Contact us today:

Author Archives: Bernard and Company

Embedded PC Now Included in Siemens Motion Control System

The embedded PC, which features a DDR3 memory and an Intel Core2 processor, is free of wear from moving parts, such as hard disks and fans. This compact motion control system provides maximum flexibility and accommodates centralized or decentralized machine concepts for PC-based applications or for applications that require a compact size.

It is designed for many different motion control applications with its multiple onboard interfaces. They support communication over Profinet, the open industrial Ethernet standard, as well as Ethernet interfaces that run at 10 / 100 / 1000 megabit speeds. Four USB interfaces make it simple to connect a keyboard, USB stick, printer or other devices. A DVI port rounds out the links so users can attach a display or monitor. The Simotion P320-3 can also be used in a “headless” configuration without a display, monitor or front panel.

LEDs on the front indicate the operating states, making self-diagnosis easy. The integrated power supply bridges temporary power failures. In the buffered SRAM memory, the process data is saved securely even in the event of a sudden voltage drop. Monitoring functions for the batteries, temperature and program execution are also included. The Windows Embedded Standard 2009 operating system, which increases the reliability of the system, is pre-installed. Additionally, the Simotion runtime system comes installed on the Simotion P320-3.

Additional information is available online at: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingZoller to Demonstrate Its Machine Tool Presetter with Siemens Motion Control Information System

Offered to customers as a standard solution, Zoller has written an interface to connect TDI to the company’s presetter, enabling data to be brought directly into the Siemens numerical control. Zoller boasts accuracy on its presetters to two thousandths of a millimeter (0.002mm) or less than eight millionths of an inch (0.00008in).

By utilizing TDI and a Zoller presetter, a machine tool end-user benefits in many ways, including faster access to tool data with no manual entry of values required. All tool data are transferred to the CNC by an automatic link in the presetter, resulting in significant cost-, time- and operator action savings. In addition, the user develops an increased understanding of tool life and tool wear patterns on various operations in the shop. The Zoller presetter writes data directly onto an RFID chip, making transfer to TDI onboard the Siemens CNC is simple and easy. Lastly, an end-user can maintain a central server that indicates the location of any tool in the shop or factory, as well as track the status of the next tool needed to perform an upcoming operation.

Included in the Siemens TDI suite are the following:

- TDI Cell / TDI Plant — grouping of existing functions on a server- and network-wide operation of client-based interfaces

- TDI HMI — additional user interfaces for TDI Plant on a client PC

- TDI Overview Tool — actual data image with evaluation functions for the current tool stock using filters and manual tool actual data control

- TDI Planning of tool requirements based on the current tool stock

- TDI Tool Handling — operator-guided loading and unloading at the SINUMERIK 810D/840D/840Di and automatic data transfer in conjunction with the interface to the tool setting station

- TDI Interface — client-connection of external tool management and planning systems

- TDI Ident-connection of Tool Ident Systems at the SINUMERIK 810D/840D/840Di CNCs via Profibus or V.24 for reading and writing tool data

- TDI Machine Stand-Alone — a non-networkable function package for tool planning and linking to the tool setting stations for tool transfer

- TDI Tool — plan generation help module for generating tool plans based on simulation of the corresponding NC programs

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

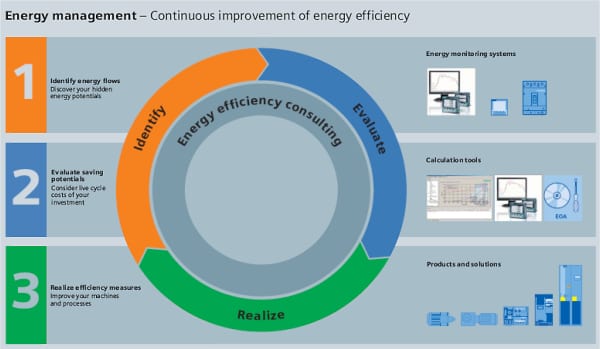

Energy Management Considerations with Today’s Drive Systems

ENERGY MANAGEMENT CONSIDERATIONS WITH TODAY’S DRIVE SYSTEMS

It’s a process, not a product; multiple drive factorscontribute to system energy efficiency

by John Krasnokutsky, Siemens Industry, Inc., Marketing Manager, Motion Control Business

Energy Monitoring Equipment Selection and Optimization (Mechatronics / Parameterization)

Hardware: Common DC Bus / Infeed / Regeneration

While it is valid to state that energy efficiency is defined as the same level of production being achieved at an overall lower energy cost, it is equally important for today’s machine builders and automation engineers alike to remember than an energy-efficient system can actually translate into higher productivity. This is achievable through a comprehensive approach to energy management.

It is a fact that most of the energy loss in a system occurs in three areas, namely, the generation, distribution and conversion of energy into useful work, the last being accomplished through heat exchangers, pumps, motors and drives. This paper will concentrate on the last product group, as it is also a fact that over 25% of all electricity consumed in America is used on industrial electric motor-driven systems. Electric motors represent 65% of the power demand in American industry and, owing to the inefficiency of most motor control systems, the potential for energy savings in an industrial facility can approach 70% for any process where electric motor power is employed.

That said, energy management is a process, rather than a product or series of products installed on a machine, or inline, to achieve a basic energy saving of kW hour consumption. This process must be ongoing and perpetual, meaning that any defined goal should be viewed as a momentary metric of achievement, rather than a final end. While any vendor, including our company, can supply the right products and support services to hit a target mark of energy savings, the mindset of the customer is key in keeping the process recurrent. This ensures a continual increase in the productivity levels achieved, defined as a factor of the energy consumed. In many ways, it can be viewed in the same manner as an ongoing, effective but constantly evolving quality management system at your company.

First, energy monitoring systems must be in place to effectively determine the current consumption. These can include, but are certainly not limited to, energy consumption displays, infeed/supply monitoring devices, power factor meters and more. Next, the proper calculation tools are needed to properly evaluate the life cycle costs of any investment. These tools can be as simple as a motor sizing chart or the software programs used to parameterize drives. However, a more formal mechatronics protocol may be beneficial to your operation. In this scenario, a thorough evaluation of both mechanical and electrical/electronic influences on your system, be it a machine or a process line, is conducted. The results can often open the eyes of machine designers, process engineers and system integrators alike. To realize the benefits this analysis the proper products and system solutions must be implemented.

This is where a competent supplier can be an effective partner for your operation. For example, the solution you need might involve a vector drive that utilizes an energy optimization function to enhance the efficiency of the motor during partial load operations. In a system with multiple motors, energy savings might be realized to a substantial degree by the use of a drive unit with a common DC bus. The designer can also select the most appropriate infeed solution for the machine, pump or process operation, given the particulars of performance and required output. This may include an appropriately sized infeed unit with regenerative capability, the ability to put unused or braking energy back on the incoming power line.

Some applications may allow the use of high efficiency standard induction motors and, in the process, realize a potential savings of 1-3%. The use of frequency converters (VFD) for speed control might raise this to an 8-10% savings. VFDs have myriad applications throughout industry on fans, pumps, blowers and compressors, as well as in wasted energy recovery on cyclical acc/dec and regeneration on lost braking energy applications.

Optimizing your entire system through mechatronic analysis of the machine or process design, can result in a potential savings of 15-20% by the avoidance of over dimensioning of motors, plus partial load optimization by means of energy-related flow control. This analysis may also point to the ability to use controlled energy infeed and recovery.

In order to determine the true efficiency of any drive system, it is necessary to demonstrate the amount of energy required by its power components and a corresponding examination of how the system uses energy. How different drive concepts used on the same system under identical power load must also be considered. This latter exercise might look into partial load efficiencies with various motor and drive combinations, straight comparisons betweens synchronous servo vs. asynchronous induction motors or direct drive vs. motor/gearbox combinations, drives with braking components vs. regenerative drive technology, as well as solutions with single vs. multi-drive, common DC bus solutions.

A corollary to this discussion should also include a review of potential hydraulic/pneumatic component change outs in certain applications where replacement with an integrated package of motion control and PLC technology might better resolve closed loop pressure control of axes, for example. Fewer components and their related power consumption can lead to overall system productivity improvements, as well as ongoing enhanced energy efficiencies. Reduced programming, diagnostic and commissioning times can also flow from such an approach, providing even more opportunities for overall machine or process improvements. Tracking the energy efficiency of such a system may seem problematic at first, but here again today’s sophisticated mechatronic and virtual production protocols can be utilized to validate the real-world performance characteristics of such designs, far in advance of their implementation.

As the emergence of new technologies has impacted many of the products used in energy-efficient systems, it is equally important to take a more holistic look at operational sequences and the overall integration scheme when designing, retrofitting or rebuilding for improved energy utilization. The results can be many, including precise process and power factor control for optimum energy use and significant cost savings, plus the collateral benefits of lower carbon footprints, reduced maintenance due to decreased mechanical stress and lower total cost of product quality derived from less mechanical wear and better production control.

Author: John Krasnokutsky

Email: john.krasnokutsky@siemens.com

Website: http://www.usa.siemens.com/motioncontrol

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

For an informative PowerPoint presentation or more information on this subject, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Siemens Controller Combines Motion Control, Safety and Standard Task in One Device

ATLANTA — Siemens announced today the release of the new Simatic® CPU 317TF-2DP controller that combines motion control, safety and standard tasks in a single device. This device is the latest solution in its totally integrated automation portfolio that integrates and combines devices for the plant floor environment, further reducing footprints and improving overall efficiencies.

The Simatic CPU 317TF-2DP controller unites a series of important features that all go together in one device to reduce the wiring, coding and the implementation times. It also benefits users by saving space on the shop floor and reducing overall total cost of ownership.

Possible applications for the new device range from controlled single-axis positioning to complex, synchronized sequences of motion, such as geared synchronous motion, curve synchronization or print mark correction. The synchronous axes can be coupled to a virtual master or a real master. For safety-oriented applications, the controller fulfills the rigorous requirements of all the relevant standards, including EN 954-1 up to Cat. 4, IEC 62061 up to SIL 3 and EN ISO 13849-1 up to PL e.

For Siemens PLC users, the Step 7 option package S7-Technology is available to simplify engineering and commissioning. The Step 7 option package, supporting simultaneous processing of up to 64 technology objects, is available to meet engineering requirements for programming and commissioning of all functions. For specific fail-safe applications, the Step 7 option package Distributed Safety offers a set of pre-configured library blocks, including emergency stop, two-hand control, muting and door monitoring. No external safety hardware is required for costly safety precautions at the machine, saving valuable space in the control cabinet.

Centralized and distributed fail-safe I/O and fail-safe drives according to PROFIsafe, the fail-safe communication standard, can be connected to the Simatic CPU 317TF-2DP. The drive safety functions SBC, SLS, SSM, SOS, SS1, SS2 and STO according to PROFIsafe can be used in addition to the familiar safety functions.

PROFIsafe both enhances this controller’s capabilities and value while further simplifying commissioning. In particular, PROFIsafe requires less wiring than other controllers available in the market, making it quicker and easier to set up while reducing the risk of errors through the commissioning process.

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

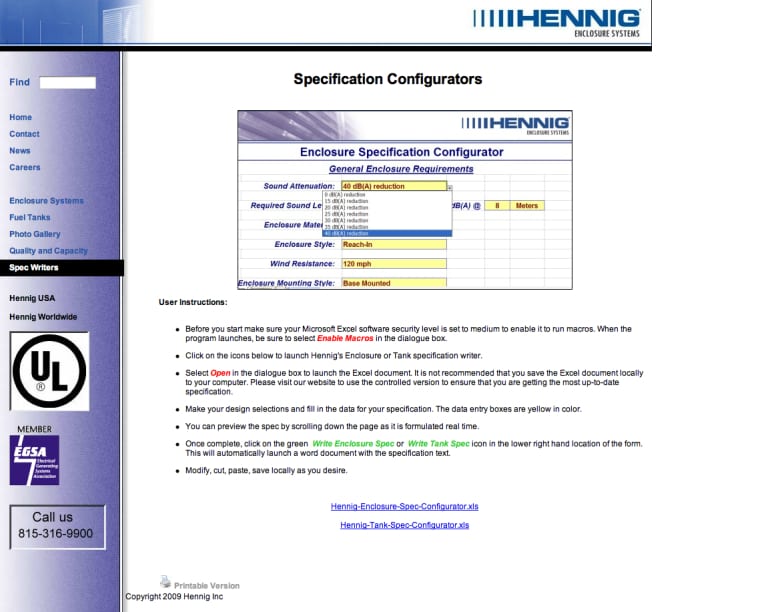

Continue readingHennig Announces New Website Configurator For Power Gen Enclosure Builds

Saves time, money and engineering through series of online selections; makes spec writing much easier

All performance and dimensional requirements are menu-selected, along with all electric, HVAC, exhaust system, roof, door and materials of construction on the enclosure. Likewise, for the sub-base diesel fuel tank, all size and accessory specs are selectable on a downloadable .xls menu for easy completion. Upon completion of the selections, a .doc is generated for the enclosure spec and another for the fuel tank.

“Through this system, the Hennig enclosure and fuel tank are precisely matched to the generator and the particular conditions of the installation. No settling for less and no need to make a standard product ‘fit’ the requirement. It really is a useful time and money saving tool,” says Robin Moore, the Hennig vice-president for engineering and operations.

Hennig manufactures all enclosures and fuel tanks in its Rockford, Illinois facility, located approximately 90 miles northwest of Chicago. Here, experienced power gen engineers work in concert with the company’s vertically integrated metalworking, fabricating, finishing and test departments to ensure the highest quality and reliable construction of the enclosures and fuel tanks to suit the specification mandated by customers. Hennig then ships the finished units to the construction site, power gen subcontractor or other location with full guarantees of satisfaction, backed by the company’s service and after-sale assistance team.

Hennig currently builds enclosures and fuel tanks to be compatible with CAT, Cummins, Detroit Diesel (MTU Onsite Energy), Kohler and all other leading brands of power generators. The company also works with the power gen distributors, plus design/engineering firms, consulting engineering firms and all levels of the building contractor community. Spec writers at all these types of companies can utilize the new Hennig configurator to save time, money and engineering effort in the construction of gensets.

To learn more about Hennig Enclosure Systems, visit www.hennigenclosuresystems.com or contact:

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

—

Hennig, Inc., at www.hennigworldwide.com, has been designing and producing custom machine protection and chip/coolant management products for state-of-the-art machine tools for over 50 years. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Hennig has manufacturing facilities in the U.S., Germany, Czech Republic, France, Brazil, India, Japan, China and South Korea. Its North American repair centers are located in Machesney Park, Ill.; Chandler, Okla.; Livonia, Mich.; Blue Ash, Ohio; Mexico City, Mexico; and Saltillo, Mexico.

Continue readingSiemens Five-Axis Milling Roadshow

Sinumerik MDynamics Milling Roadshow is coming to IMTS 2010.

If your company is looking for the way to more efficiently cut parts for aerospace, automotive or medical, one thing is certain — the demand for five-axis CNC machining has risen dramatically. And now there’s MDynamics: using one solid CAD/CAM/CNC process chain will get you to market faster than your five-axis competitors who will be lagging under a less integrated approach.

What is Sinumerik MDynamics?

“For users, it is extremely important to get from the blueprint to the finished part quickly, precisely and cost-effectively,” says John Meyer, marketing communications manager, Siemens Industry, Inc. “Sinumerik MDynamics combines our milling expertise together with our powerful Sinumerik CNC hardware platform, intelligent CNC functions, and our unique CAD/CAM/CNC process chain to form integrated technology packages for three- and five-axis milling.”

Seeing is believing.

According to Robert Scholz, international business development manager, Siemens Industry, Inc., Motion Control Business, “Together with leading machine tool OEMs, Siemens will demonstrate how users can benefit from accurate, high-speed machining and perfect workpiece surfaces. Every roadshow event will demonstrate part programming and simulation with NX CAM, followed by five-axis part manufacturing using MDynamics functions and Sinumerik CNC. With real applications for the automotive, aerospace and medical industry, we will prove to our customers that we are the perfect fit for every industry.”

From A-Z and everything in between, Siemens has you covered.

By providing a uniform and integrated system that ranges from programming directly at the CNC for simple parts, to a CAD/CAM system for complex workpieces, Siemens has the right solution for all CNC machining needs. With NX CAM, Siemens provides manufacturing engineers with an open and flexible 3D system that applies not only to the development of part models and drawings, but also to full NC programming and machining simulation. NX enables 3D and 2D construction in a full-, partial- and non-paramaterized form. The fully-integrated NX CAD/CAM system supports a complete part model to CNC program process and even offers 3D quality inspection programming in the same system. NX CAM provides optimized output for Siemens-controlled machines with additional programming commands and automated post-processor functions. During planning and into production, special focus is placed on the process related to the workpiece.

This process chain includes:

Product and process development using advanced CAD/CAM software

Part program generation for the most advanced machine tools

Optimized part program and post-processor output for maximum machining performance

Integrated and offline simulation for checking and optimization of manufacturing process on the PC

Optimized and highly-efficient manufacturing on the machine

See what Sinumerik MDynamics can do for your business!

Attend the Siemens Sinumerik MDynamics Milling Roadshow.

Roadshow schedule

20-minute demonstrations every day

during IMTS, September 13–18, 2010

12:30 p.m. — Milling for Medical

DMG/ Mori Seiki, booth S-8900

1:30 p.m. — Milling for Automotive

Grob Systems, booth S-9066

2:30 p.m. — Milling for Aerospace

MAG, booth S-8519

www.usa.siemens.com/cncroadshow

Continue reading650°F Universal Oven

A 600 CFM, 1/2-HP recirculating blower provides universal airflow to the oven. The oven is also equipped with positive latching door hardware, a solenoid operated door lock and an integral leg stand. Safety equipment is included for handling flammable solvents and the floor of the oven contains an explosion venting panel.

Controls onboard No. 898 include a digital indicating temperature controller, motor control push buttons and an on-off heat switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 HartRoad, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingHAN-KWANG INTRODUCES SERIES PL FULLY AUTOMATIC LONG BED FLYING OPTIC LASER SYSTEM

Han-Kwang USA announces immediate availability of its new Series PL, specifically Model PL 3015, a long bed, 2D flying optic laser system capable of handling 60” wide x 120” long workpieces. With a long bed gantry arrangement, less motion is required on the machine, providing greater working stability and reduced maintenance requirements.

Model PL 3015 features rapid single axis speed of 4724 ipm, simultaneous X-Y axis speed of 7900 ipm and maximum cutting speed of 1181 ipm, all with positioning accuracies better than +/- 0.004” per 118” of travel and repeatability to 0.001”. A dual shuttle pallet system is onboard to maintain optimum productivity in processing.

This Han-Kwang laser system features a powerful Panasonic CO2 laser resonator in 2, 2.5, 4 and 6 KW versions, as well as the builder’s patented beam radius control, which optimizes the beam

All machine mechanical movements and laser cutting operations are controlled by the powerful Siemens SINUMERIK 840D CNC. With its open architecture, 10GM hard drive and plain language commands, the CNC enables faster start-up and reduced time to first part for the programmers and operators alike. Further, a remote service support feature allows online communication to the CNC manufacturer for troubleshooting assistance.

An optional rotary axis is available for tube cutting up to 12” OD with this Han-Kwang laser system. Fully automated materials handling systems, pallet towers and other equipment for production improvement are also offered by the company.

For more information, the name of a local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won or Erik Kim

Siemens CNC controls all machine movements, allows remote service support

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue readingHAN-KWANG PARTICIPATES IN DEALER OPEN HOUSE

Over 400 customers attend Sominn event to see metalworking machines, meet company representatives.

Han-Kwang USA, a leading supplier of CO2 lasers and automated handling equipment for metalcutting operations, attended the Open House held on July 21-22 by its dealer, Southern Minnesota Machinery Sales (Sominn) in Dodge Center, Minnesota, just south of the Twin Cities. Over 400 customers of this major machine dealer attended the event, where Han-Kwang’s Director of North American Operations, Robert Won, was present to discuss his company’s offerings. Highlighting the Han-Kwang presentation was the new PL-3015, a dual-shuttle table, 60” x 120” workpiece, long bed CNC laser, available in various KW power models.

Sominn is the Han-Kwang dealer for Minnesota, North Dakota, South Dakota and Eastern Iowa. The company sells and services Han-Kwang plate and tube lasers, as well as over 20 other leading brands of metalworking and fabricating machinery, including various waterjet, plasma cutting, press brake, shear, saw, bending and other equipment.

The open house was held at Sominn’s 30,000 square-foot showroom, with representatives from all their lines present to discuss the equipment needs of those in attendance. Sominn President J.J. Francis hosted the event, which drew attendees from this dealer’s entire territory, during the two days.

Sominn has been a major dealer in the area for 38 years and is a member of the Machinery Dealers National Association (MDNA).

Robert Won of Han-Kwang commented, “This was a first-class event, as customers could see the substantial inventory Sominn maintains and also learn about their full sales and service capability. We had many excellent inquiries about our lasers. Han-Kwang is proud to call Sominn our partner in this region.”

For more information on this dealer, please visit www.sominn.com.

For more information on lasers, the name of your local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr

Attention: Robert Won or Erik Kim

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue readingFOREST CITY GEAR HOSTS CORN BOIL TO CELEBRATE 55 YEARS

Leading manufacturer of high-precision gears feeds, educates and entertains over 250 employees, suppliers and others

Roscoe, IL-Forest City Gear supplies some of the world’s leading companies with high-precision gear work. These include such diverse yet demanding customers as aircraft, military ordnance, every car in the starting field at the Indy 500, the winning boat in the America’s Cup and, perhaps their crowning achievement (pun intended), the Mars Rover. Already onboard Spirit and Opportunity, Forest City Gear products will deploy the solar panels and drive the wheels on the next generation of the Rover project, scheduled for lift-off in late 2011.

Meanwhile, back on planet Earth, the company celebrated its 55th year in business with a good old-fashioned corn boil on the company premises, July 24, 2010. Owners Fred and Wendy Young, along with their family, welcomed all the employees, their families, many suppliers, customers and friends of the company from the local Roscoe, IL community, to dine, socialize and stay out of the rain with them. Fred also gave tours of the facility, explaining to even the youngest visitors how a gear is made, measured and applied in the “real world” of mechanical motion, in all the industries served by this longtime market leader.

Highlight of the event were the karaoke performances by many of the employees, including the owners, who took all in attendance back to the halcyon hippie days of the 60’s with their heartfelt rendition of “I Got You, Babe” by Sonny & Cher. While the likelihood of the Young’s leaving the gear business for the glitz and glamour of the entertainment world is minute, every second of their performance brought rousing cheers from the enthralled mass, under the big top tent erected in the company’s parking lot.

There was face painting and a bouncy house for the kids, though Fred was looking at the latter with a mischievous grin, all afternoon!

In the end, despite a bit of rain, a good time was had by all, as they say. The hosts had allocated 4.5 ears of corn for all in attendance and many folks ate their quota and then some, while many were seen exiting the event with ears aplenty in hand, courtesy of Wendy!

Besides, where else on a rainy Saturday could one get a detailed explanation of the AGMA gear rating system?

See photos attached for more of the fun. For the real risk-takers, click here to see the Young’s singing for their supper!

For more information on the event or the company, please contact:

FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: sales@forestcitygear.com Attention: Fred Young or Wendy Young

PR agency contact for Forest City Gear: Tim Daro Bernard & Company 847-934-4500

Continue reading