Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Cost-efficiency and flexibility in one complete panel

This pre-wired solution is offered complete and fully tested with all necessary components mounted onto a back panel. Sinamics DC Master Base Drives are an extremely flexible and cost-effective solution for new installations and retrofits where space is limited. They are ideal for end-users and third-parties such as system integrators and Siemens solution partners.

Sinamics DC Master Base Drives offer more power per panel in the same footprint as compared to the previous two generations of base drives. These base drives are rated from 15A–850A continuous current.

Standard features of the new SINAMICS DCM Base Drive include — input fuses, output DC fuses (regen only), control transformer, AC line contactors, PROFIBUS, BOP20, UL508A Certification and 65KA SCCR rating. They are ready-to-order with deliveries available after February 2012.

For more information about the Sinamics DC Master Base Drive, visit our web page www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

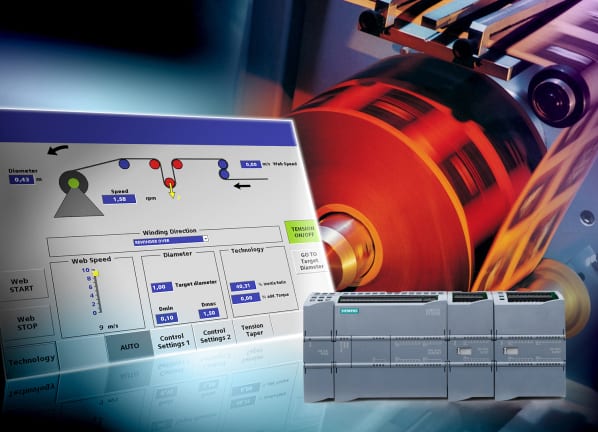

Value-added converting solutions for both the machine and the plant

The Simatic module completes the application set that includes the Simotion® module, a group of high-performance motion control converting solutions, and the Sinamics® DCC (drive control chart) module with drive-based converting solutions. It offers the capability to integrate full converting lines and machines centralized on the Simatic S7 PLC platform. Functions include center winder, sectional drive control and a host of converting process and large functions. Systems can be implemented in Ladder, structured text or in a graphical functional block language.

Machine builders are now able to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation, as much as 80 percent in some cases. It offers modular open functions, for items such as winding, laminating,

cross-cutting, calendaring, perforating, embossing, coating, flying saw, die cutting, traversing and more.

Components of the Converting Toolbox take the form of pre-programmed functions. Sample applications demonstrate how each function can be effectively and efficiently implemented into a machine design. Some of the applications are ready-to-use after only minor modifications and even include basic HMI functionality.

For more information about the Converting Toolbox, visit www.usa.siemens.com/converting.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Simotion is the scalable motion control system that quickly and easily handles increasing machine demands by enabling central machine functions to be implemented with just one controller. It is available in three variants: drive-based, PC-based and controller-based.

Simotion Scout facilitates the configuration, programming, testing and commissioning of applications. With its graphical-based programming, Scout further facilitates system configuration for new users. Users of Scout 4.2 will also benefit from new features such as automatic drive integration and detailed comparisons for graphics-based programming languages.

The most significant innovation of Scout 4.2 is its simplified interface to the Siemens Sinamics drive system. This feature provides users with an automated means of integrating drives and components into the Simotion system. Using the new symbolic assignment of technology objects (TOs) and I/Os to drive objects, users no longer manually configure communication with message frames and addresses because Simotion Scout now automates this task. Object-to-object assignment takes place via a new inter-connection screen. In this screen, all compatible partners are listed hierarchically and the symbolic connection of the components to be inter-connected takes place by simple selection.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

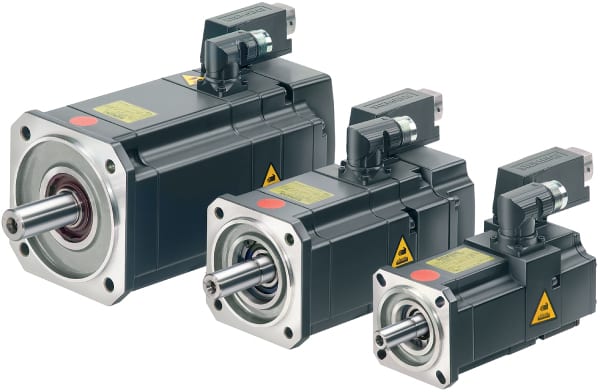

With a total of 6150 option pairings and 18 color choices, servomotors in the 1FK7 family can be configured to 110,700 possible designs. Options include stall torque and RPM rating, encoder style and bit resolution, holding brake functionality, shaft style, IP rating, AC line supply voltage and electronic nameplate recognition via Drive-Cliq®. 1FK7 geared motor options are not included in this program presently.

Siemens is now making this service available to customers in the U.S. market. With the motion controller Simotion® and the drive system Sinamics® S stocked in the United States, Siemens is also able to supply complete motion control systems in three weeks’ lead time.

According to Arun Jain, general manager, Siemens Motion Control Business, “We have made the commitment to significantly shorten servomotor delivery times. The 1FK7 family has a wide user base for motion control applications, so we have selected this very important line for our major customer service initiative. We have devised and implemented an entirely new protocol for motor manufacturing and production at our factories.”

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

The Speed Connect release makes installation and changeover, even in very restricted space applications, fast and easy. No tools are required; just a one-quarter turn locks or unlocks the bayonet-style connectors.

All Siemens Motion-Connect® cables are system-tested to guarantee optimum performance in any motion control system, whether in a Sinumerik® CNC machine tool or Simotion® general motion control application. These cables are also compatible with Sinamics® drive systems and all families of Siemens induction, direct drive and servomotors. Motion-Connect® cables are fully shielded to prevent EMC noise emissions and protect the motion control system from ambient environmental noise. Motion-Connect® cables are certified to CE, VDE, UL and UL/CSA standards.

A wide range of cabling with the new Speed Connect quick release mechanism is immediately available. For more information, visit www.usa.siemens.com/motioncontrol.

Watch an operational video HERE.

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingATLANTA — Siemens today announced the release of the new Sinamics® G110D drive platform. The latest solution in the company’s Totally Integrated Automation (TIA) portfolio, the

The Sinamics G110D combines improved functionality, increased energy efficiency, a smaller footprint, lower total cost-of-ownership and enhanced usability in a single drive. Applications for this new drive range from material handling or packaging conveyors and airport baggage carousels — to pumps, fans, compressors and other industrial equipment.

Offered as an economically-priced drive with improved features, the Sinamics G110D includes integrated plug-and-play power and control for easier installation and an optional Intelligent Operator Panel (IOP) for simple text application setup in a reduced footprint. The IOP further assists the machine operator with a greater level of control, as well as alarm status alerts and resolution advice, so troubleshooting time is greatly reduced.

The Sinamics G110D includes an optional power disconnect switch and the IP65 metal housing enclosure has a low profile for easier mounting near the motor, with no drive cabinet required, for further space savings.

The Sinamics G110D is suitable for either direct communication with a Programmable Logic Controller (PLC) or control via I/O inputs. AS-Interface bus configuration and optional maintenance and manual-auto switch are incorporated into the drive, making it easy to integrate with other hardware in an overall control schematic.

Integrated brake control and quick stop functions provide a higher degree of reliability in heavy-load operations.

The new Sinamics G110D complements the recently introduced Sinamics G120D drive, which offers many of the same features plus safety integrated design (Safe Limit Speed, Safe

Stop 1 and Safe Torque Off) and power regeneration capability back to the supply.

For more information on the new Sinamics G110D drive platform, visit: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

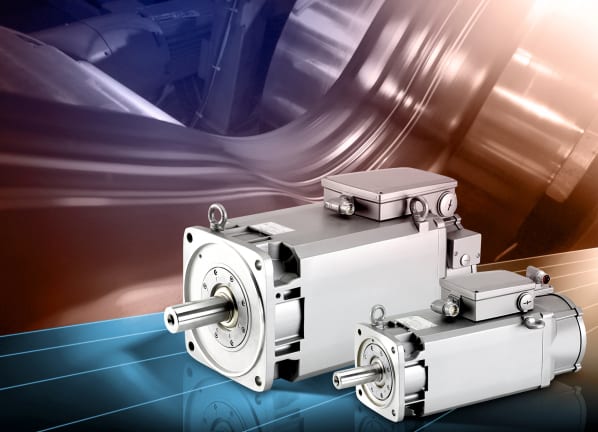

CHICAGO — After considerable research and product refinement, as well as extensive field contacts with end-users, Siemens Industry, Inc. introduced today the new 1PH8 family of high-performance induction motor drives and servomotors. Available in a wide power range, from 2.8 kW up to 1340 kW, the

This new line combines induction and high-powered servo technologies to give machine designers and end-users a greater degree of efficiency and more precision in the production process. A single stator and rotor design enables the modular adaptation of the many motor options to provide design flexibility and cost containment.

Designed for the specific performance and environmental requirements of a main spindle on a CNC-equipped machine tool, these new Siemens induction motors have myriad applications in other heavy-duty markets, such as print unit drives on printing presses; rolls and web handling on converting and packaging machinery; crane and hoist elevation; extruders and injection molding machines; metal-forming and welding machinery; assembly line robotic articulation; materials handling gantries and more.

The modular motor platform concept offers designers various options for selecting the optimum unit for an application:

The 1PH8 motor spindle line is fully compatible with the popular Siemens Sinamics® S120 drives platform to achieve faster commissioning and improved control response. All motors in this new family feature the Drive-Cliq® serial interface and electronic nameplate recognition for plug-n-play start-up.

Earlier families of Siemens motor designs can be upgraded to the new 1PH8 series without difficulty, including the 1PH7, 1PL6, 1PH4, 1PM4, 1PM6 and the upper range of the 1FT6.

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

The embedded PC, which features a DDR3 memory and an Intel Core2 processor, is free of wear from moving parts, such as hard disks and fans. This compact motion control system provides maximum flexibility and accommodates centralized or decentralized machine concepts for PC-based applications or for applications that require a compact size.

It is designed for many different motion control applications with its multiple onboard interfaces. They support communication over Profinet, the open industrial Ethernet standard, as well as Ethernet interfaces that run at 10 / 100 / 1000 megabit speeds. Four USB interfaces make it simple to connect a keyboard, USB stick, printer or other devices. A DVI port rounds out the links so users can attach a display or monitor. The Simotion P320-3 can also be used in a “headless” configuration without a display, monitor or front panel.

LEDs on the front indicate the operating states, making self-diagnosis easy. The integrated power supply bridges temporary power failures. In the buffered SRAM memory, the process data is saved securely even in the event of a sudden voltage drop. Monitoring functions for the batteries, temperature and program execution are also included. The Windows Embedded Standard 2009 operating system, which increases the reliability of the system, is pre-installed. Additionally, the Simotion runtime system comes installed on the Simotion P320-3.

Additional information is available online at: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

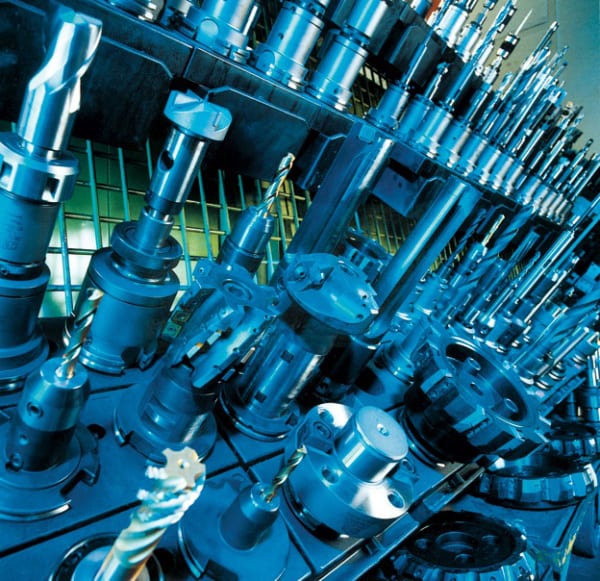

Offered to customers as a standard solution, Zoller has written an interface to connect TDI to the company’s presetter, enabling data to be brought directly into the Siemens numerical control. Zoller boasts accuracy on its presetters to two thousandths of a millimeter (0.002mm) or less than eight millionths of an inch (0.00008in).

By utilizing TDI and a Zoller presetter, a machine tool end-user benefits in many ways, including faster access to tool data with no manual entry of values required. All tool data are transferred to the CNC by an automatic link in the presetter, resulting in significant cost-, time- and operator action savings. In addition, the user develops an increased understanding of tool life and tool wear patterns on various operations in the shop. The Zoller presetter writes data directly onto an RFID chip, making transfer to TDI onboard the Siemens CNC is simple and easy. Lastly, an end-user can maintain a central server that indicates the location of any tool in the shop or factory, as well as track the status of the next tool needed to perform an upcoming operation.

Included in the Siemens TDI suite are the following:

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

ENERGY MANAGEMENT CONSIDERATIONS WITH TODAY’S DRIVE SYSTEMS

It’s a process, not a product; multiple drive factorscontribute to system energy efficiency

by John Krasnokutsky, Siemens Industry, Inc., Marketing Manager, Motion Control Business

Energy Monitoring Equipment Selection and Optimization (Mechatronics / Parameterization)

Hardware: Common DC Bus / Infeed / Regeneration

While it is valid to state that energy efficiency is defined as the same level of production being achieved at an overall lower energy cost, it is equally important for today’s machine builders and automation engineers alike to remember than an energy-efficient system can actually translate into higher productivity. This is achievable through a comprehensive approach to energy management.

It is a fact that most of the energy loss in a system occurs in three areas, namely, the generation, distribution and conversion of energy into useful work, the last being accomplished through heat exchangers, pumps, motors and drives. This paper will concentrate on the last product group, as it is also a fact that over 25% of all electricity consumed in America is used on industrial electric motor-driven systems. Electric motors represent 65% of the power demand in American industry and, owing to the inefficiency of most motor control systems, the potential for energy savings in an industrial facility can approach 70% for any process where electric motor power is employed.

That said, energy management is a process, rather than a product or series of products installed on a machine, or inline, to achieve a basic energy saving of kW hour consumption. This process must be ongoing and perpetual, meaning that any defined goal should be viewed as a momentary metric of achievement, rather than a final end. While any vendor, including our company, can supply the right products and support services to hit a target mark of energy savings, the mindset of the customer is key in keeping the process recurrent. This ensures a continual increase in the productivity levels achieved, defined as a factor of the energy consumed. In many ways, it can be viewed in the same manner as an ongoing, effective but constantly evolving quality management system at your company.

First, energy monitoring systems must be in place to effectively determine the current consumption. These can include, but are certainly not limited to, energy consumption displays, infeed/supply monitoring devices, power factor meters and more. Next, the proper calculation tools are needed to properly evaluate the life cycle costs of any investment. These tools can be as simple as a motor sizing chart or the software programs used to parameterize drives. However, a more formal mechatronics protocol may be beneficial to your operation. In this scenario, a thorough evaluation of both mechanical and electrical/electronic influences on your system, be it a machine or a process line, is conducted. The results can often open the eyes of machine designers, process engineers and system integrators alike. To realize the benefits this analysis the proper products and system solutions must be implemented.

This is where a competent supplier can be an effective partner for your operation. For example, the solution you need might involve a vector drive that utilizes an energy optimization function to enhance the efficiency of the motor during partial load operations. In a system with multiple motors, energy savings might be realized to a substantial degree by the use of a drive unit with a common DC bus. The designer can also select the most appropriate infeed solution for the machine, pump or process operation, given the particulars of performance and required output. This may include an appropriately sized infeed unit with regenerative capability, the ability to put unused or braking energy back on the incoming power line.

Some applications may allow the use of high efficiency standard induction motors and, in the process, realize a potential savings of 1-3%. The use of frequency converters (VFD) for speed control might raise this to an 8-10% savings. VFDs have myriad applications throughout industry on fans, pumps, blowers and compressors, as well as in wasted energy recovery on cyclical acc/dec and regeneration on lost braking energy applications.

Optimizing your entire system through mechatronic analysis of the machine or process design, can result in a potential savings of 15-20% by the avoidance of over dimensioning of motors, plus partial load optimization by means of energy-related flow control. This analysis may also point to the ability to use controlled energy infeed and recovery.

In order to determine the true efficiency of any drive system, it is necessary to demonstrate the amount of energy required by its power components and a corresponding examination of how the system uses energy. How different drive concepts used on the same system under identical power load must also be considered. This latter exercise might look into partial load efficiencies with various motor and drive combinations, straight comparisons betweens synchronous servo vs. asynchronous induction motors or direct drive vs. motor/gearbox combinations, drives with braking components vs. regenerative drive technology, as well as solutions with single vs. multi-drive, common DC bus solutions.

A corollary to this discussion should also include a review of potential hydraulic/pneumatic component change outs in certain applications where replacement with an integrated package of motion control and PLC technology might better resolve closed loop pressure control of axes, for example. Fewer components and their related power consumption can lead to overall system productivity improvements, as well as ongoing enhanced energy efficiencies. Reduced programming, diagnostic and commissioning times can also flow from such an approach, providing even more opportunities for overall machine or process improvements. Tracking the energy efficiency of such a system may seem problematic at first, but here again today’s sophisticated mechatronic and virtual production protocols can be utilized to validate the real-world performance characteristics of such designs, far in advance of their implementation.

As the emergence of new technologies has impacted many of the products used in energy-efficient systems, it is equally important to take a more holistic look at operational sequences and the overall integration scheme when designing, retrofitting or rebuilding for improved energy utilization. The results can be many, including precise process and power factor control for optimum energy use and significant cost savings, plus the collateral benefits of lower carbon footprints, reduced maintenance due to decreased mechanical stress and lower total cost of product quality derived from less mechanical wear and better production control.

Author: John Krasnokutsky

Email: john.krasnokutsky@siemens.com

Website: http://www.usa.siemens.com/motioncontrol

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

For an informative PowerPoint presentation or more information on this subject, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading