Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

The new Simotion D motion controllers for production machines cover all levels of performance, from simple positioning tasks to demanding applications with extremely short cycle times or large numbers of axes, up to 128.

CHICAGO, PACK EXPO — Siemens Industry, Inc. announced today the extension of the upper performance range of its popular Simotion D motion controllers. The new generation of Simotion D445-2 multi-axis controllers has new features such as onboard Profinet interfaces, high-speed I/O, and with three times the performance, a single controller can support up to 128 axes of motion.

Simotion D motion controllers are the ideal solution for production machines covering all levels of performance — from simple single-axis positioning tasks to complex synchronous applications — with extremely short cycle times on a large numbers of axes. Thanks to its scalability, Simotion D offers users a high degree of flexibility for the ever-changing demands on machine automation. The Simotion D drive-based multi-axis control not only offers PLC, motion control and advanced technology functions, but also an integrated drive control based upon Siemens Sinamics S120 drives.

Today, with the new Simotion D445-2 DP/PN and D455-2 DP/PN versions, the performance range has been extended even higher. Compared to the previous generation, the maximum quantity has been doubled to 128 axes and the memory capacity significantly expanded. This has increased the PLC and motion control performance by a factor of three. With Simotion D445-2 DP/PN and D455-2 DP/PN, the previously optional Profinet I/O interface has now been integrated on the modules as standard. This frees up the option slot for other expansion cards. The onboard interface is equipped with an integrated three-port switch and facilitates different network topologies such as line, star or tree structures, without the need for additional external switches. The interface not only supports real-time (RT), but also isochronous real-time (IRT) data exchange and can be operated as a controller and / or device of another controller.

In addition to the Profinet interface, Simotion D445-2 DP/PN and D455-2 DP/PN also have two Profibus and two Ethernet interfaces, as well as 28 digital I/Os, of which 16 can be used for technology tasks such as output cams and measuring inputs with micro-second resolution.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Advanced Machine & Engineering Co., (AME) Rockford, IL announces a new line of pneumatic rod locks. Advanced Machine & Engineering Co., a leading manufacturer of stand-alone and NFPA cylinder mount pneumatic rod locks since 1994, has now introduced the Amlok RLI, its fourth-generation power-off rod lock. This basic lock unit is in addition to the RLN and RCH, expanding the company’s rod lock product line. The RLI Metric (ISO 6431) series will complement the standard NFPA line. This fourth-generation lock is the culmination of 18 years of manufacturing and marketing of pneumatic and hydraulic rod locks.

The rod lock’s standard features include anodized aluminum construction, a heavy-duty clamp system and power-off clamping. The standard seal material is carboxylated nitrile.

The unit uses dry-filtered air, has a release pressure ranging from a minimum of 4 bar/60 PSI to a maximum of 8 bar/120 PSI. The operating temperature ranges from 10 degrees F to 180 degrees F. Maximum rod tolerance is +0.000 in./-0.002 in.

Rod lock options include stainless or electroless nickel-plated housing, viton seals, wiper scraper and sealed versions. The lock mounts to standard ISO 6431 cylinders or can be stand-alone using MXO, MF1, MF2 and MS1 mounting configurations.

The Amlok RLI is available in various sizes for rod diameters of 16mm, 20mm, 25mm, 32mm and 40mm and cylinder and bore diameters from 40mm to 160mm. Holding forces range from 200 lbs/890N to 2,450 lbs/11kN.

The RLI power-off pneumatic rod locks are particularly-well suited for holding applications in industries such as automotive, mobile, food, machine tool and military test, among others.

—

Advanced Machine & Engineering Co., located in Rockford, Ill., is a global manufacturer and distributor of precision machine components, fluid power components, fixturing/workholding, power drawbar and spindle interface components, and saw machines and blades. The company also designs and builds special machines for a variety of industries and provides machine rebuilding, retrofitting and contract manufacturing services. AME has partners and customers around the world and across the U.S.

For more information, visit www.ame.com or contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

The patented AMLOK® Type RLI is constructed of black anodized aluminum housing with a special piston and wedge locking mechanism actuated by multiple springs that mechanically lock the rod quickly and securely. The clamp is unlocked when air actuates the piston, compresses the spring and releases the locking device.

The optional sealed RLI Series design is suitable for food and wash down applications as well as pneumatic and hydraulic presses, scissor-lift tables, test and positioning equipment, amusement ride equipment, printing and paper handling equipment, theatrical equipment (platforms), assembly equipment, and machine tool applications.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, Ill., serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems; the Fluid Power – Safety market with cylinder rod locks and safety catcher devices; and the Production Saw market with our AmSaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S.

For more information, visit www.ame.com or contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

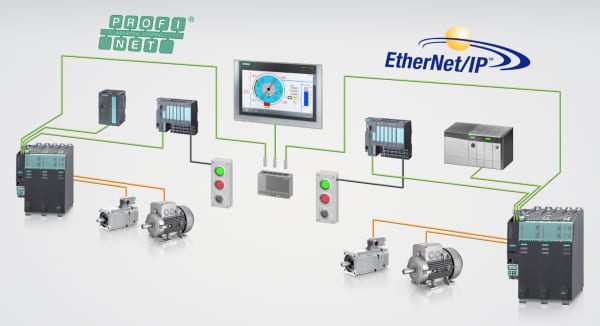

The Sinamics S120 drive platform from Siemens provides users maximum flexibility with industrial Ethernet connectivity.

ATLANTA — Siemens announced today that its versatile Sinamics S120 drive system has been expanded to include Profinet, Ethernet TCP/IP and EtherNet/IP connectivity, thus providing maximum flexibility for industrial Ethernet communication while offering innovative concepts for those wanting a single network for the entire plant.

Whether a greenfield project with multiple vendors or an OEM supporting different platforms on their machines the importance of industrial Ethernet connectivity for drive systems is today’s top requirement.

“In many instances, plant managers have the requirement for a single-plant network, particularly with large automotive, packaging, plastics, metals, food and beverage as well as material handling companies,” says Craig Nelson, Siemens product manager, Sinamics S drives. “Our Sinamics drives platform provides communications without limits to a specific network type.”

Sinamics S120 drives support, as standard, Profibus DP and Profinet to ensure seamless communications between all the components involved in a typical automation solution, including HMI (operator control and visualization) and I/O. Additional higher-level functions including Safety Integrated telegrams and synchronized mechanisms for even the highest-level motion applications are also included in these innovative solutions.

Profinet can transmit operating and diagnostics data simultaneously to enterprise-level systems using standard IT mechanisms (TCP/IP) for an integrated factory environment. The new addition of an EtherNet/IP stack offers another option for Sinamics users. Having the flexibility to communicate with the most common automation systems via Profinet, EtherNet/IP or basic Ethernet TCP/IP makes the Sinamics drive system easily adaptable to the current Industrial Ethernet boom.

Sinamics S120 drives are designed to handle virtually any drive requirement and facilitate vector, servo and variable-frequency drive (V/Hz) applications with the choice of single- or multi-axis offerings. The modular design and system architecture, combined with new communication connectivity features, makes Sinamics S120 a truly advanced drive offering in today’s market.

With a wide power range (0.25 – 1,600 hp), highly scalable solutions, including safety integrated functionality and convenient start-up with automatic configuration of the drive system, through the innovative Drive-CLiQ interface, Sinamics S120 is a powerful solution for a host of applications, including packaging, plastics molding and extrusion, textile, printing and paper machines, handling and assembly systems, machine tools, rolling mills and test stands.

For more information about EtherNet/IP connectivity to Sinamics S120 drives, visit our website: www.usa.siemens.com/eip.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Crown Equipment in Mexico bought one of the MAE straightening presses from the GMTA booth at IMTS. Crown is a world leader in forklift trucks.

The expansion of the GMTA facility in Ann Arbor, Michigan is underway and targeted for completion in several months. When completed, the new facility will house a new machine demo and training center, plus additional sales and service personnel. GMTA continues to grow steadily, representing numerous high-quality German machine tool builders in North America.

Siemens in Mexico bought a Pittler PV630 ValueLine vertical turning machine for motor manufacturing. Take a look at video of this machine in action!

For more information:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

This Grieve oven has 6” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior and four front access doors with automatic door switches to shut off the heat and blower when a door is opened. Four structural steel slide beds are provided to support the plastic sheets during processing.

Controls on No. 1026 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, SCR power controller and eight auxiliary thermocouples connected to a selector switch and temperature indicator.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

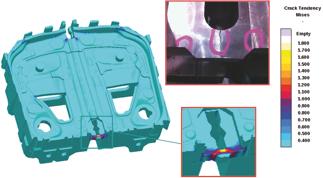

MAGMA5 5.2 now allows the direct comparison of up to four different project versions in the result perspective. Filling, solidification and stress results can be animated in a synchronized mode. A special highlight is the option to display the geometry and all MAGMA5 results in 3D stereo, using shutter or red/cyan 3D glasses and to store them as 3D images or movies. Various new tools facilitate a standardized result evaluation.

New result criteria allow for a more effective evaluation of metal cooling and critical metal speeds during filling. The progress of feeding and porosity formation can be monitored and displayed continuously during the entire solidification process. A new criterion to predict cold cracks allows the user to find stress-related casting quality problems more quickly.

The implementation of user results further offers a powerful tool to compile user-specific criteria based on any MAGMA5 results. User results can easily be defined and created automatically during a simulation or subsequently in the result perspective.

All users will benefit from the new “resume point” capability, which allows flexibility in re-starting the simulation with modified die casting process conditions, based on the previous or next-to-last casting cycle. Sand casting processes can be resumed with different conditions at the end of any process stage. The automatic enmeshment of complex geometries is now further simplified by new enmeshment criteria and procedures.

Stress simulation results can be prepared for faster post-processing. For the quantitative assessment of casting distortion in the measurement perspective, it is now possible to compare the virtual measurement with the real part geometry.

Finally, with MAGMA5 5.2, a new database of riser sleeves, which was generated by ASK Chemicals, is now available.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. MAGMA’s product and service portfolio includes the powerful, modular simulation software MAGMASOFT®,with the newest release MAGMA5 as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the global metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.

For more information on this release, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone 847-969-1001 ext. 225

Email cheisser@magmasoft.com

Continue readingNo. 873 is a 650ºF, electrically-heated inert atmosphere cabinet oven from Grieve, currently used for processing corrosive materials at the customer’s facility. Workspace dimensions of this oven measure 38” W x 50” D x 38” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 2000 CFM, 2-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road, Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com – Attention: Frank Calabrese

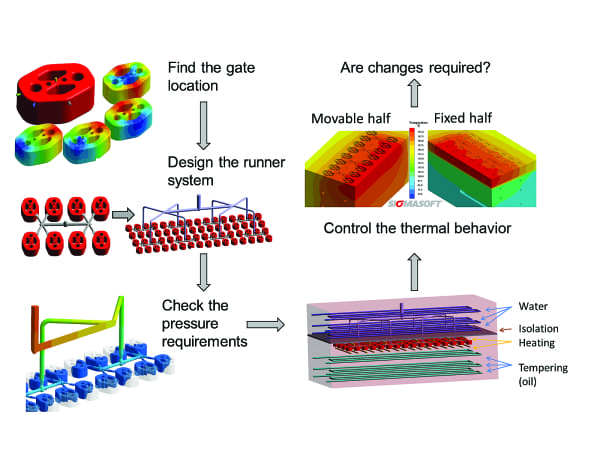

Continue readingBesides predicting the filling process, the process simulation software SIGMASOFT® can also predict the curing reaction of elastomers and the thermal performance of mold tempering systems. A major advantage is that not only the cavity is simulated, but the complete mold including all details is considered in the calculation. Therefore, the interaction between heating elements, elastomer, inserts and mold can be accurately predicted.

Simulation technology can help avoid all these typical processing problems while saving significant time and effort during the development of a new mold. When utilizing the approach of “Process Simulation”, provided by SIGMA® with its software SIGMASOFT®, all the elements of the mold can be included. This allows the molder to run a “virtual production”, including all the process stages (preheating of the mold, injection, curing), not only over one cycle, but over several production cycles. With this process, the performance of a mold design can be evaluated completely before the steel is even cut.

“Historically, elastomer molders have relied on conventional injection molding tools to predict the filling of the cavity. Many processors still think this is all simulation can do for them. However, simulation tools available nowadays are far more powerful. Besides filling, the curing reaction can be accurately predicted, and the thermal behavior can be exactly anticipated”, explains Dr. Marco Thornagel, executive director of SIGMA Engineering GmbH/Germany. “Simulation can make a company achieve its production goals faster, being more profitable”.

Simulation can analyze different variables of the design of a new mold. After determining the desired geometry, the process starts with the selection of the injection point or gate type. Understanding the flow behavior, as well as quality issues related to weld lines, air gaps or jetting, the runner geometry can be defined. In this stage, different aspects including cavity balance or the pressure requirement can be predicted.

Once the part and runner are defined, the tempering of the mold can be designed. In the simulation the tempering elements can be precisely included: it is possible to define their exact location in the mold, as well as the material and the electric power. Even the control system can be defined. Instead of assuming a mold temperature in the simulation, the exact thermal condition of the mold is predicted, including the way it fluctuates over time.

After the effect of the desired tempering system is simulated, factors in the mold which can compromise part quality can be identified. Cold spots in the mold where the material cures too late or irregular temperature distributions, which can produce different curing degrees for parts produced in different cavities, are some examples of the virtual “troubleshooting” that can be achieved with Process Simulation.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

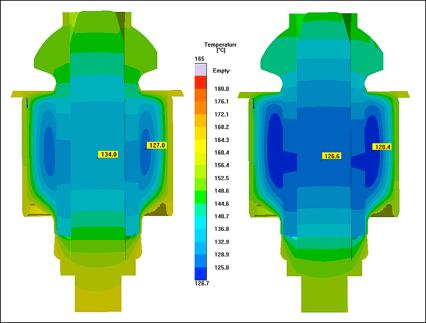

Continue readingThe process-oriented approach of SIGMASOFT® makes it possible to use injection molding simulation of elastomer applications not only for filling or cooling times, but also the non-productive times between each process phase. When the process is simulated considering the influence of operational times occurring between the main process stages, the accuracy of the simulation is dramatically improved.

Temperature distribution in a metallic component overmolded with elastomer. Left: without consideration of the mold opening time; right: considering a mold opening time of 60s.

Schaumburg, IL, September 7, 2012 – Even though it is not necessary to include them to complete an injection molding simulation, the non-productive times have a major influence on the process and on part quality. Process Simulation Software SIGMASOFT®, from SIGMA®, can include non-productive times in the simulation enabling substantial improvement in the accuracy of the results to be achieved.

Taking into consideration the times in which the mold opens and closes, the times in which it is heated up or cleaned, as well as handling times when the inserts are placed simulation makes it possible to accurately analyze the process cycle. The interaction between all mold components has to be considered and cycle times have to be predicted accurately. That way even factors that influence the part quality, such as the curing degree, can be predicted by the simulation.

An example is presented in Figure 1. In this case the mold temperature decreases during the time period when the mold stays open. If this time is not considered in the simulation, the prediction of the whole cycle time, as well as the prediction of the cooling time or curing degree, will be erroneous. Besides, the predicted quality of the parts produced can deviate from reality.

In SIGMASOFT®, such non-productive times can be defined and varied separately in the simulation. Therefore, besides calculating the whole cycle, it is also possible to perform trouble-shooting of problems at each of the production stages. Through the utilization of simulation it is possible to decide if changes in the process definition are enough to solve production problems, or if the mold has to be reworked to achieve the desired quality and productivity goals.

—

SIGMA® (www.sigmasoft.de) is 100% owned by MAGMA® (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “Design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

Continue reading