Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders companies, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

-GMTA will exhibit at several shows upcoming, including EMO in Milan and Gear Expo in Detroit. At the latter, the company will show its latest development for gearmaking, namely, the Hard Scudding process. Just a few years ago, the concept of Scudding®, developed by GMTA and its partner company Wera in Germany, left the traditional skiving method in the dust, so to speak, for internal gear production used primarily in the powertrain buildup. This process, 5-10 times faster than gear shaping, formed the surface of the workpiece through several, small enveloping cuts, providing a surface finish and part quality level that was far superior to hobbing, shaping or broaching. Scudding is a continuous generating process, meaning no idle strokes on the machine tool, as when shaping gears. Ring gears, sliding sleeves and annulus gearing, whether internal helical or spur, external helical or spur or blind spline, synchronizer parts with block tooth features and synchronizer hubs remain among the popular products in the market, made with Scudding technology.

Today, this continuous gear cutting process is widely used in production environments for internal, external, helical and spur gears, as well as splines and other components in the powertrain world. The machining can be done without the need for an undercut or groove (clearance) and lead of the gear can be manipulated via axial motions (crown/taper). It is a demonstrably superior technology and automotive suppliers have embraced its advantages for many years now.

Impressive a technology as it is, the industry took another step forward recently with our new process known as Hard Scudding™. The conventional Scudding process provides excellent results on green or soft gears, while this new advancement enables the re-machining of hardened gears with a tooth-to-tooth composite error and total composite error in the AGMA 12, DIN 5 range and a surface finish better than 1.5 Ra.

The capital investment is minimal for shops and production departments already doing Scudding, because the same gear can be run on the same CNC machine, using a solid carbide tool to do the work. Recent testing done on various internal automotive powertrain and agricultural machinery ring gears is showing extremely positive results. Stock division calculations on the tooth position are standard technology for GMTA and Profilator, so re-cutting is quick and easy. Using the latest CNC technology to control the machine kinematics, users are able to transfer this technology to Scudding machinery that is already deployed in the field. Thus, the same part can be cut on different machines at different times, allowing for more flexibility in scheduling. With today’s portable programming, onscreen or offline tool path and cutting condition simulation, plus the immediacy of call-up onscreen for all values and tolerances in real time, the busy machine shop or large production department stays flexible and demand responsive, using this Hard Scudding technology. In some cases, this new technology is applicable on near net, pre-hardened gear blanks, allowing significant step reductions in the manufacturing process.

In operation, cutting 60-100 thousandths per flank on a tooth, the Hard Scudding process can be used on a carburized or through-hardened parts; nitriding generally does not provide enough case depth to ensure sufficient stock for “clean-up”. An automotive ring gear, for example, which requires 40-50 seconds for Scudding can be produced with Hard Scudding in 25-30 seconds. This process development stands as a viable and very cost-effective alternative to conventional grind-and-hone operations, yielding a highly attractive cost per piece and extended tool life scenario. The added benefits of reduced capital outlay and a significantly more consistent end product bode well for the automotive powertrain and other gear market segments.

STOP BY BOOTH 2109 IN DETROIT, OCTOBER 20-22 TO LEARN MORE OR CALL SCOTT KNOY TODAY!

-GMTA management will be attending EMO in Milan with its partners, then exhibiting at Gear Expo, being held this year in Detroit, October 20-22.

-GMTA is running at “light speed” with their new Arnold laser work cells. Available as single or double work cells, the Arnold systems are offered as CO2 or fiber lasers, with full integration into a machining line, either by means of robotic part articulation or other automated transfer mechanisms, most of which are being supplied to customers by GMTA engineering. Leads from the last IMTS and the company’s aggressive ad program are already being developed into serious opportunities for the company, often in tandem with other machine tool lines and auxiliary equipment now offered by GMTA, according to company President Walter Friedrich. The most recent development is laser cladding, a process of simultaneous metal deposition and fusion, with an extremely high degree of control on the geometry. This technology has considerable application in the aerospace, medical, power gen and oil & gas market segments, in addition to the GMTA home base of automotive.

-The new Mexican office of GMTA, located in Queretaro, is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) there is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico from all their partner companies. At the new facility, machines are in place for demo and test runs, plus the facility is fully staffed with application engineering, technical support, after-sale service and parts inventory.

-Sales continue to be brisk on the 9- and 10-speed transmission projects in the automotive market. Scott Knoy, GMTA VP, comments, “We’re seeing a lot of activity here in the States and in Mexico, so we know our timing was right with the opening of our new facility there.”

-As part of the company’s ongoing commitment to education, GMTA Corporate Treasurer Claudia Hambleton volunteers for the Junior Achievement program in Saline, Michigan for educating K-12 students about jobs, entrepreneurship, financial literacy and work readiness in today’s competitive and changing market. She is active in the recruitment of local business people in the area to assist the program.

-The alliance with Star SU, through which GMTA is sourcing tooling locally, continues to prosper and mutually benefit both companies.

– We are proud to announce a business transaction between the Profilator Group and the Dr. Dieter Murmann Beteiligungsgesellschaft, in which Dr. Dieter Murmann Beteiligungsgesellschaft has acquired all shares of the Profilator Group, consisting of Profilator GmbH & Co. KG and the U.S. affiliate company GMTA (German Machine Tools of America Inc.). The Murmann family has long term plans with the Profilator Group to act as an autonomous business, striving for future success and ongoing technical developments. The current management team of the entire Profilator Group will remain the same, including Thomas Buchholz as Managing Director of Profilator in Wuppertal, Germany and Walter Friedrich as President of GMTA.

-GMTA is a corporate sponsor of the Smart Factory Industry Forum, being sponsored by the German American Chamber of Commerce and held at the Digital Manufacturing & Design Innovation Institute in Chicago on October 9.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Bartlett, IL (Chicago) – Effective immediately, Jeff Tanner has been appointed the new Midwest Sales Director for REP Corporation, the world leader in rubber and TPE injection molding presses. This announcement was made by Tim Graham, President of REP Corporation, at the company’s headquarters in Bartlett, IL, near Chicago.

Tanner comes to REP with 29 years of experience in the rubber industry, having previously worked at a major OEM supplier to the automotive NVH sector. He has a thorough technical background in rubber injection molding, tooling and adhesion processes, as well as new product development.

Jeff will be based in Cadillac, Michigan and cover the Midwest region for REP. He can be reached at 847-514-8160 or jtanner@repcorp.com.

His interest includes fishing, hunting and camping.

REP is the largest builder of rubber and TPE injection presses in the world, with global affiliates and multi-national manufacturing locations.

For more information, please contact:

Tim Graham, President

REP Corporation

8N470 Tameling Court

Bartlett, IL 60103

Phone: 847-697-7210

Web: www.repinjection.com

Event will feature speakers from Exact Metrology, FABTECH and Met-L-Flo to discuss the art of manufacturing and other innovative technology showcased at FABTECH 2015

WHAT: FABTECH 2015, North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry, will bring 3D scanning technology to the steps of the Art Institute of Chicago on Sept. 16. Exact Metrology, a 3D scanning solutions company, will use its Surphaser technology – known for its high accuracy and scan data quality – to 3D scan the museum’s south lion by Edward L. Kemeys (1843-1907). The guardian lions have flanked the Art Institute’s iconic Michigan Avenue entrance for more than 100 years and have become a symbol of the museum and of the city.

Attendees will have the opportunity to witness Exact Metrology’s scanning technology firsthand and hear from industry leaders as they discuss the process and benefits of 3D scanning and printing. Additionally, speakers will provide a look at what other advanced manufacturing technology will be showcased at FABTECH 2015, taking place at Chicago’s McCormick Place, Nov. 9-12.

After the scan data is captured, Met-L-Flo will use it to print approximately 300 small-scale replicas of the lion, which will be on display and used as giveaways at FABTECH.

Following the brief press conference, representatives from FABTECH, the Art Institute, Exact Metrology and Met-L-Flo, Inc., will be available for interviews.

WHO: Dean Solberg, vice president, Exact Metrology

Ed Youdell, president and CEO (FMA), FABTECH

Carl Dekker, president, Met-L-Flo, Inc.

WHEN: Wednesday, Sept. 16

9 a.m. – Press to arrive; photo opportunities

9:20 a.m. – Press conference

WHERE: The Art Institute of Chicago

111 South Michigan Ave.

Chicago, Il 60603-6110

Note: Press conference to take place on steps near the south lion, located in front of the Art Institute.

About Exact Metrology

Exact Metrology is an ISO 9001: 2008 certified company that offers contract measurement & scanning services, metrology equipment solutions, and hardware & software rentals. Its goal is to provide customers with a specifically tailored solution to their measuring needs. To accomplish this, it offers more options, more products and more experience.

About FABTECH

FABTECH is North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry. The event provides a powerfully aligned hands-on, face-to-face business growth experience, attracting more than 1,500 exhibitors and 40,000 attendees. The event is made possible by its five co-sponsors, all of whom representing the varied and diverse makeup of the manufacturing industry. They include SME, the American Welding Society (AWS), the Fabricators & Manufacturers Association, International (FMA), the Precision Metalforming Association (PMA), and the Chemical Coaters Association International (CCAI). Read more about FABTECH’s co-sponsors here.

About the Art Institute of Chicago

The Art Institute of Chicago collects, preserves and interprets works of art of the highest quality, representing the world’s diverse artistic traditions, for the inspiration and education of the public and in accordance with our profession’s highest ethical standards and practices.

About Met-L-Flo Inc.

Met-L-Flo, Inc., is a contract manufacturer specializing in 3D Printing and Additive Manufacturing services since 1991. It strives to partner with clients to implement innovative solutions for their product development and low volume production needs. Advanced applications of its technologies enable it to boost clients’ competitiveness and enhance product success. Its commitment to Quality is solidified in the company’s ITAR, ISO 9000 and AS 9100 Rev C Certifications.

As a leader in the industry, it prides itself on creating innovative, unconventional solutions that utilize both tool and tool-less applications. Products may be produced in metal, plastic, silicone, or wax including fiber reinforcement

For more information on the event, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingFirst application of CT scanning for metrology in America involves aluminum casting

Josh Schradin, one of the 3D Scanning specialists at Exact Metrology’s Cincinnati facility, recently completed a CT Scanning project involving aluminum castings measuring approximately 12” x 6” x 6” and weighing 10 to 15 pounds.

For this particular job, which represents the first use of CT scanning for metrology in America, the client was interested in wall thickness inspection as well as porosity and void analysis. The blue paint visible in some of the images was applied by the customer to indicate stress areas where leaking or breaking was suspected. Josh Schradin performed three stacked scans, each taking only about 30 minutes, to capture the entire casting. The result of the scans revealed the voids (legitimate holes) and highlighted the most serious problem areas in red-to-pink shadings.

In addition to offering the only method to get 3D views inside a part, another primary benefit of the Exact Metrology CT scanning is the true dimensional data provided in a non-destructive test manner, i.e. without cutting up or otherwise destroying the test object.

The workpiece (casting) was rotated 360 degrees in the x-ray beam’s path, with multiple readings from various angles being taken. Once the CT grey scale images were converted into voxel-based 3D point clouds, Schradin was able to generate a CAD-to-Part comparison for the customer.

If interested parties have a need for Internal Defect Analysis/3D Quantitative Porosity Analysis, Materials Structure Analysis or Assembly Control, CT Scanning (Industrial X-ray), Exact Metrology invites inquiries for immediate assistance.

Exact Metrology is an ISO 9001:2008 Certified Company.

To see videos on this new scanner’s capabilities, please visit:

VG GE casting analysis with CT hi-res at Exact Metrology

v | tome | x m CT scanner at Exact Metrology

For more information on this new system or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Connect with Exact Metrology online:

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingNo. 980 is a 500ºF (260ºC), electrically-heated universal style oven from Grieve, currently used for post curing fabric-coated silicone rubber gaskets at the customer’s facility. Workspace dimensions of this oven measure 30” W x 144” D x 30” H. 24 kW are installed in Nichrome wire elements to heat the oven chamber, while a 4200 CFM, 3-HP recirculating blower provides front-to-rear universal airflow to the workload.

This Grieve universal oven features 4” thick insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior, plus an integral oven leg stand and one pair of truck wheel guide tracks installed on the top of the floor to accept the customer’s wheeled fixture.

No. 980 includes all safety equipment required for flammable solvent processing, including explosion-venting door hardware and powered forced exhauster.

Controls on this oven include a digital indicating temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

See it at WESTEC 2015 – Booth 551!

Following its successful launch, SUHNER is presenting the BEA 16 spindle machining unit with an all new drive and control concept.

The objective of this new development was the integration of the latest servo drive and control technology from Bosch Rexroth. Software developed additionally allows the user to program six different basic cycles without prior knowledge of CNC.

By visualizing these six cycles – drilling – combined drilling (drilling and thread cutting with the one tool) – thread cutting – drilling with chip removal – drilling with jump function – undercutting, the unit has become extremely easy to program.

Plus, should the required machining cycle not be found among the standard selections or prove more complex, the unit can be switched to sentence programming.

The BEA 16 machining unit itself is a precision device from the SUHNER spindle machining unit series that has been designed for gruelling continuous use in multiple shift operations. The BEA 16 has a drilling capacity of 16 mm Æ in 450 N/mm2 steel. The max feed path is 140 mm, and the max speed is 500 rpm.

Today, rising production piece numbers and greater workpiece complexity with all-round machining are leading to a renaissance of the so-called special machine. However, today’s special machines are being used no longer as purely single-purpose solutions, but rather for whole part families.

These require different machining cycles, feed speeds, feed paths and rotating speeds, and, of course, must allow fast retooling. And it is these requirements exactly that the BEA 16 will meet to the full.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

This Grieve universal oven features 6” insulated walls, aluminized steel exterior, Type 304 stainless steel interior with 2B finish plus two 24” wide x 24” long shelves supported by rollers and each rated at 300 lb. load capacity. An integral oven leg stand is also provided.

No. 1034 controls include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Product demonstrations and technical presentations from principals impress large crowd

On May 14, 2015, Exact Metrology held an open house at its Brookfield, Wisconsin facility and the event was attended by over 125 local area companies, comprising quality assessment, design engineering and management personnel from many of the leading manufacturers in the region. Hosted by company co-president Dean Solberg, the day included ongoing product demonstrations of the various metrology equipment brands offered for sale, lease and rental by Exact, as well as the testing procedures provided as a service by this unique metrology supplier.

Services on display at the Brookfield open house included 3D scanning, reverse engineering, quality inspection, instant scan-to-CAD comparison and a full suite of PolyWorks software solutions. Equipment shown at the event included Aicon 3D systems, Breuckmann 3D scanners, Leica Geosystems, Romer and Hexagon brands of scanning devices and related hardware, all of which were available for hands-on use by event attendees.

A new product of great interest to attendees was the Breuckmann steroScan, a flexible scanning system for precise 3D digitization and metrology. Applications for this product include quality inspection, reverse engineering, rapid prototyping, deformation analysis and digital documentation. Because of the adjustable focal length of the scanner, products from small components up to large sections of automotive and aircraft parts can be scanned with high resolution and accuracy. Breuckmann is a company of Aicon 3D Systems.

During the event, technical presentations were made by Aicon, PolyWorks by InnovMetric and Exact personnel on the newest advancements in 3D scanning technologies. The presentations were given to a “full house” of interested attendees.

As Dean Solberg commented, “We seek to find the right combination of equipment and services to suit the applications and challenges presented by our customers. In some cases, it’s a matter of matching the right standard equipment to the job, while at other times we bring custom solutions and services to our customers, whether they buy, lease, rent or simply use our services to achieve the desired results on projects.” Solberg credited his staff of metrology engineers, technicians and customer service personnel for their hard work, dedication and adaptability in seeking their correct solution to all customer challenges.

Exact Metrology is an ISO 9001:2008 Certified Company.

For more information on this new system, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

The Customer’s Challenge:

Significant new business, order intake

New customers

Steeply rising monthly production rates

Building/Facility space constraints

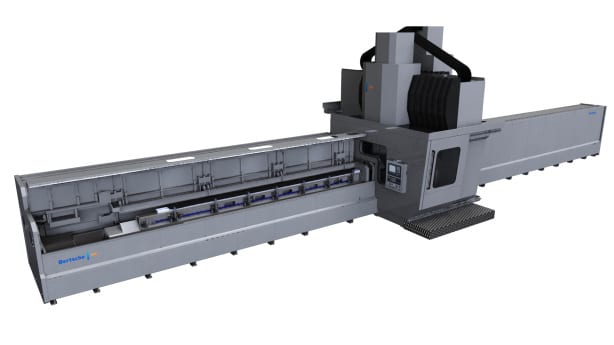

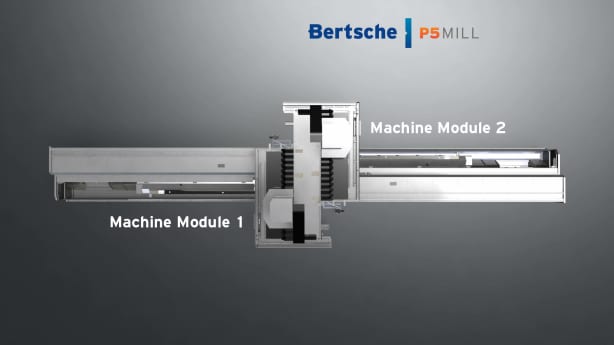

Solution: The Bertsche Two-in-One P5 Mill

Bertsche’s Dual P5 Mill allows dual work chamber manufacturing, independent or simultaneous, thereby saving considerable factory floor space for their aerospace customer.

Our aerospace customer was faced with the choice of either building a new facility to house two new milling machines or splitting their production between two manufacturing sites. Bertsche developed a new machine concept that offered the customer the productivity (throughput) of two machines and the floor space footprint requirements of one machine, thereby saving the customer the cost of building a 2nd facility and moving all production to a larger facility. The Bertsche Dual P5 Mill has all the benefits associated with having two machines, namely independent but linked CNC’s, two 5-axis machining modules ( A-side, B-side) each with separate machining chambers, the ability to machine two different parts at the same time and yet the overall machine is nearly the same size as a previously supplied single 5-axis P5 Mill. Based on the daily production requirements, the machine is operated A-side only, B-side only or A and B side together. Twin integral vacuum fixture tables are designed to accept a variety of different vacuum workholding fixtures that can be quickly changed at a moment’s notice, with a high degree of repeatability. To assist the operator loading parts, each table has retractable datum surfaces that swing into place to edge locate parts and then swing back down, when machining. Thick-walled composite structures (up to 0.625”) are milled, scalloped, edge trimmed and drilled on all sides. High accuracy hole patterns and datum holes are drilled for determinate assembly and then probed for accuracy. Parts are machined complete in a single setup and manufactured one-off to meet user ship-set kitting requirements.

With the growing trend towards cutting composites wet, flood coolant cutting was added and composite debris is flushed into a full bed length flume system. Flood coolant is constantly circulated throughout the machine for greater machine thermal stability. High volume mist collection hoods, integral to the machining compartment, collect and vent mist. A special sealing system is employed on linear ways to protect precision surfaces from very aggressive (detergent type) coolant fluids that must be used with composite materials. Multiple temperature sensors on the bed and X-axis slide accurately capture data for dynamic thermal compensation. To reduce the amount of filtration media, coolant is continuously filtered using a cyclonic filtration system.

Bertsche’s Dual P5 Mill allows dual work chamber manufacturing, independent or simultaneous, thereby saving considerable factory floor space for their aerospace customer.

Benefits:

For more information on this story, please contact:

BERTSCHE ENGINEERING CORPORATION

711 Dartmouth Lane

Buffalo Grove, IL 60089

Phone: 847-537-8757

Fax: 847-537-1113

Web: www.bertsche.com

Email: info@bertsche.com

Attention: Rich Bertsche or Erich Bertsche

High precision 3D mapping supports installation of a new beam transport line for scientific research

Fermi National Accelerator Laboratory (Fermilab), America’s premier high-energy particle accelerator laboratory, in Batavia, Illinois, collaborates with scientists from around the world to perform pioneering research, operate world-leading particle accelerators, plus experiment and develop technologies for science supporting U.S. industry.

In 2014, Fermilab contracted Exact Metrology to work on a project known by its location as “Main Injector Ring Section MI-10.” Horst Friedsam, Head of the Alignment & Metrology Department at Fermilab, led the week-long project with Exact Metrology, which involved 3D mapping of existing equipment in order to yield data to support the placement and installation of an additional beam transport line.

Exact Metrology performed the scanning in section 10 of the Main Injector Accelerator, which is situated in a tunnel about 10 m below ground with a circumference of approximately two miles. The Main Injector accelerates a proton particle beam, arriving from the 8 GeV (Giga-electron-Volts) Booster, to 120 GeV and subsequently blasts it into a stationary target to generate the world’s highest intensity neutrino beams.

Recently, Fermilab has been working on a new Deep Underground Neutrino Project (DUNE) to provide a neutrino beam to the Homestake Mine in South Dakota. This project features access to research facilities 2 miles below ground, which is ideal for neutrino experiments requiring shielding from cosmic ray events. In order to deliver a neutrino beam to the DUNE, a new beam transport line that fits within the existing beam line infrastructure was required. As a result, data scanning, full CAD modeling and photo overlays of a large section of the currently installed Main Injector equipment was needed. The collected data were crucial for the design of new beam elements and visualizing interferences with existing components.

The Alignment & Metrology Department maintained a high precision control network throughout the laboratory complex. For the scanning process, a Leica ScanStation P20 ultra-high speed 3D Scanner was used in conjunction with special laser scanner targets, modified to fit within the existing control network points. Exact Metrology’s Leica ScanStation P20 was chosen for its combination of high accuracy and low scan noise, plus its industry-leading environmental specifications for industrial as-built documentation. The software chosen to aid the process was Leica Cyclone, producing TruView—a web-enabled panoramic point viewer allowing the user to view, pan, zoom, measure and mark up point cloud data over the web. Additionally, RSL300 laser scanner target markers from Berntsen International Inc. were mounted concentric to 1.5” radius steel half spheres interfacing with Exact Metrology’s laser tracker nests. The coordinates of the control network, determined at the millimeter level, were provided to Exact Metrology to globally register all scans relative to Fermilab’s system. Thus, the end product provides information for all scanned objects in the common coordinate system used for the entire Fermilab site.

Fermilab has a long-existing relationship with Exact Metrology, having purchased and rented equipment from their instrument pool plus contracted for metrology services as on-site work, such as this scan.

Exact Metrology is an ISO 9001:2008 Certified Company.

For more information on this new system, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Or

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Or

FERMI NATIONAL ACCELERATOR LABORATORY (FERMILAB)

1117 N Washington Ave

Batavia, IL 60510

Phone: 630-840-2787

Horst Friedsam

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.