Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Understanding the application and being aware of common challenges can help make a difficult operation both productive and profitable

The global drilling tools market was valued at USD 5.79 Billion in 2016 and is expected to grow at a CAGR of 4.75%, during the forecast period, to reach USD 8.61 Billion by 2022.* Producing deep holes in an effective and efficient way is considered a challenging application. Cutting tool manufactures need to provide their customers with a product that has predictable tool life, accurate surface finish and repeatability at a good price to be competitive in the market. Thomson Mathew, ANCA Product Manager explains the different types of cutting tools for this application and how to overcome some common challenges in deep hole drilling.

Thomson Mathew starts: Deep hole drilling is a process to produce holes in metal at high depth-to diameter ratios on CNC Machines. For normal drilling processes, the length to diameter ratio will be less than five times the diameter and if the length to diameter ratio goes beyond five, the process is called deep hole drilling. This can be effective in diameters ranging from 1mm – 200mm [0.04in – 8.00 in] and will require special drills with through coolant holes to deliver high pressure coolant to evacuate chips cleanly and achieve hole tolerances and surface finish.

Some common deep hole drilling process include gun drilling, BTA drilling (Boring and Trepanning Association) and conventional carbide twist drills. All these processes have their own merits in deep hole drilling based on hole diameter and tolerances.

BTA drilling is an effective method of drilling deep holes, as it is cleaner, reliable and capable of achieving larger diameters at higher feed rates. BTA drilling is effective in holes from 20 – 200 mm [0.80 – 8.00 in], a larger size range than gun drilling and carbide twist drills.

Through coolant or internal coolant – This improves chip evacuation while cooling the cutting edge. Coolant is flushed down to the bottom of the hole, which, in turn, is pushing the chips back up toward the top. ANCA software has the ability to design and verify the coolant holes right at the design stage to avoid coolant hole breakage into flutes and eliminating scrap.

For further information, please visit:

https://machines.anca.com/Contact

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

ANCA is a partner to the NOTUS Emergency Ventilator Program, a Grey Innovation-led initiative supported by the Victorian Government and Advanced Manufacturing Growth Centre (AMGC) to manufacture and assemble components of ventilators

Coming to the aid of a medical system crushed world-wide by the COVID-19 pandemic, ANCA has joined an important consortium to rapidly manufacture invasive ventilators within Australia. This initiative directly addresses the critical supply of mechanical ventilation equipment to support COVID-19 patients requiring ventilation to survive. Banding together with other Australian manufacturing businesses, the consortium can harness various industry capabilities to make more ventilators sooner.

Co-founder and managing director, Pat Boland said: “ANCA is an advanced manufacturer that supplies to a wide range of industries, a key one being the medical industry. In fact, ANCA has been classified in the U.S. as an essential industry because so many of our customers are manufacturing medical components.”

ANCA is an Australian manufacturer of CNC machines that produce quality precision cutting tools. Their experience in advanced manufacturing means they can guarantee a micron precision, a capability which means the company could pivot and utilise its machine shop to manufacture parts for the ventilators. An Australian-based company, ANCA exports 98% of their product and boasts a global network to service global customers. Fully Australian and privately owned, ANCA machines have the capacity to machine components in brass, aluminium, plastic and steel and has skilled assembly capabilities.

Around the world it is predicted that total demand for ventilators could run into the tens of thousands, with existing manufacturers unable to meet demand.

“This is a global emergency and in my view it is incumbent on every individual in every organization to do everything they can to help deal with it. And in the case of ANCA, we have capabilities that are a good match and it’s the right thing to do. We are very good at manufacturing the kind of parts that are needed for ventilators and it is a really great way for us as an organization to give something back to the community,” said ANCA Group CEO, Chris Hegarty.

With production already in progress to meet tight timeframes; ANCA has hit the ground running with dedicated machinists willingly working weekends and over the Easter break to make parts and help combat coronavirus.

Production Operations manager, Mark Patman explains: “With an extremely tight timeframe, we’ve jumped in and started manufacturing the parts; it’s a team effort across the business to get it done. As a well-established global business, a lot of the processes required to deliver this type of project are already in place at ANCA. We can leverage off all our systems to be able to deliver the project.”

ANCA is utilizing a cross-functional team comprising manufacturing, supply chain, project management, stores logistics, and safety to support this crucial work.

Demonstrating agility in moving from machine tools to ventilators ANCA already has a working relationship with the AMGC and is pleased to be collaborating with Grey Innovation to ensure that Australia does not have a shortfall in ventilators, critical for our COVID-19 response. Answering the call from the Australian Government, rapid production will continue to supply contracts and contribute to the coronavirus crisis strategy.

For further information, please contact:

Sepideh Zandieh

Acting PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue readingAs an industry #ANCATooloftheYear celebrates the knowledge and imagination of cutting tool craftsmen, creating tools with the perfect geometry, profile, and finish that shape and build our world everyday.

Pat Boland, ANCA Co-founder said “All finalists were of a very high standard and demonstrated a deep understanding for tool geometry as well as taking full use of ANCA’s software to design unique and special cutting tools. We congratulate the winner KV Tooling, runner up Eshed Tools and Zakłady Mechaniczne Kazimieruk who we gave a special creativity award for daring Bat Man design.”

“Our entry was a very complex tool with many features incorporated into one tool. We designed the cutting tool to satisfy a customer’s problem, where our one tool replaced a machining requirement that previously required six tools. The customer was very happy with the production gains and for us to submit to ANCA Tool of The Year. We believe winning the competition makes our company more marketable and will give us great exposure and hopefully expand our customer base,” concluded Brian.

Eshed Tools entered the competition to share their special tool manufacturing skill set with ANCA users. Shmulik Arbel, Production Manager commented that they were proud of their expertise that means they can “produce special geometries that are difficult to achieve and save our clients expensive production time.”

Reflecting on coming runners up Shmulik continued, “Taking out this prize creates a great opportunity for global exposure through the Tool of the Year competition. For us ESHED tools as a small and growing tool manufacturer, world wide recognition is important and will help us expand beyond the local market.”

Zakłady Mechaniczne Kazimieruk on winning the ‘Most Creative Tool’ said: “We thought outside the box and were motivated to inspire the grinding community with our entry. During everyday work our team make a lot of customized tools so we wanted to make something fresh and unique – even to us. Furthermore, entering was a great test for our grinding skills. We relished the opportunity of seeing others craftmanship and the entries in the tool of the year competition demonstrated to us the range and type of cutting tools that are possible.”

The competition was based on the passion and the craft of tool making and celebrate our highly skilled tool grinding community. Watch the live announcement of winners at EMO 2019:

Judging Panel

The top five tools were judged on the following criteria:

For further information, please visit:

https://machines.anca.com/Contact

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Visit ANCA at EASTEC at booth 1244 to learn more about how our world-first technology developments have helped reduce production costs by 50% through lights out manufacturing

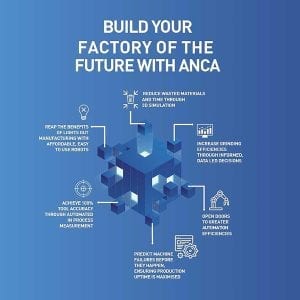

Visit us at Booth 1244 and learn more about how ANCA is enabling manufacturers to run ‘lights out’ and download our practical guide on how to build a Factory of the Future.

Thomson Mathew, Software Product Manager says: “Get a live demo of the soon to be released ToolRoom RN34 software and learn how it specializes in complex cutting tool geometries for the aerospace, die mould and power generation industry.”

ANCA’s latest ToolRoom RN 34 software release focuses on manufacturing the most complex tool geometries with a perfect balance. Visitors can get a demo of the endmill cycles for ballnose and corner radius, tool balancing and next generation fluting cycles.

Email us at marketing@anca.com to book a free demo at EASTEC 2019 to see ANCA’s latest ToolRoom version or our Management Suite software.

Ideal for light manufacturing, regrinding and full production – see the FX7 Linear at EASTEC

For customers that require increased flexibility or more spindle power, or increased automation capacity that a robot can provide, the FX7 Linear offers these. The FX7 Linear offers a wide range of options for those looking to increase productivity and accuracy. Available as an option is the AR300 robot loader to increase efficiency by automating repetitive manual tasks.

Features include:

With over 70% of ANCA customers buying machines with robotic functionality, it’s fair to say the age of the robots has come. Far from a nice-to-have add on, many CNC machines now come with operator panels that provide in-built control over both the grinding software and the robotics function, opening the door to greater automation efficiencies.

At ANCA we provide a complete solution to our customers, designing and manufacturing almost all our technology in-house. As part of this we developed our own low-cost solution for tool loading.

The 3-axes ANCA robot has a capacity of 380 tools and accommodates tool sizes up to Ø20mm (Ø3/4”) x 150mm (6”) long. The AR300 loader is contained within the compact FX Linear machine footprint, so there is no need for extra floorspace. In addition, there is no need to change gripper fingers between batches, which further maximizes productivity.

Utilizing the latest control technology from ANCA Motion, the AR300 loader is an excellent value-for-money auto tool loading solution for the FX5 Linear and FX7 Linear two-wheel changer machines. The loader provides quick tool loading, as the tool is passed directly from the pallet to the collet in a single gripping action.

For further information, please contact:

Sepideh Zandieh

PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading