Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Located in Effingham, Ill., B&L Machine & Design specializes in the remanufacturing of various printing presses and ancillary equipment. Its particular expertise is on the Harris M-1000 and M-110 series presses, as well as splicers, infeeds, chillers and folders. By redesigning all the electrical and mechanical components and subsystems, B&L exceeds customer expectations for the increased set-up, changeover and print speeds demanded by today’s publishing industry, while saving substantial capital for commercial printing companies.

Ovid Bell Press in Fulton, Mo. specializes in print runs from 5,000 to 125,000 copies and works for a variety of multi-color magazine and journal publishers. Recently, B&L needed to help this customer perform shorter-run production work as well as meet the critical make-ready time reductions. Make-ready, in this case, is defined as the period from deceleration

According to Jim Strange, manufacturing manager and electrical engineering supervisor at B&L, “I would say that the shaftless printing implementation on this particular Harris M-1000 press was the biggest part of our challenge. We had determined a shaftless design was the best solution to provide the flexibility of options needed for our core base of printing equipment, in order to compete in this new short run arena.” Strange explained that the press infeed system was converted to a belt drive, eliminating the need for gear trains and oil baths. All the web tension controls were moved to the servo motion processor, thereby further reducing component count.

Finally, the folder section of the press was rotated, creating a smaller footprint and improving the folder use, which enabled this customer to install another similar press that can feed either the existing folder or new one. This solution created a more flexible pressroom for better response to market conditions and job flow.

To help with this conversion, B&L contacted three of the largest suppliers of servo control systems for its industry. Each candidate was supplied a press layout, specifics on each piece of required equipment and print quality goals needed to achieve a successful project. A 30-day window was allotted for proposals. When all the proposals had been received and reviewed, the project was awarded to Siemens. Larry Hines, president and owner of B&L, attributed this decision to the vendor’s design assistance, technical competence, service

The Siemens solution included a Simotion D445 motion controller, Sinamics S120 drives and 1PH7 servo motors. B&L utilized the Simotion Shaftless Standard, a pre-configured application that implements the basic operations for a coordinated motion system and includes rudimentary HMI screens. This software is provided at no charge and saves a great number system engineering hours.

An all-servo design enabled B&L to eliminate drive lines and gave this remanufacturer considerable flexibility in the reconfiguration of existing equipment. Rod Davidson, senior mechanical engineer for B&L, said, “The servo drives enabled us to redesign the entire infeed, and we integrated an absolute encoder to control web tension for smoother operation. Furthermore, the servo drives in the print units let us remove a large number of existing components. Being able to access all the motor position information and scale it to our needs made it easy to build intelligent HMI screens for setting up the phasing, plate positioning and register control.” Finally, he noted the servo drive in the chill unit facilitated further reduction of component count and simplified belt drive configurations. All the mechanical and electrical reconfiguration was accomplished without the need for costly clutch components, according to Davidson.

Overall install time on the press was cut by over 25 percent, due to less drive line construction required, while manufacturing time was reduced by 20 percent, thereby benefiting B&L and its customer alike.

Mechatronics Identifies Problem During Commissioning, Helping Customer Complete Project

During the commissioning process on this Ovid Bell printing press rebuild at B&L, a mechatronics analysis and optimization protocol was conducted by Razvan Panaitescu, engineering manager for mechatronics standards and regulations at Siemens, working in tandem with his Siemens counterparts in application engineering and installation. Mechatronics is the integration of electronics and mechanical engineering, relating to the performance or the design of equipment and machinery. Razvan Panaitescu is a leading authority in this discipline for Siemens.

A problem had surfaced during the test runs on the rebuilt shaftless Harris M-1000 offset press, involving an out of tolerance registration issue. The registration points were visibly oscillating, and the cause was initially thought to lie with the controllers or drives installed as part of the new Siemens product suite onboard.

However, Panaitescu and his team determined the problem resulted from gaps between both the plate and blanket cylinders on the press. When the controllers were finely tuned in a damping optimal setting of higher integrator times

As Panaitescu mused, “Just as a doctor uses the stethoscope on patients, we listen to the drives and press cylinders. From our analysis, we determined the mesh frequency was indicating a sprocket/gear problem.”

In the end, it was determined by B&L and its supplier that an off-normal angle bore on a gear and sprocket assembly was indeed the root cause of the registration problems. Replacements were installed and the press is running well, the result of the mechatronics applied here.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

OR

B&L Machine & Design

Phone: 217-342-3918

Fax: 217-342-2081

Web: http://www.blmachinedesign.com

Email: lhines@blmachinedesign.com

Attention: Larry Hines, President/Owner

Robust design combined with smart, powerful motion control components yields high-performance shot peening machines at a user-friendly price

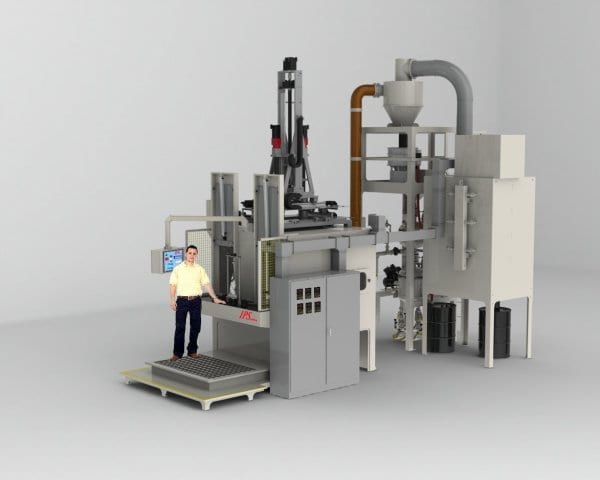

In a shot peening machine, steel shot from a reservoir (right) passes into a compressed air stream and through a nozzle to impact the surface of a part held in an enclosure (left). Photo credit: Innovative Peening Systems Inc.

When it comes to parts like airplane wings or engine blades, failure is unacceptable. To reduce the possibility of metal fatigue, manufacturers use a technique called shot peening, in which a hail of 0.014-in steel balls creates microscopic dents in surfaces of metal parts, strengthening the material and extending its lifetime. The process was once performed manually. Today, at companies like Innovative Peening Systems (IPS; Norcross, Ga.), shot peening is fully automated. IPS combines its proprietary Intelligent Motion Control (IMC) software with motion control technology from Siemens Industry, Inc. (Alpharetta, Ga.) to create reliable, high-performance machines at an economical price.

At first, surface deformation might seem more likely to reduce material strength than enhance it. In reality, the rounded dents generated by shot peening convert tensile stresses, which tend to compromise material integrity, into compressive stresses that act to hold the material together. The shot peening effect extends into the material roughly three times the depth of the dents.

Most automated peening machines leverage computer numerical controlled (CNC) technology. CNC technology is designed for high-precision applications like milling and diamond turning, however, and offers performance somewhat beyond what’s necessary in this, essentially, high-tech sandblasting operation. The design team at IPS, working with Siemens, who happens to be the market leader in CNC, realized that, by using alternative intelligent motion, it could produce a shot peening machine that would perform just as effectively¾and far more economically.

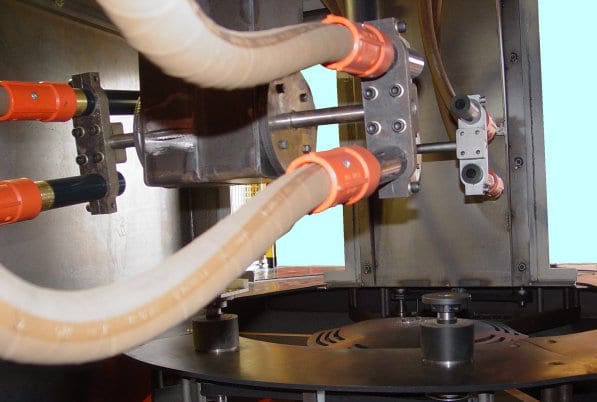

In this three-axis machine, the nozzle (upper left) sprays shot at a part installed on the turntable.

Designing for robustness

In a shot peening machine, a reservoir introduces steel shot into a compressed-air stream that passes through a nozzle to strike the part. The process takes place inside an enclosure that protects both operator and machine¾but only to a point. A typical machine contains about 2,000 pounds of shot, which amounts to hundreds of millions of particles flying around at high velocity. The potential for damage to components exposed to the shot makes the punishment inflicted by caustic washdown seem mild. “The 0.014-inch shot is the perfect size to make its way inside the seal of any kind of moving part and lock it up,” says Nick Hart, electrical engineer at IPS. “Metal shot will get inside anything it can and short it out electrically.”

The IPS team realized early in the process that the solution was to pull the motion control elements outside of th

e enclosure. The resultant six-axis nozzle manipulator consists of a three-axis (x,y,z) gantry that rides above the machine and drives a rigid arm tipped with a nozzle. The arm extends into the enclosure through a single hole with a carefully designed seal; everything else is protected.

The x,y,z motion of the gantry essentially provides coarse positioning for the arm. To ensure that the stream of shot strikes even conformal surfaces at normal incidence, the nozzle itself provides two additional degrees of freedom: rotation about the x-axis(the A-axis) and the y-axis (the B-axis). The actuators for the A-axis and B-axis are sealed inside the solid housing of the arm; the motors and drives remain outside of the enclosure. The final, sixth degree of freedom lies in an axis that rotates the part itself (C-axis).

Rather than redesigning each machine from scratch, IPS started with a standard motion platform, adjusting the enclosure for a particular project. In the case of large parts like 100-ft-long airplane wings, for example, it might gang together multiple nozzle manipulators. “We used standardized components that have been proven in the industry, but we customize every enclosure to fit the customer’s product,” says company president Dan Dickey. “They get a machine that fits their part, at a good price, but it’s not a new invention for us, every time we build a machine.”

Designing for performance

The specifications called for the nozzle manipulator to move at a maximum speed of 500 in/min. On the face of it, such a requirement is more demanding than challenging. The problem is inertia; fully charged with shot, the assembly weighs around 2000 lbs. It requires a lot of muscle to accurately position that much mass at 500 in/min. For a solution, the team again turned to Siemens.

The selected system combines Sinamics S120 drives in Booksize format and servomotors from the 1FK7 family. Although the S120 drives feature onboard memory and processing power, the IPS team chose to use them in a centralized control architecture, in part because the components were already grouped together on the nozzle manipulator carriage and in part to provide additional protection from contamination.

In this shot peening cabinet, a part on the turntable (bottom) projects up between the sets of nozzles for treatment. This type of design is best suited for parts with high production rates.

If Sinamics supplies the muscle, Simotion provides the brains in the form of the D435 drive-based controller. “It allows us the flexibility to create custom software [IMC] for the shot peening application, whereas some of the alternatives in the industry do not give you a lot of freedom,” says Hart. The milling and turning applications typically performed by a CNC machine are inherently rotational, while shot peening is raster-based with a different coordinate system. As a result, engineers using CNC technology for shot peening must write additional code to adapt the system. Motion control with the Simotion D435 enabled the IPS team to develop its shot peening software directly, simplifying engineering and enhancing performance. “In some of the other applications, you are trying to take a product that was designed for a milling machine and teach it how to run a shot peening machine,” Hart says. “This time, we just designed a shot peening machine from the ground up.”

The Simotion system stores parameters on a removable memory card that can be swapped out to instantly update software. The controller also offers trapezoidal motion profiles, compensating for the inertia of the nozzle manipulator at high speed by providing controlled acceleration and deceleration. This approach improves performance while reducing motor wear and, consequently, points of failure.

In this shot peening machine, metal parts in the chamber (right) are exposed to a high-pressure stream of shot, which modifies internal stresses to strengthen the material. A filtering system allows undeformed shot to be reused and deformed shot via spiral discharge to be ejected from the system.

Of course, the most common source of failure is cabling. Connecting the components with Siemens Drive-CLiQ helped create a reliable solution. An Ethernet backplane based on a 100 Mb/s serial interface, Drive-CLiQ automatically captures nameplate data and validates components, speeding device integration. In the harsh shot peening environment, Drive-CLiQ offers other benefits. Manually terminating cables requires closing up open connectors on the factory floor, always a risk for contamination. Drive-CLiQ connectors are pre-sealed at the factory, which speeds commissioning and gives engineers one less problem to worry about.

Ultimately, the machine design leveraged Siemens solutions throughout. Working with a single vendor brought benefits like simplified ordering and integration, as well as reduced cost of ownership. “The members of the IPS team were unfamiliar with Siemens technology at the start of the project, but once they got comfortable with it, they became fans. Initially, we only decided to go to Siemens for that one particular machine, but after we saw what it could do, it pretty quickly turned into something that we are going to use in several applications,” says Hart. IPS is actively pursuing international business and its value proposition gets a boost from the global support offered by Siemens.

Not to mention the performance. In addition to meeting the speed spec, the system positions to 0.001 in, repeatable to within 0.005 in. The company has multiple machines deployed. “The first machine has 18 months in the field,” says Hart. “I just talked to the customer and they say the machine is repeatable, accurate and reliable. They have no complaints.” That is impressive, considering the machine is operating 16 hours a day, five days per week. The others are running around the clock, five days per week, and Hart has heard of no problems, thus far.

In addition to providing robust, intelligent, accurate motion control technology, Siemens supplied the engineering assistance that helped springboard IPS to success with their machines. “The technical support was really outstanding. Anytime I had a question or problem, I could pick up the phone and find someone to help me work through it, or I could go to their facility and simulate the problem on some of their equipment,” Hart says. “They were really helpful in getting this project up and off the ground.”

For more information:

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

By combining careful engineering and high-functionality motion control components from Siemens, R.A. Jones produced a high-speed, high-flexibility cartoner that had the customer coming back for seconds.

By: John Ryan, Packaging Industry Consultant, Siemens Industry, Inc.

The HMI (left center) operates the cartoning line (silver and black enclosure at left), which is capable of packaging 330 bottles per minute, the result of Siemens motion control technology and R.A. Jones engineering. The enclosure at center right holds empty cardboard cases after the carton blanks are removed. Photo credit: R.A. Jones

There is a saying in retail that the package sells the product. While this might not be true across the board, for OEM machine builder R.A. Jones, located in Covington, Ky., the package does indeed sell the product—the company builds packaging machines and cartoners for a wide range of applications. When a U.K.-based spirits distiller changed to a new carton for its high-end Scotch, it turned to R.A. Jones for a cartoning solution. With the help of Siemens motion control components, software and engineering support, the resulting machine was so successful that the company ordered a second version even while the first was being commissioned.

One of the challenges of this project was the speed required¾the process needed to run at 300 bottles per minute with a 10 percent surge capability. The machine had to separate the incoming bottles, transfer each into an article bucket, bring the bucket into the machine, erect the carton, transfer the bottles from bucket to carton, close the carton, stand it up, then discharge it from the machine. This complex sequence had to be performed at a rate of five times per second.

Additionally, the project had very stringent quality requirements. Because the product was a high-end Scotch, there was virtually zero tolerance for any marks on the bottle, the label or the box. The customer wanted the ability to reject individual cartons, individual bottles or cartons with no bottles in them, all without derating the line. The line needed to be able to switch rapidly and easily among packaging 700 ml, 750 ml, and 1 L bottles for two premium brands. To further complicate the process, the bottling plant is located in Scotland, while R.A. Jones is based in the United States.

R.A. Jones has a standard line of product platforms, but where it really shines is in customization for challenging applications. “In general, we are known for high speed and flexibility,” says William Kaup, Technical Sales Manager at R.A. Jones. “While we have standard product lines, many customers come to us for custom or complicated projects.” Often, the OEM machine builder develops a solution by making a few modifications to an existing platform. That was not the case for this project, however. The engineering team nominally started with R.A. Jones’ Meridian cartoner design, but instead of augmenting 80 percent standard platform with 20 percent customization, the project followed the opposite ratio. “We knew it would be an engineering-heavy, custom application,” says Kaup. “The high number of axes required for this project, in and of itself, placed this system at the high end of the complexity scale that we see.”

Getting smart with SIMOTION

The cartoner incorporates 27 axes powered by Siemens servo motors and Sinamics S120 drives. Although much of the machine leverages what Kaup characterizes as fairly standard coordinated motion, some aspects required more. To address all these needs, the engineering team chose the Simotion D445, which integrates the capabilities of a PLC and a motion controller to offer significant intelligence and processing power in a compact form factor.

“The D445 works with compiled code versus assembled code, so it is faster,” says Jason Barter, Application and Development Engineer at R.A. Jones. The Simotion D445 provided all the processing muscle for the cartoner, allowing the team to use the Sinamics S120s as passive drives. “This solution worked well,” Barter adds. “For a 27-axis machine with one processor, the overall throughput of the machine was very efficient.”

To connect the drives to the D445, the team used Siemens’ Drive CLiQ. An Ethernet backplane based on a 100 Mb/s serial interface, Drive CLiQ automatically captures nameplate data and validates components, simplifying device integration and replacement by maintenance staff. After all, plug-and-play operation only works if the right device is being plugged in. “Basically, [Drive CLiQ] recognizes that the correct motor and drive for that particular axis have been connected, so someone would not be able to put in the wrong size motor or wrong size drive,” says Barter. “It helps the client get the right components in the right place.”

Maintaining continuous operation at 300 bottles per minute required an automated carton-loading system to ensure a steady supply of packaging materials. In the carton-loading system, a robotic arm from an outside vendor picks up cases of carton blanks from a pallet, inverts them, and sets them, case and all, in the magazine of the cartoner. The Jones flexbot, a two-axis pick-and-place unit powered by Siemens servo motors, lifts the case off of the stack of blanks and sets the empty case on a trash conveyor. The two-axis pick-and-place unit was controlled from the cartoner’s D445 controller as part of the 27 axes. The Siemens support staff developed custom function blocks to allow the R.A. Jones team to more easily program the equipment.

With a system consisting of a 27-axis cartoner, the robotic-arm carton loader and a pallet handling system, the number of connections added up. “We had two racks of Siemens ET200S I/O on the cartoner,” says Barter. “It was quite an extensive machine.” The pallet handler and de-palletizing robot formed a system by themselves. The pallet handling system was controlled by a Simotion D425, which interfaced with the robot controller over Profibus. The design team integrated the pallet handling system with the cartoner by way of a Profibus connection between the D445 and D425. “We interfaced the robot controller with the Siemens D425 controller just to get some [communications] back and forth and also interfaced that controller to the cartoner,” Barter continues. “We connected the D425 to the main cartoner machine controller (the D445) over Profibus, and then ultimately those two machine controllers communicated with one HMI over Ethernet.”

Although the interface between the D425 and the robot was straightforward, having two machine controllers communicating with a single HMI provided more of a challenge. The Siemens engineering team stepped in to help. “Between Siemens and our distributor, we had quite a bit of support to ensure that we could progress through the development and factory acceptance test of the equipment as rapidly as possible,” Kaup notes.

Troubleshooting at a distance

This upstream view of the cartoner shows the pallet stacker of the robotic system (yellow-paneled enclosure) and the main electrical panel (right). Photo credit: R.A. Jones

In addition to the performance specifications, the customer wanted to incorporate remote access to allow R.A. Jones support engineers in the United States to be able to access the machine online. Here, too, Siemens supplied a solution: the Scalance S612 security module, an industrial-Ethernet switch that provides secure remote access through Internet gateways. Using the Scalance security module and standard Siemens engineering software, R.A. Jones engineers can troubleshoot the machine as though they were standing right in front of it.

The approach not only saves the cost of flying in support staff, it reduces the downtime spent waiting for them to arrive. On a packaging line that processes high-end spirits at 300 bottles per minute, this is an important benefit¾an hour of downtime alone can add up to hundreds of thousands of dollars. The Scalance S612 has already been used to resolve minor issues, Kaup says. As an important side benefit, R.A. Jones engineers have also been able to combine that connectivity with the machine network to access the robot arm on the pallet handling system, even though it is not a Siemens product.

The finished cartoner was shipped from the R.A. Jones facility to the spirits distiller’s plant in Scotland on nine full-sized pallets packed into three freight airplanes. With its combination of hardware, software, and engineering, the machine has achieved a maximum speed of 330 cartons per minute, which meets specification with the required 10 percent surge. “The machine is running well, with only a few application specific issues to be resolved,” says Barter. Based on the success of the first machine, a second one was ordered.

“Although we had used the Siemens Simotion D on several of our other standard product lines, there was a learning curve [with the first machine] because this project was on a much larger scale than we had previously done,” says Kaup. “The second machine went much more smoothly.”

The success of the project came from a combination of quality components, careful design and a tight engineering collaboration. “I think the engineering support provided by Siemens and our local distributor, C&E Sales, was vital to the success of the project,” says Kaup. “I do not think the development could have been done in the timeframe required without that assistance.”

The package may sell the product, but in this case the product sold the packager and the result was repeat business, a satisfied customer and a new set of tools to use for success.

About the author

John Ryan is a Packaging Industry Consultant at Siemens Industry, Inc., Drives Technologies, Motion Control, Production Machines, John.Ryan3@siemens.com.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

The float glass industry is facing multiple challenges, not the least of which is a growing array of applications requiring a broader offering of products and sizes, and competition from offshore producers.

The need for more flexibility and speed in the production process has never been so important. Similarly, the necessity to reduce production costs and optimize profit margins has never been so critical. Smart glass producers are finding that replacing manual functions with streamlined automation is not only meeting these objectives, but also has become a requirement for long-term stability and success.

Of all the functions on the float glass line, stacking remains the most labor intensive, and therefore a key target for automation. Glass producers have been looking for a more efficient, reliable and cost-effective method to stack the expanding selection of glass sizes they manufacture. Some producers have automated their stacking, but have experienced difficulties with speed of throughput, because of glass stacking displacement causing breakage.

But many more float glass producers are still handling stacking manually without the aid of any controls automation.

Fully automated cold-end line

Effectively streamlining the uniformity and quality in the making of plate glass – a new generation of glass-handling equipment has emerged, which is destined to change the landscape of cold-end line process efficiencies. Developed by Grenzebach, in tandem with Siemens, a new line of glass-handling equipment is being released featuring integrated controls systems that provide a fully automated solution to the handling of finished float glass. Every function of the cold-end line is being integrated into one controls automation platform – including take-over of the glass from the lehr, cutting the glass ribbon into sheets of optimum size, glass snapping, rejection of faulty glass sheets, sorting according to size and quality, and stacking into glass racks with robotics.

The cold-end line requires that multiple, continuously-operating functions be precisely and sequentially connected. Grenzebach and Siemens have effectively brought each of these functions into one complete and totally integrated automation controls system, with the net effect of reducing production costs and increasing throughput. This package of automation controls is equally applicable to individual machines in the line, so additional line equipment can easily be added to the system at the discretion of the plant.

Grenzebach

Grenzebach is a pioneer in float glass cold-end equipment. In 1974, the company developed the world’s first processing systems for automated float glass production. In addition to machines for transport and handling operations, and cutting and breaking lines, systems for identifying flaws, glass quality control and optimization of material yield have also been created.

Grenzebach Corporation is the U.S. subsidiary of Grenzebach Maschinenbau GmbH of Hamlar, Germany, which is a global manufacturer of production equipment for the flat glass and construction material industries. It is recognized as an international mechanical engineering company, with development and production facilities in Germany, the United States and China. Worldwide, the Grenzebach Group has some 1,400 employees.

High-Speed Stacker

The first piece of Grenzebach equipment to exclusively utilize this advanced automation technology is the company’s new High-Speed Stacker. Designed to increase glass manufacturer’s efficiency and flexibility, it was developed for stacking small glass formats with high cycle times, and is currently the only device which can stack glass sheets in less than a one-second cycle. The new system is the world’s most flexible glass stacker.

It is a robot-assisted float glass stacker, which reaches its speed from quickly forming sub-packs of glass and achieves its flexibility by stacking the sub-packs with a robot. The system improves employee working conditions and stacking accuracy and efficiency, while decreasing product damage and ultimately costs. The High Speed Stacker is an ideal answer to today’s flexibility and speed demands in the glass manufacturing industry.

The High-Speed Stacker stacks glass formats from 12” x 18” up to 73” x 97”, and then transports glass sheets by a suction belt into a packet frame, where each sheet is placed successively until a sub-pack has been created. Next the packet is transported to a robot for take-off, either from above or from the side, to be stored on a glass rack that is used to transport the product to other facility locations or to end customers.

The system’s six-axis robots are capable of correcting the stacking alignment and creating precise glass stacks. For small glass sheets, two packets are built up and stacked parallel. Using this production method, up to 80 glass plates per minute can be taken off and stacked. The robots have a payload capacity of up to 220 lbs. and also feature integrated energy supply systems to reduce floor space.

The stacker can stack multiple sizes of glass with varying orientation – landscape or portrait, tin side in or tin side out with accuracy and speed. The High-Speed Stacker offers manufacturers the flexibility to adapt to product variations and rack and equipment changes. Feeding can be performed in a double stream, so that two packets are built up and stacked in parallel. It can be integrated into existing side-legs, but also demonstrates its stacking qualities in off-line cutting operations.

High-Speed Stackers can automate the entire packing capacity of a typical float glass production line, and can completely eliminate manual packing of glass.

Ideally, the angle of the glass rack is known and accurate. Since glass is heavy and the racks are being exposed to rough handling during regular operations, this angle can change over time compromising the structural integrity of the rack. As a result, a conventional stacker would not stack the glass in an optimal manner and glass breakage could occur. The robot of the Grenzebach High-Speed Stacker scans the rack for dimensional and angular discrepancies and adjusts its stacking program according to the actual geometry of the rack.

“Our customers have been demanding a better solution for stacking the many different glass sizes that they manufacture,” says Gerald Haas with Grenzebach Corporation. “Until now, they have had to rely on manual labor for their stacking operations. With the High-Speed Stacker, not only do they improve their employee’s working conditions, but they increase their operational efficiency and flexibility.”

Grenzebach’s totally automated cold-end line, and specific application to the High-Speed Stacker, is functionally based on Siemens’ concept of Totally Integrated Automation (TIA). TIA is characterized by its unique continuity. It provides maximum transparency at all levels with reduced interfacing requirements. It encompasses the field level and production control level, up to the corporate management level.

It also provides maximum interoperability, covering the controller, HMI and drives, up to the process control system. This reduces the complexity of the automation solution in the plant.

Motion Control, PLCs and Tech functions in one system

Central to Siemens’ TIA system in place with the Grenzebach line and High-Speed Stacker is SIMOTION®, Siemens latest generation of motion controller. SIMOTION, which includes a palate of high-tech control system components which are optimally harmonized.

Most machines require motion control (positioning, synchronous operation), PLC functionality and technology tasks (i.e. pressure control and temperature control).

The fusion of these functions into one system – as with SIMOTION – has a number of advantages, such as lower engineering costs, higher machine performance, the elimination of time-critical interfaces between individual components and simple, uniform and transparent programming and diagnostics for the entire machine with a single tool. The focus here is placed on a simple and flexible solution for numerous motion control tasks.

The motion controller, the drives and the motors encompass the scope of the Grenzebach cold-end line needs. This was a very big step forward technologically for Grenzebach, in terms of the wiring, drive integration and motion control. Taking standard, off-the-shelf Siemens technologies and applying them to a machine solution presented significant advantages to Grenzebach as an OEM.

Integrated with SIMOTION is Siemens SIMATIC® S7-300 automation system. Applicable for centralized and distributed configurations, it has the ability to integrate powerful CPUs with Industrial Ethernet/PROFINET interface. It can be set up in a modular configuration without the need for slot rules with I/O modules.

The Siemens SIMOTION motion control and SIMATIC controller provide a fusion of motion control, PLC and technology functions in one unit. This means that the new sophisticated stacking robots in use with the High-Speed Stacker can now be more easily controlled and operated.

Improved safety

A critical requirement of machine manufacturers and operators is seamless safety between humans and machines.

A truly safety-integrated system is a complete and consistent safety portfolio, which covers all tasks to be accomplished in the field of safety technology – ranging from detecting through evaluating, to reacting. In float glass production, safety is a critical concern. The automation built into the Grenzebach system greatly increases safety with handling sheet glass, resulting in far less accidents and injuries.

The Siemens S7 controllers are SIMATIC Safety Integrated, which provide the highest level of safety for humans, machines and environ¬ment. They are used to prevent accidents and damage resulting from a fault or mal¬function. The safety SIMATIC controllers monitor themselves, detect faults autonomously and immediately change into or remain in a safe mode when a fault occurs. They are optimized for use in production engineering and provide air-tight safety for all operations.

Fail-safe CPUs have been exercised for safety-oriented applications with the Grenzebach High-Speed Stacker and all other equipment on the cold-end line. The PROFIsafe profile for safe communication via PROFIBUS and PROFINET allows the integration of safety-related functions into standard automation environments.

Automation for a changing market

“We are making the SIMOTION and SIMATIC technology available to float glass producers so they can benefit from its system-wide controls capability and streamline their cold-end line production,” says Chad Shaffer with Siemens.

“This totally-integrated solution has been successfully applied to many other industries, but it is quite unique to float glass production until now.”

“Siemens has teamed with Grenzebach to help effect production efficiencies in the glass industry,” continues Shaffer. “More efficient equipment, safer production systems and a better bottom line for glass producers are our objectives.”

As glass producers deal with the influence of an increase in cheaper off-shore glass being imported and a more diverse product mix, production automation is more important than ever before. With new equipment providing better solutions, like the High-Speed Stacker equipped with a truly integrated controls package, glass fabricators stand in a much better position to operate their plants more efficiency and maintain a more competitive stature in the market.

Grenzebach Corporation can be reached by contacting: www.grenzebach.com

Grenzebach is a pioneer in float glass cold-end equipment. In 1974, the company developed the world’s first processing systems for automated float glass production. In addition to machines for transport and handling operations, and cutting and breaking lines, systems for identifying flaws, glass quality control and optimization of material yield have also been created.

The first piece of Grenzebach equipment to exclusively utilize this advanced automation technology is the company’s new High-Speed Stacker. Designed to increase glass manufacturer’s efficiency and flexibility, it was developed for stacking small glass formats with high cycle times, and is currently the only device which can stack glass sheets in less than a one-second cycle.

OR

SIEMENS INDUSTRY, INC.

Drive Technologies — Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Seamless integration of Siemens drives, automation and controls products enabled faster startups and improved system productivity with Curt G. Joa, Inc. production machines in the nonwovens industry.

by Bill Gilbert, Application Engineer with Siemens Energy and Automation

In the market of baby diapers and personal hygiene products, competition runs high. Major players in this market know that the slightest changes in product features can yield huge profits for those manufactures that are first to reach the market with a more absorbent, comfortable or easier to use product. Behind this high-stakes competition, however, is another player, Curt G. Joa, Inc., one of the world’s leading manufacturers of machinery for the production of disposable products including baby diapers, sanitary napkins, incontinent pads and related single-use items. Before these products can come to market the production machines that make them need to be designed or retooled. The machine re-design process is frequent as product changes are ongoing. Additionally, there is tight security surrounding these machine design developments. In a first-ever move, however, Joa has allowed a rare glimpse into its manufacturing facility, spotlighting machine automation and a solution developed in concert with Siemens Energy & Automation, Inc.

Since 1932, Curt G. Joa, Inc. (Joa) has earned a worldwide reputation for leadership in the design and manufacture of quality equipment for converting non-woven’s, plastics, paper, films, foil, tape and elastics. The company has machinery operating in over 55 countries throughout the world.

It has created an engineering environment that provides the utmost confidentiality and personalized service. The company maintains a fully-staffed team of mechanical and electrical design engineers representing a complete range of machine-building disciplines. SolidEdge, AutoCAD and EPlan are the drawing standards it uses. The company builds machines to meet a variety of worldwide codes and standards.

Joa goes beyond process design, however, providing rapid prototyping of complete manufacturing processes. Using a broad array of existing converting modules, it builds, tests and verifies the processes for its clients. The company’s multiple test stands are capable of performing a wide variety of web processes at speeds of more than 450 mpm. Its machines can be configured to slit raw materials, apply adhesives, weld web layers, apply discrete patches of one material onto another and perform complex product folding. With this approach, Joa can efficiently provide shortened machine delivery schedules and validated process concepts to its clients.

From engineering and design through installation, Joa provides a complete web manufacturing solution to its clients for new systems and equipment upgrades and improvements. It is one of few global designers in the industry that does not outsource key manufacturing and assembly operations. It does, however, closely collaborate with qualified solution providers, such as Siemens on machine controls automation.

The company’s machines feature modular designs that reduce product changeover times and make future upgrades simple. The modular design drives the configuration of automation, human interface, operations and maintenance. Optional process features permit high-speed production of a wide array of product configurations. Depending on product type and machine design, maximum process speeds can range up to 1200 products produced per minute. Projects can range in technology from a simple rotary cut-off unit to major converting machines over 50 meters long, each using upwards of 150 servo axes.

“A disposable products manufacturer recently contacted us about customizing a piece of equipment to go into its primary production line,” says Kevin Zeinemann, manager of Electrical Engineering with Joa, “The company was adding a new feature into one of its existing products. We began building a 8-meter machine section for them at our location. We were having some difficulty translating their machine’s existing program because we were attempting to cut and paste our new functionality into our client’s existing machine core functionality. Since this was not working we decided to put a stand-alone Siemens PLC into our machine section, bringing in Siemens techs to guide us through the process.”

“It worked out so well that when it was time to marry up the new machine section with our client’s existing machine at their location, they decided to move all of the information out of their main PLC and put it into the Siemens PLC that we had built,” continued Zeinemann. “The Siemens controller slated for use on the new 25-foot machine section, started as a tag-along and then eventually took over full ownership of the entire machine process because it had better functionality.”

The PLC that Joa integrated was Siemens SIMATIC® S7-400. An established platform, the S7-400 controller provides the highest performance in the Siemens SIMATIC S7 family.

A strong feature of the S7-400 is its modularity that is optimized for high-performance machine and factory automation, facilitating integrated and economical system solutions in centralized and distributed architectures. It has a CPU with integral I/O and integrated technology functions and integrated communications interfaces which create efficient processing speed for short machine cycle times.

“Our clients have different control configurations in place, and different comfort levels and preferences with their automation systems,” adds Zeinemann. “So, we work within their control specifications. I will say, however, that Siemens PLCs have excellent speed and performance. Our client has been quite happy with their functionality as well.”

“The Siemens processor also has an embedded safety functionality,” Zeinemann says. “Instead of having hard wired devices we were able to do a lot of safety interlocking via the PLC itself, and then network to our many different devices with a simple ProfiNet connection.”

The S7-400 controllers with safety integration provide the highest level of safety for humans, machines and the environment. They are used to prevent accidents and damage resulting from improper operation. The safety integrated controllers monitor themselves, detecting faults automatically and immediately.

Single Master Drive with Cascading Motion Commands

For the drives, one of the features uniquely designed into the system is the Siemens FM458 drive controller module within the S7-400 PLC. This controls a single master drive that cascades multiple virtual masters to control subsequent groups of drives. Instead of making a synchronized speed change, gear ratio correction or phase advance to each virtual drive, just one change to the master is needed, and every drive in that group will follow.

“Our client also needed 34 additional servo drives to be installed into their new 25-foot machine module,” continues Zeinemann. “They already were using 300 to 400 Siemens Masterdrive® servo motors on the equipment in their plant, so we specified Masterdrives into our new section as well for compatibility.”

The Masterdrives offload much of the performance that the PLC would normally have to handle. It puts it into the drive enabling the processor to pick up speed. The S7-400 PLC communicates to all 34 of servo drives and parameterizes them to send information back and forth. The drives follow at whatever speed they are told to run.

Siemens Masterdrive servo motors are ideal where high dynamic performance and intelligent motion control functions are required. They can handle the most complex motion sequences.

High-Speed Communications Link Improves Performance

As the demand for performance increases, automation networks used to control drive systems have become a limitation to quality and throughput. While open networks have been developed to control, configure and parameterize drives, they are limited by the overhead required to carry out non-control functions. To remedy this, Siemens developed SIMOLINK® designed to be a 100 percent control bus with none of the bandwidth stealing functions that could be carried out over a standard fieldbus.

Integrated into the Siemens control systems used on Joa machines, SIMOLINK provides the high-speed communications link required to synchronize set points from a single external master. It enables peer to peer data transfers between drives, and synchronizes the processor time slices of multiple drives and controllers. While operating at 11 megabits per second with very little overhead, 100 pieces of 32 bit data can be transmitted in 0.63 milliseconds. A high-speed synchronization pulse ensures that the data is acted upon in every drive at the same time. SIMOLINK provides Joa equipment with the high-speed communications required to reduce process variance and increase quality.

Totally Integrated Controls Automation – Faster Start-Ups and Improved Productivity

The Siemens automation solution that Joa employed is based on a concept called Totally Integrated Automation (TIA). TIA is characterized by its unique continuity, providing maximum transparency at all levels with reduced interfacing requirements. Its influence covers everything from the field level and production control level, up to the corporate management level. It also provides maximum interoperability, including everything from the controller, HMI and drives, to the process control system. This reduces the complexity of the automation solution in the plant.

Working closely together, Joa engineers and Siemens were able to develop this project in only a couple weeks. The commissioning was extremely short. Joa sent the machine over to its client and it operated flawlessly when it arrived at the plant. This was one of eight similar machine kits that Siemens jointly produced for this particular Joa client.

“Siemens was closely involved with us on this project from beginning through the final installation,” says Zeinemann. “They spent many hours with us on location, training us and ensuring we were comfortable with the system and their infrastructure and architecture. With Siemens programming assistance, we were able to do the initial bench testing. Additionally, when the project was installed, Siemens was with us at our client’s site working to ensure the installation went smoothly.”

The net result of the project was reduced machine design time and lowered total project costs, realized through faster startup and commissioning, as well as thorough testing, diagnostics and debugging prior to shipment. After observing the results of the first machine, the end user requested that eight other machines in its plant also be upgraded to match this solution design.

Machines in this aspect of the converting industry are very complex, requiring a comprehensive solution. Siemens and Joa were able to deliver a total controls automation solution, providing seamless integration of drives, automation and control products that enabled faster startups and improved system productivity.

To find our more about Curt G. Joa, Inc. visit its website at www.joa.com.

About Siemens

Siemens Industry, Inc., Drives Technologies, Motion Control is a division of the Siemens operating company in the U.S. Headquartered in the Atlanta suburb of Alpharetta, Ga., Siemens Industry, Inc. manufactures and markets one of the world’s broadest ranges of electrical and electronic products, systems and services to industrial and construction market customers. Its technologies range from circuit protection and energy management systems to process control, industrial software and totally integrated automation solutions. The company also has expertise in systems integration, technical services and turnkey industrial systems.

Siemens AG (NYSE:SI) is a global powerhouse in electrical engineering and electronics, focusing on the three key sectors of healthcare, industry and energy. Founded 160 years ago in Germany, Siemens AG reported sales of $96.6 billion in fiscal year 2007 (ended September 30). Siemens today employs more than 470,000 people in some 190 countries. In the United States alone, Siemens had sales of over $25 billion (including export sales), fueled largely by infrastructure projects and innovative solutions in the industry areas of medical, automation and control, power, transportation and lighting. Headquartered in New York City, Siemens in the U.S. employs nearly 72,000 people in all 50 states and Puerto Rico. The U.S. is also home to the global headquarters of nine of Siemens’ worldwide businesses. For more information on Siemens in the United States, go to www.usa.siemens.com.

For more information

SIEMENS INDUSTRY, INC.

GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/simotion

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

by Bill Gilbert, Application Engineer with Siemens Energy and Automation.

Continue reading

Production boost of 20% reported by Amgraph on food packages

As a result of the retrofit, Amgraph can now produce a wider variety of coated plastic and foil flexible food packages, cut material expenditures and improve throughput, while boosting productivity.

Improved Web Tension

Siemens Solutions Partner, Circonix, located in Ringwood, N.J., knew that by upgrading the machine’s analog drives and discrete controls to the latest Siemens motors and Sinamics S120 digital drives, Amgraph could accommodate new materials, manufacture packages with thicker coatings, achieve uptime of 95 percent or better, and increase throughput by 20 percent or more.

“Initially, the machine had four different motors with analog drives and controls, each with their own wiring harness and relay logic, which really made the machines a challenge to maintain,” explained Circonix Vice President of Engineering Andrew Alaya. “Only one of the sections was capable of tension control, which forced Amgraph to operate the extrusion machine in draw mode. This meant that the machine could only handle certain types of coatings without breaking the web and going down. Improving that uptime through better tension control was the main goal of the project.”

Circonix engineers decided to retrofit the Extruder’s four existing analog drives with Siemens motors and Sinamics S120 drives, while adding four load cells inline, and a new Fulton Machinery dancer to the machine’s two unwind spindles. Also, two Vetaphone treaters were added inline as part of the retrofit. These effectively eliminated the need for the primer coater, and served as pull stations for the machine, which were driven by Siemens motors and drives. These modifications allowed the machine to work in closed-loop tension control mode. By changing values on the HMI and PLC, Amgraph’s Production Manager, David Rand, could now precisely control the speed and thickness of the web, turn various systems such as treaters, laminators, and tension control systems on or off, and apply either thinner coatings to package materials without worrying about additional web breaks and downtime, or thicker coatings to meet special customer needs.

“Now that we have more control of the system, we’re looking at replacing thicker films that we used to purchase from other vendors with extruded materials we make ourselves, which saves us money,” says Amgraph’s Rand. “Our initial trials have been successful.”

The new motors, upgraded digital drives and new controls also increased the extrusion machine’s uptime, throughput and productivity. The high bandwidth of the Sinamics S120 digital drives allows for improved speed regulation and faster response, both of which are key to improving tension control. Amgraph set aggressive goals of 95 percent uptime for the retrofitted extrusion machine. “We’ve had some success since the machine was installed in January,” says Amgraph’s Rand. “We spent a few months fine-tuning operations, [but] recently, we’re starting to see [uptime] benefits. We should have some firm numbers in the next few months.”

In addition to increasing uptime and the number of products the machine can handle, Rand says the retrofit has increased throughput by up to 20 percent, depending on the product line. “We’ve definitely increased production speeds,” he said. “We’re happy where we are now, but we still have opportunities to improve throughput.”

On time, Within Budget

Customers may also want to use specific equipment providers for certain systems. In this case, Amgraph was familiar with third-party HMI and PLC technology, which meant Circonix needed to interface the Sinamics S120 drives with third-party systems. However, thanks to Circonix’s close partnership with Siemens as an official Siemens Solutions Provider, Siemens’ STARTER drive engineering/commissioning software and the easy integration of the Sinamics S120 drives using the electronic name plate capabilities of Drive-Cliq for the motors and drive components, the project was delivered to Amgraph on time and within budget.

“We used Profibus to tie the drives together and an SST module in the PLC to talk to the Siemens drives,” Alaya explains. “It was easy to meet Amgraph’s development schedule. With Siemens DC bus line up, all the drives fit in a single cabinet that was smaller than the space of one of the previous motor control systems. We were able to eliminate the wiring mess and relay logic that came with the older analog controls, which significantly simplified maintenance and troubleshooting for the customer while improving performance and uptime.”

Circonix started engineering development for the system in July of 2008, and just six months later, installed and commissioned the retrofits.

“We gave them a pretty intense schedule,” says Amgraph’s Rand. “What’s remarkable about this project is that it was done on-time. We have some machines that came in before we did this project and they’re still not up and running.”

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

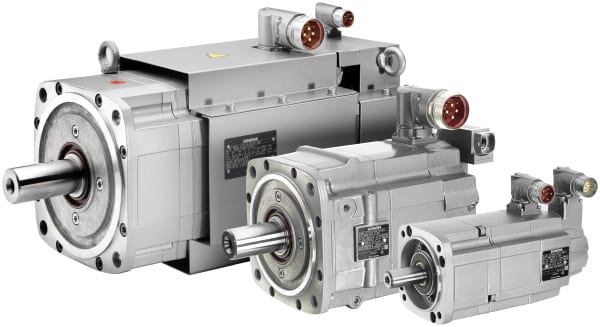

New Siemens 1FT7 servo motors, shown (l to r) in forced ventilation, water-cooled and air-cooled styles

Siemens introduces the 1FT7, a line of high-performance servo motors for such demanding motion control applications as machine tool CNC interpolation, production machine indexing control and more. Their use results in higher dynamic response, due to a 30% shorter design and 4x overload capacity versus 3x on the predecessor family of servos. Less downtime also results from the rigid vibration-insulated encoder mounting, which also enables the OEM or end user to exchange the encoder in the field in less than five minutes, without encoder alignment.

Design engineers have a choice in selecting this servo, as it is available in air-cooled, forced ventilation and water-cooled designs. The water-cooled design of the 1FT7 is provided with stainless steel piping in the stator.

Start-up and commissioning personnel will appreciate the Siemens electronic nameplate and digital encoder interface on this new servo, DRIVE CLiQ, as it simplifies start-up or replacement by not requiring all electronic data to be entered, as the DRIVE CLiQ cable recognizes all drive system components. With this feature, these motors become essentially plug-n-play devices. The drive recognizes the motor automatically and optimizes the parameterization accordingly. This digital encoder interface further allows users to route all their different encoder types along one signal cable.

High-resolution encoders, currently 22 bit, enable these servos to become highly precise motion control system components and these new high-dynamic 1FT7 motors also feature very low rotor inertia, thereby making them practical in applications where it was previously impossible to drive a servo. Such applications include sorters in the printing industry, which previously required mechanical cams but can now utilize electronic cams for better energy efficiency and less wear.

For a catalog or more information on these new servo motors, please contact:

SIEMENS INDUSTRY, INC.

GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications