Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

MC726/MT-2C machining center from Stama America; 30% smaller footprint than conventional mill/turn centers

Allows six-sided processing of parts in two independent operations in five axes on single machine; twice the speed of conventional MT centers with 30% less footprint

Stama America, Itasca, Illinois announces the introduction of its MC 726/MT-2C mill/turn, twin spindle machining centers for the automotive, fluid power, tooling, medical and other industries, where parts needs to be milled and turned in production operations. This new machining center is the latest iteration of the popular TANDEM concept mill/turn centers, introduced by Stama in 2007.

Two independent spindles are onboard, each on a traveling column assembly and each supporting an independent swivel table, one of which acts with a bar feeder mechanism. Workpieces are introduced to the turning spindle, then transitioned by a conveyorized gripper assembly to the milling indexer and fed to the milling spindle, before finally exiting the work area.

Complete six-sided machining is possible between the two cutting operations, all on one machine with approximately twice the speed of a conventional m/t center in 30% less footprint. Since the first part is being milled simultaneously to the next part being turned, the overall production operation is greatly enhanced, nearly doubling in many applications.

For more information on this new machining center, please visit our website or contact:

STAMA AMERICA

1063 Hawthorne

Itasca, IL 60143

Phone: 630-233-8101

Fax: 630-773-1660

Web: www.stama-america.com

Attention: Simon Knecht, Sales Engineer

Simon.knecht@stama-america.com

GM realizes “weeks to hours” reduction in line change and transmission build dynamics at Toledo Powertrain, resulting from Flexible Assembly Configuration System (FACS) and Siemens control/communication

A tried and true euphemism nowadays, “thinking outside of the box” usually refers to a pattern of thought or action that results in rapid innovation, enhanced relationships being developed from established concepts as well as new ones, plus a genuine willingness to forego past practices in favor of a better way. Enter the GF6 six-speed, front wheel transmission line at General Motors Powertrain on Alexis Road in Toledo, Ohio.

Here, a new front wheel drive transmission line for smaller, more fuel efficient vehicles such as the popular Chevy Malibu and new Chevy Cruze is currently ramping up to its initial goal of 2200 units per day. Nothing new about such an event, until a closer look reveals the method used to program this line, implement changeover, stage the workpiece flow, perform all machining, secondary operations and assemble the finished transmissions.

Greg Nazareth, GM controls engineer, demonstrates the reconfiguration procedure on the FACS server, part of the overall Flexible Assembly Configuration System, provided by Elite Engineering of Rochester Hills, Michigan.

During the development of this line, several years ago, GM engineering contacted its longtime controls suppliers to investigate ways of significantly reducing the workflow through the line, as well as enable faster changeover, reduce reprogramming and prevent the curse of all automated manufacturing lines, situations where one out-of-spec machine caused complete shutdown. Another key driver in the development of the GF6 line was the need to minimize maintenance time by installing PLCs, drives and component pallet recognition devices outside the conventional cabinetry found on traditional assembly lines. In addition, controllers were distributed throughout the system, which allowed for removal of typical zone controllers and, in turn, substantially increased system flexibility.

Following considerable investigation into the process for the new line, the major obstacle remained changeover and the need for a more flexible yet highly automated system of transmission builds. In consultation with the controls provider on the existing six-speed, rear wheel drive line, Siemens Automotive Center of Competence (Troy, Michigan), as well as third party software package provider, Elite Engineering (Rochester Hills, Michigan), a deterministic study was undertaken and the result was the line now in production. Siemens provided the PLC, CNC, HMI, RFID and its high-level Ethernet protocol, Profinet, to run on the GM network. Overlaying this hardware and communications topology, Elite Engineering delivered its Flexible Assembly Configuration System (FACS), complemented by Siemens to create its SIFACS solution, wherein all the control elements for every assembly operation and test stations would be fully integrated. SIFACS largely focuses on the integration of the core PLC software blocks and functionalities of the individual stations with the RFID tags on each of the workpiece pallets, according Jim Remski, manager of powertrain activities for Siemens.

Siemens CNC and HMI technology combine with its Profinet high-level Ethernet communications and RFID pallet tags to execute the machining, assembly and testing at this transmission plant, currently targeting an output of 2200 units/day.

AN INTEGRATED APPROACH

Within any flexible automated assembly system, the keyword is flexible. All hardware and related software must be designed with a deterministic functionality that is both valuable to the customer’s build strategy and cost-competitive, as well. Working with technical specialists in safety integrated systems and industrial communications alike was the key to the success of this project at GM Toledo. By creating a decentralized control network that was nonetheless in complete harmony with the overall workflow of the plant, GM and Siemens devised the optimum modular yet flexible architecture for the entire system. This totally integrated automation approach not only addressed multiple families of hardware involved, it also coordinates all code development, safety and communications functions into a seamless and interdependent yet highly flexible and adaptive control scheme.

This integration is nowhere more visible than in the modular and open controller and I/O rack assemblies located throughout the facility. A Siemens Simatic® S7 CPU, the Siemens Safety Integrated drives platform and all I/O, including RF antennas for RFID tag reading are configured and reside here.

Diagnostics in the system are similarly integrated, according to Matthew Thornton and Jeremy Bryant, who consulted from Siemens. “We devised pre-made templates and blocks important to the powertrain build process, as our starting point,” commented Thornton, who further noted the importance of placing the critical performance data on all the HMI panels in the system for easy operator access. “With all motion and safety functions integrated into the drives, there was no need to build a separate troubleshooting architecture for what would be a more traditional safety network of relay cabinetry.”

Bryant continued, “Only a few components talk on the Profibus system, all other I/O and automation components communicate over Profinet.

Reinhold Niesing of the Siemens Automotive Center of Competence further explained the contact process between his group and the provider of the FACS. “They provided the configuration and monitoring system, while we (Siemens) provided the automation run time system. Both systems needed to run in sync to provide GM with configurable options, when changes in production or manufacturing enhancements were needed.”

Each RFID tag carries all the information needed to produce the part at each of the machining and assembly stations in the line.

The result of this collaboration, coordinated under the Siemens Transline solution, whereby all operational, visualization and diagnostic functions are streamlined in a consistent control scheme, was the Transline HMI Lite CE package. This package provides uniform user interface for operational and diagnostic functions on the vast majority of the various machine tools, transfer lines, robotics, assembly machines, sensing devices and vision systems throughout the entire facility. As Michael Grass, project manager for Siemens, explains, “The best part is that the package can be customized to meet specific user needs and preferences. It provides our SIFACS (see sidebar) system of configurable assembly automation very useful information, as the two systems complement each other quite well.” In the safety communications area, he also noted that GM is currently reviewing another Siemens option for open safety communications technology on distributed automation systems.

RFID GETS THINGS STARTED

As a workpiece proceeds through the line, having been delivered by an AGV in most cases, each pallet is equipped with an RFID tag. Reinhold Niesing, engineering manager on the project for Siemens, explains, “The key here is the data throughput in the system, as it directly impacts the cycle time or takt time (maximum allowable time to produce one finished part or product) of the line. The tags must be able to function in static mode, whereby the data on the part must be read before the process begins. Model number, serial number and build status information are all contained in the tag. The faster we read the information, the faster the process begins.” Niesing also detailed the dynamic mode of operation for this RFID system, in which the information at subsequent line stations must be read “on the fly” without any line stoppage, as is often seen in conventional packaging, shipping or other line applications for RFID. In this case, all data are read as the tag passes by the antenna.

Often, in less sophisticated applications, the signal can degrade over time and number of reads. Here, according to the Siemens technical specialists, two interface protocols are supported, namely, ISO 15693 (open standard) and a proprietary Siemens-developed standard, Simatic RF300. The latter uses a state-of-the-art chip paired with highly optimized communications to achieve the faster data read/write rates. Large amounts of data (64kB) are handled in faster cycle times, while the overall RFID solution is applied in a high-speed, non-stop environment. One of the key drivers in the system is the fact that each RFID tag has both EEPROM and FRAM. The 20-byte EEPROM is actually designed to be a one-time programmable memory chip (OTP), a security feature that was deemed most desirable by GM for this application. Meanwhile, the FRAM can be written and rewritten many times for optimum utilization of the hardware, over time.

Despite this level of sophistication in the RFID hardware, the system easily communicates over the existing Profinet, Profibus and other common protocols.

LOGIC BLOCKS ALL AROUND

The overall thrust of the line development, according to George Jewell, the GM engineer responsible for the implementation of the FACS online at the Toledo plant, was to have consistent, even identical logic blocks at every station. This would allow, as is seminal to the FACS architecture, immediate successive modifications to be made in the machine or assembly operations performed, throughout all stages of the line. When rebalancing was needed, when an upturn/downturn in current production was required or when an entirely new model came onto the line, the changeover needed to happen in hours, rather than in weeks, as was the industry norm.

By standardizing on the hardware, software and communication protocols used, engineering costs could be contained and, as a collateral but vital side effect, maintenance on the system could be made much more efficient with much of the system hardware exposed on the line, rather than enclosed in electrical cabinets, again the norm for the industry in the past. Flexible modules would allow more rapid reconfiguration, product changes and a genuine synergy with the ongoing GM commitment to continuous improvement in the line, as the new GF6 transmission ramped up to incremental target levels of production.

Jewell noted that Siemens responded to the challenges, “…with a plug-and-play technology approach, coupled with an understanding of the processes we utilize.”

From the utility perspective, he also noted that the run-time component in the system would function without the full configuration system being online, further complementing a decentralized architecture. Bob Raven, GM controls manager, further commented, “The Siemens commitment to provide this value added functionality geared towards flexibility within our manufacturing principles has substantially supported GM Powertrain’s efforts to standardize processes, controls and continuously improve.”

Currently, GM uses the FACS at various plants in Mexico, China, India, Thailand, Korea and the U.S. — and soon in Canada and Eastern Europe, for the production of transmissions, engines and even the generator on the new Chevy Volt. These products, it should be noted, can be manufactured, assembled and tested, all within the same flexible control architecture, while supporting standardized GM processes.

Rather than textbook product life cycle management, Jewell sees FACS as more of a production line life cycle management tool, as its inherent adaptability means common hardware can be made to do diverse tasks, at varying rates, with on-the-fly changeover, in far less time than previously possible.

TYPICAL STATION DYNAMICS

On one automated assembly station, Hanwha produces the various sub-assemblies of the transmission, as other lines produce the components that go into the sub-assemblies. Adding a station, as Greg Nazareth, GM controls engineer, explained, requires simply adding a PLC with the standard SIFACS logic, desired process devices and downloading an eFACS configuration. In contrast to the traditional zone control, this reconfiguration is not a building block concept; rather, the instructions being given impact the entire line. Nazareth worked with the full GM controls team, headed by Ron Goeckerman, to implement FACS with the host server.

By contrast, all manual workstations on this line have the same download received to a PLC, provided by Siemens in its Simatic lines. While not reliant on the server network in a deterministic mode, the manual stations nonetheless utilize the same software to execute quick tooling changes, machine sequence variations, line balancing and report tracking. Operators received training from both Siemens and Elite Engineering personnel for these tasks.

All part build histories, troubleshooting and machine debugging are recorded for further analysis.

CONTROLS CALL THE BALL AT EVERY STEP

Throughout the metalcutting process here, mostly in the gear and spline forming, hobbing, grinding and finishing, CNC technology is onboard dozens of machine tools. Most of the machines here are controlled by Sinumerik® 840D, the highest-level CNC offered by Siemens. The control not only processes the particular part dimensions in the cutting theater of the machine, it also coordinates all motion control and movements into and out of the machine. Working in tandem with the other hardware and communication network software in the line, for example, ring gears cut on a Wera Profilator machine are indexed from one station to the next, in timed sequences, to coordinate with predetermined production requirements. This operation occurs in a fully automated mode, requiring no operator intervention, except for maintenance and planned inspections.

Likewise, in the machining of valve bodies and transmission cases, each step of the process is controlled by the Siemens CNC to produce the required components in the proper sequence for subsequent assembly and testing operations. During those subsequent operations, other motion control devices and software solutions provided by Siemens execute, monitor and control the assembly process, through the SIFACS solution set. (See sidebar.)

PROFINET TALKS THE TALK

Through a decentralized and cabinet-less design, GM achieves highly integrated RFID control with easy access and true out-of-the-box solutions for the control architecture installed on this line. A Profinet solution provides GM with a high-performance, reliable network with minimum bandwidth impact or additional network load achieved at this plant, all with no special hardware required, a further cost savings for GM.

SAFETY FIRST — AND LAST

Safety features are numerous here, resulting in a complete failsafe system across all Siemens Simatic PLC, I/O devices and safety-integrated drives. All safety devices are networked over Profisafe protocol, a certified safety network, eliminating time-consuming and difficult to maintain traditional hardwired safety connections. All safe I/O, failsafe drives are part of the Siemens Totally Integrated Automation (TIA) protocol. Since it is fully integrated, this protocol provides comprehensive system diagnostics,

Rear wheel drive, six-speed line has been in full production, while the new line is producing front wheel drive, six-speed transmissions for vehicles such as the Chevy Malibu and new Cruze models.

which can help guide maintenance staff to exact fault location and mitigate downtime. Since the drives, starters and machine safety are integrated into the multi-functional machine mount I/O system, Simatic ET 200pro, the overall engineering complexity is reduced because of simplicity in panel design, wiring architecture and seamless integration to the project level hardware configuration, which is reduced due to the totally integrated automation design. For service requirements in the event of a fault, hot swapping of an I/O module is possible during operation, without switching off the entire station. There is nonetheless a very high degree of integral protection, to IP65/67 standards. The fact that an enclosure is not required also helped save on the total cost of the project for GM.

MAJOR INVESTMENT PAYING OFF

Between the two lines here, GM Toledo has invested $872 million on its six-speed, rear- and front-wheel drive transmission production at this 2 million square-foot facility, which currently employs 1400 employees, most members of UAW Local 14.

The highly fuel-efficient rear-wheel drive Hydra-matic 6L80 transmission is now joined by the GF6 front-wheel drive, six-speed

units being produced on this new line under the FACS control solution that supports flexible manufacturing while driving standard processes.

As George Jewell, the GM engineer who spearheaded the implementation of FACS, stated, “From our first installation in Ramos Arizpe (Mexico) to this Toledo plant, we’ve seen great results, with activities that took months reduced to weeks and what took weeks reduced to hours. There’s less ramp-up time, plus the changeover and line balancing upsides are already proving this was a beneficial investment.”

Please direct all inquiries generated by this story to:

John Meyer

Siemens Industry, Inc.

Marketing Communications

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Email: SiemensMTBUMarCom.sea@siemens.com

Wera Profilator gear profiler run by a Sinumerik 840D, the highest level CNC in the Siemens line, used for fully automated production of ring gears.

SIFACS — THE SIEMENS SOLUTION FOR THE FLEXIBLE ASSEMBLY CONFIGURATION SYSTEM (FACS)

Working in tandem with GM process specialists and Elite Engineering, the third party provider of the unique Flexible Assembly Configuration System (FAC

S) used at this GM Toledo transmission plant, Siemens personnel created SIFACS, a solution that integrates the host IT system at the facility with all hardware and software in the line.

SIFACS is quite literally the hub of the information management system for this line, as it coordinates all demand input from the GM server and FACS configuration stations, transmits it via the Profinet communications network in the plant to all the onboard PLC, HMI, motor starters, frequency converters, safety-integrated drives and other controls at the various machine tool, assembly and test stations.

Likewise, the feedback data from all RFID, smart sensors, RS-232 interfaces, hand scanners and other I/O devices are tracked and captured for detailed analysis by production management here.

In this way, not only is the system’s production output closely controlled, but also the line stations themselves can be reconfigured, using a unique Siemens micro memory card that allows easy component replacement, without a laptop. All PLC logic, hardware configuration and process data are embedded on the card, which is interfaced to three Ethernet and one Profibus ports for instant communications.

Critical for a continuous moving line such as those found here, the Siemens Simatic control systems are executing motion commands read from the RFID devices at 8000 bytes/sec, far in excess of the ISO 15693 standards for read and write performance.

SIFACS HMI screen extensions with Cognex Vision View further permit constant monitoring by both a team leader and a conveyor controller, eliminating a PC dedicated to a vision system.

All the smart devices on the line are also interfaced to the SIFACS solution, including fastening, leak test and pressing systems, plus barcode readers, barcode printers, robotic articulation and handling devices, vision systems and protocol gateways.

eFACS functionality is finally integrated into the SIFACS, as this feature of the Elite Engineering system provides connection establishment and monitoring, as well as configuration, process and status data exchanges, plus management of the model configuration data, all stored on the system.

On the most practical of levels, even the data structures feed to the Andon boards for in-plant display is integrated through the resident IT system via SIFACS.

Process Improvement Tools and Process Efficiency Tools, provided with the FACS, enable both process and production engineers to collect data and fine tune the system in real time, keeping build status and cycle time information always current. Line and station balancing can likewise be achieved on-the-fly, with complete process efficiency, operator loading, anticipated cycle time, even individual process operation time calculations being made, charted, displayed and rapidly analyzed by the team leader or station control personnel, in a hierarchy of need-to-know, need-to-act protocol.

The net effects of the Siemens SIFACS® system and the Elite eFACS are sustainable, highly flexible production scenarios, coupled with lower life cycle costs, as the controls and station hardware need not be re-invented for each new model, as well as lean manufacturing strategies, since the line can be constantly tuned without interruption. The flexibility, data analysis and transparent metrics of these systems further allow all employees to understand the current line performance in real time and to make suggestions for improvements that can be implemented almost immediately.

“It’s a win-win-win for all parties involved,” commented George Jewell of GM, whose team pioneered the development and application of these systems for his company’s various plants. Further advancements in FACS and SIFACS are currently being introduced at other GM facilities worldwide, according to Jewell.

For additional product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingCHICAGO — During this year’s IMTS, Siemens raffled off a 10th anniversary motorcycle built by Orange County Choppers (OCC), the custom build shop owned by Paul Teutel

The winner was Bob Pool, machining supervisor at Riverview Manufacturing Inc., located in Palmyra, Missouri and a division of Doyle Equipment Manufacturing Company, across the Mississippi River in Quincy, Illinois. Doyle is a major manufacturer of dry bulk handling machinery and Riverview fabricates large-capacity fertilizer spreaders and other equipment for its parent company.

As Bob tells his story, “I’d gone to IMTS with a colleague from Riverview and we noticed the crowd at the Siemens booth. We were waiting in a very long line to get our picture taken with Paul Teutel from Orange County Choppers and the nice young lady who was registering us asked if we wanted to sign up to win the motorcycle. I’d ridden bikes all my life but never owned one. I figured I’d take the chance, but didn’t think about it much, after signing up. The photographer said the photos would be up at the website a couple days later and, when I checked, I couldn’t find them, so I called Siemens. The next morning, I came into the shop and saw a message from Siemens. I called and asked about the photos and got steered to the right spot on the website, but the person said he was really calling for another reason. To my surprise, he said I’d won the bike!”

Riverview is a 25-person shop with full CNC machining, welding and assembly capabilities, all used to produce the 6- and 8-ton spreaders and other Doyle brand equipment built here. Bob says he looks forward to taking very good care of his new bike and using it for many years to come. “I’m really enjoying it and am sure glad I stopped by the Siemens booth at IMTS!”

For more information:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingATLANTA — Siemens today announced the release of the new Sinamics® G110D drive platform. The latest solution in the company’s Totally Integrated Automation (TIA) portfolio, the

The Sinamics G110D combines improved functionality, increased energy efficiency, a smaller footprint, lower total cost-of-ownership and enhanced usability in a single drive. Applications for this new drive range from material handling or packaging conveyors and airport baggage carousels — to pumps, fans, compressors and other industrial equipment.

Offered as an economically-priced drive with improved features, the Sinamics G110D includes integrated plug-and-play power and control for easier installation and an optional Intelligent Operator Panel (IOP) for simple text application setup in a reduced footprint. The IOP further assists the machine operator with a greater level of control, as well as alarm status alerts and resolution advice, so troubleshooting time is greatly reduced.

The Sinamics G110D includes an optional power disconnect switch and the IP65 metal housing enclosure has a low profile for easier mounting near the motor, with no drive cabinet required, for further space savings.

The Sinamics G110D is suitable for either direct communication with a Programmable Logic Controller (PLC) or control via I/O inputs. AS-Interface bus configuration and optional maintenance and manual-auto switch are incorporated into the drive, making it easy to integrate with other hardware in an overall control schematic.

Integrated brake control and quick stop functions provide a higher degree of reliability in heavy-load operations.

The new Sinamics G110D complements the recently introduced Sinamics G120D drive, which offers many of the same features plus safety integrated design (Safe Limit Speed, Safe

Stop 1 and Safe Torque Off) and power regeneration capability back to the supply.

For more information on the new Sinamics G110D drive platform, visit: www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

No. 863 is an electrically-heated 1400°F(~760°C) box furnace from Grieve, currently used for preheating molds. 52 KW are installed in nickel chrome wire coils supported by a stainless steel frame. A

The unit has 7” thick insulated walls with stainless steel covers. The oven was specially built with inert atmosphere construction. This consists of a continuously welded outer shell, high temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet and inert atmosphere outlet.

Controls onboard No. 863 include a motor-operated vertical lift door and a 4-point strip chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web:www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingNo. 983 is an electrically-heated 550°F(~287.78°C) bench oven from Grieve, currently used for curing medical instruments. 3KW are installed in Incoloy sheathed tubular heating elements.

The oven has 3” insulated walls, a Type 304, 2B finish stainless steel interior and a #4 brushed finish stainless steel exterior. Two 13” x 4” access slots are equipped with insulated covers on the rear wall of the oven. An 8” x 10” double-pane Pyrex window is used for viewing the oven chamber. An interior oven light is also provided.

Controls onboard No. 983 include recording and programming temperature controllers and a recirculating blower for this oven.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

-0-

Photo enclosed

The unit has 4” insulated walls and a Type 430 stainless steel interior. A 1000 CFM, 1-HP recirculating blower provides horizontal airflow to the workload. Stainless steel pans are held by three tiers of seventeen shelf supports on a 3” vertical center.

Controls onboard No. 834 include a digital indicating temperature controller, recirculating blower airflow safety switch and a manual reset excess temperature controller with separate contactors.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

NEWS RELEASE: THE GRIEVE CORPORATION

Agency contact: Tim Daro 847-934-4500

Continue readingSignificantly reduces inventory, changeover time for lathe and mill/turn users

See the U-Tec video HERE.

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled at IMTS.

U-Tec® is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-Tec® system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-Tec® allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-Tec® system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-Tec® system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-Tec® system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading

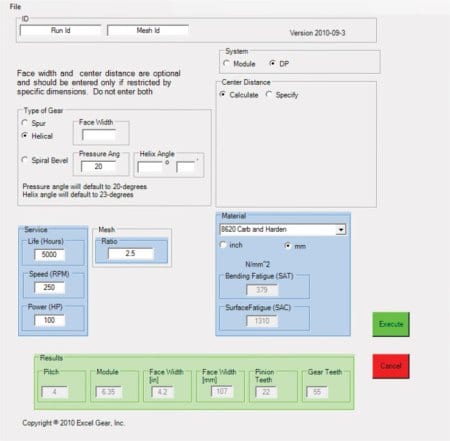

In response to the gear market’s need for optimization software, which has been lacking for many years, Excel-LentTM gear/gearbox design and analysis software has been developed by Excel Gear, Inc. (Roscoe, IL) and written in Visual Basics.Net. This software has been written by engineers who also design and manufacture gears for their own use, according to company president N.K. “Chinn” Chinnusamy.

Mr. Chinnusamy further comments, “Although commercial software has long been available in the gear industry, it has been too expensive or too complicated to be used by engineers without specialized gear design knowledge. Our software is specifically designed with a user-friendly interactive input screen providing defaults and options in accordance with the AGMA 2001 standard (American Gear Manufacturers Association).” The users of Excel-Lent software can easily navigate through the input screens to edit, analyze and produce reports on the optimum gear and gearbox design for various industrial and other applications.

“This software is not designed for any specific industry,” continues Chinnusamy. It can be used for machine tools, heavy materials handling equipment or even the wind turbine industry. For the wind turbine industry, for example, the designer needs a full understanding of all the operating loads on the gear members to arrive at the required power rating.

The key calculations performed are the AGMA power rating and load calculations, including bending strength geometry factor (J) and pitting resistance geometry factors (I). Output from the software is a single page of data printed in a format that is easy to read and interpret. Other commercial software typically prints five or six pages of information, which may be confusing to most design engineers unless they are gear experts, Chinnusamy further observed.

The users of Excel-Lent need not be familiar with AGMA standards to use this software. Those who are not gear engineers can also benefit from the gear engineering knowledge embedded in the software package.

Excel-Lent contains three sections – design, analysis and gear dimensions. Any of the sections can be used individually to run calculations. On a typical job, according to Excel Gear, hundreds of hours typically spent doing the calculations can be saved.

The three sections are detailed below:

Key values calculated are the diameter and face width of the pinion required to achieve the surface fatigue power rating and optimized DP or module (based on the calculated diameter) required for the bending fatigue power rating. The data are automatically exported to the analysis program for detailed analysis. The results are the power ratings for 5,000 -100,000 hours of B1 life (reliability factor of 1).

If required, other values such as face width or center distance may be entered but Excel Gear recommends leaving the face width and center distance values blank for optimized gear design. Design and analysis programs are used to design one gear stage in sequence on an external or internal spur and helical gear mesh.

ANALYSIS: This program calculates the power rating of a gear set for 5,000, 10,000, 25,000, 50,000 and 100,000 hours of B1 life (reliability factor of 1). Reliability factor of 1, 1.25, or 1.5 can be selected, as required. The user needs to input mesh type (spur, helical, internal and external), pressure angle, helix angle (if applicable), pinion speed, number of teeth in pinion and gear, material (from the list provided in the software), face width, DP or module and quality required. Crown and/or profile shift, if used, can also be entered. The program will calculate the power rating of the gear set and show HP or KW capability along with torque, tangential force and static capacity. Static capacity is based on yield strength and, if bending stress exceeds yield strength at any time, permanent deformation or even tooth breakage may occur. If the results are satisfactory, the user can print the single page results only or, optionally, also print all the AGMA factors used in making the calculations.

Most commercially available gear software will generate five or six pages of output along with required bending and surface fatigue strength of the gear set. The user therefore needs knowledge of metallurgy to select proper material and heat treatment or must consult a metallurgist. By contrast, the Excel-Lent software program lists commonly used gear material for the user to select. If the results are not as required, the user can select another material or change other design criteri

DIMENSIONS: In the opinion of the manufacturer, this Excel-Lent gear dimension software is the most versatile program available in the market. The program will calculate the manufacturing dimensions for a new pinion and gear or calculate the dimension of a pinion or gear to mate an existing pinion or gear. This can be done for external gears, internal gears or a gear rack. Users need only to enter the type of mesh (spur or helical, internal of external), pressure angle, helix angle(if helical gears), number of teeth in pinion and mating gear, DP or module and the quality of the gears.

The program will then calculate the center distance, dimension over pins, span measurement, form diameter, roll angles and all gear tolerances to match the quality required (AGMA, DIN, or ISO). The program will calculate the helix angle required to match a specified center distance if the user chooses that option.

The program displays plain English error messages when input is questionable or in error. For example, if the center distance is incorrect, the program will flash error messages such as, “Center distance specified is too large/small.”

The program calculates optimized profile shifts for pinion and gear operating at a non-standard center distance, if the operating center distance is specified. If the profile shift required to operate is large and makes the top land narrow, the program will flash warning messages and display the proper profile shift amount to avoid narrow top land.

Excel-Lent software further provides users the option to balance beam strength or specific sliding of gear and pinion, if desired. This is a key requirement for wind turbine gears. The program will also calculate gear blank tolerances to achieve the desired quality level, if shaft and bore diameters are entered. Users can switch between inch and metric dimensions with one click.

For further information or a test demo, available on CD or onsite, please contact:

EXCEL GEAR, INC.

11865 Main Street

Roscoe, IL 61073

Phone: 815-623-3414

Fax: 815-623-3314

Web: www.excelgear.com

Email: sales@excelgear.com

Attention: N.K. Chinnusamy or Bill Powers

ABOUT EXCEL GEAR

Excel Gear brings over 50 years of machine tool experience to the design, manufacturing and quality analysis of its various gear, gearbox, fluid bearing, spindle, CNC gimbal head, nutator and special equipment production. ANSYS software for FEA on stress, strain, deflection, as well as modal analysis, time and frequency domain, our Spindle Analysis Program, MATLAB/Simulink, AutoCAD/SolidWorks/CADAM and other programs are all utilized to affect the best solutions to customer requirements. Excel also builds two-axis CNC gimbal heads with 20,000 RPM motorized spindle, 15,000 RPM cartridge type spindle assemblies and CNC rotary tables for major machine tool companies. Our high-accuracy gear grinding equipment produces to AGMA 15 (DIN 2) tolerances for quality that meets or exceeds the increasing customer demands for high-speed and high power transmission with smooth, quiet operation. Recently, the company has entered the emerging wind turbine market to provide various gears and gearbox components, as well as extensive maintenance and system performance engineering assistance.

PR agency:

Tim Daro

Bernard & Company

tdaro@bernardandcompany.com

The unit has 4” insulated walls and an aluminized steel interior and exterior. It is also equipped with a removable top-mounted heat chamber (shown on floor in photo) and a motor-operated vertical lift door.

A 4200 CFM, 3-HP recirculating blower provides vertical upward airflow to the workload. Ten 200 lb. capacity carriers with roller surfaces, 31” wide x 14” long, are supported on each side by a heavy-duty roller chain. The carriers are driven through the conveyor by a 3/4-HP drive motor controlled by a variable frequency drive. Fifteen loading baskets are included with the oven. A loading table with rollers lines up with the rollers on the carriers and a latch holds the baskets in place on the carrier.

Controls onboard No. 961 include a digital temperature controller, recirculating blower airflow safety switch, 10” diameter circular chart recorder and a manual reset excess temperature controller with separate contactors.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.