Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

New HLM-10 Linear Motion Machine, First of Hunter’s New Product Line, Unveiled at Cast Expo 2013

Minimizing maintenance while promoting stability, HLM Series combines and integrates magnetically coupled rodless cylinders and linear bearings for movements of squeeze platen, cope flask, sand measuring hopper, and other components on machine. Separation of hydraulic power system facilitates maintenance, while linear motion-operated, programmable access doors maximize operator protection. Linear motion machine also features CESAR™ vacuum pattern spray recovery system.

See the HLM in action HERE!

Hunter Demos JetSlinger™ Air-Amplification Product At Cast Expo 2013

JetSlinger™, the newest add-on to industry innovator Hunter Foundry Machinery Corporation’s latest products, helps ensure improved pattern definition, as well as uniformity of mold hardness and surface integrity.

JetSlinger™ is an available option for the new Hunter HLM linear-motion machine, as well as a retrofit option for the company’s XL automated matchplate molding machines. It is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines.

See the JetSlinger™ in action HERE!

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

In the news…

-DVS, the parent company of Pittler, Praewema and WMZ in Germany, has plans to expand its North American operations, owing to the success achieved with GMTA in this market

-Scudding® technology, pioneered by Profilator, continues to impact the North American gear and spline markets, due to its superior performance compared to other methods of production; several competitors trying to offer it, proving that indeed, “Imitation is the sincerest form of flattery.”

-The renovation of the GMTA facility in Ann Arbor, Michigan is now complete with plans in the works for future expansion of the campus. Additional floorspace, showroom capacity and training facilities, plus more personnel, are planned, according to company VP Scott Knoy.

-Now in final runoff with anticipated start-up in June, GMTA has provided eight machines (16 spindles total) for the advanced cylinder lining program to the Caterpillar operation in Mapleton, Illinois; project for GMTA valued at $15,000,000

-Order received from Chrysler for Phase III transmission line at IPT1 in Indiana

-GMTA and DVS will have joint booth space, considerably expanded, at IMTS 2014

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Workspace dimensions of this oven measure 30” wide x 96” deep x 24” high. A 2’ long open belt loading zone, 8’ long insulated heat zone with recirculated airflow and 2 ½’ long open belt unloading zone constitute the full heat processing system. 48KW installed in Nichrome wire heating elements provide the heat, while a 4200 CFM, 3-HP recirculating blower furnishes vertical downward airflow to the load.

This Grieve oven features 4” insulated walls, a Type 304, 2B finish stainless steel interior, stainless steel exterior with #4 brush finish, as well as a 24” wide, 1” x1” Type 304 stainless steel flat wire conveyor belt with ¼-HP motor drive, variable speed from 0.9 to 17.6 ipm. A side door allows access to the unit’s workspace.

Safety and control equipment on-board No. 853 include PVC electrical conduit, a remote control panel, 325 CFM stainless steel powered forced exhauster, six-point thermocouple jack panel through the oven wall, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

TCT Stainless Steel, Inc., a Lebanon, Tennessee metal service center, is proud to announce the commissioning of a new 64” wide heavy gauge EMAG slitter. This line is capable of slitting .035 to .3125 gauges. Maximum coil weight is 40,000 lbs. with a maximum 72” outside diameter uncoiler/recoiler. The line is complemented with an Alcos (8) position carousel packing line.

This new line is in addition to the existing 20” Stanat light gauge slitter commissioned by TCT in late 2012, which slits .005 gauge.

The addition of this line complements the other (4) slitters, rolling mill, edger and cut-to-length capabilities that TCT currently offers to customers. With these additions, TCT now offers more in-house capabilities and services than any service center in the Southern United States, according to a company spokesperson.

TCT invites all interested parties to visit the company at 711 Maddox Simpson Parkway, Lebanon, TN for a personal tour or visit www.tctstainless.com for a virtual tour. Let TCT show you what these new lines can do to benefit your operation.

For more information, please contact:

TCT STAINLESS STEEL, INC.

711 Maddox Simpson Parkway

Lebanon, TN 37090

1-800-877-8366

Phone: 615-443-4657

Fax: 615-449-6079

Web: www.tctstainless.com

Email: tcttn@tctstainless.com

Attention: Sherry Shaub, General Manager

TCT Stainless Steel, Inc. is one of the steel industry’s leading service centers. Our vast, in-house capabilities include virtually every facet of coil processing. Our capabilities include slitting, tempering, gauge reduction, cut-to-length, edging, buffing and tension leveling. TCT currently serves the aerospace, medical, electronic, telecommunication, automotive, lift equipment, building trade and other markets.

The combined inventory of our Michigan and Tennessee service centers include annealed and tempered stainless, aluminum, carbon and coated steels. Our dedication to providing high-quality products, short lead times and reliable delivery has always been the key to our success. We are constantly improving our facilities to include state-of-the-art technology, SPC and quality control standards.

Customer satisfaction is our specialty. Whether it be heavy or light gauges, narrow or wide widths, small or large quantities – TCT guarantees satisfaction and dependability at competitive prices. Our outstanding reputation for product quality is backed by our dedicated, customer-oriented team. Our sales staff welcomes all orders and inquiries and will respond quickly with reliable service and industry leading lead times.

Using the process-oriented approach of SIGMASOFT® makes it possible to consider all of the molding times present in an actual injection molding cycle. In the injection molding simulation of elastomeric applications, SIGMASOFT® not only considers the filling and curing times, but also the non-productive times between each production cycle while the mold is opened and closed. If the simulated process considers the influence of multiple consecutive molding cycles, the accuracy of the simulation is dramatically improved.

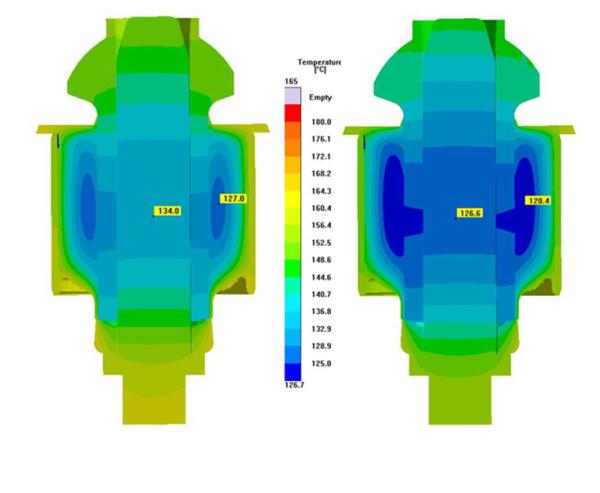

Figure 1 – Temperature distribution in a metallic component over-molded with rubber. Left: without consideration of the mold opening time; right: considering a mold opening time of 60 seconds, where significantly lower temperatures and long curing times are observed.

Even though it is not necessary to include them to complete an injection molding simulation, the “non-productive” times have a major influence on the mold temperature and thus on the process and on the part quality. With the Process Simulation Software SIGMASOFT®, from SIGMA Plastic Services, Inc. (Schaumburg, Illinois), all the non-productive times can also be included into the simulation of multiple consecutive production cycles and a substantial improvement in the accuracy of the results predicted can be achieved.

Considering the times in which the mold opens and closes, the times in which the mold is heated or cleaned, as well as handling times in which the inserts are placed or the parts removed, makes it possible to exactly describe the real multi-cycle production process. The interaction between all components present in the mold is considered with the local temperature dependent material properties, along with the heat that escapes the mold into the environment while it is both opened and closed and the exact timing of each event are coupled together inside of SIGMASOFT® to provide a comprehensive understanding of a very complex system. In this way, even factors that influence the part quality, such as the mold temperature and curing degree, can be predicted before the mold is ever built.

An example is presented in Figure 1. In this case, the mold temperature drops significantly while it is in the open position because heat radiates from both heated mold surfaces. If this time and open condition are not considered in the simulation, the mold temperature calculation will be higher than actual; resulting in a faster curing reaction and a shorter cycle time than what is actually possible. Other events will also be incorrectly calculated such as curing degree during filling and required injection pressure.

In SIGMASOFT®, non-productive times can be defined and individually modified in the simulation. For this reason, it is also possible to optimize the entire production process or mold design simultaneously. Through this simulation, it is possible to decide if changes in the process definition will solve production problems, or if the mold has to be modified to achieve the desired quality and productivity goals.

For more information:

Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue readingWith the process-oriented approach of SIGMASOFT®, the injection molding simulation for elastomers is no longer limited to predicting the cavity filling while designing the part, or to answering questions regarding balanced filling. Based on an accurate simulation of the curing reaction (vulcanization), it can be used for designing the mold, identifying process windows and troubleshooting during production.

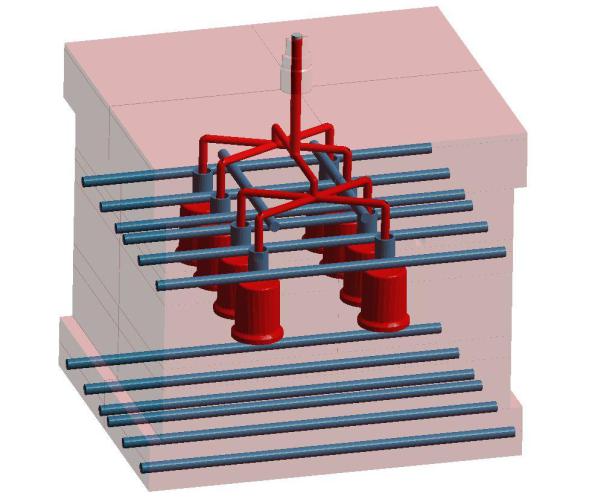

Figure 1 – The process-oriented approach of the Injection Molding Simulation Software SIGMASOFT® allows all relevant information (Part, Insert, Venting, Material, Mold, Heaters, Thermocouples, Process, etc.) to be used in the calculations.

SIGMA Plastic Services, Inc., Schaumburg, IL presents the latest functionality of its 3D Injection Molding Simulation Software SIGMASOFT®. The focus is on reduction of development and production costs using these new developments in process simulation.

Many factors in elastomer injection molding have an influence on product quality and costs. Here it is of little help to solely focus on a single aspect; part design, material, mold design, or molding process. To ensure a competitive advantage, the entire system must be considered simultaneously. Only when everything is optimized during the design phase, before the mold is shipped, can the largest cost savings be achieved.

By means of process simulation, molding feasibility and initial process parameters can be evaluated. Parting line and venting channels can be developed, as well as the optimal type and position of the injection point. Where are weld-lines acceptable, where must they be avoided? How much injection pressure will be required? Ultimately, the complete mold and process must be optimized. What wattage and heater design is most beneficial? Where is the best thermocouple location for each heater? Do inserts need pre-heating and how will they influence the curing? How long is the curing cycle, what areas of the part cure late and why? These questions are all related to the mold design and the production process and they are all important factors regarding part quality.

The simulation results provide answers to all of these questions in a clear and meaningful way, allowing injection molders a way to virtually test the mold before it is built. Costs can be reduced significantly during development, and existing processes can continuously be improved, while substantially reducing material waste and improving quality.

The latest developments in the thermal solver allow for the integration of all mold components and their individual temperature dependent material properties. In this way, an accurate reproduction of the real temperature profile in the mold is possible, even over several consecutive injection molding cycles. The simulation set-up is optimized for the requirements of process engineers. This allows production-minded engineers to use this technology without a simulation background. For example, a process engineer can determine how heating cartridges influence mold temperature and part quality, simulating them with their respective electric power and thermocouple control.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue readingSpokane Industries, a family-owned company established in 1952, is a steel foundry, metal products and precision castings facility of more than 240,000 square feet in Spokane, Washington. Spokane Industries serves customers in many industries from aerospace, construction and agriculture, to transportation, aggregate processing and general manufacturing. Proud to be a family-owned company, many employees here are second and third generation who are personally and professionally committed to their customers. Customers are not just coming to Spokane to buy castings, but they are coming to solve problems. With that in mind, experience, expertise, effort and the latest technology, including MAGMASOFT® process optimization software, are used to differentiate Spokane Industries in the marketplace. Spokane strives to create quality products delivered on time and as a result, their customers’ businesses are more successful and profitable.

The Spokane Steel Foundry Division is the foundation of Spokane Industries and is committed to staying on the cutting edge of technology, upgrading its facility to optimize production and enhancing quality control procedures. Spokane Steel Foundry has been serving commercial and industrial customers around the world for more than 50 years, still maintaining some of their original customers; some are still ordering castings from their original patterns.

Experiencing decades of steady growth, Spokane Industries operates an environmentally clean, well-managed and technologically advanced organization dedicated to meeting the needs of its customers. Today, the foundry’s output includes durable wear parts for impact crushers as well as a wide variety of high specification quality castings for the construction, mining, manufacturing, transportation, aluminum and defense industries, striving to meet the demand with each project.

By introducing MAGMASOFT® at the company, Spokane quickly saw how this software’s capabilities of simulating the entire casting process start to finish, was not only an invaluable engineering tool, but also a tool that impacted the entire business. CFO Ken Vorhees reported, “Having MAGMASOFT® has improved our ability to reduce the number of samples and bring quality products to market faster through meeting specifications, tolerance and metallurgy, most often on the first run.” Foundry Division President, Tyrus Tenold, adds, “This is a very powerful tool, giving us the ability to virtually see the entire casting process before we have invested significant time and materials. We now catch problems before they become problems. By the time we are ready to run the part, we have confidence we will have a quality part on the first run, in most cases.” Using the software to run detailed process optimization for the entire casting process enabled Spokane to catch process issues anywhere in the casting process before the first actual run. The software enables the engineers here to catch potential problems with a casting before the part even hits the foundry floor and resolve them faster than any competitor not using this technology.

Having now utilized its MAGMASOFT® license for 2 years, Spokane has seen a significant change in their entire casting process. Rod Grozdanich, Technical Director, states, “We use the software to help customers refine their designs as well as convert many of their weldments into castings. Being able to simulate the entire process helps a lot, in that regard.” The software being one of the foundry’s business tools has helped them support their selling point that they are more cutting edge and in a leading group of local vendors with the latest technology and equipment.

Antonio Melendez, Design Engineer, points out, “By having MAGMASOFT®, we find that our customers expect more of us. We are confident that we can deliver and have always lived up to and exceeded the challenges our customers have given us.” He adds, “It has become common that when we go back to a customer with a design change that effects them, costs them more money, like adding a riser, they want to know why. MAGMASOFT® gives us that credibility and additional technical support for our case.”

Spokane employees discussing MAGMASOFT’s benefits – Antonio Melendez, Design Engineer, David Jolin, Quality Assurance Manager, Rod Grozdanich, Technical Director

David Jolin, Quality Assurance Manager, says, “We do see both current customers and potential customers requiring that we run the casting through a solidification program. There have been times where we have been directly told that in order to be awarded a particular job, we need to show them simulation capability. We are seeing this as a requirement, more often nowadays.”

A big part of justifying the cost of the software was being able to go back and simulate past projects to make designs changes and improve the quality of the castings for future runs. Grozdanich says, “We found many jobs that we set up with our previous simulation software where we really couldn’t see the shrink, and now with MAGMASOFT®, we can see what’s happening and we can fix it. We had chronic instances with issues on jobs in the past that we just could not solve and with MAGMASOFT® we have been able to go in and fix them all.”

Simulating the entire process from design to finished part helps save time and money by creating all the changes and making all the mistakes virtually rather than during actual production. Melendez states, “We are trying to minimize the number of samples before releasing a casting for production. The idea is to do all the tweaking on the computer without spending money to pour multiple samples. This year, we have significantly reduced the number of samples and are more likely to produce a quality part on the first run.”

In addition to the ability to simulate the entire casting process, Spokane has found a solid partner in MAGMASOFT® by taking advantage of the resources extended to them as a user. “The user group meeting every year is a very good tool to keep us informed of new developments and get everyone up to speed on anything we feel we would like to improve upon. Peer-to-peer discussions on how we each utilize the software are invaluable,” Melendez says.

Of the four capabilities that make up Spokane’s license with MAGMASOFT®, namely filling simulation, solidification simulation, heat treatment and stress analysis, Spokane utilizes all these processes to the fullest extent, including macro segregation simulation. Grozdanich points out, “In the last 10 months, on the dozen or so new projects we have put out, all but one or two were quality parts on the first run. Our time to first quality part has therefore been greatly reduced.” Jolin adds, “Being able to simulate the entire casting process has significantly fixed our shrink issue, which was quite a struggle from my end before MAGMASOFT®.” Melendez offers, “One of the main advantages of the software is one can see roadblocks before they actually happen and can compensate for them, specifically with predicting the distortion of the casting and other issues that might arise before we actually build it.”

In addition, the software helps gain understanding and provides clues to what can be happening when issues arise that initially don’t make sense. It’s proving to be a reliable troubleshooting tool by helping to gain clarity where there are issues that arise that are initially not understood. MAGMASOFT® is the missing link that helps lead to that solution, according to Spokane engineers. Antonio Melendez observes, “The software verifies what is going on, gives clarity and enables us to pass on not only an opinion, but provides credibility to support our opinion to our customer. The software is able to set particular processing parameters. For example, when pouring through a sleeve with a filter, there were scrap issues with the filters breaking. After doing some simulations and flows through that method, we could see that, for one ladle, we needed to use an inch and a half diameter nozzle, that way the flow is just right for this particular set up.”

Melendez adds, “Each casting is different, the number of iterations are different. It is more a question of how tough is the part. For example, if you have a part with isolated hot spots and you don’t have clear filling patterns, you are going to struggle. The advantage with MAGMASOFT® is you can see those trouble spots and focus on resolving the issues before creating the first sample. Even if you need to do 200 iterations in the right direction, that’s okay, because we are no longer shooting in the dark.”

At this foundry, it’s clear that their use of process optimization software is yielding benefits across the entire business environment, from design through material use, production through part validation and in differentiating Spokane Industries from its competition in the marketplace. The result is more work being processed more efficiently, with the plant’s capacity utilization being much higher and more profitable, according to Spokane personnel.

For more information on this story, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-969-1001 ext. 225

Email: cheisser@magmasoft.com

Web: www.magmasoft.com

Heimatec is a world leader in the development and manufacturing of live tools, angle heads and multi-spindle drill heads. With U.S. head quarters located in the Chicagoland area and company head quarters and manufacturing in Renchen Germany, we are dedicated to supplying our customers the most innovative tooling technology possible.

Check out the new look at www.heimatecinc.com!

For more info on Heimatec:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading

This Grieve cabinet oven features 4” insulated walls, aluminized steel exterior, Type 304, 2B stainless steel interior, a silhouette plate with removable cover inside the door opening and an oven hearth driven by a ¼-HP motor through a gear reducer with a torque limiting device variable from 1 to 27 RPM. This 19” diameter oven hearth is constructed from Type 304 stainless steel with 1” studs on 1” centers to support the paint coupons in process.

All safety equipment required for handling flammable solvents are onboard No. 987, including explosion-venting door hardware.

Controls onboard No. 987 include a digital indicating, time proportioning temperature controller and excess temperature controller with separate heating element control contactors. An auto door switch stops hearth movement when the oven door is opened.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

This Grieve oven has 4” insulated walls, top-mounted heating chamber, aluminized steel interior and exterior, plus five (5) monorail tracks mounted at the top of the oven’s workspace.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment are included on this walk-in oven, including a 325 CFM, 1/3-HP powered forced exhauster.

Controls on No. 889 include a digital programming temperature controller and 6-point strip chart recorder with 1-point air temperature, 2-point vacuum and 3-point load temperature recording capability.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese