Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Noark’s Extended Rotary Handle (ERH) and Flange Handle Mechanism (FHM) can be used anywhere MCCBs are used

The Extended Rotary Handle (ERH), part of the MCCB family, is UL Listed with UL Type 1/3R/12 or 4/4X. It meets cULus standards in U.S. and Canada. The unit is offered in black/grey or red/yellow handles and is available in shaft lengths of 7.9/12.6/19.7 inches. It has a simple and robust NEMA handle operating mechanism and can be used anywhere MCCBs are found. A new safety feature of the ERH allows operation of the enclosed circuit breaker without the need to open the cabinet door. The external handle quickly shows the state of the circuit breaker without opening the panel and a new, larger handle design gives the user more leverage than previous models. It is available for the 65kAIC rated M1/M2 MCCBs, as well as the M3/M4 MCCBs.

The ERH has NEMA type extended rotary handle mechanisms to mount on front of an enclosure door and operate externally. They are used with the NOARK UL MCCB series. The mechanism includes three components: external handle, shaft and handle operating mechanism. The NOARK ERH is available as a kit or individual components and is available immediately for delivery.

The Flange Handle Mechanism mounts on the flange of an enclosure door, occupying less space inside the enclosure. The units are specially designed by NOARK for UL MCCB use. The flange mechanism includes three components: flange handle, flex shaft and operating mechanism. It is available as a kit or individual components and will be available for sale in December, 2016.

NOARK Electric will display these new products and many other components for the HVAC market at the upcoming AHR 2017 show in Las Vegas, January 30 through February 1. Visit Noark at booth N7939.

NOARK Electric (North America), located in Pomona, California, is a leading global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative found at www.noark-electric.com or email: nasales@noark-electric.com.

Continue reading

The oven travel comprises an 1-1/2’ long open belt loading zone, 20’ long insulated heat zone with recirculated airflow, 1’ long open zone, plus a 12’ long cooling zone and an 1-1/2’ long open unloading zone.

This Grieve belt conveyor oven features 4” insulated walls, aluminized steel exterior and stainless steel interior. Two 12” diameter tubeaxial fans, each driven by a ½ HP motor, push/pull air through cooling zone and a 12” wide, ½” x ½” high carbon steel flat wire conveyor belt with 1/3 HP motor drive, variable from 16 to 44 inches per minute, are also onboard the oven.

Controls on the No. 866 include a 10” diameter circular chart recording temperature controller and a manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210.

Web: www.grievecorp.com.

Email: sales@grievecorp.com.

Attention: Frank Calabrese.

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German and other metalworking machine builder companies, including Profilator GmbH, Praewema, K + G, Rasoma, FIMAT and BvL, as well as Arnold lasers and other equipment. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® and now the game-changing Hard Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or fully-engineered machine tool and laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on “News of Note” at GMTA.

In the news…

GMTA Mexico exhibited BvL parts cleaning technology and our full line of machine tool and laser offerings at ExpoMaq in Leon.

For more information on any items in this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Customer needed post-assembly validation of fine wire configuration

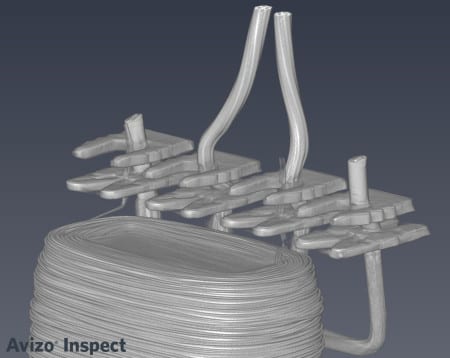

Scans of wire bobbin, showing precise path taken by 0.008” diameter wires inside; scan completed after final assembly of the unit, an inspection process not possible without CT scanning capability

Exact Metrology, working at the company’s Brookfield, Wisconsin location, has successfully used its ProCon industrial CT scanning technology to validate the position of a wire configuration in the bobbin of an electronic lock assembly for one of its customers.

As techician Sean Plastine explains, “A customer came to us to verify the position of a 0.008” diameter wire inside its electronic lock assembly. The position of the wire could not previously be verified while the components of the lock were being assembled. Inspection of the wire bobbin after assembly was also impossible.”

By using its CT scanning technology on the completed lock assembly, Exact technicians were able to determine the wire’s precise position without the need for disassembly or other compromise on the finished article. Any deviation of the wire’s nominal position could be noted, allowing for subsequent changes in the assembly protocol, as needed.

The CT scan clearly shows the path that the wire pair follows inside the lock assembly.

Plastine adds, “We are very excited by the possibilities of this technology, as it’s opening new doors for our contract services at many existing and many more new customers.”

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company.

For more information on this application or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

Dean Solberg, President

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development assistance and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingProduct demonstrations and technical presentations from principals impress large crowd at dual open house

On March 17, 2016, Exact Metrology held a tech event in Cincinnati, Ohio with partner company, 3DVision Technologies at both of their offices. Held on St. Patrick’s Day, the event was cleverly titled “Lunch, Learn & Luck,” and had a “March Madness” theme with basketball games playing on multiple widescreen televisions. The event was attended by over 100 people from local area industries, including automotive, aerospace and consumer goods.

Co-Hosted by Steve Young, Exact Metrology co-founder and President, and Todd Majeski, President of 3DVision Technologies, the day included presentations and product demonstrations of the newest products transforming the manufacturing industry in 3D printing and 3D scanning. The informative event provided insight and hands-on experience, while displaying the newest technology that is reshaping the traditional manufacturing process.

The day began at 3D Vision Technologies office, (a provider of engineering solutions & 3D printing for manufacturing companies), with a presentation by Todd Majeski. Majeski discussed the company’s long-term partnership with Exact Metrology, and how both companies work together to improve processes, increase quality, and get their customer’s products to market faster through 3D scanning and reverse engineering. After several presentations and a question-and-answer session, attendees were welcomed into a showcase of 3D printer demonstrations and product displays of printed samples from miniature to lifesize versions, including a skateboard, helmet, and an automotive front grill.

The second part of the tech event was held at Exact Metrology’s office, conveniently located just a short walk away. Participants walked together and, after a St. Patrick’s Day themed lunch, began the afternoon session with a presentation by Steve Young. Young discussed the newest technology in CT (Computed Tomography) scanning systems, which allows users to not only scan the outside of a part, but to actually see inside of it without taking it apart, or damaging the item. Until recently, this technology was used primarily in the medical field but is creating much excitement within a variety of industrial markets now, as it enables manufacturers to check for defects, internal contact points after assembly, porosity and dimensional accuracy, comparing actual scans to point cloud data, CAD files etc. According to Young, this type of 3D scanning has been a “huge success” for his company, which he co-founded with Dean Solberg, who runs the company’s facility in the Milwaukee area.

Products displayed at the event included the P40 Leica Scanner, a long-range scanner, which, according to presenter Jacob Wallace, Processing Engineer at Exact, can be set up and ready to scan in 30 seconds. The scanner has a 150-meter range and will show everything in the surrounding area. Wallace recently scanned an entire office to make an accurate 3D model, complete with windows, doors, ceiling and wall thickness. Other uses of these long-range scanners include collecting topography of roadways (without stopping traffic) and large buildings of 500,000 square ft. or more, to collect information inside and outside of the building, all within a reasonable timeframe.

Other products displayed and discussed at the expo were the Romer Absolute 77, an Articulated Arm with a Laser Line Scanner, the Atos Triple Scan, the Artec EVA Handheld Portable Scanner and the NDI ScanTrak Large Volume Laser Scanner.

Exact Metrology ended the afternoon with a St. Patrick’s Day raffle, with two lucky attendees winning a 48” high-def television and a MakerBot 3D printer.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training.

For more information on this new equipment, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Exact Metrology is an ISO 9001:2008 Certified Company.

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Leader in 3D and CT scanning for industrial, commercial concerns achieves key aerospace supplier metric

As the certification notes, Exact has its recognition for “…sales and supply of 3D non-contact and contact measuring equipment for inspection and reverse engineering to the commercial, aerospace, medical, automotive and industrial manufacturing industries.”

The AS9100 is a vital certification for the work this facility performs in the aerospace sector.

Exact is a prime supplier of equipment as well as the services that utilize various portable and stationary 3D scanning devices, plus one of the first industrial-grade CT scanners, a unit that can examine the internal geometric and material composition of various substrates on molded, cast and forged products, as well as food ingredients and packaging for seal integrity and safety.

Exact Metrology is also an ISO 9001:2008 Certified Company.

For more information on this development or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingAnn Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German and other metalworking machine builder companies, including Profilator GmbH, Praewema, K + G, Rasoma, FIMAT and BvL, as well as Arnold lasers and other equipment. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® and now the game-changing Hard Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on “News of Note” at GMTA.

In the news…

-General Motors has selected GMTA to partner on the CVT 250 project for gear hones.

-Ford Motor has selected GMTA as a supplier for Scudding® sun gears on its new transmission lines.

-Scudding and now the Hard Scudding process, in which hardened gears can be cut and finished on the same machine, using the company’s unique adaptive software, are fast gaining acceptance in the market. Already the leader in high-precision internal gear processing, the result of our unique Scudding® technology, which leaves skiving and other methods far behind, GMTA has taken another giant step forward in gear production with the development of Hard Scudding. The Scudding process provides excellent results on green or soft gears, while this new Hard Scudding advancement enables the re-machining of hardened gears on the same machine, with a tooth-to-tooth composite error and total composite error in the AGMA 11, DIN 6 range and a surface finish better than 1.5 Ra. This all happens due to the adaptive software developed by GMTA.

-A new series of operational videos on Arnold lasers in action is now viewable on the GMTA website, www.gmtamerica.com. The website is currently undergoing substantial upgrades, but remains visible to all.

-The new Mexican office of GMTA, located in Queretaro, is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically (here) in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico with all their partner companies. At the new facility, machines are in place for demo and test run, plus the facility is fully staffed with application engineering, technical support, after-sale service and parts inventory.

-Sales continue to be brisk on the 9- and 10-speed transmission projects in the automotive market. Scott Knoy, GMTA VP, comments, “We’re seeing a lot of activity here in the States and especially in Mexico, so we know our timing was right with the opening of our new facility there.”

-GMTA attendance at Gear Expo in Detroit was highly productive, as we saw old friends and made many new ones! The demonstration of Hard Scudding was given and we met with all the top editors from the gear market media during the show. The Motor City is still the place to be for us gearheads!

-GMTA is now representing Rasoma machining centers, used primarily in the gear and spline markets, as well as FIMAT, an Italian builder of machining centers. These agreements cover full sales engagement for North America. Meanwhile, an agreement has been signed by GMTA to represent BvL parts washers exclusively in Mexico. The BvL line now means GMTA can be a single integrating source for machining, part cleaning and laser joining of power transmission products.

-Our Claudia Hambleton again braved the elements and brought a class of German language students from Saline, Michigan to Chicago for Christkindlmarket, as well as tours of the Museum of Science & Industry and the new Maggie Daley ice rink! A good time was had by all…and everyone made it back on the bus! She assures us all the gluwein consumed was strictly non-alcoholic!

-Our Christmas party was a good time to connect with our GMTA family and exchange presents. Some of the guys, who are themselves brilliant mechanical techs and machine tool engineers, tried to wrap their own presents and failed miserably, according to Claudia! “It takes a talent these guys clearly do not possess,” she mused.

For more information on any items in this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Procon X-RAY GmBH, a leader in custom-designed industrial CT scanners, will be available in USA through Exact Metrology

November 30, 2015 – Exact Metrology announced today the signing of an agreement with ProCon X-Ray for exclusive rights to distribute the company’s product line throughout the USA.

ProCon, located in Germany, has been developing x-ray systems for non-destructive testing since 2004. The company is a state-of-the-art manufacturer of x-ray and CT (computed tomography) systems designed specifically for industrial applications.

ProCon offers several standard models, ranging from portable units and desktop models to full-size, stand-alone systems. Each of the company’s standard units can be customized to meet customer specific job requirements. The systems are all offered with high-resolution focus x-ray technology.

ProCon works directly with customers to determine the scope of requirements, then develops and designs a unit to meet the individual application needs. Units can be designed with multiple x-ray sources and multiple detector set-ups. This process results in customers obtaining exactly the type of metrology equipment required, without any unnecessary features. Turnaround time in production of the equipment is thereby reduced to a minimum. ProCon systems are also user-friendly and easy to use in operation, according to Exact VP Steve Young.

Exact Metrology offers a complete line of portable scanning and measurement technologies, as well as contract measurement for 2 and 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training, plus its recently announced CT scanning services, usable by all types of manufacturing, packaging and product integrity concerns.

For more information on this agreement, please contact:

Steve Young, VP

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local 513.831.6620

Toll Free 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Pomona, California (November 30, 2015)… NOARK Electric, a leading low-voltage electrical product manufacturer, announces the latest edition to the B1N miniature circuit breaker family: the UL 489 B1NQT. This recyclable, quick-connect breaker is available in three curves (B, C and D), ranges from 0.5 to 63 A and has an optional detachable shield to make it faster and easier for the installer.

NOARK Electric provides reliable products, improves profitability and maintains the highest performance levels. The NOARK B1N breaker series is suited for a host of industrial applications, including HVAC equipment and other component sub-assembly designs. NOARK offers exceptional value with local support and inventory for a wide range of UL 508A panel designs, all backed by the industry’s first 5-year limited warranty.

NOARK Electric will display this new product and its full line in booth #1379 at the upcoming AHR 2016 show in Orlando, Florida. Additionally, NOARK will present a brief session to the HVACR industry, covering the B1NQT and additional NOARK product lines on Tuesday, January 26 at 4:00 p.m. in Theatre C, room N320G. Free AHR show passes can be obtained by contacting NOARK.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative or email: nasales@noark-electric.com

Contact:

Jessie Jones, Marketing Manager

NOARK Electric (North America)

2188 Pomona Blvd.

Pomona, CA 91768

Phone: 626-330-7007

Website: na.noark-electric.com

Email: nasales@noark-electric.com

No. 812 is a 650°F (343°C), high temperature top-loading oven from Grieve, currently used for heating stainless steel prior to welding at the customer’s facility. Workspace dimensions of this oven measure 72” W x 36” D x 36” H. 40 kW installed in Incoloy-sheathed tubular elements heat the workspace, while a 3300 CFM, 2 HP recirculating blower provides horizontal airflow to the workload.

This Grieve top-loading oven features 5” insulated walls, aluminized steel interior and exterior, plus a reinforced ¼” steel plate top. Features also include an air-operated rear hinged door and wear bars at the sides of the workspace. The floor of the workspace is reinforced for 3000 lb. loading at removable subway grate.

Controls on No. 812 include a digital indicating temperature controller, manual reset excess temperature controller with separate heating element control contactors and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese