Contact us today:

Author Archives: Bernard and Company

New Look for Heimatec Website

Heimatec is a world leader in the development and manufacturing of live tools, angle heads and multi-spindle drill heads. With U.S. head quarters located in the Chicagoland area and company head quarters and manufacturing in Renchen Germany, we are dedicated to supplying our customers the most innovative tooling technology possible.

Check out the new look at www.heimatecinc.com!

For more info on Heimatec:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingWhat To Look For In A Carbide Saw

Saws built for low vibration work best

by Willy Goellner, CEO, Advanced Machine & Engineering, Rockford, IL

Carbide saws equipped with carbide or coated cermet-tipped blades are designed to cut extremely hard materials. How effective the blade is depends in large part on how the saw is built.

The relatively brittle carbide or cermet tips require very rigid and backlash free machines, operating with low vibration to avoid cracking of the cutting tips and ensure an equal chip load on each tooth of the saw blade. This is especially important with the spindle drive. The spindle drive gears must have low backlash and must be supported by preloaded, heavy-duty bearings to minimize vibration. The same is true with the blade feed mechanism and the head slide or pivot mechanism.

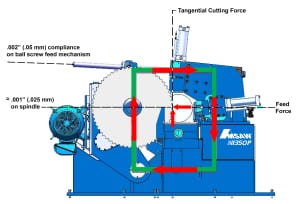

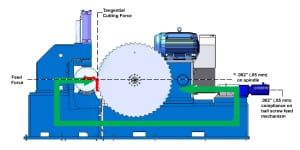

Generally, there are two types of saws, differentiating in the way the blade is fed into the work piece: slide-type or pivot-type saws. The more common saws are slide-type machines, where the head slide could be arranged in a vertical, horizontal or angular position. The preloaded slide could glide on box ways or preloaded linear ways. Experts still argue whether box ways using low friction lining and hydraulically preloaded way clamps have a better dampening effect than linear ways with hardened balls, rollers and blocks.

Pivot-type saws are simpler, have fewer components and, if properly designed with oversized taper roller bearings, can be made very rigid by preloading the pivot bearings to the limits. Built for extreme stiffness, a pivot mechanism for the spindle gear box would be nested in a rigid base close to the floor, fed by a heavy duty ball screw attached to an upper sub-assembly, such as the fixture frame, and having the spindle located between the pivot point and the feed mechanism. Due to the feed force and the center of gravity of the head, the ball screw is always under tension, which eliminates the need for a preloaded ball screw and provides a very positive feed for interrupted cutting, enhanced longevity and efficiency.

This arrangement provides a closed loop force distribution since closed frames are stiffer than open profiles. It also subsequently reduces the remaining deflection of the feed mechanism due to the ratio of ball screw and spindle in relation to the pivot point and contains the cutting forces within the machine structure.

Compared to a standard slide machine (Fig. 1), a pivot machine would be stiffer and less expensive. Pivot saws are built to saw material up to 24” (600 mm) stock size and have proven themselves in various standard and special saw systems.

Circular carbide tipped blades are limited to a maximum of 80 inch blade diameter and can therefore only cut up to about 30 inch diameter material. However, the cutting volume per minute is much higher with circular carbide saws, compared to carbide tipped band saws. In this range up to 30 inch material, carbide saws using circular blades really shine.

For more information, visit www.ame.com or contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

New Sinamics DC Master Base Drive for New Installations and Retrofits

Cost-efficiency and flexibility in one complete panel

This pre-wired solution is offered complete and fully tested with all necessary components mounted onto a back panel. Sinamics DC Master Base Drives are an extremely flexible and cost-effective solution for new installations and retrofits where space is limited. They are ideal for end-users and third-parties such as system integrators and Siemens solution partners.

Sinamics DC Master Base Drives offer more power per panel in the same footprint as compared to the previous two generations of base drives. These base drives are rated from 15A–850A continuous current.

Standard features of the new SINAMICS DCM Base Drive include — input fuses, output DC fuses (regen only), control transformer, AC line contactors, PROFIBUS, BOP20, UL508A Certification and 65KA SCCR rating. They are ready-to-order with deliveries available after February 2012.

For more information about the Sinamics DC Master Base Drive, visit our web page www.usa.siemens.com/motioncontrol.

Please forward all inquiries to:

Siemens Industry, Inc.

Motion Control Business

390 Kent Avenue

Elk Grove Village, IL 60007

Attn: Marketing Communications

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Siemens Presents the TCP3000 Temperature Controller for Plastics Applications

The ideal and efficient solution for closed-loop temperature control

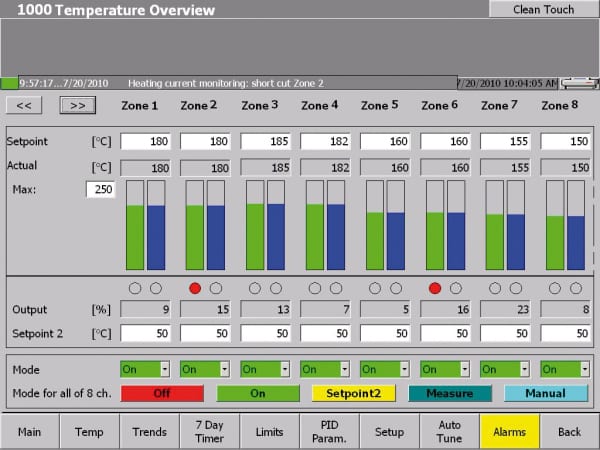

The improved TCP3000 temperature controller from Siemens is a scalable, pre-engineered solution to make plastics extruder machines more simple and economic

ATLANTA — Siemens Industry, Inc. unveiled today its improved TCP3000 temperature controller for plastics machines making extruders more simple and economic.

This pre-configured solution allows OEMs to save time and expense when equipping their machines; provides users with the highest degree of flexibility, scalability and performance; and offers simple and clear operator screens for temperature zone monitoring and control.

The TCP3000 can be operated using the new Simatic Multi-Panels including the 10-inch MP 277 and the 12-, 15- or 19-inch MP 377. It is supported by standard Simatic PLC software from Siemens, which requires no special high-level programming expertise.

Machine operators, technicians and maintenance engineers have a wide range of screens

at their disposal for easy and convenient operation and service. These include:

- A graphical user interface for temperature and trend analysis

- Controller settings including separate parameters for heating and cooling

- Tolerance and control-loop monitoring

- Control system identification for each temperature zone

- Wire break monitoring with a programmable controller response

- Timer clock and limits

For more information about our solutions for extrusion, visit our website: www.usa.siemens.com/plastics.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingHigh-temp Cabinet Oven from Grieve

This Grieve cabinet oven features 4” insulated walls, aluminized steel exterior, Type 304, 2B stainless steel interior, a silhouette plate with removable cover inside the door opening and an oven hearth driven by a ¼-HP motor through a gear reducer with a torque limiting device variable from 1 to 27 RPM. This 19” diameter oven hearth is constructed from Type 304 stainless steel with 1” studs on 1” centers to support the paint coupons in process.

All safety equipment required for handling flammable solvents are onboard No. 987, including explosion-venting door hardware.

Controls onboard No. 987 include a digital indicating, time proportioning temperature controller and excess temperature controller with separate heating element control contactors. An auto door switch stops hearth movement when the oven door is opened.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Drilling Technical Services Develops Die Cut Thin Film Blank Accumulator with Siemens Motion Control

VR Series “cut and stack” accumulator utilizes leading-edge motion control products to efficiently transfer film blanks from point of cutting to positioning in counted stack

Drilling Technical Services Inc. (DTS) in Milford, Ohio is machine builder specializing in the mid-width and narrow web press market. Its sister company, Pre-Owned Press & Parts Solutions, offers full reconfiguration engineering and remanufacturing services, plus full installation and commissioning on pre-owned presses

As a machine builder specializing in the design, engineering and system integration of narrow and mid-web label solutions as well as flexible packaging and folding carton machinery, Drilling Technical Services (DTS) of Milford, Ohio sees this global industry from many perspectives. Much of the machinery and equipment solutions devised by DTS end up on the production lines of major label and filmic product producers worldwide. Recently, company owner Joe Drilling and his team had one of those “light bulb moments” where a specific market need could be addressed by a better solution.

It involved the delicate world of thin film substrate processing and the need for a high-speed cut-and-stack solution.

The VR Series “cut and stack” accumulator stacker machines for thin film in-mold label (IML) substrate processing features Siemens HMI, drives and servomotor technology to handle the delicate thin film substrates processed, with precision, accuracy, high speed and with fast changeover for the machine user

As Joe Drilling explains, “The primary challenge was to create a solution that took into consideration the unique environmental and material factors of each customer. The materials our machines process are normally very thin film products that accumulate static quite easily. Due to their structural instability, it always requires special transport

techniques to convey these products from the point of cutting to the point of positioning in a counted stack.” Superior blank control throughout the process, converting blank shapes in multiple streams and integrating the equipment into continuous print cut processes or offline converting systems further complicated the challenges.

DTS team handles the design, engineering, build and line integration of the company’s various machine types for customers in the label, film, packaging and printing industries

Further, the DTS team saw the industry trends toward smaller footprint equipment, greater energy savings, quick changeover and portability. Collectively, these factors presented a daunting set of circumstances to Drilling and his design staff.

DTS realized the control scheme on the machine would be vital, so they turned to their longtime partner Siemens for assistance. Through the integration of high-precision Sinamics drives and Simotion motion control, coupled with the complementary suite of Simotics servomotors and Simatic HMI touchscreen product, the VR Series of in-mold label (IML) accumulator stacker machines began to take shape.

Unique blank shapes are accumulated in 1, 2 or 3 streams on a small footprint machine requiring only 3’ x 4’ of floor space, capable of handling web widths from 13”-26”. The VR Series machines from DTS provide end users with simple matrix separation, while diverting scrap at the process start-up or as a component in the overall quality inspection system. The machines can create serialized groups through a “bottom up” stack format with total static control, so they can be utilized in a normal press room environment.

Noting the high-precision servo technology and motion control accuracy of the Siemens equipment onboard the VR Series, Drilling observed, “The axes communication and control are also extremely compact and this facilitated our designing a very portable machine with quick changeover capability, something our customers consistently demand.”

DTS further relies on the Siemens international sales and technical support teams, as this builder’s equipment is found in labeling, printing and converting plants worldwide. Drilling notes his company has received a high level of consistent service, application engineering assistance and support from the Siemens personnel and affiliated contractors.

—

Joe Drilling has a pride in his company that’s classic American entrepreneur. After years at a leading label machine builder, he founded DTS as a virtual engineering company specializing in the mechanical, electrical and process engineering of mid-width and narrow web printing, drying, converting, RFID and digital print equipment. DTS has a particular emphasis on web transportation, die-cutting and laminating solutions. As the installed base grew and in response to current market conditions, Drilling founded a second company in Milford, Pre-Owned Press & Parts Solution LLC (POPPS), specializing in the evaluation, reconfiguration, remanufacturing, sale, commissioning and servicing of pre-owned presses.

Another vital component of the business models at both DTS and POPPS is the engineering of energy recovery systems for containment of utility costs, an ongoing challenge in the printing and labeling industries. The two companies primarily serve the needs of the flexible packaging, folding carton, tag and label, health and beauty, wine and beer, plus other label market segments.

For more information on this story, please contact:

DRILLING TECHNICAL SERVICES INC.

6062 Kells Lane

Milford, OH 45150

Phone: 513-831-2952

Fax: 513-831-4825

Web: www.drillingtechservices.com

Email: jdrilling@drillingtechservices.com

Attention: Joe Drilling, President

or

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Gas-heated Walk-in Oven from Grieve

This Grieve oven has 4” insulated walls, top-mounted heating chamber, aluminized steel interior and exterior, plus five (5) monorail tracks mounted at the top of the oven’s workspace.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment are included on this walk-in oven, including a 325 CFM, 1/3-HP powered forced exhauster.

Controls on No. 889 include a digital programming temperature controller and 6-point strip chart recorder with 1-point air temperature, 2-point vacuum and 3-point load temperature recording capability.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Hennig Introduces 2-1/2” Pitch Steel Belt Chip Conveyors

Whether the application involves producing/removing chips or moving parts/scrap pieces, Hennig can provide the chip conveyor for all machine tool requirements. The company’s new 2-1/2” pitch steel belt can be made for most applications in the field when the standard 1-1/2” pitch belt is not effective for the particular conditions present.

Conveyors from Hennig, a leading supplier of chip conveyors to the global machine tool market, can be manufactured in widths from 4” to 80”, depending on the need. The unique Hennig belt hinge is designed as one continuous piece, whereas many competitive brands do not have this feature. The manufacturing of these belts is done on Hennig’s in-house press equipment.

Hennig recognizes the special requirements needed when designing a parts conveyor on which direct loads contact the belt. Impact plates are just one of the many options to be considered when customizing a conveyor for these applications.

Chip volumes can also vary between applications, so speeds and sizes are always evaluated by Hennig’s engineers. Special incline covers (top hat design) can be included when larger amounts of stringy/balled chips are to be evacuated from the machine.

As adjunct to this new 2-1/2” pitch steel belt conveyor, Hennig also offers complete filtration systems, as needed. The company’s Chip Disc Filtration (CDF) systems can also be used with the new 2-1/2” pitch conveyor. These systems can filter down to 25 microns and additional bag filters can be included to achieve the through-spindle requirements on most machine applications.

Whether the need involves moving chips into a hopper, evacuating larger volumes of chips through a plant wall into a truck/dumpster or hauling scrap parts from the machine, Hennig can assist machine builders and end users alike with any specific requirements.

Innovations and new developments in machine tool design present myriad opportunities for the engineers at Hennig (www.hennigworldwide.com), who have been designing and producing custom machine protection and chip/coolant management products for state-of-the-art machine tools for over 50 years. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Hennig has manufacturing facilities in the U.S., Germany, Czech Republic, France, Brazil, India, Japan, China and South Korea. Its North American repair centers are located in Machesney Park, Ill.; Chandler, Okla.; Livonia, Mich.; Blue Ash, Ohio; Mexico City, Mexico; and Saltillo, Mexico.

For more information, contact:

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

European Contact:

Hennig GmbH, Überrheinerstr. 5, 85551 Kirchheim, Tel. 49 089 96096140

Continue readingBuck Benefits from Hunter Mold Handling Lines

Custom configured solution from Hunter allows major Pennsylvania foundry to integrate mold handling line with other brands of automatic molding machines

See the video HERE.

Schaumburg, Illinois (USA) – The Buck Company is an ISO 9001: 2008 Certified foundry in Quarryville, Pennsylvania, near Lancaster and nestled in the Susquehanna Valley near the Maryland border. Here, ferrous and non-ferrous castings of ductile, gray and malleable iron, as well as aluminum and brass are poured in medium and long runs to produce a wide variety of end products for the agricultural, metalworking, materials handling, marine, military and other market segments.

A challenge was presented to Buck’s longtime molding machine supplier, Hunter Automated. Another brand of molding machine had been acquired at Buck for a particular use in the non-ferrous foundry. Hunter was asked to provide a mold handling line for the particular conditions and footprint available at Buck and to devise a “handshake” mechanism to interface with this new machine.

It was determined that the best solution for the floor space and pouring equipment logistics was a Hunter HLH linear mold handling line. However, the pouring height of the Hunter line did not match the mold discharge height of the other machine brand, so an elevation change mechanism was needed to accommodate the difference between the mold’s exit height from the machine and its placement onto the pouring line section of the Hunter line.

The solution was found in a walking beam (boardless) conveyor line devised and patented by Hunter, combined with an articulating arm and elevator mechanism that could raise the mold onto the pouring line for loading of the weight and jacket, all without risking mold shift.

As the mold exits the machine, in this case at Buck, a series of walking beams gently sequence the molds forward to the elevator station. The “traffic cop” on this conveyor is a plurality of proximity sensors, used to monitor each location along the conveyor section and coordinate with the pouring operation, so mold collision and back-up are avoided. As pattern changes are made, work breaks occur or melts are prepped, these sensors remain in operation to protect the integrity of the process.

Once the mold reaches the end of this standard boardless walking beam conveyor section, an articulating arm and elevator mechanism gently raise the mold to the standard height of the Hunter handling system. Achieving this result saved Buck considerable manpower in materials handling, plus floorspace and capital investment, while allowing this Hunter customer to maintain high productivity in this section of its non-ferrous foundry operation.

As Dean Martin, sales manager for Hunter, explains, “We had a meeting of the minds with the automatic molding machine builder and we worked out a feasible plan to solve the handshaking issues presented by this production scenario. There were really no serious setbacks or conflicts, as we had the common goal of satisfying Buck’s requirements with the optimum production results plus an on-target budget.” He further described how the machine builder and Hunter’s seamless working relationship helped develop this transitional walking beam (boardless) conveyor system.

Buck used the expertise of its projects manager Art Tout and non-ferrous foundry superintendent Steve Ward to work with the molding machine builder and Hunter to achieve the best solution. As Steve noted, “The Hunter linear line was more practical than the rotary turntable design, which we also have in another section of the foundry. With a smaller footprint and relatively low maintenance, it was a good solution.” He joked, in describing the way Hunter worked with the machine builder, “They played well in the sandbox together.”

The typical mold being handled on this line weighs 400-500 lbs. (181-227 kg), having been produced on the molding machine with a 20” x 24” plate dimension.

Matt Sullivan, president at Buck, discusses the unique solution devised for the mold handling with Dean Martin, sales manager for Hunter. View the video from this sit-down HERE

Buck President Matt Sullivan observed, “We were very impressed by the way everyone responded. The machine builder and Hunter actually needed very little input from us. We’d presented Hunter with some very tight floorspace restrictions and they worked hard to overcome the challenges for us. We had good experiences with the HLH lines in other parts of the foundry in the past and we were confident it would do the job here, even being modified. We knew the HLH would work from morning to night with few, if any, problems. The option of going vertical with the mold cooling was vital, given the floorspace.” He also noted the installation and the modification of the overall system was seamless.

Martin concluded by noting, “…the boardless conveyor system used here at Buck, while a special modification to our standard board conveyor design, was completely designed, engineered and built by Hunter personnel. We’ve used this solution and others at several companies since the Buck install, with very satisfactory results.”

Hunter holds several patents on the unique features of its mold handling systems, which can be utilized with any boardless molding machine.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive

Schaumburg, Illinois 60196-1094

USA

Phone: +1 847 397 5136

Email: sales@hunterfoundry.com

Web: www.hunterfoundry.com

Attention: Bill Hunter or Dean Martin

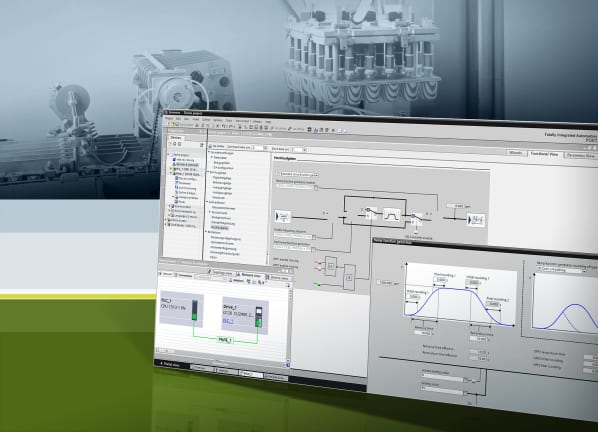

New Sinamics Startdrive Enables the Seamless Integration of Sinamics G-Drives Into TIA Portal

Sinamics Startdrive from Siemens now enables seamless integration of the drive system into the Totally Integrated Automation (TIA) Portal

CHICAGO — Siemens announced today that the latest version of the Totally Integrated Automation (TIA) Portal now gives users the ability to commission and configure Sinamics G120 drives using Sinamics Startdrive.

As an engineering framework designed for maximum efficiency and ease of operation, TIA Portal offers seamless integration of the drive system using Version 12 of Sinamics Startdrive. This allows users to quickly and easily configure Sinamics G120 drives from a single graphical user interface. The same applies to drive parameterization, which is easy-to-handle thanks to the use of graphical screens. The task-based sorting of drive functions reduces the start-up time for users as they are guided directly to functions via the specific task. As with the Simatic programmable logic controllers (PLCs) in TIA Portal, the Sinamics drive is also displayed as a station in the project navigator. Simotics motors can be easily integrated into the engineering framework via Sinamics Startdrive. In addition, optimized safety function views have been integrated into Startdrive to ensure efficient commissioning of safe drive systems, which means that engineering for standard and safety-based programs can be implemented with TIA Portal.

Efficient drive engineering in TIA Portal is possible thanks to the identical handling of controllers, human-machine interfaces (HMIs) and drives. Sinamics G120 drives can be configured in the same manner as an existing controller. The hardware catalog stored in the program can be used to add components. Bus connections can also be made via simple drag-and-drop. Since TIA Portal’s library is used, uniform data storage and consistency are assured. Existing parameterization can be reused in the same or in a different project via the library. Additionally, since the power module is easily replaced via drag-and-drop menus, engineering can be quickly modified even when power requirements change. This saves time when implementing follow-up projects.

Communication settings are uniform for every device as a part of the integrated device and network configuration, avoiding duplicate entries and consistency errors. The package includes the Profidrive drive profile for all industry-based applications, as well as Profisafe for failsafe communication. Using Step 7 Motion Control to optimize interaction between the Simatic S7-1500 controller can reduce the time and effort involved in engineering and Sinamics G120 drives. The uniform application engineering for controller and drive includes a guided configuration and parameterization of Sinamics drives and allows fast access from the Portal view.

Sinamics Startdrive permits intuitive and efficient drive diagnostics. Information and status messages are displayed without the need for programming. As part of the uniform display concept, status messages for the drive are available in plain text in TIA Portal, the CPU display, the HMI and the web server. Detailed information can be called up in the diagnostic and online editors, which support fast troubleshooting and help to significantly reduce downtimes.

The new Sinamics Startdrive features an integrated trace function to optimize motion sequences and increase application productivity. Up to eight signals can be monitored in two separate trace jobs simultaneously. User guidance is identical to Simatic-S7-1500-Trace, with controller and drive traces being managed centrally in TIA Portal, making the complete diagnosis possible without the need for an additional tool. Since the motion sequences are intuitively recorded and optimized, there is less mechanical stress on the machine or system.

Siemens is continuing to develop TIA Portal with the intention of opening up the intelligent engineering framework for more and more hardware components. The ultimate goal is to reduce the time and effort required for engineering, thereby, maximizing efficiency in order to boost user productivity and competitiveness. TIA Portal’s intuitive and efficient software architecture allows users to design every engineering and production process throughout the entire value chain from one single screen.

For more information about Siemens solutions for the conveyor and material handling industry:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications