies.

Interested parties can speak to Preben and Luke Hansen at the show regarding special applications or machining of exotic materials.

Visit Platinum Tooling at booth 5148 during EASTEC.

For more information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts, Hommel + Keller QUICK tools, REV broaching tools and Dunner specialty and adaptive guide bushing systems in North America. In addition, Platinum Tooling represents Rineck Shrink Fit Tooling in the United States and Mexico.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, introduced Grant Govel as their Business Development Representative. Since his appointment in July, Govel has worked to generate new business opportunities.

A graduate of Penn State University, he received his Bachelor of Science in Business Economics. He has a unique 30+ year blend of technology (hardware and software), finance, marketing and industrial experience, with substantial experience in new business generation and client retention.

Throughout his career, Govel honed his sales and customer service skills in various industries including computers, scrap metal, paving and lighting. His responsibilities included finding new customers (through cold calls, emails and networking), acting as the first point of contact for customers, developing proposals, managing inventory and closing the deal.

In his role at E-Z LOK, Govel mostly enjoys, “… interacting with clients and prospects [and] helping them find solutions and savings to their manufacturing needs.”

Kyle Lindsly-Roach, E-Z LOK Director of Sales & Marketing looks forward to all the ways Govel can expand E-Z LOK’s business, stating, “Grant is a dynamic sales executive and business leader with strong communication skills that produce positive results. His track record proves he’s committed to ensuring customer satisfaction and continued company growth.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

On December 5, 2025, our strictly industrial ad/PR agency will celebrate our first 50 years in business. First, a thanks to the great employees and clients who’ve made this milestone possible. By definition, a service business requires those who serve and those who get served. That dynamic cooperation, especially in the marketing of highly technical products to an equally technical audience, presents some unique challenges and we welcome them daily. We balance our creativity and service with the clients’ engineering and manufacturing muscle to reach the optimum audience on time and on budget. That aspect of Bernard & Company will never change, though much else has, over the years.

On December 5, 1975, Fred Bernard incorporated Bernard & Company, having ventured out from a large Chicago agency to plant his own flag. He quickly realized the continuation of his service to his clients would compound the time needed to get the business up and running. So, he put out the word to magazine reps that he was seeking a copy/contact (old Leo Burnett concept for the account executive function at an ad agency) and he found a kid freelancer named Tim Daro. Though they had almost nothing in common, besides the ability to write copy, Fred brought the kid onboard to help with his clients. At the time, a major client whom we ended up serving for 63 years, was a leader in industrial ovens and furnaces. Tim thought the client made pizza ovens and residential furnaces, his lone points of previous contact with those generic equipment terms. Tim had a lot to learn.

As the early years continued, Fred and Tim would set goals for office enhancements…a water cooler, a fax machine etc., tied to monthly profits. It worked and we grew. Like all agencies, many clients were with us for a short time, others stayed the course and grew with us, reaping the benefit of our talents. Service remained the cornerstone. Unlike other agencies with a “one size fits all” biz model, we worked on the Harvard Business School concepts of zero-based budgeting and the task method. In short, tell us what you want to accomplish, we give you a list of strategies and tactics plus dollars to get there, then we cooperatively trim from the bottom up til the optimum plan is derived. So much for methodology. Many of our clients are the #1 or #2 player in their respective sandboxes. Four had record sales last year and, gee golly, they are our largest media clients.

Again, in a service business, it’s the people and their ideas that win the day. Technology gobsmacked the ad agency business with the invention of the Mac and things changed permanently. Printers came to our clients, offering to do free artwork in exchange for print work. Today, printed literature has faded in favor of online catalogs, online data exchanges, machine sim software etc., so clients and we have changed with the times. Likewise, the emergence of digital media has impacted our world, though our landmark study on how engineers get the info needed to do their jobs today drives our planning to a significant degree. (Ask me about that, anytime. And yes, print still plays a significant role, as do trade shows.)

Today, I’m privileged to continue running Bernard & Company, after buying the agency from Fred in 1982. Though much has changed in the business we do and the way we do it, one commandment is indeed set in stone. We will continue to service the needs of our clients, providing the creativity, market/media knowledge and innovative marcom tactics that have made our clients and us successful, over the years. For that, I say thanks to all those who’ve prospered from our service and especially those who’ve provided it here.

Onward!

Tim Daro

President