Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood has a wide range of installation tools available regardless of the type of threaded insert being used. These include drive tools for E-Z LOK™ (Solid Wall) inserts, Knife Thread, Coil and Hex Drive.

E-Z LOK™ tools install Solid Wall inserts for metal without engaging the insert internal threads. This speeds up the installation process and eliminates the possibility of cross-threading or stripping. Furthermore, drive tools fit standard power drills and drill presses for an easy and efficient installation process. They are versatile and adaptable to various metalworking applications ranging from industrial projects to automotive repairs. Drive tools are designed for threaded insert installation in metal as well as woodworking.

Installation tools for E-Z™ Knife threaded inserts are engineered to improved accuracy, reduce effort, prevent insert damage, enhance strength of connections and increase project efficiency. It ensures that threaded inserts are installed correctly and securely. Optionally, power drive wood insert tools provide efficiency and consistency, making them ideal for high-volume projects.

The E-Z Coil™ tools can quickly fortify, or repair tapped holes in soft metal materials. Each mandrel-style insert tool and manual tang break tool offer a low-cost solution for efficiently installing the company’s premium inserts. Installation tools are available for every insert size E-Z LOK offers.

Hex drive installation tools are high-grade and ideal for softwood installation applications. These tools provide the needed control to achieve precise and snug threaded insert installations each time. Versatility is at the core of the tool collection. Threaded insert tools are constructed using top-quality materials, ensuring they are durable, dependable and ready to tackle numerous installations without faltering.

FREE SAMPLE ON REQUEST

CAD files on this product can be downloaded in over 100 file formats from the E-Z LOK website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, offers E-Z Fin™ brass threaded inserts for wood.

Also known as Finserts, these threaded inserts provide robust, metal threads in softwood materials. They are capable of distributing stress over a greater surface area, which allows for permanent fastening that minimizes the possibility of thread erosion. Simply press the inserts into place and the OD fins grip the wall of the hole and lock in place. To accommodate for varying material thicknesses, E-Z Fin™ inserts are available in single, double or triple fin designs. Internal threads sizes range from #6 to 5/16.

Features include easy and fast press-in installation, design that reduces splitting and splintering and they can be applied to composition board, MDF and pine. Additionally, when using Finserts it is possible to tighten and loosen threads an unlimited number of times. If normal wood screws were tightened and loosened, the hole would be enlarged and lessen the grip.

FREE SAMPLE ON REQUEST

CAD files on this product can be downloaded in over 100 file formats from the E-Z LOK website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

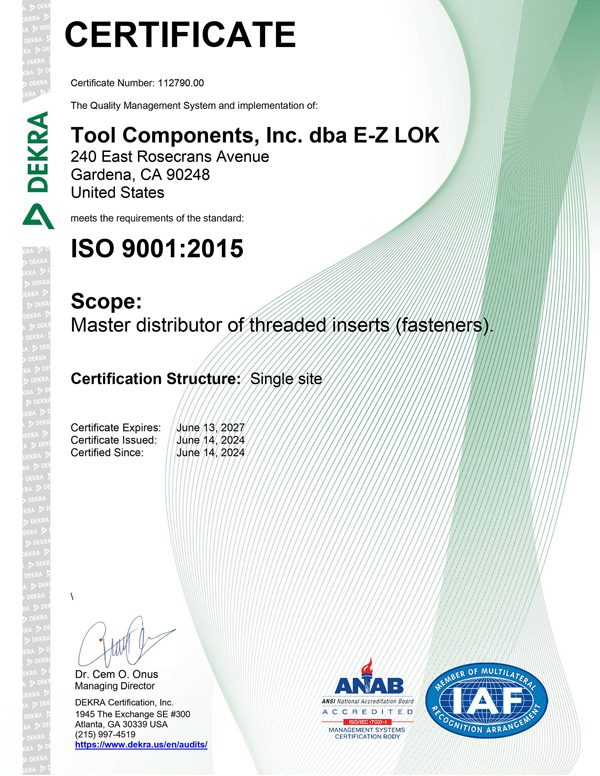

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, just announced it has received ISO 9001 certification. The announcement was made by Kyle Lindsly-Roach, Director of Sales & Marketing at the company’s Gardena, California headquarters.

With a quality management system that confirms to ISO 9001 standards in place, the company can now meet customer and other stakeholder needs within statutory and regulatory requirements related to their products.

The company started the certification process in January of this year because they saw the need for ISO certification to better support current and future customers. To do so, E-Z LOK partnered with a consulting company to design and build out their quality management system (QMS). Then, they implemented the QMS within their company. Lastly, the QMS was audited by an external company, thus verifying that the QMS was in place and effective.

Commenting on the benefits of the certification, Lindsly-Roach said, “This gives us the potential to work with OEMs and distributors who need a robust quality system in place for their vendors. It opens up additional business opportunities for us with those customers who require an ISO certification for their suppliers.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x 221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood now offers E-Z Hex™ (Hex Drive) inserts along with drive thread insert kits.

Generically referred to as Type D (flanged) or Type E (flush) insert nuts, E-Z Hex™ inserts provide sturdy machine threads in soft woods. These hex drives are an ideal solution for any application where assembly or disassembly could lead to thread erosion or stripping. This threaded insert for wood features broad external threads that provide superior holding power in materials like pine, composition board, MDF and plywood. E-Z Hex™ internal thread sizes range from #8 to ⅜-16, plus M6 and M8. Die-cast from a durable zinc alloy, these threaded inserts install quickly with an Allen wrench or optional drive tool.

Threaded inserts for wood are used in ready-to-assemble (RTA) furniture, drawer pulls, display cases, crating and anywhere threaded inserts are installed in softwood.

E-Z Hex™ threaded insert kits offer the parts needed to provide solid reinforcement to threaded holes in softwood materials. Depending on project requirements and available tools, the company offers standard hex drive threaded insert installation kits with the drive tool, drill bit and specific size inserts in both flanged and flush designs. Another option is threaded insert assortment kits that provide a variety of different insert sizes without the drive tool and drill bits.

FREE SAMPLE ON REQUEST

CAD files on this product can be downloaded in over 100 file formats from the E-Z LOK website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-

in ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Developed in 1998 with guidance from the International Fastener Institute, the CFS advanced technical training program is the most noteworthy measurement of technical aptitude for fastener professionals. With more than 1,400 alumni of the CFS program, the Fastener Training Institute has helped professionals and businesses nationwide advance the fastener and manufacturing industries by improving safety and championing professional development.

Wanting to further his education on the technical side of fastener related products, Lindsly-Roach participated in the CFS program. To receive the designation, participants must complete seven full-day training sessions or a weeklong intensive Fastener Training Week program (offered throughout the year) and pass a final exam. Classes feature topics such as: fastener specifications/terminology, dimensional/material specifications, the bolted joint, quality assurance and testing. Furthermore, the intensive training also includes plant tours.

Between December 4-8th 2023, Lindsly-Roach participated in the Fastener Training Week. Then, he took the CFS test mid-December. Upon passing, Lindsly-Roach received the CFS title/plaque. Commenting on how the certification adds value to his work at the company, he said, “This certification helps me be a more complete technical resource to our team at E-Z LOK on a variety of fastener related topics. It was also a great opportunity to network with like-minded individuals and companies in the fastener industry.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Sharing a booth with its sister company TCI Precision Metals

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood will display its products during IMTS 2024, in Chicago, September 9-14 in Booth 432123. The company will be co-located with its sister company TCI Precision Metals, a leading supplier of metal materials and near-net shapes to machine shops and fabricators. Highlight of the show for E-Z LOK will be its new line of ultrasonic/heat-stake metal inserts and staking tools for plastics, which can be used for OEM builds as well as retrofits and even injection molding over core pins for creation of strong components with higher torque and pullout strength in use.

In addition, the full line of E-Z LOK threaded carbon inserts with factory-applied LOCTITE™ 204 adhesive coating will be displayed. Once installed in a metal substrate for repair or added strength in an OEM application, the adhesive seals against liquids and gases to 6000 psi and can perform in temperatures up to 300°F. These proprietary inserts were developed by the current owner Ben Belzer’s grandfather for the aerospace industry as an alternative to helical inserts.

A new feature of the E-Z LOK website, www.ezlok.com is the CAD file, which allows an engineer to incorporate any of the thousands of E-Z LOK insert into a design.

Director of Sales & Marketing, Kyle Lindsly-Roach and a team of E-Z LOK engineers will attend the show, displaying the full line of E-Z LOK products. Emphasis will be placed on the company’s threaded inserts for metal, wood and plastic. Speaking about his hopes for the show, Lindsly-Roach said, “We are excited to be able to present our portfolio of products to a wide range of customers, including engineers, OEMs and distributors. We hope to be able to expand our customer base and the industries where our products are, as well as our existing supply chain partners in the OEM, fastener distributor and machine shops.”

Visit E-Z LOK at IMTS Booth 432123 during the show.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional and national industrial distributors, as well as direct to major OEM’s in a variety of end user market segments.

Continue reading

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood will display its products during Fastener Fair, May 22-23th at the Huntington Convention Center in Cleveland, Ohio.

Fastener Fair is North America’s premier trade show and conference for the fastener industry and its allied manufacturing sectors. It covers every facet of the industry from manufacturers to master distributors, equipment makers, processors, packagers, and end-users. Industries represented include advanced manufacturing, aerospace, agriculture and off-highway, appliances, automotive, construction, distribution and electronic/telecom. Additional industries are furniture, industrial machinery, maintenance, marine military and renewable energy.

The event provides a unique opportunity for attendees to network with peers, exchange ideas and establish new relationships. They can explore the latest products and technologies in the fastener industry and gain insights into emerging trends. Furthermore, expert-led sessions and workshops offer valuable insights into the latest industry developments, best practices and regulatory updates. Companies can source new suppliers, evaluate products/services and compare prices to make informed purchasing decisions. Lastly, Fastener Fair provides participants with the ability to enhance their professional skills, expand their knowledge base and stay abreast of industry trends and advancements.

Director of Sales & Marketing, Kyle Lindsly-Roach will be at the show, displaying the full line of E-Z LOK products. Emphasis will be placed on the company’s threaded inserts for metal, wood and plastic. Speaking about his hopes for the show, Lindsly-Roach said, “We are excited to be able to present our portfolio of products to a wide range of customers, including engineers, OEMs and distributors. We hope to be able to expand our customer base and industries our products are used in.”

Visit E-Z LOK at stand 542 during the show.

FREE SAMPLE ON REQUEST

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Continue reading

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood is now offering E-Z™ Knife brass and stainless steel threaded inserts for wood.

Suited for use in hardwoods like oak, cherry and maple, these inserts are ideal wherever assembly or disassembly could cause thread erosion or stripping. E-Z Knife™ threaded inserts use a proprietary external “knife” thread to slice into the wood and provide superior holding power. They are most often machined out of brass when internal thread sizes range from #4 to ⅜ or M3 to M8. Notable features include superior hardwood holding power with sizes available in inch (coarse/fine) and metric. The inserts easily install with a bolt/jam nut or optional drive tool.

Brass inserts are ideal for furniture, cabinetry and partitions, while stainless steel is used in marine applications. Several industries including shipping containers, outdoor furniture and storm shutters use either.

E-Z™ Knife threaded inserts and thread repair kits provide an easy solution for adding machine threads to hard woods. They can also be used for softwood, but they are not recommended for plywood. A proprietary external thread for superior holding power is used by these inserts.

FREE SAMPLE ON REQUEST

CAD files on this product can be downloaded in over 100 file formats from the E-Z LOK website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Continue reading

E-Z Lok, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood offers E-Z Press™ inserts.

Press-in Inserts are designed for post-molding installation in either thermoset plastics or thermoplastics. A slotted design with diamond-knurled OD allows for “cold” installation with optimum torque/pull-out resistance. When the E-Z Press™ insert is installed, it compresses slightly along the slot. As the fastener is threaded into place, the insert expands and the diamond knurl is pressed into the wall of the hole, securing the insert in place.

Cold installation of threaded inserts reduces the costs of moldings and eliminates the need to “chase” threads after molding. Furthermore, they also help cut reject waste caused by misaligned and faulty inserts and assist in proper installation without a precise hole depth.

E-Z Press™ inserts are available in three styles: flush, flanged, and reverse slot. All three types press into place for fast, easy installation. Anything from a rubber mallet to an arbor press can be used for installation.

CAD files on this product can be downloaded in over 100 file formats from the E-Z Lok website at https://www.ezlok.com/cad-downloads

FREE SAMPLE ON REQUEST

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z Lok

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z Lok is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hard wood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z Lok is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Continue reading

E-Z Lok, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood now offers E-Z Coil™ and thread repair kits.

Wire or helical coil threaded inserts quickly repair or reinforce tapped holes in soft metals. Made from 18-8 stainless steel wire, these helical coil inserts are corrosion resistant and can withstand temperatures up to 800°F. Furthermore, they offer corrosion resistance and protection from wearing and stripping.

E-Z Coil™ helical insert coils are manufactured by forming the stainless steel wire into a diamond shape and then winding it into a spring. Prior to installation, the insert diameters are larger than the tapped hole. During installation, the insert diameter of the helical coil insert is reduced, allowing the insert to thread into the hole. Once properly installed, the radial pressure of the released insert holds the insert firmly in place.

Thread Repair kits are available in both standard and economy, and in a variety of sizes. Each Economy E-Z Coil™ Thread Repair kit includes a set of inserts, an STI tap, and an installation tool. The standard kit also includes a tang break tool and drill bit.

CAD files on this product can be downloaded in over 100 file formats from the E-Z Lok website at https://www.ezlok.com/cad-downloads

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z Lok

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z Lok is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for soft wood and brass knife threads for hard wood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z Lok is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Continue reading