Contact us today:

Author Archives: Bernard and Company

SIGMA Plastic Services, Inc. Presents the Latest Developments in Simulation for Elastomer Processing

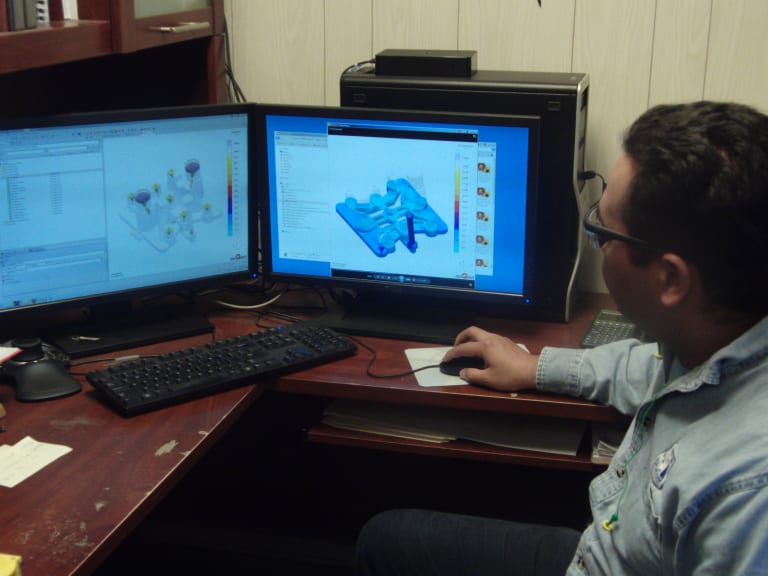

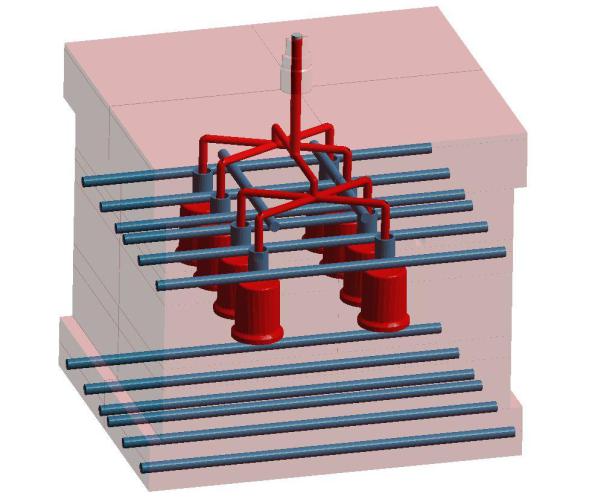

With the process-oriented approach of SIGMASOFT®, the injection molding simulation for elastomers is no longer limited to predicting the cavity filling while designing the part, or to answering questions regarding balanced filling. Based on an accurate simulation of the curing reaction (vulcanization), it can be used for designing the mold, identifying process windows and troubleshooting during production.

Figure 1 – The process-oriented approach of the Injection Molding Simulation Software SIGMASOFT® allows all relevant information (Part, Insert, Venting, Material, Mold, Heaters, Thermocouples, Process, etc.) to be used in the calculations.

SIGMA Plastic Services, Inc., Schaumburg, IL presents the latest functionality of its 3D Injection Molding Simulation Software SIGMASOFT®. The focus is on reduction of development and production costs using these new developments in process simulation.

Many factors in elastomer injection molding have an influence on product quality and costs. Here it is of little help to solely focus on a single aspect; part design, material, mold design, or molding process. To ensure a competitive advantage, the entire system must be considered simultaneously. Only when everything is optimized during the design phase, before the mold is shipped, can the largest cost savings be achieved.

By means of process simulation, molding feasibility and initial process parameters can be evaluated. Parting line and venting channels can be developed, as well as the optimal type and position of the injection point. Where are weld-lines acceptable, where must they be avoided? How much injection pressure will be required? Ultimately, the complete mold and process must be optimized. What wattage and heater design is most beneficial? Where is the best thermocouple location for each heater? Do inserts need pre-heating and how will they influence the curing? How long is the curing cycle, what areas of the part cure late and why? These questions are all related to the mold design and the production process and they are all important factors regarding part quality.

The simulation results provide answers to all of these questions in a clear and meaningful way, allowing injection molders a way to virtually test the mold before it is built. Costs can be reduced significantly during development, and existing processes can continuously be improved, while substantially reducing material waste and improving quality.

The latest developments in the thermal solver allow for the integration of all mold components and their individual temperature dependent material properties. In this way, an accurate reproduction of the real temperature profile in the mold is possible, even over several consecutive injection molding cycles. The simulation set-up is optimized for the requirements of process engineers. This allows production-minded engineers to use this technology without a simulation background. For example, a process engineer can determine how heating cartridges influence mold temperature and part quality, simulating them with their respective electric power and thermocouple control.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue readingSiemens Introduces Sinumerik 808D — The CNC for Entry-level Milling and Turning Machines

During EASTEC 2013, Siemens will present its newest solution for the job shopfloor, the Sinumerik 808D, an attractively-priced CNC for entry-level milling and turning machines.

Over 50 years of Siemens CNC experience have been brought to the development of this control, which is specially designed for the highly competitive, high-volume 230V, three-phase and economy machine tool market. With up to three-axis plus spindle control capability in milling or turning applications, the 808D is offered as a package with Siemens Sinamics drives and Simotics motor solutions. The Sinumerik 808D will be immediately available for OEM machine tool builders and in-the-field retrofit installation by Siemens business partners worldwide.

Start with an IP 65 enclosure, easy-to-load USB port, mechanical, hot and soft keys for easy, intuitive operation, clamp-mounted front panel and a modular design that allows customizing by machine model or with out-of-the-box operation. Plus, the machine control panel is connected using plug-and-play technology using a simple USB interface. On a turning machine, the Sinumerik 808D provides high contour accuracy and maximum machine productivity on high-volume production runs. On a milling machine, likewise, the Sinumerik 808D offers machine builders of vertical machining centers all the benefits of the Siemens MDynamics velocity control for mold and die section work.

A 7.5-inch LCD color display with 640 x 480 resolution for easy reading, selectable function keyboard, rotary dials for speed and spindle override, LED tool number display, durable buffer battery and rear connection ports for USB, RS232 C, distributed and onboard I/O, setpoint to feed axes and spindle, spindle encoder, fast I/O, e.g., for probes and handwheel operation are all standard on the Sinumerik 808D.

With 80-bit nano floating point accuracy and intelligent jerk limitation for smoother path cutting and less mechanical stress on the machine structures, workpiece accuracy and repeatability are improved. Whether turning with a C-axis changeover or milling mold sections where path control is paramount, the Sinumerik 808D has been designed to significant heighten the performance level of basic machine tools.

With programGuide Basic, a wide range of pre-determined technology cycles are available, in addition to the standard G-code and coordinate transformation language. Standard ISO codes can also be intermixed with high-level Sinumerik CNC commands on the 808D. The onboard contour computer further allows complex programs to be created and modified at the CNC without the need for a CAD/CAM system.

For routine or even online help with maintenance or troubleshooting issues, a simple push of a button is the only requirement, as the complete library of system parameters is accessible onscreen.

Commissioning is made easier with a ready-to-run PLC program. Customizing the PLC is simpler, as well, with function and data blocks for program testing and debugging built-in. The Sinumerik 808D further allows easy connection to the PLC I/O of other machine devices, whether proximate or remote. The open architecture of Siemens CNC has not been sacrificed on the 808D, so customized HMI screens and menu trees are easily defined and created.

Finally, with Manual Machine Plus (MM+) function on this new CNC enables transition from conventional machining to CNC programming. A machine equipped with MM+ can be operated using handwheels but with all the benefits of CNC-assisted technology cycles.

The Sinumerik 808D is offered with full THREE-YEAR WARRANTY on parts and labor.

FOR END-USERS

In addition to the above features and benefits for the machine builder, shop operators and programmers alike will appreciate the Sinumerik 808D for its many end-user advantages, including simplified keyboard entry of all program values, named part programs in subfolders just like a PC, convenient shortcut keys to access tool offset lists or the Program Manager, intelligent jog features easily identified and graphically-supported, precise tool handling and tool wear data readily available onscreen and a powerful simulation routine. An operator can access all system information and obtain online help, whenever needed.

The multimedia training materials include on-screen tutorial video and full step-by-step procedures to go from the blueprint to the finished part. For offline training, a fully operable software machine control panel on a PC is available to end users.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

Sinumerik 828D Basic for Milling and Turning Machines in the Mid-range Job Shop Market

At this year’s EASTEC Show in West Springfield, MA, Siemens will demonstrate new versions of its popular, compact CNC for the job shop, the Sinumerik 828D.

The Sinumerik 828D BASIC T is designed to address the needs of shopfloor turning machines.

It combines CNC, PLC, operator panel and axis control for five axes/spindles, including live tooling. Milling and drilling operations on a turning machine, both for face and peripheral surfacing, are therefore possible. In tandem with the new Sinamics S120 Combi drives package, the 828D BASIC T represents a new level of efficiency and virtually maintenance-free operation, as the fans, hard disks and batteries of past CNC generations have been eliminated.

With rugged diecast magnesium front panel on an IP65 enclosure, the BASIC T enables an Ethernet connection, USB or Compact Flash (CF) card program loading. An 8.4-inch color display for easy readability and simple QWERTY keyboard provide fast ramp-up for the operator. Various communication ports in USB, Ethernet, Drive-CLiQ, PLC I/O interface, RS232 C and NC inputs/outputs are standard.

In operation, reliable 80-bit nano accuracy means contour control precision and a better workpiece, every time, while Siemens intelligent kinematic transformations provide the proper orientation of machining plane to work surface.

Though simple command language is provided for operator ease, the BASIC T functions with the highest level of ISO programming language. Established cutting cycles can be utilized with fully Animated Elements for the faster visualization of part production on various levels with combinations of Sinumerik CNC and ISO programming languages possible, as well.

SINUMERIK 828D BASIC M

Similarly, the new Sinumerik 828D BASIC M class features the same quality performance as the T class, but for use on milling machines. Even in complex moldmaking operations, mirror-smooth surfacing and reduced machining times are enabled. Again, in tandem with the Sinamics S120 Combi drives package and Simotics feed and spindle motors, the 828D BASIC T will operate a milling machine at the highest level of performance possible. Superior axis and spindle dynamics within a broad speed bandwith yield quality workpieces, every time.

All the other benefits of the Siemens CNC family, including the Sinumerik Operate graphical user interface platform as well as ShopMill and ShopTurn easy programming are offered in these new 828D CNCs.

SINUMERIK 828D

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. This control family is ideal for single-part and small-batch production. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming systems, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

Also included with this expansion of the Sinumerik 828D family of CNC, modern PC and mobile phone technology are also available for the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate data networks.

Through the use of its Easy Message functionality, the Sinumerik 828D family offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile settings, the machine tool can transmit information about workpiece machining status, report on the tool condition currently

in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

Two-Compartment Cabinet Oven for Preheating Large Dies

This Grieve cabinet oven features 8” insulated walls, removable top-mounted heat chamber, aluminized steel interior and exterior, plus two tiers of four 300 lb. capacity shelves supported by rollers to extend 14” in front of the oven for easy access.

Controls onboard No. 1028 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch, SCR power controller and circuit breaker disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Turbine Blades Produced With Highest Precision

Turning-milling centers with coordinated drive and CNC engineering achieve superior accuracy and repeatability

Hamuel CEO Dr. Markus Stanik (right) and his sales manager Jochen Schaede agree: “The Sinumerik 840D sl CNC complements perfectly the capabilities of our five-axis turning-milling centers in the HSTM Series. Because of this fact, we can usually convince leading turbine manufacturers from the aerospace and automotive industries about the dynamics, high-performance and precision of these machines.”

The complete machining of turbine blades requires striking a balance between powerful roughing and ultra-precise finishing, a task for which the modern five-axis turning-milling centers are ideal, when robust machine construction is combined with high-quality drive and control engineering. Experience is the solid basis on which the Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany, can offer a great deal: with 85 years of machine tool manufacturing, 35 years of CNC machining, 25 years of five-axis simultaneous machining and over 10 years in the construction of five-axis turning-milling centers. CEO Dr. Markus Stanik knows that experience by itself cannot be any yardstick for the quality of machine tools, noting, “It certainly helps us, together with the right partner companies, to design and build the machines so that our customers can be successful in the marketplace.” This machine builder and its many customers have developed correspondingly positive accomplishments together. Today, Hamuel stands on three standards:

- The production of machine-tool components (such as axis units, machine bases and machine bodies)

- The development and construction of CNC-gantry milling machines

- The production of five-axis turning-milling centers

The latter, as evidenced by Hamuel’s HSTM (high-speed turning-milling) series, has been marketed since 1999 and makes a decisive contribution to the sales and success of the company. Leading turbine manufacturers from the aerospace and power-generating industries have been particularly impressed by the dynamic response, capability and precision of these machines. Even the smallest faults are unacceptable on turbine blades

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

The HSTM that runs on the Sinumerik 840D sl CNC controllers is used mainly to manufacture turbine blades and blisks (turbine disks) deployed in stationary steam and gas turbines as well as in mobile turbines for aircraft jet engines and large turbochargers. These products always consist of high-strength materials, such as titanium or high-alloyed steels. Form deviations are taboo in such applications, because even the smallest error would significantly reduce the efficiency of the turbines. Correspondingly high and comprehensive are the requirements placed on the machine tools. Hamuel sales manager, Dipl.-Ing. Jochen Schaede, explains: “Our customers normally manufacture large turbine blades longer than approximately 1000 mm from forging blanks. In contrast, shorter workpieces are milled from a solid piece of material with a stock-removal ratio of approximately 80 percent. This makes it obvious that our machines must not only rough-cut very productively but also finish with high precision.” Whereas productivity takes precedence for rough-cutting, accuracy is more important for the subsequent finishing of the spatial free-form surfaces. “With regard to accuracy, our high-performance machining centers achieve a precision in the micrometer range coupled with excellent surface quality,” added Schaede.

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

Key to this capability is the combination of compact machine construction together with perfectly matched drive and control engineering. The basis is the robust machine design with a one-piece machine base – either as welded construction cast with special concrete or latterly directly as polymer-concrete made from a single piece of material. The careful distribution of the masses ensures the best dynamic rigidity. The experience of the developers at Hamuel paired with the knowledge of the Siemens mechatronic experts make such results possible, as Jochen Schaede confirmed: “Thanks to various simulation tools, the Siemens engineers could provide us with very exact data to which we could add or remove masses. It was certainly advantageous that we could procure all components required for the dynamics from Siemens starting with the spindle, including the axis drives, and ending with the CNC. This means we needed only a few iteration loops in order to obtain a perfect dynamic rigidity in the machines.” It is also important that all components are arranged so that the horizontally clamped turbine blades and blisks can be machined optimally. This is also facilitated by the 45°-inclined orientation of the axes that ensures a favorable swarf removal further augmented by the permanent rinsing of the machine internal area. The accessibility has also been enhanced by this inclined axis orientation. Such designed and built HSTM machines equipped with precise direct drives from Siemens achieve a maximum positioning accuracy of 5 µm with traversal speeds exceeding 40 m/min in all linear axes. Indeed, the extremely fast rotary axes have a positioning accuracy of 3 µm. This allows the user to achieve maximum productivity, accuracy and surface finishes in the range of Ra = 0.8 µm, and so fully meet the industry requirements placed on the blade machining. CNC ensures optimized surface transitions at the inlet and outlet edges One of the biggest challenges for the turbine-blade manufacturing industry concerns the critical surface transitions (leading and trailing edges) of the turbine blades. To achieve a high quality, the milling paths described with curve interpolation points must have a constant machining speed. As a consequence, the leading and trailing edges demand extreme angular accelerations. The number of curve interpolation points to be described is correspondingly quite high.

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

The controller now faces the challenge to reliably process the generated NC steps that are supported by the fast block cycle times and the look-ahead function of the CNC. “Hardly any other controller can supply the drive information for all five axes in the required short time as reliably as the Sinumerik 840D sl controller,” confirmed Jochen Schaede, who added, “The new Advanced Surface motion control that includes among other things an optimized look-ahead function is also excellent. And I would also like to mention the five-axis high-speed turning-milling of free-form surfaces requires a continuous spatial reorientation of the geometry vectors.” This leads to the use of the Traori (transformation orientation) principle in the Sinumerik 840D sl. Hamuel’s customers can therefore achieve reproducible results with the best-possible surface finish, exact contour accuracy and with the maximum possible machining speed.

Despite being a high-end controller that offers many modern features, the Sinumerik 840D sl CNC is easy-to-use.

In addition to the primary properties of precision, productivity and reliability, Hamuel also appreciates other properties of the Siemens drive and control engineering – an example: the DRIVE-CLiQ interface. When this digital connection is used, all appropriately equipped drive components are detected automatically. Only a cable for the connection is required to achieve this result. Equivalent circuit diagram data for the motors and the characteristic values of the installed encoder systems are all stored. This avoids the need for manual data input during the commissioning and so makes this task more reliable and much faster, according to Hamuel engineers. Sales manager Schaede is also impressed with the “know-how” protection onboard the control. With the help of innovative software, his customers can protect all their programs and their application know-how, using individual passwords and so largely prevent unauthorized access. According to Hamuel, the Teleservice offered by Siemens has proven to be an important advantage for its machine users who often operate globally. It allows not only software problems to be rectified but also updates to be installed fast and reliably without needing to be present onsite. Manufacturing operations save time and money and they always remain up-to-date with the latest software releases, via this service. Powerful motor spindle with Hirth gearing

Leading turbine manufacturers are particularly impressed by the dynamics and high-performance of the HSTM machines. The perfect interaction of the robust Hamuel machine construction and the high-quality Siemens drive and control engineering provide the basis for this satisfaction.

The capability of the turning-milling center also depends greatly on the 54-kW motor spindle made by Weiss Spindeltechnologie GmbH (a Siemens subsidiary). Equipped with a HSK A63 tool holder, it is able to provide the high torque required for roughing plus speeds as high as 16,000 rpm for finishing. This means an optimum cutting speed is always guaranteed. As a practical detail, the Hamuel engineers also emphasize the integrated Hirth gearing that makes it possible to clamp the spindle and relieve load on the bearings during the turning process. The machine sizes in the HSTM Series are oriented to the length of the workpieces to be produced in standard ranges from ≤ 500 mm (HSTM 300) to 1750 mm (HSTM 1500). On special request, Hamuel also builds larger machines. A project for machining blades as large as 2500 mm in length is currently running in the field. CEO Markus Stanik explains, “Thanks to our modular machine construction, we are able to satisfy special requests and build turning-milling centers in these dimensions.”

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

New developments already in the introductory phase are also evolving at Hamuel. For example, in the near future, a special gas will be able to be used to cool the tool in the HSTM machines. A machine base made of mineral casting is also now offered. One of the first machines of this type has already been presented at EMO. “This material not only exhibits excellent properties with regard to vibration suppression but we have also been able to reduce somewhat our dependency on steel suppliers,” noted Markus Stanik. For the machine user, this makes itself apparent directly in improved surface quality and a significantly longer tool service life. CNC gantry milling machines of the HSM (high-speed milling) series In addition to the component production and the construction of the HSTM series, the company’s HMS Series machines are another mainstay for Hamuel. These simultaneous five-axis machining centers are designed for high-speed cutting (HSC). They feature not only the modern Siemens drive and CNC control engineering, but also the optimized milling-head systems and the high-performance high-speed spindles, providing this capability. HSM machines allow high-performance roughing and ultra-precise finishing. With regard to the size of the HSM machines, the manufacturer adapts the designs specifically based on the customer requirements. As a component producer, Hamuel also has its own machines in constant use at its factory.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

About Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany

Hamuel was founded in 1927 and is now part of the Hamuel Reichenbacher company group. More than 2000 CNC machines from this enterprise group are currently in use globally for the machining of a wide range of materials. The focus of Hamuel Maschinenbau comprises three areas: the production of machine-tool components, CNC gantry milling machines (HSM) and five-axis CNC turning-milling centers (HSTM).

Continue readingCustomers come to Spokane to buy castings and solve problems

Spokane Industries, a family-owned company established in 1952, is a steel foundry, metal products and precision castings facility of more than 240,000 square feet in Spokane, Washington. Spokane Industries serves customers in many industries from aerospace, construction and agriculture, to transportation, aggregate processing and general manufacturing. Proud to be a family-owned company, many employees here are second and third generation who are personally and professionally committed to their customers. Customers are not just coming to Spokane to buy castings, but they are coming to solve problems. With that in mind, experience, expertise, effort and the latest technology, including MAGMASOFT® process optimization software, are used to differentiate Spokane Industries in the marketplace. Spokane strives to create quality products delivered on time and as a result, their customers’ businesses are more successful and profitable.

The Spokane Steel Foundry Division is the foundation of Spokane Industries and is committed to staying on the cutting edge of technology, upgrading its facility to optimize production and enhancing quality control procedures. Spokane Steel Foundry has been serving commercial and industrial customers around the world for more than 50 years, still maintaining some of their original customers; some are still ordering castings from their original patterns.

Experiencing decades of steady growth, Spokane Industries operates an environmentally clean, well-managed and technologically advanced organization dedicated to meeting the needs of its customers. Today, the foundry’s output includes durable wear parts for impact crushers as well as a wide variety of high specification quality castings for the construction, mining, manufacturing, transportation, aluminum and defense industries, striving to meet the demand with each project.

By introducing MAGMASOFT® at the company, Spokane quickly saw how this software’s capabilities of simulating the entire casting process start to finish, was not only an invaluable engineering tool, but also a tool that impacted the entire business. CFO Ken Vorhees reported, “Having MAGMASOFT® has improved our ability to reduce the number of samples and bring quality products to market faster through meeting specifications, tolerance and metallurgy, most often on the first run.” Foundry Division President, Tyrus Tenold, adds, “This is a very powerful tool, giving us the ability to virtually see the entire casting process before we have invested significant time and materials. We now catch problems before they become problems. By the time we are ready to run the part, we have confidence we will have a quality part on the first run, in most cases.” Using the software to run detailed process optimization for the entire casting process enabled Spokane to catch process issues anywhere in the casting process before the first actual run. The software enables the engineers here to catch potential problems with a casting before the part even hits the foundry floor and resolve them faster than any competitor not using this technology.

Having now utilized its MAGMASOFT® license for 2 years, Spokane has seen a significant change in their entire casting process. Rod Grozdanich, Technical Director, states, “We use the software to help customers refine their designs as well as convert many of their weldments into castings. Being able to simulate the entire process helps a lot, in that regard.” The software being one of the foundry’s business tools has helped them support their selling point that they are more cutting edge and in a leading group of local vendors with the latest technology and equipment.

Antonio Melendez, Design Engineer, points out, “By having MAGMASOFT®, we find that our customers expect more of us. We are confident that we can deliver and have always lived up to and exceeded the challenges our customers have given us.” He adds, “It has become common that when we go back to a customer with a design change that effects them, costs them more money, like adding a riser, they want to know why. MAGMASOFT® gives us that credibility and additional technical support for our case.”

Spokane employees discussing MAGMASOFT’s benefits – Antonio Melendez, Design Engineer, David Jolin, Quality Assurance Manager, Rod Grozdanich, Technical Director

David Jolin, Quality Assurance Manager, says, “We do see both current customers and potential customers requiring that we run the casting through a solidification program. There have been times where we have been directly told that in order to be awarded a particular job, we need to show them simulation capability. We are seeing this as a requirement, more often nowadays.”

A big part of justifying the cost of the software was being able to go back and simulate past projects to make designs changes and improve the quality of the castings for future runs. Grozdanich says, “We found many jobs that we set up with our previous simulation software where we really couldn’t see the shrink, and now with MAGMASOFT®, we can see what’s happening and we can fix it. We had chronic instances with issues on jobs in the past that we just could not solve and with MAGMASOFT® we have been able to go in and fix them all.”

Simulating the entire process from design to finished part helps save time and money by creating all the changes and making all the mistakes virtually rather than during actual production. Melendez states, “We are trying to minimize the number of samples before releasing a casting for production. The idea is to do all the tweaking on the computer without spending money to pour multiple samples. This year, we have significantly reduced the number of samples and are more likely to produce a quality part on the first run.”

In addition to the ability to simulate the entire casting process, Spokane has found a solid partner in MAGMASOFT® by taking advantage of the resources extended to them as a user. “The user group meeting every year is a very good tool to keep us informed of new developments and get everyone up to speed on anything we feel we would like to improve upon. Peer-to-peer discussions on how we each utilize the software are invaluable,” Melendez says.

Of the four capabilities that make up Spokane’s license with MAGMASOFT®, namely filling simulation, solidification simulation, heat treatment and stress analysis, Spokane utilizes all these processes to the fullest extent, including macro segregation simulation. Grozdanich points out, “In the last 10 months, on the dozen or so new projects we have put out, all but one or two were quality parts on the first run. Our time to first quality part has therefore been greatly reduced.” Jolin adds, “Being able to simulate the entire casting process has significantly fixed our shrink issue, which was quite a struggle from my end before MAGMASOFT®.” Melendez offers, “One of the main advantages of the software is one can see roadblocks before they actually happen and can compensate for them, specifically with predicting the distortion of the casting and other issues that might arise before we actually build it.”

In addition, the software helps gain understanding and provides clues to what can be happening when issues arise that initially don’t make sense. It’s proving to be a reliable troubleshooting tool by helping to gain clarity where there are issues that arise that are initially not understood. MAGMASOFT® is the missing link that helps lead to that solution, according to Spokane engineers. Antonio Melendez observes, “The software verifies what is going on, gives clarity and enables us to pass on not only an opinion, but provides credibility to support our opinion to our customer. The software is able to set particular processing parameters. For example, when pouring through a sleeve with a filter, there were scrap issues with the filters breaking. After doing some simulations and flows through that method, we could see that, for one ladle, we needed to use an inch and a half diameter nozzle, that way the flow is just right for this particular set up.”

Melendez adds, “Each casting is different, the number of iterations are different. It is more a question of how tough is the part. For example, if you have a part with isolated hot spots and you don’t have clear filling patterns, you are going to struggle. The advantage with MAGMASOFT® is you can see those trouble spots and focus on resolving the issues before creating the first sample. Even if you need to do 200 iterations in the right direction, that’s okay, because we are no longer shooting in the dark.”

At this foundry, it’s clear that their use of process optimization software is yielding benefits across the entire business environment, from design through material use, production through part validation and in differentiating Spokane Industries from its competition in the marketplace. The result is more work being processed more efficiently, with the plant’s capacity utilization being much higher and more profitable, according to Spokane personnel.

For more information on this story, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-969-1001 ext. 225

Email: cheisser@magmasoft.com

Web: www.magmasoft.com

Jim Fitzgerald Named COO at Hunter Automated

An announcement from Bill Hunter, CEO of Hunter Automated Machinery Corporation, the world leader in automated matchplate molding machines, mold and sand handling equipment for the foundry market, Jim Fitzgerald will assume the newly created position of Chief Operating Officer, effective Friday – February 1, 2013.

Jim began his career as a machine assembler for Hunter in 1977, shortly after his graduation from Central College in Pella, Iowa. For the past 35 years, he has been dedicated to shop operations and manufacturing management at Hunter. He was promoted to his current position as Vice President at the company, following Art Hisel’s retirement in 1992.

Jim’s responsibilities as COO will include all Schaumburg, IL-based activities, with the exception of Sales and Marketing. His goals will include maintaining and building upon the company’s reputation for producing the world’s highest-quality foundry machinery and for providing superior after-sale support.

“Jim brings the education, proven ability and determination to help Hunter achieve these goals. His leadership and commitment to our company is unquestionable and exemplary,” said Bill Hunter in making this announcement.

For more information on this news, please contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive

Schaumburg, Illinois 60196-1094

USA

Phone: 847-397-5136

Email: sales@hunterauto.com

Energy savings with “E-motion”

Servo-electric pump drive optimizes hydraulic presses — from a technical and energy efficiency perspective

The servo-electric pump control for presses, developed by Lasco Umformtechnik GmbH in Coburg, uses far less energy than conventional valve control systems, often well into the double-digit range, according to this press builder.

A hydraulic pump directly coupled with a servomotor is an energy-efficient solution that delivers a highly dynamic performance with double-digit energy savings typical. The press manufacturer Lasco uses this servo-electric pump drive for solid and sheet metal forming presses. “This drive system provides us many performance advantages,” says Harald Barnickel, Head of the Electrical Engineering Department at Lasco Umformtechnik GmbH.

Harald Barnickel, Head of the Electrical Engineering Department at Lasco Umformtechnik:

“The innovative servo technology that we have developed for hydraulic presses was previously not available on the market.”

“Our new servo technology provides substantial energy savings for companies operating our presses,” says Harald Barnickel, Head of the Electrical Engineering Department at Lasco Umformtechnik GmbH, a machine tool builder in Coburg, Germany, in describing the significant advantages of this innovative forming press technology. This well-known manufacturer of systems for solid forming and sheet metal forming produces screw presses, forging hammers, forging and cross wedge rolls, and even complete plants that are used by the building materials industry to produce sand-lime products. When Lasco was first founded in 1863, the main focus was on the iron foundry. However, just a few years later, it began producing water turbines, followed by forging machines in 1880. Since then, the company has concentrated on producing machines for forming technology, and has been active worldwide for many years. “As a solution provider, we develop customized systems for optimized workpiece transport within the press as well as for feeding and removing workpieces,” Barnickel reports. The company has a strong focus on continuous improvement in its processes and technology. And the servo technology mentioned above is exactly this kind of technological milestone, as demonstrated through Lasco’s implementation in a recently delivered deep drawing press with a press force of 800 tons for up to 40 strokes per minute.

A fast controller at the core

At the core of this type of solution is a Simotics 1PH8 servomotor from Siemens, which directly drives the hydraulic pump. This drive is controlled by the Sinamics S120 drive platform. A Simotion D445 motion control system handles the complete path, velocity and position control of the axes —

the Simotion controller and Sinamics drive are both from the same manufacturer. With a response time of 250 µs, up to 256 axes can be rapidly synchronized and precise axis motion and curve profiles are executed. “The initial applications have demonstrated that this type of servo technology provides outstanding results,” says Barnickel. This applies to the closed-loop control performance as well as to its energy efficiency and the application as a whole.

The challenge on the deep drawing press was to control the press force and press speed, based on a motion profile that could be set individually. The hydraulic force and thus the press force can be adjusted at the servomotor by means of the torque. The plunger speed is controlled by the motor speed and thus by the volumetric flow rate of the pump. For the project described, axial reciprocating pumps with a fixed displacement per revolution were used.

Scalability of the pump systems is a significant advantage

Four such pump systems connected simultaneously for a maximum pressure of 250 bar supply the pressure line for the press stroke of the plunger; three additional pump systems are responsible for the return stroke of the press plunger. “The possibility of scaling, in other words adapting this kind of standard servo solution to the actual requirements, is another advantage of this new technology that certainly cannot be underestimated,” notes Barnickel.

The hydraulic oil tank of the deep drawing press holds about 2377 gallons (9,000 liters). Because of the high flow rate of 16,000 l/min, filling valves are used for the fast downward motion of the plunger. The servo pumps provide the required flow rate for the actual pressing operation, with a speed of up to 100 mm/s. In the past, high-precision control valves with zero overlap were necessary to obtain the precise traversing profiles. Today, this function is handled by the motion control system, in conjunction with the servo pumps. Thanks to this new technology, the valve systems in the press can be reduced by up to 40 percent. The remaining valve technology is mainly needed to comply with machine safety specifications.

Energy milestone

As a result of the new technology, expensive, traditional valve systems were eliminated, and energy efficiency has been significantly improved. Electrical expert Barnickel knows this only too well. “In the past, the large cooling systems for the hydraulic oil had to be installed before the first test run at Lasco. But now, with servo technology, significantly smaller units can be used, and they are not required until the press is actually operational at the customer’s facility.” One reason for this is that the oil is no longer forced through the narrow gaps at the control edges of the control valves, which means that these types of technology-related losses no longer occur in the first place. The press manufacturer is seeing efficiency improvements well into the double-digit range depending on the application, significantly reducing users’ electricity costs, compared to older machines.

When comparing the new technology with very basic hydraulic presses using conventional technology, the amount of energy saved is certainly less than with presses equipped with complex control systems. The energy-saving effect is especially apparent during the drawing operation, during which the drawing pressure is provided by a pump equipped with a servomotor, with the motor of the die cushion pump thereby operating as a generator.

Another advantage of the electrical system used here is that energy can actually be recovered when the hydraulic fluid decompresses. This happens when the system is decompressed after the pressing operation and the main cylinder pressure must be reduced from 250 bar down to approximately 10 bar before the filling valve to the tank can be released. This operation takes approximately 100 ms. In the case of a compressibility of the hydraulic oil used of approximately 2.5 percent by volume, with a cylinder volume of approximately 800 liters of oil, the “spring energy” in the oil flows through the axial reciprocating pump and drives the servomotor. This effect is amplified when the press mechanical system is relieved. In this so-called generator or regenerative operation, the corresponding electrical energy is fed into the DC link of the S120 drive during each cycle. “However, in addition to the energy recovered, the other advantage is that there are no additional power losses in the form of heat, as would be the case with conventional concepts,” Barnickel explains.

Straightforward optimization — and everything immediately documented

Although the Siemens Simotion controller has been specifically optimized to address motion control applications, Simotion can also control the complete system. However, Lasco’s philosophy is to separate the various press tasks, and it therefore uses a separate PLC for the system control. As a fail-safe control, this also addresses the safety technology requirements. Simotion can be programmed in various ways, for instance, with high-level-language, graphic programming, or Motion Control Chart (MCC) as well as a classic logic control. The trace function with eight-channel plotter supports commissioning engineers and ensures detailed documentation of the press operation. Control parameters are saved in the drive, which guarantees seamless documentation of the drive system.

The drive unit for the pump control consists of Simotics servomotors, Sinamics S120 drives and Simotion D445 motion control devices from Siemens.

Safety technology simply integrated

In addition, the fail-safe Simatic S7-319 F 3PN/DP PLC from Siemens, used here as the press system control, allows all safety technology to be implemented without any major additional expense. The fail-safe signals are read via distributed Simatic ET200S I/O stations from the same manufacturer and transferred to the control via Profisafe. This represents a simple yet complete solution for Lasco press engineer Harald Barnickel, who notes, “As a consequence, we obtain a clear machine structure.”

For instance, there are generally two monitored valves, which monitor the reduced traversing speed of the plunger, when setting up. The new solution is far more precise, where the fail-safe S120 drive also monitors the reduced speed (Safely Limited Speed: SLS) as well as a safe stop (Safe Stop 1: SS1).

Simple parameterization through a seamless, integrated system

The press experts at Lasco also view the integrated, seamless nature of the Siemens systems as an additional benefit. For example, the drive automatically identifies the servomotor and reads its parameters. Another interesting feature of this servo solution is that the 1PH8 motors are available either as synchronous or asynchronous motors. The application itself, or more specifically, the dynamic performance required, is the decisive element in selecting the appropriate motor type, according to Barnickel.

Both versions have the same mechanical mounting dimensions, the same wiring and the same encoder connection. Here, too, this state-of-the-art technology has some significant advantages. For instance, instead of a typical 17-core cable, a single cable with RJ45 connector is sufficient.

And finally, this new drive concept for hydraulic presses, based on a servo-electric pump control, results in a significant overall improvement: “In addition to the energy savings, its extremely precise controllability is far superior to that of a classic valve control,” says Harald Barnickel. As he further noted, any defined motion profiles can be precisely implemented using this concept.

The motion control system has also proven itself to be extremely valuable in certain steps of the pressing process. For instance, if the plunger moves to upper dead center, then the closed-loop position control in Simotion ensures that any leakages are compensated. “A far higher precision is achieved when using servo technology than when using pure valve technology,” Barnickel summarizes.

Servo technology ensures dynamic performance of the press

The development of new servo technology for large hydraulic presses, based on the Simotion motion control system from Siemens, has already awakened significant interest among customers of Lasco Umformtechnik GmbH. However, it is not only when building new machines that this dynamic company of 400 employees benefits from lower costs and improved quality; the drive concept described is also suitable for modernization and retrofit projects.

With the standard concept, comprising the Simotics 1PH8 servomotor, the Sinamics S120 drive platform and the motion control unit, Lasco Umformtechnik GmbH has clearly demonstrated that, when hydraulic presses are equipped with servo-electric pump drives instead of pure valve technology, the dynamic performance, precision and especially energy consumption on the press are improved. This results in tangible press improvements that are decisive in the marketplace. For Barnickel, it’s clear: “Anyone who addresses the challenges of press technology with E-motion (energy in motion) is creating innovation.”

For more information on this story, please contact:

Siemens Industry, Inc.

Drive Technologies — Motion Control Business

5300 Triangle Parkway, Suite 100

Norcross, GA 30092

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

NOARK Enters North American Market

The NOARK value proposition centers on products that improve the profitability and maintain the highest levels of performance for customer end products, through the combination of local support with local inventory, exceptional value and superior product quality, backed by the industry’s first 5-YEAR WARRANTY.

- 9B1N-DIN Rail Miniature Circuit Breakers

- 9B1H-Thermal Overload Relays

- 9B1E-Definite Purpose Contactors

- 9B1A-Definite Purpose Contactors

- 9M1-Molded Case Circuit Breakers

- Ex9C-IEC Contactors

- Ex9R-Overload Relays

- Ex9C-Definite Purpose Contactors

ALL ABOVE NOARK PRODUCTS ARE UL489 LISTED.

NOARK Electric, Inc., the North American headquarters of the company, was previously located in Rockford, IL and, due to its rapid growth and inventory commitments, has recently moved to a larger facility in Oak Creek, WI, just south of Milwaukee.

The company is currently in the process of establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries.

A global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1000 associates. Sales for the company exceed $2 billion worldwide.

For more information, please contact:

NOARK Electric, Inc.

9817 South 13th Street

Oak Creek, WI 53154

Phone: 414-304-8189

Website: www.noark-electric.com

Email: tony.diaz@noark-electric.com

Attention: Tony Diaz

Siemens and Biglia Offer Full Flexibility in New “Quattro” Series of Turning Centers

Highlights include two-sided machining and servo drive technology

Recently, Northern Italian machine tool manufacturer Biglia introduced its multi-functional turning centers of the ‘Quattro’ series with the Sinumerik 840D sl CNC. The mechanical concept, together with the scalable control, provides users with the most diverse standard turning and milling operations. The result is increased flexibility and higher speeds for end users. That quality machine tools are built in Northern Italy is nothing new. And this fact is confirmed again by the “Quattro” series from the machine tool manufacturer Biglia. These machines are multifunctional turning centers that are valued throughout Europe for their high reliability and performance power. The machines are available in different versions from 11 to 15 CNC axes. They are also intended for different turning diameters (45, 52, 65, 71 and 80 mm).

Biglia has equipped its turning centers of the ‘Quattro’ series with the Sinumerik 840D sl CNC control. The individual machines have 11 to 15 NC axes.

The two opposing spindles form a special feature of the “Quattro” series. This allows the workpiece to be machined from two sides, which reduces the machining time. The second spindle can also be moved linearly in two directions (lengthwise and crosswise). This provides some leeway in the case of additional milling operations, but it can also be used for automatic workpiece unloading. Two turrets, mounted on the y-axis, ensure proper positioning of the necessary tools.

The turning centers from Biglia have two spindles and two independent tool turrets for simultaneous machining.

This innovative machining technology allows the creation of not only rotary but also prismatic workpieces – including polygons. Dealing with everything in one setup not only reduces cycle times, it also enhances accuracy. The machines are developed on the basis of a modular concept that ensures flexible application options – from the universal CNC lathe, to complete machining of complex workpieces with powered tools (c- and y-axis).

Getting it right, from the start

By offering the Siemens Sinumerik 840D sl CNC control, Biglia now wants to expand its previous options and its own market by combining its technologies with that of the Siemens control. “In this project, which is of personal significance to all of us who worked on it and of strategic significance for Biglia, we wanted to do everything perfect right from the start and to get the most out of it,” says Giovanni Delmondo, Business Development Manager for machine tools with Siemens Italy. The result is an all-round successful machine series with a highly modern control that already includes the innovative system expansions of recent months – including increased energy efficiency options offered by the control and drive systems from Siemens.

To illustrate this, Giovanni Delmondo points out that “the fans on the spindles are shut down automatically when they are not required, or certain services such as hydraulics, lubricant supply, or compressed air are deactivated during machine standstill times. This is handled via special screen forms on the control and is extremely simple, using the Run MyScreens function.”

Also notable is the standard energy efficiency solution from Siemens in the Sinamics S120 drives onboard this machine series. This includes automatic power factor correction or regenerative feedback of the energy generated in braking operations, a substantial factor in energy savings.

Performance and scalability

The centerpiece of the automation concept of these Biglia turning centers is the Sinumerik 840D sl control. This is a universal and flexible CNC system, implemented in the Sinamics S120 design (see Fig. 3). It is suitable for up to 31 NC axes. Whether you are turning, drilling, milling, grinding, laser-machining, nibbling or punching, the Sinumerik 840D sl is suitable for use in the most diverse machining technologies. The CNC control also has PLC (programmable logic controller) functionalities, so that a special PLC can be eliminated, if applicable.

This high-end control from Siemens is ideally suited to medium and complex tasks and production and can be adapted to the task, thanks to scalable hardware. The CNC is also characterized by openness, so the operator interface and also the software present few limits to specific job adaptability. This applies all the way to supplementing the NC core of the control; however, a special license is required for this adaptation.

On the Biglia turning centers, the control was equipped with the Sinumerik Operate user interface, making operation simple and intuitive. Three different methods of parts programming are possible: Classic ISO code programming, programming with the help of the integrated ProgramGuide with graphical support of the selected cycles, and the new two-channel ShopTurn with graphical 3D simulation. The user is led step-by-step through the cycles, whether for simple metal removal, drilling, thread cutting, pocket milling, groove milling or engraving. Complex programming cycles for complex contours are also possible. The “ProgramSync” function for automatic synchronization of the machining programs via two channels ensures a significant increase in machine productivity. The control is equipped with a 15″ monitor and integral keyboard.

The Quattro series from Biglia also uses the highly effective personnel and machine protection system provided by the Sinumerik control concept with the Sinumerik Safety Integrated package.

Biglia is also breaking new ground with servo drives. Thus, the new servo motor generation 1PH8 from Siemens is used for the main spindle motors in this series. The linear axes are further equipped with the new 1FK 7 G2 series of permanent-magnet synchronous motors. These motor types from Siemens enable onsite replacement of the encoders without having to dismantle the complete motor. This combination of machine and CNC control in the Quattro turning centers from Biglia provides users with greater flexibility.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensSiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading