Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Award-winning – the VL 2 from EMAG is one of the most energy efficient machines in the world.

According to the “Future Panel” of the IW – the Institut der deutschen Wirtschaft (Institute for German Economic Research) – energy efficiency is becoming increasingly more important in the metalworking industry. The IW suggests that over 60 percent of the companies interviewed for the award are hoping for “a push forward toward innovation”. EMAG is an initiator of such innovations. Its experts develop machine tools and production processes that consume significantly less energy then its competition. In honor of this, EMAG has received the “Energy Efficiency Award” from the ZF Group. This award states that EMAG’s contribution has been honored as one of the top five.

From their efficient manufacturing technology to economical design and construction, the machine builders at EMAG have shown their in-depth know-how and experience in one of the most important fields of industrial development, to compete for the “Energy Efficiency Award” from ZF. The result convinced decision makers at ZF and EMAG’s competition entry called “Energy-efficient Production Machines” has been honored as one of the “Top 5 Projects“. In fact, in this particular sector EMAG was the only machine builder honored. Before the competition as part of its “Year of Energy”, ZF contacted approximately 600 of its suppliers, inviting them to participate in the competition. From 30 eligible entries, the specialists in driveline and chassis technology picked the top five. These five companies were invited to present their particular approach to efficiency on September 13th at ZF, Saarbrücken.

EMAG has been focusing on energy efficiency for years

“We are very pleased to have received this award”, declared Dr. Guido Hegener, Managing Director of EMAG Salach, Maschinenfabrik GmbH. “It is an incentive for us to continue on the chosen path. Our focus has been on energy efficiency for years.” During his presentation Dr. Hegener highlighted the various developments at EMAG:

“We have established how much energy each component consumes and where the biggest potential for savings lies”, explained Wolfgang Rummel, Head of Control Technology Development and Design at EMAG Salach Maschinenfabrik GmbH. He also referenced the concrete measures taken: EMAG includes the most efficient components in their standard machine design – for instance hydraulic packs with greater efficiency, low-wattage valves and intelligent auto-standby circuitry.

At the end of his competition presentation Dr. Hegener introduced a new overall objective: the development of the “sustainable factory”. He suggested that in future the production – together with the building in which it is situated and its technological contents – will be evaluated as a single entity. In conclusion, he expresses his belief that the measures taken to reclaim and recycle energy can lead to a potential saving of up to another 40 percent.

SAVINGS POTENTIAL PLATFORM 2

46.9% over existing machines

9.6% – optimization cooling systems

8.0% – hydraulics (e.g. DvP units)

6.9% – drive cooler with through-hole technology (only on Fanuc)

6.6% – reduced air seal, system pressure pneumatics

6.6% – standby circuitry

3.2% – IE2 motors (IE3 option)

1.9% – low-loss gear motors (option)

1.8% – frequency-controlled auxiliary drives (option)

1.7% – timed relief valves, flat-jet nozzles (options)

0.6% – low-wattage valves

53.1% – remaining machine consumption

At EMAG energy efficiency comes as standard.

Energy savings are implemented on the machines with Platform 2, as compared to similar earlier models = 46.9%.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

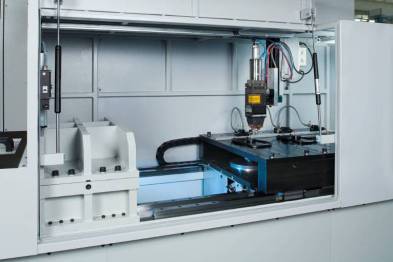

The ELC 250 DUO – a compact laser welding cell for the machining of differential housings. The DUO variant features two spindles. The twin-station operation allows for cycle time-concurrent loading and unloading of the work spindles.

“From Dual-Clutch Transmission to the classic differential: modern transmission technology is a pivotal research sector in the automotive industry. With new materials and altered geometries, designers optimize the functionality of the different gearwheels. Furthermore, these wheels are required in ever larger quantities, owing to the fact that the number of speed-gears in many passenger cars is on the increase. The innovations that promote the effectiveness of the production processes being applied include, for example, laser welding. With their ELC series of machines, the specialists at EMAG have developed integrated solutions for the application of processes with high output rates. The company’s in-depth knowledge of the production processes used for many transmission components has added to its competency in machine development.

(See the video HERE)

Herr Dr Andreas Mootz is Managing Director of EMAG Automation GmbH, Heubach, and responsible for the development of the production laser welding technology.

A first glance at a typical transmission component makes it plain where the challenges lie: even a small wheel with integrated synchronous gearing represents a relatively complex design. To manufacture it efficiently and at the highest precision calls for the two different parts to be produced separately and subsequently joined in a joining+welding process. It is at this point in modern transmission manufacture that laser welding comes into its own”, explains Dr. Andreas Mootz, Managing Director of EMAG Automation. “The process allows you to concentrate a carefully dosed amount of the energy emitted by the laser beam on the welding point, minimizing possible warping, while still achieving high welding speeds.” Furthermore, the welding process from EMAG uses solid-state lasers of outstanding energy efficiency. Whereas a classic carbon dioxide laser will achieve an efficiency factor of just about eight percent, the EMAG specialists can rely on an efficiency factor of approximately 20 percent with their technology. In other words, the power used to achieve the same optical performance is noticeably less, with energy costs in the production department massively reduced.

Machining area of the ELC 160 Laser Welding Machine for the welding of gearwheels. On up to three stations, the wheel assembly is pre-heated, joined and laser welded.

Stationary welding device scores heavily

Similarly effective within the total process is the integration of different production sequences on the ELC system. For starters, the work spindle uses the pick-up principle to load itself. The components involved are then clamped and pressed together in the joining press. The clamping technology used ensures the highly accurate positioning of the components, providing ideal conditions for the welding process. The design of the stationary optic ensures great operating safety and optimal stability of both machine and welding process. Depending on the workpiece material, the components can be induction-preheated prior to the welding process and brushed after it – and whatever is required, the process is completed in a single setup. The complete joining+welding process for a gearwheel takes just 12 seconds. This ensures that the components for a differential are thus finish-welded within no more than 40 seconds.

Laser welding the differential housing and the crown gear has meant a weight reduction of 1.2 kg or 2.65 lbs for this assembly.

Laser welding leads to advances in lightweight construction

The differential housing, as an example, clearly shows the possibilities the laser welding technology opens up in the general development of vehicle production. For some time now, automotive companies have been replacing the screw-type connection between differential housing and crown gear with a welded seam. The result: the cost of materials reduces and the weight of the assembly falls by approximately 1.2 kg or about 2.65 lbs. “When looking at the advances made in lightweight construction in the automotive industry, this kind of savings means the world”, explains Dr Mootz.

Laser welding a synchronous wheel onto a gear. The new fibre laser on the ELC 160 cuts operating costs in half.

The customer benefits from practical knowledge

Seen in context, the welding specialists from EMAG Automation in Heubach, Germany are able to look back on a truly impressive history of success. Over 50 ELC systems have been sold in the last decade. All leading automobile manufacturers are using them. EMAG is a world leader in solid-state laser systems for the production of transmission and powertrain components. How did this success come about? “It is of decisive importance that we have at our disposal a large reservoir of know-how in the manufacture of these components. We understand the entire manufacturing process, from turning and grinding, and from welding right up to the concluding ultrasound testing process”, emphasizes Dr Mootz. “We can develop and construct the whole of the process chain. This significantly simplifies the planning of new production sites and the expansion of existing ones.“

Laser-welded gearwheel

General market development is positive

The general market development does play into the hands of the German machine builder: It is not only the successful dual-clutch transmission that ensures the need for more gears. Conventional transmission systems also tend to have more speed gears, as this reduces gas consumption and improves the driving comfort. “Having said that, we are offering a well proven welding technology that provides an energy-saving, high-precision manufacturing process and, at the same time, helps to advance lightweight construction and reduce production costs. This is no doubt a very successful and persuasive combination”, concludes Dr Mootz.

Joining a gear and a synchronous ring on the ELC 160.

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

Continue readingIncreasing demands made on precision and the push for the decrease of price of modern components is pushing traditional manufacturing processes. EMAG offers three production technologies that complement or replace traditional processes such as turning, milling and grinding.

PECM for nickel- and titanium-based alloys

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

With its PECM technology (Precision Electro-Chemical Machining) EMAG presents a production process that opens up completely new fields of application. PECM is a process for the machining of high-alloyed materials, such as nickel- and titanium-based alloys. The disadvantages of traditional metal cutting – tool wear, mechanical stresses, micro-fissuring caused by heat, oxidization layering and the need for subsequent deburring operations – are eliminated, because this process is a non-contact one without heat input. All electro-chemical machining processes are characterized by stress-free material removal, smooth transition points and surfaces without ridge formations.

The ECM process is used to deburr components only at the points where material needs to be removed, and without it having any mechanical or thermal impact on the workpiece.

The advantages that the PECM process provides for different branches of industry are best shown with the example of a turbocharger for the automotive industry. The electro-chemical process is one that can be used to effectively in the machining of many high-alloy components, especially those in the high-temperature sector of the turbocharger – it also offers a much shorter and very efficient process chain. The typical clean-up operations necessary when traditional machining processes are used – such as deburring after milling – are no longer necessary. PECM machining operations are burr-free. And there is hardly any tool wear. The result: downtimes are minimal, when compared to milling (which requires regular tool changes). The process as a whole is sturdier and less prone to errors. And another important factor that our example of the turbocharger shows: the superb surface finish of the PECM process, where Rz-values of 0.3 micron can be achieved.

Will camshafts ever again be made of a single piece?

Another highlight is EMAG’s heat-shrink assembly technology, a process that scores particularly well in camshaft production. The high degree of precision achieved with the joining process drastically reduces the number of cam profile grinding operations or – with the use of precision cams – avoids them altogether. Another benefit of the process is the ability to combine different materials in the construction of the shaft, such as forged cams (e.g. in 100Cr6) and sintered cams, which do not require regrinding. Accessory components, such as plugs and end pieces, can – like the shaft itself – also be made of better materials. This allows for the camshaft to be adapted to the requirements of the engine and to be optimized in load bearing capacity and manufacturing costs.

Operating costs reduced by 50 %

Production laser welding is already a highly productive process in the manufacturing of gearwheels. The use of diode-pumped solid-state lasers – such as disc or fiber lasers –reduces operating costs by up to 50%. EMAG has been involved with the use of solid-state lasers in the welding of powertrain components from an early stage and is considered a pioneer in the technology. EMAG again has fulfilled a promise to their users offering them the lowest possible cost-per-piece, by coming up with an innovative technology that brings true cost benefits.

For many applications, solid-state lasers allow welding without shielding gas. This not only reduces operating costs, it also avoids having to follow the annoying logistics imposed by the use of shielding and laser operating gasses. In many cases, the welding process can also be sped up considerably. This increases productivity and – through a reduction in energy input per unit length – reduces welding distortion, resulting in better component quality.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

No. 893 is an 850ºF, electrically-heated walk-in oven from Grieve, currently used for heat treating parts on rollout shelves at the customer’s facility. Workspace dimensions of this oven measure 54” W x 72” D x 78” H. 80KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6000 CFM, 5-HP recirculating blower provides combination airflow to the workload.

This Grieve oven has 8” insulated walls comprising 2” of 1900ºF block and 6” of 10 lb/cf density rockwool insulation, plus an aluminized steel interior and exterior, top-mounted heat chamber and three rollout shelves, each 48” wide by 60” long and rated at 200 lbs.

Controls on No. 893 include a digital programming and recording temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, SCR power controller and fused disconnect switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingCrown Equipment in Mexico bought one of the MAE straightening presses from the GMTA booth at IMTS. Crown is a world leader in forklift trucks.

The expansion of the GMTA facility in Ann Arbor, Michigan is underway and targeted for completion in several months. When completed, the new facility will house a new machine demo and training center, plus additional sales and service personnel. GMTA continues to grow steadily, representing numerous high-quality German machine tool builders in North America.

Siemens in Mexico bought a Pittler PV630 ValueLine vertical turning machine for motor manufacturing. Take a look at video of this machine in action!

For more information:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

This Grieve oven has 6” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior and four front access doors with automatic door switches to shut off the heat and blower when a door is opened. Four structural steel slide beds are provided to support the plastic sheets during processing.

Controls on No. 1026 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, SCR power controller and eight auxiliary thermocouples connected to a selector switch and temperature indicator.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingNo. 873 is a 650ºF, electrically-heated inert atmosphere cabinet oven from Grieve, currently used for processing corrosive materials at the customer’s facility. Workspace dimensions of this oven measure 38” W x 50” D x 38” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 2000 CFM, 2-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road, Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com – Attention: Frank Calabrese

Continue reading

This Grieve cabinet oven has 6” insulated walls, aluminized steel exterior, Inconel 600 interior with continuously backwelded seams and special exterior paint. The oven also features full inert atmosphere construction, including pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all-welded expansion connection in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings.

No. 873 has a 650 CFM blower to pull air through the air jacket on the inner oven for cooling, plus automatic dampers. A hinged door jacket with 4” diameter connector to allow the jacket to be ventilated is also provided.

Sixteen pairs of shelf supports to support thirty-two Inconel 600 pans, with two pans on each level, plus loading truck tracks on the floor of the workspace, are built into this Grieve oven.

Controls on this inert atmosphere cabinet oven include a programming temperature controller, manual reset excess temperature controller, SCR power controller and fused disconnect switch.

No. 1022 is a 550ºF, electrically-heated, two-zone, dual belt conveyor oven from Grieve, currently used for encapsulation curing of large electrical coils in fixtures at the customer’s facility. Workspace dimensions of this oven measure 8’ W x 40’ D x 18” H. 480KW (240KW per zone) are installed in Incoloy-sheathed tubular elements to heat the oven chambers, while two 20-HP recirculating blowers provide a 49,000 CFM vertical downward airflow to the workload.

This Grieve conveyor oven comprises a 2’ long open belt loading zone and 3’ long insulated, unheated entrance vestibule, two 20’ long insulated heat zones with independent recirculated airflow and temperature control, 3’ long insulated unheated exit vestibule and finally a 2’ long open unloading zone for the workpieces.

No. 1022 has 6” insulated walls throughout, aluminized steel interior/exterior and is split into two sections for shipping. Side doors along the length of the oven permit access to the workload and heating chambers. This Grieve conveyor oven is built with all safety equipment required for handling flammable solvents and is constructed to NFPA 79/NEMA 12 electrical standards.

The oven further features two 3’ wide, 1-3/16” diameter cross bar conveyor belts with 1-HP motor drive, variable from 0.5 to 9 ipm. The conveyor belt drive is used in either index or continuous mode. Removable drip pans are provided below the conveyor assembly.

Controls on the oven include separate power and control panels, plus photo eyes at the unload station to signal an alarm, if the workpiece unloading is not cleared before conveyor indexing, SCR power controller for each zone and a tower light to indicate oven status. All control functions are accessed through a touch screen HMI connected to the onboard PLC.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

Ann Arbor, Michigan –Effective June 11, 2012, American Wera is now officially renamed German Machine Tools Of America (GMTA) and continues to represent various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema, WMZ and MAE. These machines are sold for gear and spline production, vertical turning, flexible machining solutions (blank to finish part solutions), as well as bar, pipe and tube straightening plus wheelset pressing. The company’s target markets include automotive, off-highway, OCTG, rail, wind energy, aerospace and other heavy equipment manufacturing.

This announcement was made jointly by GMTA President Walter Friedrich and Vice President of Sales Scott Knoy.

“The reason for the name change is simply that the parent company wished to use a name that is more representative of all the lines we handle in North America,” said Knoy.

Originally formed as the North American subsidiary for Wera in Germany, GMTA today provides application engineering, sales and service for a broad range of machine tools and metal fabricating equipment. GMTA has representatives throughout the U.S., Canada and Mexico.

Other key company individuals include Claudia Hambleton, Treasurer; Doug VanDeven, Service/Parts Manager and Shawn Wilkin, Senior Service Engineer. Joseph Kemple remains the dedicated Product Manager for the MAE line of straightening and wheelset presses.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Facebook: GMTA

Twitter: @GMTA_US