Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

The ideal solution for industrial-grade applications

With the new Sinamics G120C, Siemens is extending its product portfolio of inverters. This compact device is suitable for industrial-grade applications including pumps, compressors, fans, mixers and extruders, as well as conveyor belts and materials handling machines.

Siemens Industry, Inc. released today the new Sinamics G120C, a compact inverter designed for various industrial applications such as pumps, compressors and fans, as well as mixers, extruders, conveyor belts and materials handling machines. With a rated power range of 0.75 to 25 hp (0.55 to 18.5 kW), the Sinamics G120C sets new standards in the industry with its compact dimensions, fast commissioning times, simple operation, ease-of-servicing and highly-integrated functionality.

This compact inverter offers one of the highest power densities in its class. Compared to conventional systems on the market, the Sinamics G120C requires up to 30 percent less space, with up to 40 percent higher power output. Quick-connecting plug-in terminals allow faster installation.

An optional operator panel may be mounted to the inverter for commissioning. A port for inserting a memory card is also available for faster inverter commissioning. It can be configured using a PC, via USB interface, as well. Standard protective coatings on the PC boards make the unit extremely robust in hostile or corrosive environments. The new Sinamics G120C is designed for ambient temperatures of up to 140ºF (60ºC).

Each Sinamics G120C inverter features Safety Integrated as standard. The unit is equipped with dual safe inputs to control the STO (Safe Torque Off) function without the need for external devices. The G120C offers users the performance of the Siemens Sinamics platform, enabling precise, cost-effective control and more energy-efficient operation of induction motors.

For network communications, this new Sinamics G120C supports Profibus. It can also be directly integrated into other widely-used communications structures via USS protocol, ModBus RTU and CAN Open. The default setting on each G120C enables field bus operation without time-consuming configuration.

See the SINAMICS Drives video on YouTube here.

For more information about the Sinamics G120C, visit www.usa.siemens.com/drives.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingCost-efficiency and flexibility in one complete panel

This pre-wired solution is offered complete and fully tested with all necessary components mounted onto a back panel. Sinamics DC Master Base Drives are an extremely flexible and cost-effective solution for new installations and retrofits where space is limited. They are ideal for end-users and third-parties such as system integrators and Siemens solution partners.

Sinamics DC Master Base Drives offer more power per panel in the same footprint as compared to the previous two generations of base drives. These base drives are rated from 15A–850A continuous current.

Standard features of the new SINAMICS DCM Base Drive include — input fuses, output DC fuses (regen only), control transformer, AC line contactors, PROFIBUS, BOP20, UL508A Certification and 65KA SCCR rating. They are ready-to-order with deliveries available after February 2012.

For more information about the Sinamics DC Master Base Drive, visit our web page www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

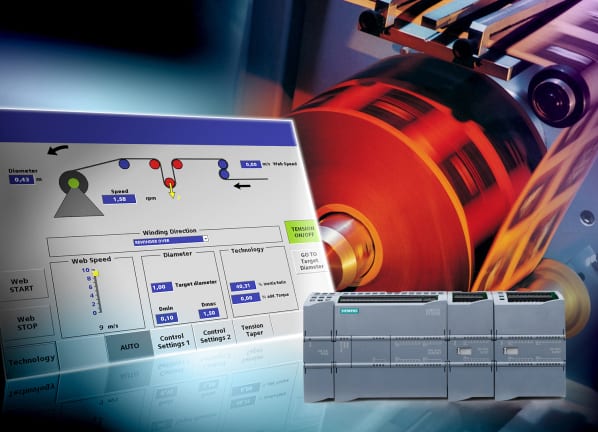

Value-added converting solutions for both the machine and the plant

The Simatic module completes the application set that includes the Simotion® module, a group of high-performance motion control converting solutions, and the Sinamics® DCC (drive control chart) module with drive-based converting solutions. It offers the capability to integrate full converting lines and machines centralized on the Simatic S7 PLC platform. Functions include center winder, sectional drive control and a host of converting process and large functions. Systems can be implemented in Ladder, structured text or in a graphical functional block language.

Machine builders are now able to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation, as much as 80 percent in some cases. It offers modular open functions, for items such as winding, laminating,

cross-cutting, calendaring, perforating, embossing, coating, flying saw, die cutting, traversing and more.

Components of the Converting Toolbox take the form of pre-programmed functions. Sample applications demonstrate how each function can be effectively and efficiently implemented into a machine design. Some of the applications are ready-to-use after only minor modifications and even include basic HMI functionality.

For more information about the Converting Toolbox, visit www.usa.siemens.com/converting.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Simotion is the scalable motion control system that quickly and easily handles increasing machine demands by enabling central machine functions to be implemented with just one controller. It is available in three variants: drive-based, PC-based and controller-based.

Simotion Scout facilitates the configuration, programming, testing and commissioning of applications. With its graphical-based programming, Scout further facilitates system configuration for new users. Users of Scout 4.2 will also benefit from new features such as automatic drive integration and detailed comparisons for graphics-based programming languages.

The most significant innovation of Scout 4.2 is its simplified interface to the Siemens Sinamics drive system. This feature provides users with an automated means of integrating drives and components into the Simotion system. Using the new symbolic assignment of technology objects (TOs) and I/Os to drive objects, users no longer manually configure communication with message frames and addresses because Simotion Scout now automates this task. Object-to-object assignment takes place via a new inter-connection screen. In this screen, all compatible partners are listed hierarchically and the symbolic connection of the components to be inter-connected takes place by simple selection.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Simotion D motion control systems are the ideal solution for production machines covering all levels of performance — from simple single-axis positioning tasks to complex synchronous applications — with extremely short cycle times on a large numbers of axes. Thanks to its scalability, Simotion D offers users a high degree of flexibility for the ever-changing demands on machine automation. The Simotion D drive-based multi-axis control system not only offers PLC, motion control and advanced technology functions, but also an integrated drive control based upon Siemens Sinamics S120 drives.

Today, with the new Simotion D445-2 DP/PN and D455-2 DP/PN versions, the performance range has been extended even higher. Compared to the previous generation, the maximum quantity has been doubled to 128 axes and the memory capacity significantly expanded. This has increased the PLC and motion control performance by a factor of three. With Simotion D445-2 DP/PN and D455-2 DP/PN, the previously optional Profinet I/O interface has now been integrated on the modules as standard. This frees up the option slot for other expansion cards. The onboard interface is equipped with an integrated three-port switch and facilitates different network topologies such as line, star or tree structures, without the need for additional external switches. The interface not only supports real-time (RT), but also isochronous real-time (IRT) data exchange and can be operated as a controller and / or device of another controller.

In addition to the Profinet interface, Simotion D445-2 DP/PN and D455-2 DP/PN also have two Profibus and two Ethernet interfaces, as well as 28 digital I/Os, of which 16 can be used for technology tasks such as output cams and measuring inputs with micro-second resolution.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol. Join the community by following us on Facebook: www.facebook.com/siemens.dt.us and talking to us on Twitter: www.twitter.com/siemens_dt_us.

The new Simotion D motion controllers for production machines cover all levels of performance, from simple positioning tasks to demanding applications with extremely short cycle times or large numbers of axes, up to 128.

Please forward all inquiries to: Siemens Industry, Inc. Motion Control Business 390 Kent Avenue Elk Grove Village, IL 60007 Attn: Marketing Communications

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications

or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com

Siemens Industry

Siemens Industry, Inc. is the U.S. affiliate of Siemens’ global Industry Sector business—the world’s leading supplier of production, transportation and building technology solutions. The company’s integrated hardware and software technologies enable comprehensive industry-specific solutions for industrial and infrastructure providers to increase their productivity, sustainability and profitability. The Industry Sector includes six divisions: Building Technologies, Industry Automation, Industry Solutions, Mobility, Drive Technologies and Osram Sylvania. With nearly 204,000 Siemens Industry Sector employees worldwide, the Industry Sector posted a worldwide profit of $4.7 billion on revenues of $47.3 billion in fiscal 2010. www.usa.siemens.com/industry

Drive Technologies

A division of Siemens Industry, Inc., the Drive Technologies Division is the world’s leading supplier of electrical and mechanical products, applications and solutions that cover the entire drive train. Drive Technologies is the global leader in energy-efficient motors and drives, as well as products and services for production machinery and machine tools. Technologies include standard products, industry-specific control and drive solutions, as well as mechatronics support and online services for web-based fault management and preventive maintenance. Drive Technologies provides its customers with energy-efficiency, productivity and reliability in industries as diverse as clean and renewable energy, transportation, oil and gas, utilities, metals and mining, machinery manufacturing and machine tools. With nearly 36,000 employees worldwide, the Drive Technologies Division posted worldwide revenues of $9.5 billion in fiscal year 2010. www.usa.siemens.com/drives

Continue reading

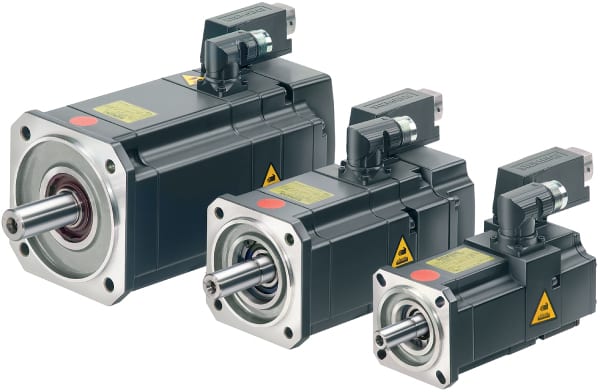

With a total of 6150 option pairings and 18 color choices, servomotors in the 1FK7 family can be configured to 110,700 possible designs. Options include stall torque and RPM rating, encoder style and bit resolution, holding brake functionality, shaft style, IP rating, AC line supply voltage and electronic nameplate recognition via Drive-Cliq®. 1FK7 geared motor options are not included in this program presently.

Siemens is now making this service available to customers in the U.S. market. With the motion controller Simotion® and the drive system Sinamics® S stocked in the United States, Siemens is also able to supply complete motion control systems in three weeks’ lead time.

According to Arun Jain, general manager, Siemens Motion Control Business, “We have made the commitment to significantly shorten servomotor delivery times. The 1FK7 family has a wide user base for motion control applications, so we have selected this very important line for our major customer service initiative. We have devised and implemented an entirely new protocol for motor manufacturing and production at our factories.”

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

CHICAGO — During this year’s IMTS, Siemens raffled off a 10th anniversary motorcycle built by Orange County Choppers (OCC), the custom build shop owned by Paul Teutel

The winner was Bob Pool, machining supervisor at Riverview Manufacturing Inc., located in Palmyra, Missouri and a division of Doyle Equipment Manufacturing Company, across the Mississippi River in Quincy, Illinois. Doyle is a major manufacturer of dry bulk handling machinery and Riverview fabricates large-capacity fertilizer spreaders and other equipment for its parent company.

As Bob tells his story, “I’d gone to IMTS with a colleague from Riverview and we noticed the crowd at the Siemens booth. We were waiting in a very long line to get our picture taken with Paul Teutel from Orange County Choppers and the nice young lady who was registering us asked if we wanted to sign up to win the motorcycle. I’d ridden bikes all my life but never owned one. I figured I’d take the chance, but didn’t think about it much, after signing up. The photographer said the photos would be up at the website a couple days later and, when I checked, I couldn’t find them, so I called Siemens. The next morning, I came into the shop and saw a message from Siemens. I called and asked about the photos and got steered to the right spot on the website, but the person said he was really calling for another reason. To my surprise, he said I’d won the bike!”

Riverview is a 25-person shop with full CNC machining, welding and assembly capabilities, all used to produce the 6- and 8-ton spreaders and other Doyle brand equipment built here. Bob says he looks forward to taking very good care of his new bike and using it for many years to come. “I’m really enjoying it and am sure glad I stopped by the Siemens booth at IMTS!”

For more information:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

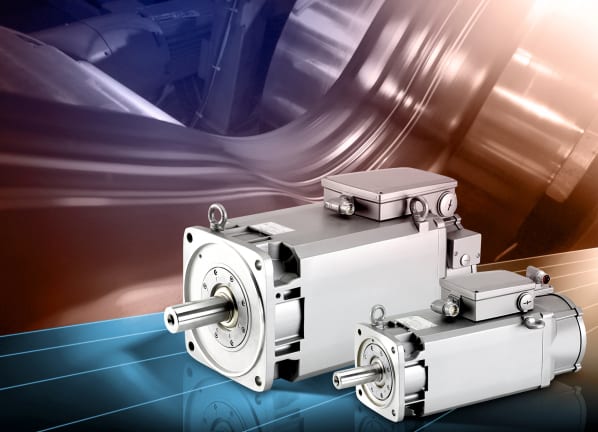

Continue reading CHICAGO — After considerable research and product refinement, as well as extensive field contacts with end-users, Siemens Industry, Inc. introduced today the new 1PH8 family of high-performance induction motor drives and servomotors. Available in a wide power range, from 2.8 kW up to 1340 kW, the

This new line combines induction and high-powered servo technologies to give machine designers and end-users a greater degree of efficiency and more precision in the production process. A single stator and rotor design enables the modular adaptation of the many motor options to provide design flexibility and cost containment.

Designed for the specific performance and environmental requirements of a main spindle on a CNC-equipped machine tool, these new Siemens induction motors have myriad applications in other heavy-duty markets, such as print unit drives on printing presses; rolls and web handling on converting and packaging machinery; crane and hoist elevation; extruders and injection molding machines; metal-forming and welding machinery; assembly line robotic articulation; materials handling gantries and more.

The modular motor platform concept offers designers various options for selecting the optimum unit for an application:

The 1PH8 motor spindle line is fully compatible with the popular Siemens Sinamics® S120 drives platform to achieve faster commissioning and improved control response. All motors in this new family feature the Drive-Cliq® serial interface and electronic nameplate recognition for plug-n-play start-up.

Earlier families of Siemens motor designs can be upgraded to the new 1PH8 series without difficulty, including the 1PH7, 1PL6, 1PH4, 1PM4, 1PM6 and the upper range of the 1FT6.

For more information, visit www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

The embedded PC, which features a DDR3 memory and an Intel Core2 processor, is free of wear from moving parts, such as hard disks and fans. This compact motion control system provides maximum flexibility and accommodates centralized or decentralized machine concepts for PC-based applications or for applications that require a compact size.

It is designed for many different motion control applications with its multiple onboard interfaces. They support communication over Profinet, the open industrial Ethernet standard, as well as Ethernet interfaces that run at 10 / 100 / 1000 megabit speeds. Four USB interfaces make it simple to connect a keyboard, USB stick, printer or other devices. A DVI port rounds out the links so users can attach a display or monitor. The Simotion P320-3 can also be used in a “headless” configuration without a display, monitor or front panel.

LEDs on the front indicate the operating states, making self-diagnosis easy. The integrated power supply bridges temporary power failures. In the buffered SRAM memory, the process data is saved securely even in the event of a sudden voltage drop. Monitoring functions for the batteries, temperature and program execution are also included. The Windows Embedded Standard 2009 operating system, which increases the reliability of the system, is pre-installed. Additionally, the Simotion runtime system comes installed on the Simotion P320-3.

Additional information is available online at: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

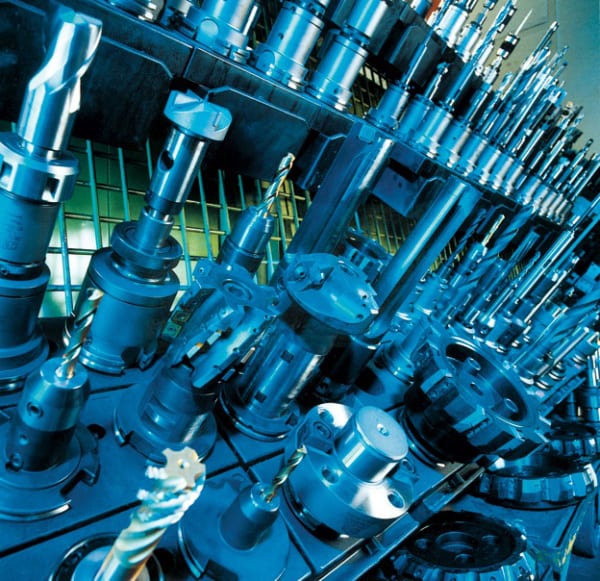

Offered to customers as a standard solution, Zoller has written an interface to connect TDI to the company’s presetter, enabling data to be brought directly into the Siemens numerical control. Zoller boasts accuracy on its presetters to two thousandths of a millimeter (0.002mm) or less than eight millionths of an inch (0.00008in).

By utilizing TDI and a Zoller presetter, a machine tool end-user benefits in many ways, including faster access to tool data with no manual entry of values required. All tool data are transferred to the CNC by an automatic link in the presetter, resulting in significant cost-, time- and operator action savings. In addition, the user develops an increased understanding of tool life and tool wear patterns on various operations in the shop. The Zoller presetter writes data directly onto an RFID chip, making transfer to TDI onboard the Siemens CNC is simple and easy. Lastly, an end-user can maintain a central server that indicates the location of any tool in the shop or factory, as well as track the status of the next tool needed to perform an upcoming operation.

Included in the Siemens TDI suite are the following:

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading