Contact us today:

Author Archives: Bernard and Company

Family, Friends and Industry Mourn Loss Of Roger Guillemette

A. Roger Guillemette, 81, of Narragansett, Rhode Island, died Friday, June 5th. Born in Providence, RI, he was the son of the late Joseph Arthur and Yvonne (Roy) Guillemette, both Canadian born.

Roger graduated from Coventry High School and served as a machinist in the US Army, 600th Engineering Aviation Maintenance Co. He was stationed in

He and his wife Claudette raised their four children in the village of Phenix, RI where they hosted many a sing-a-long around their piano. Among the many other things in life he thoroughly enjoyed, Roger loved playing Skip-Bo with his family and friends.

An entrepreneur, he established several businesses throughout his lifetime, creating long-term steady employment opportunities for many people. Guill Tool & Engineering Company was established in 1962 and remains in operation today, as a global leader in extrusion tooling. Until recently, Roger was very active as the CEO and always an inspiration to his employees, as his passion for engineering quality products and customer solutions never waned. He had been a fierce advocate for U.S. manufacturing on local and national levels; participating in many organizations as well as advocating for STEM education in the state of Rhode Island.

Professionally, Roger was SE MA Chapter past President of NTMA-RI and a longtime member of the Wire Association and Society of Plastic Engineers. Guill Tool, as a result of Roger’s leadership and drive, remains active in the Rhode Island Manufacturers Association, National Association of Manufacturers, National Institute of Manufacturing Skills, the Rhode Island STEM Center and other local endeavors for the betterment of the industry and community.

Memorial contributions may be made to The Johnny Cake Center of Peace Dale, 1231 Kingstown Rd., Peace Dale, RI 02879. Visit www.nardolillo.com for online condolences.

For more information, please contact:

Rich Guillemette

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

www.guill.com

rguillemette@guill.com

500ºF Electric Walk-in Oven

No. 901 is a 1200ºF (649ºC), electrically-heated walk-in oven from Grieve, currently used for heat treating at the customer’s facility. Workspace dimensions of this oven measure 48” W x 60” D x 72” H. 120 kW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 12,500 CFM, 10-HP recirculating blower provides horizontal airflow to the workload.

This Grieve high-temp walk-in oven features 10” thick insulated walls, comprising 2” of 1900ºF block and 8” of 10 lb/cf density rockwool; inner and outer door gaskets with the inner gasket sealing directly against the door plug, while the outer gasket seals against the front face of the oven; doors equipped with expansion joints on the inner face to guarantee uniform sealing at all temperatures; aluminized steel exterior; Type 304, 2B finish stainless steel interior; 7” insulated floor with truck wheel guide tracks and a 2000 lb. capacity stainless steel shelf oven truck with shelf supports on 6” centers.

Controls on No. 901 include a 325 CFM stainless steel powered forced exhauster with motorized dampers for cooling, manual reset excess temperature controller with separate contactors, recirculating airflow safety switch, 10” diameter circular chart recorder, digital indicating and programming temperature controller and an SCR power controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Siemens Enhances Sinamics G120 Drive Platform with Industrial Ethernet Connectivity

See it at Pack Expo 2015! Siemens Booth: S-6137

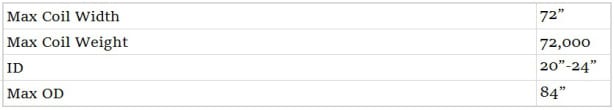

Siemens has announced that its versatile Sinamics G120 drive system has been enhanced to include EtherNet/IP connectivity, thus providing maximum flexibility for industrial Ethernet communication while offering innovative concepts for those wanting a single network for the entire plant.

“In many instances, plant managers have the requirement for a single-plant network, particularly with large automotive, packaging, plastics, metals, food and beverage as well as material handling companies,” says Robert Soré, Siemens product manager, Sinamics G drives. “Our Sinamics G120 drive provides communications without limits to a specific network type.”

Sinamics G120 drives support, as standard, Profibus DP and Profinet to ensure seamless communications between every component involved in a typical automation solution including HMI (operator control and visualization) and I/O. Additional higher-level functions, including Safety Integrated telegrams and synchronized mechanisms for even the highest level control applications are also included.

Profinet can transmit operating and diagnostics data simultaneously to enterprise-level systems using standard IT mechanisms (TCP/IP) for an integrated factory environment. The new addition of an EtherNet/IP stack offers another option for Sinamics G120 users. Having the flexibility to communicate with the most common automation systems via Profinet or EtherNet/IP makes the Sinamics G120 drive system easily adaptable to the current Industrial Ethernet boom.

The Sinamics drive platform from Siemens provides users maximum flexibility

with industrial Ethernet connectivity.

With a wide power range (0.50 – 350 hp), highly scalable solutions, including safety integrated functionality and convenient start-up with Siemens Starter software, the Sinamics G120 drive is a powerful solution for a variety of applications, including packaging, plastics molding and extrusion, textile, printing and paper machines,

handling and assembly systems, rolling mills and test stands.

For more information about Siemens connectivity to EtherNet / IP platforms, visit www.usa.siemens.com/eip-drives.

For more information about the Sinamics G120 drive platform, visit www.usa.siemens.com/sinamics-g120.

—

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingEngineering White Paper: Check Weighing Systems

Introduction

This news release discusses the challenges, options and solutions for process manufacturers when checking packages for the consumer and/or processing industry.

Background on Check-Weighing

Check-weighers are automated systems designed for checking the weight of packaged commodities for the purposes of internal control and external trade application. The checking process is usually found at the end of production processes in any given industrial process flow.

For external trade applications, legal requirement is obligatory. The worldwide O.I.ML. (International Organization for Legal Metrology) recommendation R51 outlines these rules, while the MID (Measurements Instruments Directive) is Europe specific and the NIST Handbook 44, edition 2014, covering check weighers in chapter 2.24 is relevant to the United States.

There are two types of check weighers:

- Category X: determine and compare the weight within defined tolerances for purposes of acceptance or discarding of a package. Such tolerances are typically mandated, similar to the e-mark registration. Packages that are outside of the given tolerances are automatically removed from the process line.

- Category Y: determine the package mass which is useful when establishing price calculations based on weight

Both categories can be static or dynamic. In the latter case, the package is in motion for example on a conveyor belt. This will typically have an adverse effect on the weight due to accelerations and vibrations of the mechanical parts. Under such circumstances PENKO instruments excel because of their sophisticated state-of-the-art filtering processes. Furthermore, they are certified in accordance with the MID directive and OIML R51 recommendation. For registration purposes, PENKO offers specifically designed e-marking software.

Measurements Instruments Directive (MID) Requirements

Background information on required accuracies is found in OIML recommendation R 51-1, edition 2006, tables 1, 2 3, 4 and 5.

Category Y instruments

The following image shows a typical example of a combination of eight class Y check weighers; in this particular case for bulk loading of trucks. The graph shows a negative dosing effect.

Category X instruments

Below are two typical examples of a static or dynamic class X check weighers. The first graphic depicts a pusher – ; the second image shows discrimination of under- and overweight.

Note: these combinations of belt conveyors belt can also be used, optionally without pusher(s) for class Y applications.

Competitive Advantage

A high resolution filtering system combined with high speed – high accuracy measuring, offers smart weighing results for any operation environment.

All instruments are certified and approved with an accuracy of 10.000d. The combination of measuring at high speed (1600 samples/s) with a high internal resolution (24 bits), smart filters and sufficient computing capacity, make the SGM800, 1020 Controller and FLEX range suitable for any check application. The combination of the high resolution and conversion speed guarantees the best achievable mass control accuracy even at high speeds, thus preventing eliminations of packages and recalls.

Product Solution

The SGM800 range of digitizers/controllers, model 1020, model FLEX-2100 and FLEX.

Conclusion

PENKO instruments control the filling system as well as the checking application all in one. All PENKO systems are “Slave” systems.

Checking packages for trade at high speed and accurate while adhering to regulations in the most effective way, remains a challenge throughout the processing industry and will vary from one manufacturer to another. Consideration not only needs to be given to dynamic effects, but the prevention for not correct filled packages to enter the market and disapproving of parties of packages and recalls.

To engineer the most efficient way per industry, per product, per manufacturer, there is no “one-size-fits-all” solution. Engineers at PENKO work out the best and most effective way this can be done.

For more information, please contact marketing manager Susanne Krause at Penko.

Email: skrause@penko.com

Rattunde Hosts Open House For Customers and Suppliers To Showcase New Facility

Major German supplier of finished length tube and solid bar processing equipment greets 100+ at new 30,000 square-foot facility in Grand Rapids area; plans to expand for full machine builds here

Rattunde Corporation, a German-based manufacturer of finished length tube and solid bar production systems, has been operating in the North American market for over eight years. The company’s success was celebrated with a technology open house on May 13-14, during which guests saw a resident machine in action, taking steel tube lengths and producing finished, cut-to-length, chamfered and machined tubing sections, automatically stacked for shipping, all within the work envelope of the machine.

Rattunde Corporation President Richard Stadler proudly opened the doors to the company, a 30,000 square-foot facility in Caledonia Township, near the company’s previous location in Grand Rapids, Michigan.

The plant houses the North American sales and service operations, plus spare parts inventory and manufacturing operations for the production of machine tooling. Areas within the new facility also house a technical center with a machine onsite at all times for demonstration and training. Future plans call for an expansion of the building to over 100,000 square feet, enabling Rattunde to produce their entire finished length tube and solid bar production systems here. This decision was reached, after an analysis of the current and anticipated business needs of the company, according to Stadler. “Our growth in North America has been rapid, though not unexpected, due to the unique nature of our equipment and the reliability and performance characteristics of our machines.” Stadler further noted that solid growth of the company into diverse markets throughout North America made the new facility a logical choice.

In commenting on the new facility, Richard Stadler noted, “There were several reasons why we wanted to remain in the greater Grand Rapids area, but one of the main reasons is the excellent talent base here. Companies are built on people and, whether you are looking for an experienced veteran of industry or a fresh graduate from one of our ranking high schools, colleges or universities, outstanding people can be found here in the Grand Rapids area.”

Concurrent with this development, Rattunde has expanded its workforce with technical service and administrative personnel. As Stadler explains, “Whenever a machinery company grows quickly, there’s an ever-present need for more customer service and technical personnel. Of course, new people must be found and trained.” Stadler went on to explain that rapid growth also means working smarter. Rather than waiting for a customer to reach out to Rattunde in a time of need, Rattunde is proactively sending technicians to the customer and performing comprehensive machine inspections, identifying and correcting small issues before they become large ones.

In the end, Stadler says, “This new facility solidifies our North American presence in the high-volume tube and solid bar production markets, thus benefiting our current and future customers in many ways. It’s a purpose-built building, with a forward-looking eye on all we will need to build our machines and systems from the ground up.”

Over 100 guests joined in this two-day event, watching the machine operate, examining the dedicated tooling Rattunde will produce onsite, participating in the technical sessions, led by Stadler and VP Alec Banish, plus enjoying the outdoor barbeque, as the weather cooperated nicely.

The attendees comprised Rattunde personnel, sales representatives from the North American network, honored guests from the parent company in Germany, plus numerous customers, prospective business partners and suppliers to the company. A good time was had by all!

For more information on this development, please contact:

RATTUNDE CORPORATION

5080 Beltway Drive SE

Caledonia, Michigan 49316 USA

Phone: 616.940.3340

Contacts: Rick Stadler, President or Alec Banish, Director of Business Development

Emails: r.stadler@rattunde-corp.com or a.banish@rattunde-corp.com

Web: www.rattunde-corp.com

550°F Universal Oven for Heating Heavy Metal Dies

This Grieve universal oven features 6” insulated walls, aluminized steel exterior, Type 304 stainless steel interior with 2B finish plus two 24” wide x 24” long shelves supported by rollers and each rated at 300 lb. load capacity. An integral oven leg stand is also provided.

No. 1034 controls include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Take A Look Inside! Exact Metrology Opens Its Doors

Product demonstrations and technical presentations from principals impress large crowd

On May 14, 2015, Exact Metrology held an open house at its Brookfield, Wisconsin facility and the event was attended by over 125 local area companies, comprising quality assessment, design engineering and management personnel from many of the leading manufacturers in the region. Hosted by company co-president Dean Solberg, the day included ongoing product demonstrations of the various metrology equipment brands offered for sale, lease and rental by Exact, as well as the testing procedures provided as a service by this unique metrology supplier.

Services on display at the Brookfield open house included 3D scanning, reverse engineering, quality inspection, instant scan-to-CAD comparison and a full suite of PolyWorks software solutions. Equipment shown at the event included Aicon 3D systems, Breuckmann 3D scanners, Leica Geosystems, Romer and Hexagon brands of scanning devices and related hardware, all of which were available for hands-on use by event attendees.

A new product of great interest to attendees was the Breuckmann steroScan, a flexible scanning system for precise 3D digitization and metrology. Applications for this product include quality inspection, reverse engineering, rapid prototyping, deformation analysis and digital documentation. Because of the adjustable focal length of the scanner, products from small components up to large sections of automotive and aircraft parts can be scanned with high resolution and accuracy. Breuckmann is a company of Aicon 3D Systems.

During the event, technical presentations were made by Aicon, PolyWorks by InnovMetric and Exact personnel on the newest advancements in 3D scanning technologies. The presentations were given to a “full house” of interested attendees.

As Dean Solberg commented, “We seek to find the right combination of equipment and services to suit the applications and challenges presented by our customers. In some cases, it’s a matter of matching the right standard equipment to the job, while at other times we bring custom solutions and services to our customers, whether they buy, lease, rent or simply use our services to achieve the desired results on projects.” Solberg credited his staff of metrology engineers, technicians and customer service personnel for their hard work, dedication and adaptability in seeking their correct solution to all customer challenges.

Exact Metrology is an ISO 9001:2008 Certified Company.

For more information on this new system, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Siemens Expands Its Sinamics V20 Drive Family For Basic Applications

Siemens announced today the release of its new single-axis Sinamics V20 AC drive, frame size E, with both Low Overload (LO) and High Overload (HO) ratings. The V20 family features easy setup and operation with excellent cost and energy efficiency. With a power rating ranging from 1/6–40hp at 480V AC, Sinamics V20 drives are available in five frame sizes and are ideal for material handling, conveyor, pump, fan and compressor applications.

This compact drive can be connected and installed the conventional wall-mounting method or, optionally, mounted with heat sinks pushed through the enclosure wall. Since no additional modules or add-on options are required for operation, installation time is minimized.

The integrated Basic Operator Panel (BOP) enables trouble-free commissioning and operation on-site. Besides the universal serial interfaces that allow for easy connection to Simatic programmable logic controllers (PLCs), a Modbus interface is also included for communication with third-party controls. Pre-built connection and application macros are used for facilitating application-specific settings. For units with power ratings higher than 10hp, a braking resistor can be connected directly to the integrated braking chopper.

Operating the Sinamics V20 drive is just as easy as commissioning. Parameters that have been optimized for one application can easily be transferred to other drive units using SD cards via the Basic Operator Panel or the battery-operated Parameter Loader. The built-in display has the ability to list only those parameters changed from the factory default values rather than having to scroll through all of them.

Tailored inter-connectivity and application macros (i.e. for pumps, fans and compressors) provide the correct settings for the particular application. The Keep Running Mode automatically adapts the V20 drive to the power supply to achieve higher availability when operated on unstable networks. In this mode, line fluctuations are compensated for internally and error messages are acknowledged autonomously. Thanks to enhanced cooling and coated PCBs and electronic components, the Sinamics V20 is extremely rugged, making the unit reliable even in harsh environments.

The demand-driven regulation of the motor speed also provides increased energy savings even for many applications. The Sinamics V20 is equipped with an energy-optimized control mode (ECO-mode) for increased energy efficiency. ECO-mode automatically adapts the magnetic flux in the motor to the optimum operating point. The DC link coupling enables efficient energy utilization of drives grouped together. The Sinamics V20 can also be set to hibernation mode, which prolongs the service life of the motor and also reduces system component wear (i.e. pumps). Additionally, by displaying real-time energy consumption on the operator panel display, the operator always has the drive’s energy and cost efficiencies in focus at all times.

For more information about the Sinamics V20 drive, please visit:

www.usa.siemens.com/sinamics-v20-pr

—

For specific product information and inquiries, call (800) 879-8079

ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com

Chemcoaters Announces New Price Matrix For Steel Sheet Coil Cleaning

Green coil coater also provides coil cleaning services, now at substantially reduced cost to mills, service centers, fabricators and OEM’s

Effective immediately, the following pricing matrix is effective until December 31, 2015 for Chemcoaters coil cleaning services, according to Mike Tieri, Director of Sales & Marketing for the company, a leading green coil coater based in Gary, Indiana.

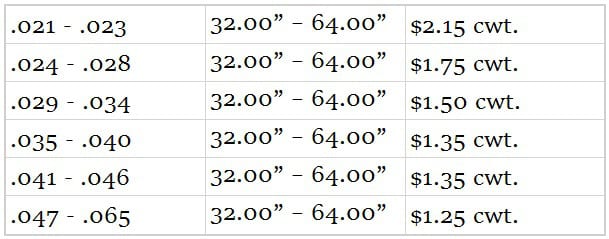

Sheet Steel Coil Cleaning Pricing Matrix

Pricing Good 4/7/2015-12/31/2015

* Matrix for coils up to 45,000#

* This price includes standard VCI wrap

* Single Paper Wrap $100 / Double Paper Wrap $200

Subject to Individual Pricing

All coil cleaning is performed on the processing line at the company’s main location in Gary, Indiana and comprises hot wash, chem rinsing and hot air drying, followed by careful recoiling and packaging for delivery back to the customer or other specified recipient.

Based in Gary, Indiana, Chemcoaters, Inc. is a leading supplier of green coil coatings, as well as traditional prepaint and protective coil coatings such as dry film lubes and other RoHS-compliant coatings. Virtually no VOCs or HAPs present in the process.

The company’s patented InterCoat® ChemGuard 300 coating is formulated with trivalent chrome vs. hexavalent chrome, making it environmentally friendly in all building, architectural, transportation and consumer appliance applications. InterCoat® ChemGuard 300 coating has superior corrosion resistance, as well. Chemcoaters offers a presentation that evidences this fact to all interested parties.

—

For more information, please contact:

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Connect with Chemcoaters online:

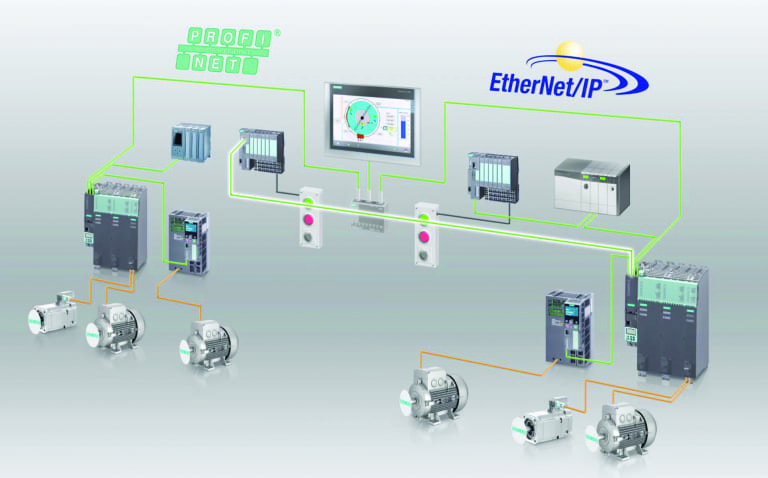

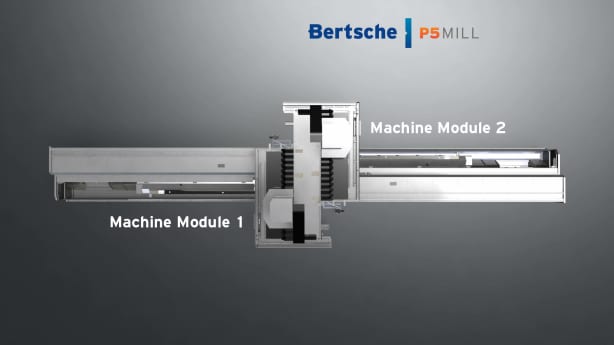

Dual P5 Mill from Bertsche

The Customer’s Challenge:

Significant new business, order intake

New customers

Steeply rising monthly production rates

Building/Facility space constraints

Solution: The Bertsche Two-in-One P5 Mill

Bertsche’s Dual P5 Mill allows dual work chamber manufacturing, independent or simultaneous, thereby saving considerable factory floor space for their aerospace customer.

Our aerospace customer was faced with the choice of either building a new facility to house two new milling machines or splitting their production between two manufacturing sites. Bertsche developed a new machine concept that offered the customer the productivity (throughput) of two machines and the floor space footprint requirements of one machine, thereby saving the customer the cost of building a 2nd facility and moving all production to a larger facility. The Bertsche Dual P5 Mill has all the benefits associated with having two machines, namely independent but linked CNC’s, two 5-axis machining modules ( A-side, B-side) each with separate machining chambers, the ability to machine two different parts at the same time and yet the overall machine is nearly the same size as a previously supplied single 5-axis P5 Mill. Based on the daily production requirements, the machine is operated A-side only, B-side only or A and B side together. Twin integral vacuum fixture tables are designed to accept a variety of different vacuum workholding fixtures that can be quickly changed at a moment’s notice, with a high degree of repeatability. To assist the operator loading parts, each table has retractable datum surfaces that swing into place to edge locate parts and then swing back down, when machining. Thick-walled composite structures (up to 0.625”) are milled, scalloped, edge trimmed and drilled on all sides. High accuracy hole patterns and datum holes are drilled for determinate assembly and then probed for accuracy. Parts are machined complete in a single setup and manufactured one-off to meet user ship-set kitting requirements.

With the growing trend towards cutting composites wet, flood coolant cutting was added and composite debris is flushed into a full bed length flume system. Flood coolant is constantly circulated throughout the machine for greater machine thermal stability. High volume mist collection hoods, integral to the machining compartment, collect and vent mist. A special sealing system is employed on linear ways to protect precision surfaces from very aggressive (detergent type) coolant fluids that must be used with composite materials. Multiple temperature sensors on the bed and X-axis slide accurately capture data for dynamic thermal compensation. To reduce the amount of filtration media, coolant is continuously filtered using a cyclonic filtration system.

Bertsche’s Dual P5 Mill allows dual work chamber manufacturing, independent or simultaneous, thereby saving considerable factory floor space for their aerospace customer.

Benefits:

- Very efficient use of available floor space with 2x the productivity compared to a previously installed machine

- Lower operating costs due to greater efficiencies

- Flexibility to better match daily production demands to available machine capacity

- Operate as single or twin machine

- Easier to manage work area

- Labor cost savings

- Longer tool life due to wet cutting composites

- Better air quality due to wet cutting (dust management)

- High response 2-axis head and spindle

- Thermal growth control

- Thermal growth compensation

- In machine probing, calibration and position verification (bore ring, sphere)

- Part drying provided as part of post machining operations

For more information on this story, please contact:

BERTSCHE ENGINEERING CORPORATION

711 Dartmouth Lane

Buffalo Grove, IL 60089

Phone: 847-537-8757

Fax: 847-537-1113

Web: www.bertsche.com

Email: info@bertsche.com

Attention: Rich Bertsche or Erich Bertsche