Contact us today:

Author Archives: Bernard & Company

REP Corporation Relocating Headquarters

Company moving HQ to Kodak, Tennessee, near Knoxville; plans to retain Chicago area facility for sales and service of its molding machinery

REP Corporation (Bartlett, Illinois), the market leader in rubber molding machinery, today announces plans to relocate their corporate headquarters to Kodak, Tennessee, near Knoxville. The new facility is currently under construction and will be open in early 2019, according to company President Tim Graham. From the new location, REP Corporation will conduct sales, service, engineering and machine demonstrations, plus parts warehousing, for customers in North America. REP Corporation is a subsidiary of the REP International, based in Lyon, France.

REP Corporation management shown with Mayor Larry Waters of Sevier County, Tennessee, upon completion of the agreement to relocate the corporate headquarters. Shown left to right: Brian Boyle, Regional Sales Manager Jeff Tanner, Regional Sales Manager Josh Beachum, Technical Director James Wirtz II, Aftersales Director Larry Waters, Mayor Sevier County Timothy Graham, President REP Corporation Derek Williams, National Sales Director Anna Seel, Accounting Director

Plans include the employment of approximately 20 people for administration, engineering, sales and field service. REP Corporation currently maintains an install base of more than 3000 machines and has been selling in the North American market since 1970.

The current facility in Bartlett, Illinois near Chicago, will be maintained as a sales and service office for the company.

Aftersales Director Jim Wirtz explains, “We began our search about two years ago, recognizing the migration of the rubber industry to the South, as it follows the primary automotive OEM. We were impressed by the efforts of Sevier County in Tennessee, especially Sevier County Mayor Larry Waters plus Allen Newton and his team at the Economic Development Council. This is a major step for REP, as we’ve occupied essentially the same location in Chicagoland since we began here in 1970. We look forward to broadening our presence in the country and becoming part of this vibrant new industrial community in Kodak.”

Technical Director at REP, Josh Beachum, adds, “One of the strong factors in our decision was the talent pool of young engineers in this area, combined with the technical training options available to us. The rubber molding business has a very unique set of chemistries and manufacturing technologies that require ongoing training and mastery.”

Anna Seel, the Accounting Director at REP Corporation, notes, “We will provide very competitive wages and benefit package to our new employees, most of whom will come from the local community. This second location will help us provide support to our customers more effectively.”

National Sales Director Derek Williams further states, “This move represents an opportunity to support our transplanted existing customers who have followed the auto industry to the South, plus the newly emerging markets here.”

Tim Graham, concludes, “We’ve received a very enthusiastic welcome from the local business community here, making this decision to relocate from our longtime Chicago headquarters an easier move.” He added the company plans to relocate immediately upon completion of the new facility, located in the Smith-Thomas Technology Park in Kodak.

REP provides the North America rubber industry with a full range of injection and compression presses, plus laser mold cleaning and other ancillary equipment, as well as REP Pack 4.0, its proprietary software suite for the management of all press parameters and machine kinematics, providing manageable data for the digital factory and Industry 4.0, the rapidly advancing standard for rubber factory operations.

For more information on this announcement, please contact:

REP Corporation

8N740 Tameling Court

Bartlett, IL 60103-8146

Phone: 847-697-7210

www.repinjection.com

Attention: Tim Graham or Jim Wirtz

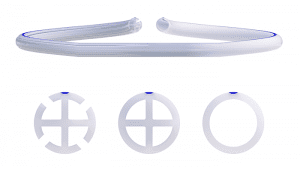

Guill Introduces Reciprocating Head

Automated extrusion process drastically changes the extruded profile

While cost and value stream activities are reduced, quality is improved. Only one extrusion run is needed to produce a finished product, as opposed to multiple extrusion runs with tooling changes along with a manual assembly operation to connect different tubing shapes. Guill’s new reciprocating head eliminates an assembly operation. It also eliminates in-process inventory. Thus, there is no need for storage of various tubing shapes and connectors needed for assembly, fulfillment of orders and replenishment of finished goods.

Furthermore, the reciprocating head eliminates a connecting piece, allows JIT production and products made-to-order. Lastly, it reduces total run time from receiving the order to shipping.

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Telephone: 401-828-7600

www.guill.com

bconley@guill.com

GMTA Now Represents WEMA Glauchau GmbH

The full line of WEMA grinding machines includes internal, universal, external, roller bearing, and customized solutions.

German Machine Tools of America is now the North American distributor of WEMA Glauchau GmbH. These high precision grinding machines will be shown by GMTA at IMTS 2018.

WEMA’s internal grinding machines maximize operating times with more efficient and integrated procedures. A repeatedly allocable tool and workpiece headstock are guided on up to six axes with an accuracy of 0.1 μm. WEMA SI is scalable and is adapted to the clients’ needs through specific mounting for the greatest machining efficiency. Powerful drives ensure quick availability with additional work and peripheral modules reducing costly non-productive times. Available in 4 different series (S2I, S3I, S6I and S10I), it offers machining of chuck and shaft-shaped parts. In addition, the internal grinding machines are equipped with internal cylinder/ cone, internal polygons, internal screw threads, up to 4 applicable grinding tools and high rigidity through the use of cast beds/hydropol beds.

The company’s external grinding machines can machine parts up to 1,500 kg with external lengths of Ø 600 mm and 2,700 mm. Grinding wheels are available in Ø 500, 600, and 750 mm. Typical workpieces include railway axles, rollers, pipes and shafts.

Although the company’s grinding machines cover a wide range of possible applications, they also build and design grinding machines to order ranging from more or less customized adaptations to complete designs of the machine.

For more information, please contact:

Scott Knoy

Vice President

German Machine Tools of America (GMTA)

Ann Arbor, Michigan

Office: 734-973-7800

Fax: 734-973-3053

Email: scott@gmtamerica.com

www.gmtamerica.com

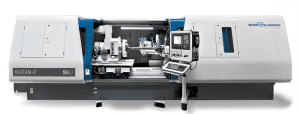

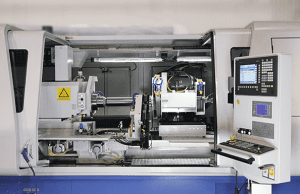

Schütte Offers Its SCX, CNC Multi-Spindle Automatic Lathe

In today’s industrial production, more complex workpieces are being produced in smaller batch sizes and shorter life cycles. To remain competitive, manufacturers have to react quickly and flexibly to market requirements.

These conditions have been met with the creation of Schütte’s multi-spindle automatic lathes. Everything that is not directly related to the production of workpieces has been eliminated from the machining area. There are no drives, cables, slides, lubrication lines or cooling lines within the tooling area. The clean and freely accessible machining area provides clients with the greatest possible configuration flexibility and the simplest retooling and tool retrofitting.

The SCX from Schütte offers several benefits. Some of these are free speed selection and free falling chips. Furthermore, extended machining options are available on the second workpiece side through exact transfer and three additional spindles. Expansion of the machining range is achieved through extended rear-side machining including C-and Y-axis. Lastly, multi-spindle production provides clients with a wide variety of workpiece geometries.

For further information, please contact:

Brittany Oulch

SCHUTTE USA, LLC

4055 Morrill Road

Jackson, MI 49201

Phone: 517-782-3600 ex.10

www.schutteusa.com

boulch@schutteusa.com

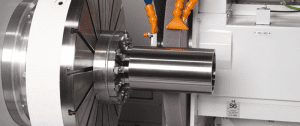

Guill Introduces Large Die Cart with Crosshead

Additionally, the tooling section features quadrant heating. Guill’s crosshead stand is equipped with an integral alignment station and concentric role guide. The stand is also an integral cleaning station, so clients don’t need to remove the crosshead for cleaning. Lastly, this crosshead has “on-the fly” catenary adjustment and can be easily maintained with simple hand tools.

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

www.guill.com

Longtime Chemcoaters Director, Bill Krippes, Retires

Bill has been in the coil and mill-applied coating industry for over 46 years, serving in R&D, Technical Service, and Sales roles. He started his career developing products for JM Eltzroth before moving on to spend more than a decade at PPG specializing in mill-applied coatings, with a specialty in dry film lubricants (Chemform) and mill-applied zinc phosphates. In 2001, Bill brought his experience and knowledge to Chemcoaters in Gary, Indiana. While here, Bill has been a staple of the organization. His expertise in dry-film lubes for stamping and his product development skills have helped advance Chemcoaters’ core business and aided in educating a future generation of employees.

In August, Bill will officially retire but will continue to serve as a New Business Development Consultant. In that role, he will continue to help Chemcoaters’ customers find coating solutions to overcome issues with stamping and corrosion.

As Bill moves into his new consulting role, Brit Capizzano will move into the role of R&D manager. Brit has spent the last 6 years under the guidance and mentorship of Bill. Moving into the future, Chemcoaters will continue to provide customers with unique coating solutions and unparalleled expertise.

Based in Gary, Indiana, Chemcoaters, Inc. is a leading supplier of green coil coatings, as well as traditional prepaint and protective coil coatings such as dry film lubes and other RoHS-compliant coatings. Virtually no VOCs or HAPs are present in the process. The company’s patented InterCoat® ChemGuard 300 coating is formulated with trivalent chrome vs. hexavalent chrome, making it environmentally friendly in all building, architectural, transportation and consumer appliance applications. InterCoat® ChemGuard 300 coating has superior corrosion resistance, as well. Chemcoaters offers a presentation on their unique and proprietary patented coating that evidences this fact to all interested parties.

For more information, please contact:

Bill Capizzano, President

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: billc@chemcoaters.com

or

Mike Tieri, Vice President, Sales & Marketing

Phone: 708-715-7759

Email: MikeT@chemcoaters.com

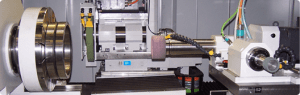

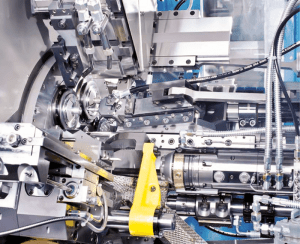

Schütte Offers PC Multi-Spindle Automatics

Often, manufacturers need automatics that have greater capabilities. These include the machining of non-ferrous metal or steel, a combination of heavy roughing and accuracy, simple programming combined with versatility and a single machine that performs several production processes. The answer to these challenges is Schütte’s PC series.

Automatics in the PC series are machining centers. They are used whenever classic cam-controlled automatics reach their limit. Besides turning, PC multi-spindle automatics perform tapping, mill cutting, polygon cutting and eccentric drilling operations. Six or eight work spindles, endworking and cross slides can be controlled independently of each other. Rear-side machining can have up to three tools. Over 56 CNC axes can be easily programmed with Schütte’s SICS 2000 system.

PC multi-spindle automatics are designed for material removal of geometrically sophisticated parts made of hard solid materials. The machines are designed to be robust, durable and technically flexible for complex drilling operations. Furthermore, they provide ready-to-install precision parts in large and small batch sizes. Machines in the PC series feature short setup, non-production and part production times.

These machines are used by automobile manufacturers and suppliers, the fittings, pneumatics and hydraulics sector, as well as in the production of precision parts.

For further information, please contact:

Brittany Oulch

SCHUTTE USA, LLC

4055 Morrill Road

Jackson, MI 49201

Phone: 517-782-3600 ex.10

www.schutteusa.com

boulch@schutteusa.com

Major Automotive Supplier Expands Its Market with Schuler Presses

Huissel utilizes MSP servo presses for high production of complex stampings

Canton, Michigan – Huissel, well-known as a reliable die and sheet metal part supplier for the European automotive and supplier industry, looked to Schuler presses to help expand their market.

“We examined suppliers from Spain and Italy to Germany,” says Peter Busalt. “But only the MSP series from Schuler currently has the functions we need.” Gerald Schug adds, “The ease of operability of the machine was important for us, for example, because this aspect helps even inexperienced employees quickly achieve good results in regard to taking advantage of the full potential of the servo press.”

The commissioning of the new press is also considerably faster thanks to a digital twin. Here, the virtual system model is connected to the real control system with the machine and system visualization system. All functions of the MSP 800 can be simulated on the computer in this manner. The functionality and operation of the system can therefore be tested and trained on the real machine.

Huissel will set up a new building in its Enkenbach-Alsenborn factory for the MSP 800. As a whole, this project is the largest single investment in the company’s 100-year history. Huissel also intends to attach dies that it has manufactured in its Frankenthal factory 25 miles away to the new servo press. The tie rod structure of the MSP 800, which offers particularly high rigidity, also guarantees the quality of the parts production.

Schuler presented the MSP 400, a smaller version of the MSP 800, to the general public at the EuroBLECH trade fair in Hanover for the first time. The smallest members of the group, the single-rod automatic blanking press CSP 100 and the double-rod automatic blanking press MSP 200, are already in use at stamping companies. What all these presses have in common is the innovative knuckle-joint drive with highly dynamic servo motors and additional smart functions, such as condition monitoring.

Schuler is currently in development and will soon offer a press force of 1,250 tons.

For more information, please visit:

www.schulergroup.com/servopresses

For further information on Schuler Inc., North America, please contact:

Jeferson Valerio, Director of Sales

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

info@schulerinc.com

www.schulergroup.com

Hoist Attachment Handles All 55 Gallon Drums

The HCB hoist attachment safely lifts steel, fiber and plastic drums weighing up to 2000 lbs. using Liftomatic’s exclusive “Parrot-Beak®” drum handling attachment. The model HCB-BC attaches to any overhead hoist, crane or boom and engages drums automatically. Liftomatic’s exclusive mechanical clamping system engages the top lip of the container, assuring a safe and reliable pick-up each time.

An adjustable counter-balance on the main frame of the unit allows for safe handling of all drums from 15 to 27 inches in diameter. A padded belt cradle protects the drum sidewall during transport. The model HCB is available in 1 or 2 drum configurations, including stainless steel units for food grade and pharmaceutical applications.

Liftomatic Material Handling, Inc. is an acknowledged leader in the design and manufacture of drum handling equipment. Headquartered in Buffalo Grove, Illinois, Liftomatic maintains manufacturing, engineering and sales facilities around the globe. Liftomatic currently sells products in over 40 countries and sells to more than 400 of the Fortune 500 companies.

For more information, please contact:

Liftomatic Material Handling, Inc.,

700 Dartmouth Lane, Buffalo Grove, IL 60089,

Sales Dept. 847-325-2930

Web: www.liftomatic.com

Email: info@liftomatic.com

For more product information, please contact:

George Gambini

Liftomatic Material Handling

700 Dartmouth Lane

Buffalo Grove, IL 60089

sales@liftomatic.com

847-325-2930 ext. 1226

www.liftomatic.com

Increasing Static Friction with Laser

By Gerhard Flores, Manager of Technology Development and Intellectual Property

Gehring, Farmington Hills, Michigan

Note to editor: Information in this article was derived from the presentation given by Gerhard Flores at AGMA’s Fall Technical Meeting between September 24th and 26th in Chicago.

Gerhard Flores discusses the need for flat and curved surfaces with the functionality of high static friction for force-fitted nonslip power transmissions. This need is especially true for con rod and cam structuring for high torque resistance or front face connections of sprockets, gears or cam shaft adjustments. He details that expensive solutions like diamond layers, coatings or form fitting design are being substituted. Instead, innovative manufacturing is now performed by a modified laser process with defined exposed micro structures. The prerequisite for high friction is exposed micro melting burrs of smaller micrometer height with martensitic material structures. As a result, high static friction surfaces can be produced economically with repeatability of small tolerances in high-volume productions.

The principal feature of the adhesive system was revealed in a stress test. In it, hardened and structured contact surfaces are loaded against non-structured and unhardened ones with an axial force of 80 kN over 60 seconds for a twist angle of 4 degrees. The course of torque was indicated as target value. The contact areas (di= 15 m, da= 30 mm) were dry and free of grease. At the junction of adhesive and sliding friction, there is a maximum of adhesive value.

Using the adhesive friction bench or the functional aggregate, the effects of structure can be evaluated. Every structure that increases adhesive friction is characterized by a raised profile contour that has influence on the counter body. Next, manifold micro form profiles are produced to absorb shearing forces. Furthermore, the micro form profiles result in a frictional connection with high adhesive friction value. Due to the thermal effect of the laser beam, hardness is generated due to the short heating time.

There are significant differences in the laser structured adhesive friction surfaces of cams, connecting rods, front face connections and pre-treated substrate surfaces. Cam topographies can be raised with low profile elevations and without deepening. Material melts evenly. The structure lines of connecting rods are equidistant superposed. Both cam shafts and connecting rods can absorb torque of shaft hub joints. Between the structures of front face connections, there are often deepenings caused by material transfer. Lastly, pre-treated substrate surfaces display a squamous structure with micro recesses and are suitable to join layer materials to substrates.

Laser structuring of adhesive friction surfaces in rigid friction type connections can substitute positive locking design connections or other expensive friction type connections like diamond interlayers. The achievable adhesive value depends on the depth of the height, the profile shape of the laser structured roughness profile, the arrangement of the structure density, the martensitic properties of lasered materials, the normal force and whether the lubricant is embedded in the contact surfaces or not.

Different connections with torsional strength have different cylindrical contact surfaces. A shrinking connection with the laser structured inner surface of the cam and the shaft, enables the cost effective built cam shaft in serial production. In the case of the clamping connection shaft and the hub, the laser structured contact surfaces are engaged by clamping. This replaces the costly alternative of positive connections. In this way, pin or fitting connections can be replaced by friction type contact surfaces with high adhesive friction generated by the laser structured process.

Another category is the frictional connections of plain functional surfaces for the transmission of shearing forces of torques. The laser structured front surface, often designed with an alignment element replaces cost-intensive solutions like form-locked joint coupling with frontal tooling or inserted diamond or SiC interlayers as slices for the increase of the friction value. Applications related to the combustion engine like pinion, cam shaft adjuster, ball bearing or related to the chassis frame are becoming frequently demanded alternatives to the expensive solutions with slices and interlayers.

Laser structuring of the connecting rods is realized by means of the crank pin, which joins the connecting rod and the crankshaft. The design of the bearing consists of the rod eye, the bearing shell and the crank pin of the crankshaft. There is a rotational relative movement between the crank pin and the inner side of the bearing shell. The joint is laid out as a sliding bearing and works with low friction. However, there is no movement allowed between the outer side of the bearing shell and the connecting rod bore. Here, a sufficient high adhesion is required to absorb the frictions within the sliding bearing. Next, a frictional connection is necessary to deliver the suitable torque strength by means of the elevated topography of the connecting rod and the resulting adhesion.

For the process of laser structuring, a solid body laser with scanning optics is used. The two beam sources are arranged above the connecting rod eye laterally, the connecting rod bore. The beam sources work simultaneously and structure each of the two areas with the connecting rod bore. In each unit, the pulsed beam is guided by the galvanometer scanners with two galvanometer mirrors each. There is no mechanically actuated displacement or positioning of the beam and the focal movement is carried out quickly, line by line, with the highest precision and simultaneously by the movable optics of the integrated scanning heads.

The laser structuring of cams takes place after the shaft and cams are machined as single parts and are assembled by thermal friction type connected processes. In order to achieve sufficient torque strength of the cams, their bores are structured for enhanced adhesion.

Friction type connections are applied in several sectors of mechanical engineering and vehicle design for the transmission of shearing forces and torque. Frontal face connections with plain contact surfaces are laser structured in serial production. Cam shaft adjuster, chain pinions or gears are the focus of the central valve of Schaeffler with the cam shaft in serial production. This valuable technology reduces carbon dioxide emissions. By laser structuring of the main bearing, a high torsion strength of the bearing shell can be realized by the roughly structured areas of a cylindrical type connection as well as heat transfer by the smooth unstructured areas.

In conclusion, the advantage of laser structuring with integrated scanning is that the structuring segments on curved and plain surfaces can be freely dimensioned and positioned. In addition, the structure data and the tolerances of the different surface values can be adjusted by the beam parameter. The structuring process is completely automatable and can be integrated in a production line. Laser structuring allows an increase of static friction up to 5 times. Compared with diamond interlayers, the costs and number of parts is significantly lower.

For more information, please contact:

Jacqueline Fette

Marketing Manager

Gehring

24800 Drake Road

Farmington Hills, Michigan, 48335

Cell: +1 248 954 8383

Email: Jacqueline.fette@gehring-group.com