Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Substantial increase of 30% in production resulting from large workspace, cutting capabilities and new generation Heidenhain CNC onboard

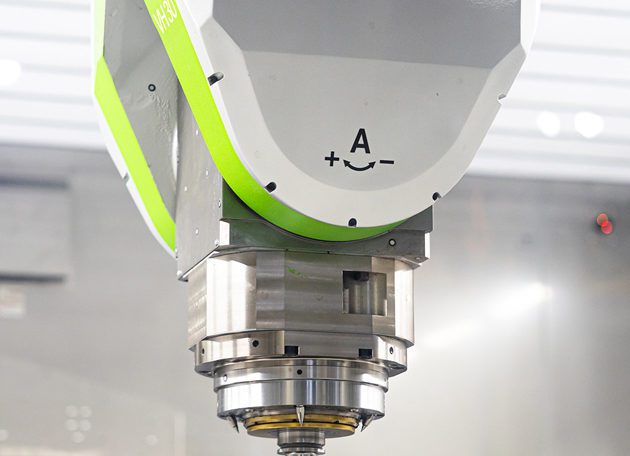

Wixom, Michigan- Zimmermann, Inc. has installed and commissioned its FZU37 portal milling machine, with a 5m x 4m x 1.5m workpiece capacity, at Century Tool, a major tool and die manufacturer in Fenton, Michigan and part of the Tooling Tech Group. The machine has already proven its worth, according to the customer’s Director of Manufacturing, Tom Bradford, who notes, “The table size, speed and accuracy of this Zimmermann machine have already increased our capabilities by 30% or more.” Bradford and the operator on the machine, David Hawes, further note the benefits of the Heidenhain TNC7 control, one of the first machine tool installations in America for this advanced CNC, as a key factor in production planning, CAD/CAM integration, cycle performance and data logging. The CNC also features a visual simulator of the cutting path for cycle validation and in-process monitoring.

According to Cornelius Kiesel, President of Zimmermann, Inc., his company was approached for the discussion of a new machine, which would be replacing an existing, smaller machine that was no longer in operation, plus expand the capabilities of other machines on the floor at Century. “We determined the spec of the new machine and its tasks for Finishing and Semi-Finishing. The primary goal was to cut down the immense number of hours for such processes on the very large workpieces at Century, while enabling them to run the roughing process on their existing equipment.”

Kiesel continues, “To keep things simple, we selected the FZU37 machine, so the foundation of the replacement machine could be filled up to make it flush without a major foundation rework. After several conversations and a few adjustments on the accessories, we were able to lock in the layout. These layout improvements allowed us to go even wider for a total of 5000mm x 4000mm x 1500mm (197” x 157” x 59”) of travel, which was 79% more travel in the same amount of floor space. The FZU37 was subsequently ordered with the state-of-the-art spec for an advanced machine shop such as Century, including our Tool Changer, Top Cover, mist extraction, high-pressure coolant, Tool Laser, Touch Probe and more. Century Tool also wanted to step up their control to the new generation Heidenhain TNC7.”

Lastly, Kiesel notes, “Zimmermann also integrated an extended Spindle housing for deeper cavities plus the side walls were raised to create enough clearance and the machine table reinforced for the challenging molds our customer expected to be produced on this machine. When all these machine parameters got worked out and finalized, we completed the machine rather quickly, commissioned it, did the training onsite and helped Tom and his team start up.” Tom Bradford cited Alfio Campagna, project manager for Zimmermann, for his critical help in getting the machine into production at Century, as this was the first Zimmermann portal mill purchased by the moldmaker.

Bradford also commended the Heidenhain team, who provided three days of training on the CNC at their Chicago location and two more onsite at Century. Operator Hawes commented that he had substantial experience on Heidenhain controls, so the training went quickly for him, though the new control has numerous new features, including its Smart Programming, a graphical programming feature that allows the user to draw contours directly onto the touchscreen, after which the CNC converts the result into a Klartext (German for clear text) program. Century uses Visi as its main CAD program and Tebis as its CAM software and Bradford noted the seamless matching of these programs with the onboard CNC software to configure programs and posts made startup and run a smoother process.

In addition, the new CNC offers the user its Component Monitoring feature, which can protect the spindle bearing from overloading, while also detecting increased component wear in the drive train, all while the machine is running. This feature provides valuable data for predictive maintenance and evaluation of the process capability of the machine. This is vital at Century, who uses the Zimmermann machine exclusively for large, one-off mold prep, often removing over 90% of the material from a workpiece, over multiple days of machining.

Also, the ergonomics of the CNC are extremely user-friendly. Screen layouts and touchpad controls can be adapted to suit user preferences.

Finally, the intuitive contour programming is enabled by symbolic gestures on the touchscreen. Since Klartext remains the main format for files and exporting from the Heidenhain control, existing NC programs can continue in use.

Currently, the Zimmermann machine at Century is running on two shifts, often remotely tended in a low-light or lights-out mode.

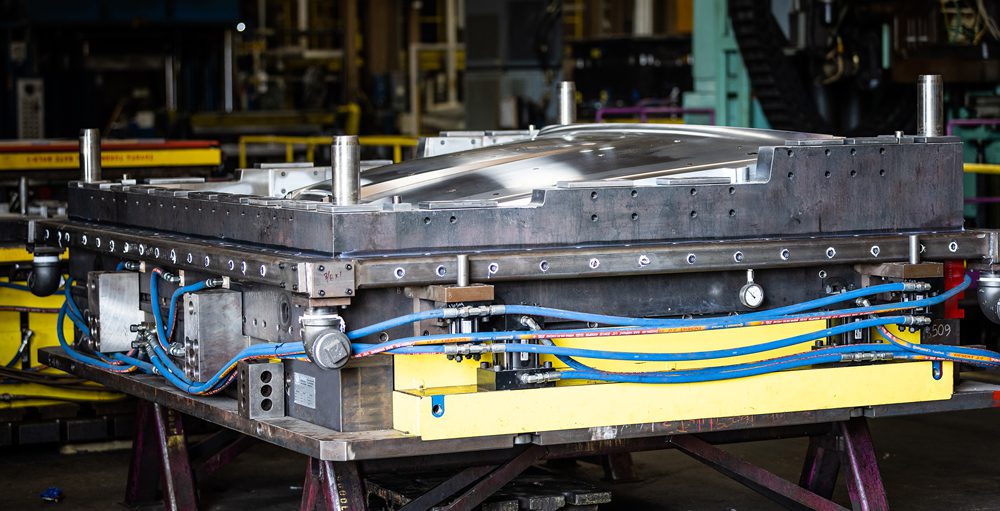

Tom Bradford comments on the Zimmermann machine performance. “We do a lot of large tools for compression molding of composites and other substrates. We work for a variety of industries, from automotive to heavy truck, off-highway to agriculture, power sports to infrastructure such as water tanks. Century specializes in Class-A exterior body panels, so the surface finish is critical. During the very long runs we do on the Zimmermann, maintaining tight tolerances is key and the machine plus its onboard control technology make that happen for us.”

Brian Czapla, Director of Sales at Century, adds, “The trend toward high-strength, lightweight composites and large dimensioned, unitized parts for auto and heavy truck make this machine a real asset in our operation.”

In use, the typical workpiece on the Zimmermann is P20 steel, the industry standard for molds, as well as various aluminum materials. HSK 63 and HSK 80 are the primary toolholder types, used for cutting and laser touch probing here. Standard carbide cutting tools and inserts are typical, as well.

Bradford further notes, “As a tooling source, we serve the Tier One and OEMs in the manufacturing space. We have a strong reputation in automotive and heavy truck and we’re looking to expand into aerospace and other consumer products as well. As Brian noted, our core strength in composite molds gives us a real advantage in entering these other markets. The Zimmermann machine helps us achieve superior RA finishes with consistent quality, even on much larger structures.”

Century Tool is part of the Tooling Tech Group. With roots that go back over 40 years, Tooling Tech Group (TTG) has grown to be a leading manufacturer of tooling in the United States. They provide solutions for thermoform molding, high compression composite molding, blow molding, rotational molding, die casting and stamping, as well as custom automation systems for assembly, joining and inspection applications in a variety of industrial sectors. TTG comprises Century Tool, Century Automation for post-molding materials handling and assembly strategies, Die Cad for tooling design & simulation, Majestic for production of stamping dies, Tooling Technology for turnkey cast & billet aluminum tooling solutions, Alpha Integration for assembly automation and G&H Tool & Mold for high-pressure die cast molds.

About Zimmermann

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

Zimmermann, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors.

About Century Tool

Our skill in machining complex geometries and exacting tolerances has positioned Century Tool as a premier composites mold supplier capable of meeting the exceptional surface quality required by manufacturers in the automotive, marine, agriculture, and other industries.

Our Team has mastered the production of molds capable of delivering excellent surface finishes required by Class-A exterior body panels. We have provided the tools used for high-visibility, high-demand vehicles like the Corvette, Jeep, and the Ford Bronco.

About Tooling Tech Group (parent company of Century Tool)

Tooling Tech Group has combined a growing number of industry-leading automation and tooling brands, pooling their collective knowledge and experience to support our efforts to design and build the most innovative automation and tooling solutions for our customers’ greatest manufacturing and product challenges.

Tooling Tech Group is the largest provider of tooling in the United States with 600+ employees, 12 modern facilities and over 1-million square feet of manufacturing space across five states.

We build custom tooling for a variety of applications including thermoforming, compression molding, blow molding, die casting, and stamping, as well as secondary equipment and automated solutions for these applications. We have experience in many industries including automotive, appliance, lawn and garden, agricultural, aerospace, marine, and off-road vehicle industries, among others.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Or

CENTURY TOOL

200 South Alloy Drive

Fenton, MI 48430

Phone: 810-629-0784

www.toolingtechgroup.com

Ms. Amy Stegmuller, Chief Commercial Officer

astegmuller@toolingtechgroup.com

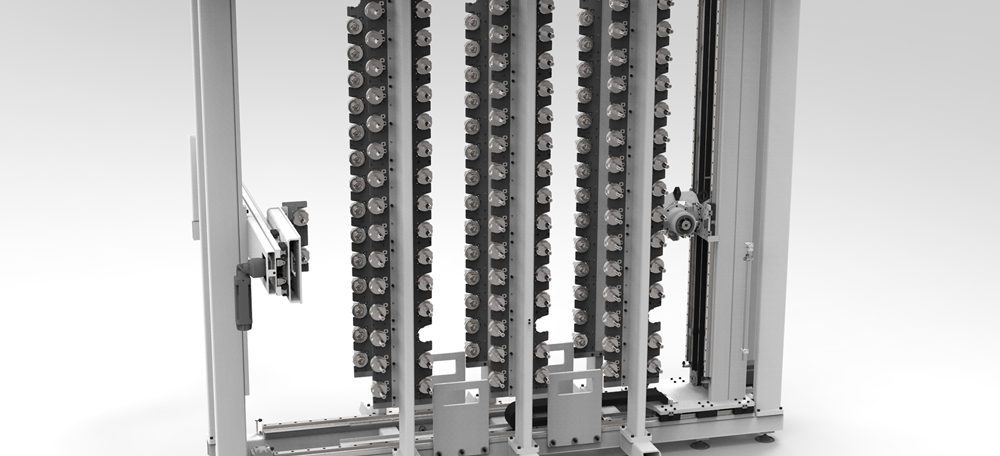

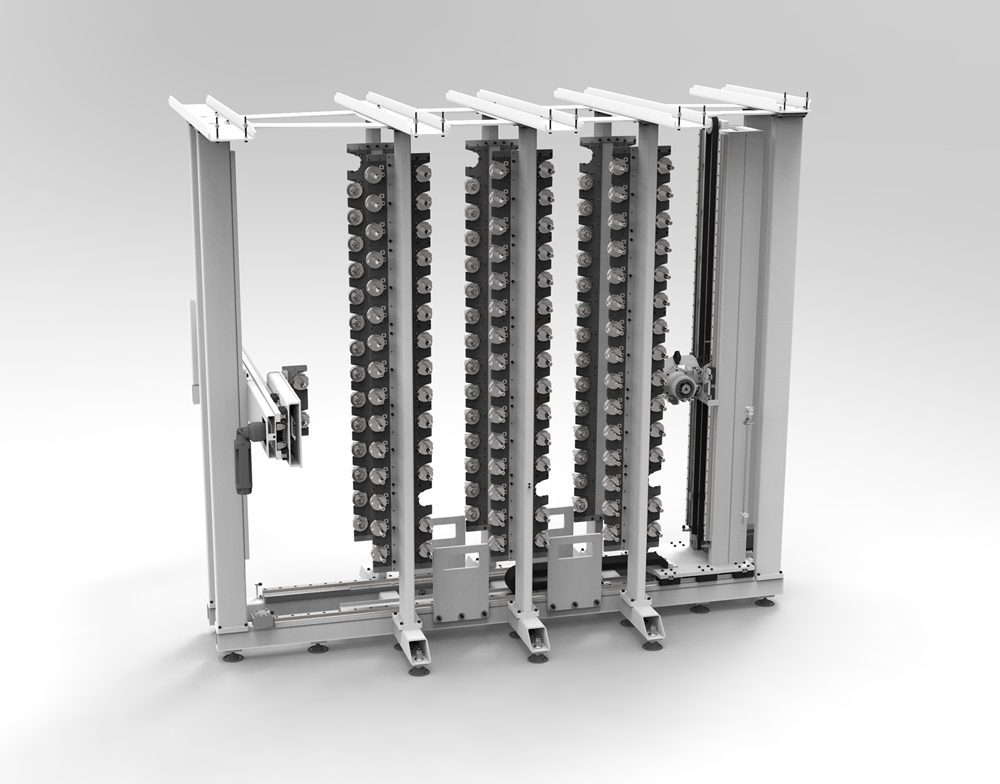

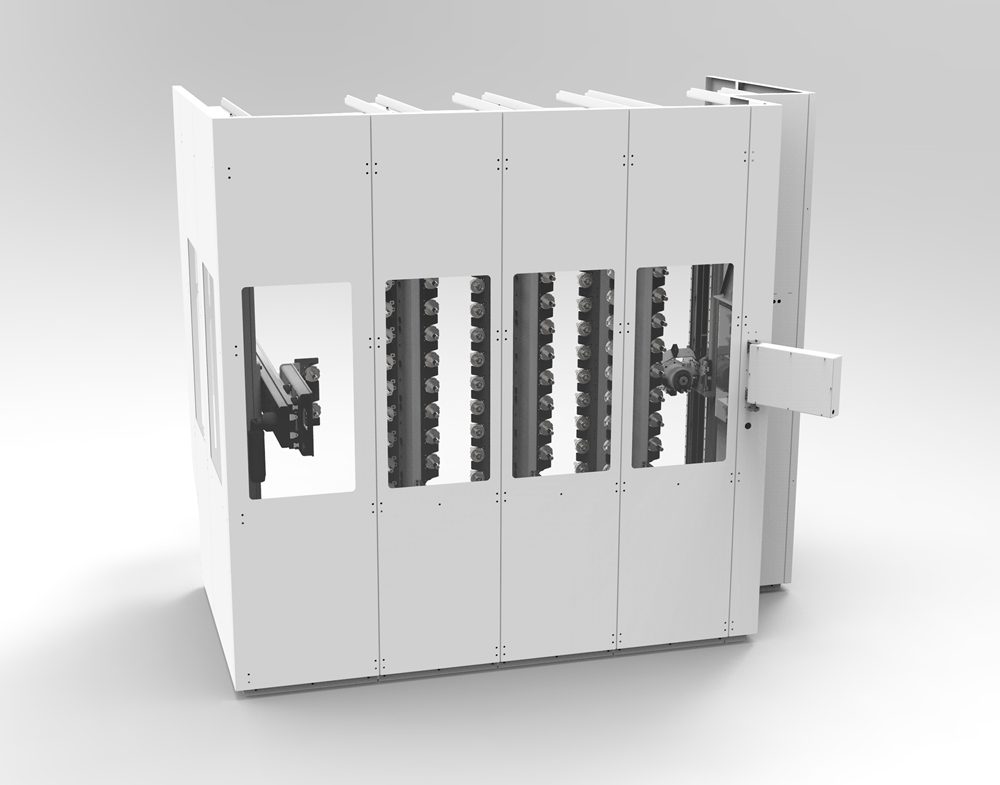

With the FZ rack magazine ZIM Rack, Zimmermann has developed a compact tool changer for its portal milling machines which can be expanded to accommodate several thousand tools. This modularity allows clients to tailor the system precisely to their production without requiring additional storage space.

Tool availability plays a major role in ensuring uninterrupted production for customers. Whether it’s a machine demanding challenging materials or very different components, the right tools must be available quickly and easily due to the high level of wear or diversity. To solve this need, Zimmermann created its own tool changer.

The basic version offers 60 positions and can be expanded in increments of 30 up to several thousand. The operating principle is independent of the number of tools. Thus, the operating personnel have enough space to change all the tools before starting work and to work with them uninterrupted until the next shift. This eliminates the need for a separate storage area.

The tools are stored horizontally in the holders and can be removed via a manipulator. Unlike a conventional chain system, not all tools are moved, but only the necessary ones. Customers can adapt the ZIM Rack to their production. Since both the machine and the changer are from the same source, Zimmermann provides better and faster support when needed.

To see short video of the ZIM Rack, visit: https://www.youtube.com/watch?v=F0a4ygvGqEY

About the company

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

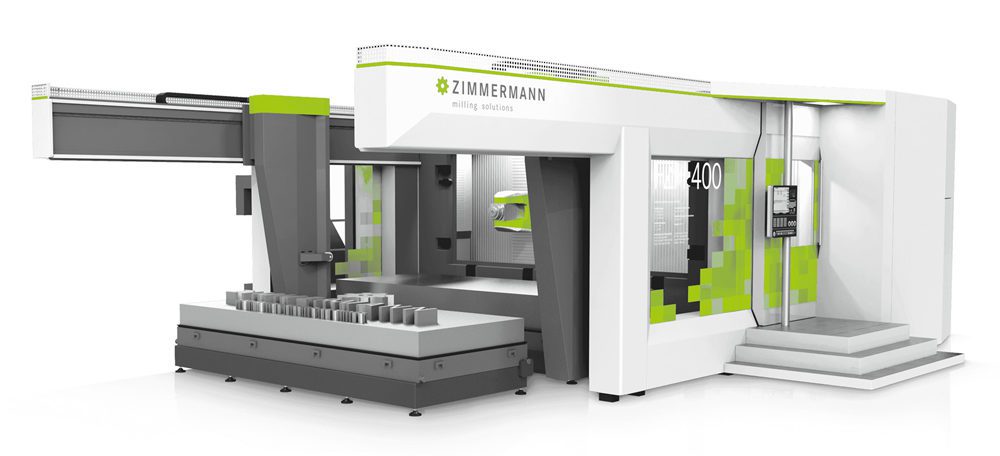

With the FZU22, Zimmermann enters the lighter weight 5-axis gantry mill applications at an attractive price point

With the introduction of FZU22, Zimmermann has added a 5-axis portal milling machine for the machining of various workpiece shapes, sizes and materials. Aluminum, plastic, wood and other substrates can be processed, plus the machine is ideal for the finishing of carbon fiber reinforced and other composite materials. The overhead gantry provides precise production of models and molded parts. The standard machine includes a toolchanger for 24 tools and a CNC from Siemens or Heidenhain for full motion control and tracking. A specially developed 5-axis milling head with 15kW spindle is suitable for machining contours and tight pockets in large molds.

As Zimmermann Inc. President Cornelius Kiesel observes, “With this new machine, being introduced in our booth at IMTS to the North American market, Zimmermann enters a new arena, that is, the lighter weight machining applications for large structures at an economical price. Our recent acquisition of a company in Germany allows us to partner with a reliable source for this type of machine, enhanced by the unique features which have made Zimmermann a standard in the aerospace and large mold market segments.”

The FZU22 boasts a substantial working range, from 71”-98” in the X-axis, 118”-138” in the Y-axis and 49” in the Z-axis. A feed rate of 2756 ipm in the X- and Y-axes is standard while the acceleration on the machine is max. 118-197 in/sec2. With a compact footprint of 11’ x 15’, the machine fits in the corner of any shop. ISO 230-2 accuracy is provided. A choice of milling heads is offered on the machine to suit a variety of applications.

Optional equipment is offered on the FZU22, including touch probe, tool measuring system, work area cover, tool changer, chip conveyor, mist/dust extraction system, minimum quantity lubrication and a vacuum system.

The machine to be displayed at IMTS also features an ultrasonic system for cutting aerospace insulation.

About the company

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel. This year, Zimmermann Inc. is celebrating 20 years in business.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

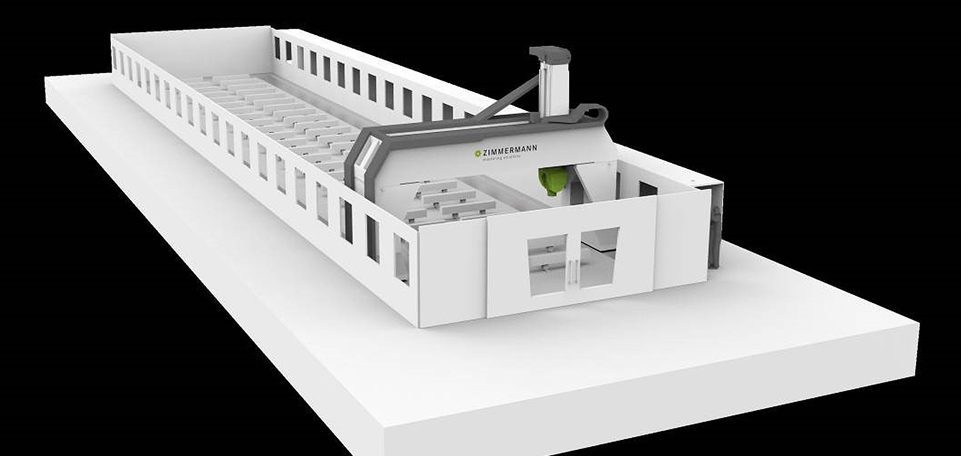

With the FZG, Zimmermann introduces a portal milling machine with a low rail gantry

With the new machine line FZG, Zimmermann has added a 5-axis portal milling machine with a low rail gantry to their portfolio, which is well-suited to process particularly long components. Accessible from the side, the FZG allows easier loading and unloading processes. The developers were utilizing the well-proven thermo-symmetrical portal concept and modified its basic design, resulting in a distinct benefit. With the FZG, the user will receive a stable system which provides the highest precision, even when processing large and long components.

“Especially in future-oriented industries such as the aerospace, energy or rail sector, producers must be able to efficiently process large and, above all, particularly long components. We have recently received many more requests with these exact requirements,” reports Daniel Demlang, technical leader at Zimmermann. To meet the needs of the market, the machine manufacturer developed this new machine series, the FZG, in line with customer specifications. For this line of machines, the engineers relied on the innovative concept of the thermo-symmetrical design, which has already proven its worth with the Zimmermann machine lines FZP and FZU. However, the engineers redesigned its base structure. “We lowered the machine onto ground level, enabling the portal to be moved horizontally in almost any desired length,” explains Mr. Demlang. Zimmerman can adjust this design for any custom application. Therefore, the line is suited for processing complete components, such as wing structures for the aviation industry, entire railway wagon side sections for the rail sector, tanks in the energy sector, exterior components for the aerospace industry as well as components for the defense industry.

With the new FZG machine line by Zimmermann, large and long components can be manufactured with highest precision.

The proven modular system from Zimmermann acts as the base structure of the new FZG line. It offers many different length and height variants as well as extensive equipment options, such as process cooling with minimum quantity, lubrication or an onboard movable vacuum dust extraction system for abrasive materials and plastics. An onboard movable tool changer is standard. The energy supply and covers are recessed into the floor.

“The thermo-symmetrical design makes the machine less vulnerable in adverse environmental conditions,” continues Cornelius Kiesel, president of Zimmermann in America. The idea behind this is that incurring thermal influences can be substantially absorbed by the machine structure itself. “To achieve this, we appropriately designed and intelligently arranged all structural and drive unit components, guides and other components responsible for accuracy, for all the machines in our extended portfolio. This way, the structure can expand in non-critical directions,” says Kiesel. The centrally guided Z-slide of the portal in double-bridge construction makes the machine particularly stable. By using this design, Zimmermann achieves very high rigidity. Since there isn’t any possibility of one-sided temperature rise, accuracy is greatly increased, thus making the machine line suitable for very high-precision applications.

“For us, this combination of thermo-symmetrical machine design and the modified base structure was a logical next step,” says Mr. Demlang. Because the core machine relies on proven technology, this development was possible in a relatively short timeframe. Additionally, the synergetic benefits of the FZG, due to the existing portfolio, also have a positive impact on the profitability of the machine.

About the company

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

With the FZU/FZP42 machine line, Zimmermann Inc. offers users efficient 5-axis portal milling machines for heavy workpiece machining. The specific aspect of these improved machines is a thermo-symmetrical design, incorporating a centrally-guided Z-slide. This particular construction, as well as the guide layout, increases machine stability, while also saving weight – resulting in a more dynamic, productive and energy-efficient machine.

“We have developed suitable machine designs for light processing, such as composite materials or aluminum used in aerospace, as well as for highly dynamic heavy machining,” reports Cornelius Kiesel, president at Zimmermann Inc. in Detroit, the U.S. operation of F. Zimmermann in Germany. While further developing its machine portfolio in the last several months, heavy machining for automotive, other transportation and off-highway are gaining an even higher priority in the company’s market targets. At the same time, Zimmermann is on the cutting-edge in its traditional segments, explains Frieder Gaenzle, CEO of F. Zimmermann. “We are focusing less on classic heavy machining, using large tools and high material removal rates per cut. Instead, the FZU/FZP42 model range provides tool and mold makers with a 5-axis system for highly complex components, which enables more dynamic milling of free-form surfaces.”

Dynamic heavy machining is precisely the challenge in this new market segment. Because the more difficult it is to process the materials, the higher the requirements for rigidity in the machine, Kiesel further notes. Weighting in at several tons on average, the machines are quite massive. How can this massive design deliver great dynamics, so that users can work even more productively?

“Our machines mill out contours with a maximum speed of 60 m/min and may accelerate with 3 m/s2, if needed. “This resembles a motorcyclist, accelerating in a curve to run it more dynamically,” says Kiesel. Despite the acceleration, the machines must be able achieve very high accuracy as well as high-quality surfaces. “This connection of dynamics and heavy machining may be compared to a truck, loaded with stones, performing in a Formula 1 race,” Kiesel muses.

Thermo-symmetry for more precision

In order to achieve this result, Zimmermann is setting up its complete machine portfolio thermo(load)-symmetrically. This occurs because changing ambient temperatures, as well as processing temperatures, inevitably influence machine geometry featuring a portal design. The idea behind a thermo-symmetrical design is based on the ability to substantially absorb incurring thermal influences, achieved by the design of the machine structure itself. Considering this factor, Zimmermann engineering has appropriately designed and intelligently arranged the machine structure and drive unit components and guides, as well as other components responsible for accuracy, for all machines in this newly developed portfolio. In this way, the machine structure may expand in directions that are non-critical.

The centrally guided Z-slide of the portal in double-bridge construction has a large cross-section which makes it especially stable. Using this design, Zimmermann achieves a very high degree of rigidity. Since there is no possible one-sided temperature rise, accuracy is greatly increased, as well. With this structural design, the machine manufacturer constructively reduces the effects of error-inducing variables to a minimum. Due to the fact that less leverage forces apply in comparison to a serial design with a classic guide layout, Zimmermann has increased rigidity of the FZU/FZP, without having to increase the cross- sections of the components. Because less mass needs to be moved, the machine works faster and more dynamically. “Moving less mass also requires less energy. This results in clear cost benefits”, states Kiesel. Additionally, the thermo-symmetrical design makes it possible to omit complex cooling circuits, which also has a positive impact on cost reduction.

By offering the new FZU/FZP42 machine lines, Zimmermann seeks to gain a better foothold in heavy machining. For a long time, the machine manufacturer only occasionally sold systems in this market segment. This has changed following these new developments. “We are already seeing the first successes in the market, says Kiesel. “We were able to sell three ‘heavy’ machines in the first quarter alone.” The company’s customers are equally convinced about the technical data and the price-performance ratio. “A particular customer only wanted to purchase one of our machines for post-processing, since they were already using a heavy machining system provided by a competitor. During the discussions, they then spontaneously decided on a second machine from Zimmermann,” notes Kiesel.

Among the new customers for this line is an automotive manufacturer, who required a new machine for their tool making, in order to process large sheet-metal forming tools and to replace older systems. In the end, Zimmermann was able to successfully assert itself against the competition with its FZU42 machine. The customer realized that this innovative machine concept will enable them to meet their requirements to a high machining accuracy with excellent surfaces on their tools. The high tool weights of up to 40 tons do not pose a problem for the FZU42 system, because the components are not being moved. The movement system, consisting of the portal, Z-slide and milling head, can operate with consistently high dynamics, regardless of the tool weight.

Flexible setup

“We were able to successfully impress the customer with our concept and our price-performance ratio,” says Kiesel. Another important aspect adds to this scenario. The FZU system does not require a solid machine foundation and can therefore be placed flexibly on the factory floor. Extensive construction, which creates high costs and disrupts manufacturing, are completely eliminated.

“We continue to develop and are able to find the right answers for many applications, concludes Frieder Gaenzle. “We have the right overall package. We offer these improved machine concepts in all market segments. Besides the machine structural upsides, these improvements include fitting mounts for the spindles, milling heads for the tools and an extensive service package for our customers.”

About the company

F. Zimmermann GmbH in Germany is a leading global high-tech builder of portal milling machines. These machines are characterized by large workspaces, substantial machine dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 250 employees worldwide. With its product range, this innovative company has one goal above all: to offer the right solution for its customers and to be able to guarantee high economic efficiency. “Quality made in Germany” is its motto. Zimmermann special machines are used worldwide in the automotive, aerospace, off-highway, moldmaking and transportation sectors. The company has its North America headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Suhner recently introduced the ROTOmax 2.2, a powerful and universal system unit in which the drive and the tool are run separately using a flexible shaft.

Since the ROTOmax 2.2 can be used almost anywhere, it is put to work in foundries, tool production, the pharmaceutical industry, food tech processing plants, aviation technology, boiler making and in mechanical workshops.

The Suhner ROTOmax 2.2 offers applications in cutting machining, grinding, rust removal, brushing or polishing.

For more information, please contact:

Zach Mann, Sales Manager, Abrasives Division

Suhner USA, Inc.

zach.mann@suhner.com

www.suhner.com

The new EFC-02 combines a century of Suhner’s abrasives and material removal expertise with smart automation for the highest surface quality results.

Rome, GA – Recognizing the role robotics plays in adding efficiency and lowering production costs for manufacturers of all types and sizes, Suhner continues to expand its robotics offering. The fully electric EFC-02 delivers precise, constant force throughout robotic grinding, sanding and deburring processes – resulting in superior, consistent surface quality.

Introducing EFC-02 – Suhner’s Electric Force Compliance System

Active compliance for robotic material removal

With today’s supply chain and labor challenges, manufacturers of all types and sizes are looking for solutions to help them do more with fewer resources. That’s what smart manufacturing is all about – and why Suhner is expanding its suite of robotic grinding accessories and tools with the fully electric EFC-02 active compliance system.

Smart Automation for High Surface Quality Results

Exact contact force with the surface is the single most crucial factor in robotic grinding, sanding and deburring processes. It’s also one of the biggest challenges, especially for hard-to-reach areas. Thoughtfully designed based on Suhner’s decades of material removal process know-how – the EFC-02 helps overcome that challenge.

As with any end-of-arm tooling, the EFC-02 connects a grinding machine – angle grinders, orbital sanders, angle polishers, straight grinders and others – to the robot. What makes Suhner’s system unique, however, is its compact design and fully electric operation.

The lightest and smallest in its category, the EFC-02 can be used for material removal or surface finishing even in tight or narrow spaces often found when processing stainless tanks and vessels for the food and pharma industries or fiberglass bathtubs and sinks. The all-electric technology also allows high-frequency measurements to monitor force and acceleration throughout the process. An advanced control algorithm then dynamically adjusts force and automates grinding processes based on pre-programmed parameters.

The result? Constant contact force with each movement from start to finish for a consistent surface quality – regardless of the surface type, shape, size or orientation.

In Line with Industry 4.0 Standards to Support Digital Transformation

Robotic processes are no longer just for mass production. As the technology has evolved, robotics have become easier to use and more flexible – making them ideal for both small- and medium-sized manufacturers looking to add efficiency, lower production costs or both.

Suhner engineered the EFC-02 with this in mind, giving users:

One stop for a custom, end-to-end solution

The end-of-arm EFC-02 active compliance system is fully compatible with Suhner’s end effectors, including angle grinders, orbital sanders, angle polishers and straight grinders. Optional automatic changers for abrasives or belts, which integrate easily with the EFC-02, are also available. By storing and dispensing new abrasives for pickup by a sander – these automatic changers effectively help speed processes and increase productivity.

Suhner also gives its customers access to one of the most comprehensive ranges of abrasives in the market from all the industry’s leading manufacturers. Plus, Suhner’s ABRACare customized, volume-based pay-as-you-go inventory management program ensures you always have the abrasives you need.

Working with Suhner means more than having access to industry-leading tools and abrasives – manufacturers also have access to a global network of seasoned abrasives and material removal experts ready to help you solve virtually any challenge.

Put Suhner to Work for You Today

The EFC-02 combines over a century of Suhner’s abrasives and material removal expertise with smart automation for the highest surface quality results. Its compact size, all-electric technology and simple programming make it possible to replicate and automate most grinding, polishing, sanding and deburring on a variety of surfaces. This gives manufacturers a cost-effective, low-maintenance solution for replacing many time-consuming and tedious manual processes – saving time and money.

Get in touch with your local Suhner representative to take control and let the robots grind.

The company will showcase the EFC-02 at Booth #1850 at the upcoming AUTOMATE 2023, May 22-25, in Detroit, MI.

For more information, contact:

Suhner USA, Inc.

43 Anderson Road S.W.

Rome, GA 30161

706-235-8046

machining.us@suhner.com

https://robotic-grinding.suhner.com/en/

Global EDM supplier also moves to new location to enhance production and service capabilities

Batavia, Ohio- Beaumont Machine is a world-class builder of Electrical Discharge Machines (EDM) for the aerospace, power gen and electronics production industries. Founded by Ed and Tanya Beaumont over 30 years ago, the company was recently repurchased, after the owners had sold the business in early 2013. As Ed Beaumont explains, “We had a great relationship with the new owner but we believed the company needed a revitalization to benefit our customers, employees and the evolving EDM industry. In addition to repurchasing Beaumont Machine, we have reassumed the day-to-day operation of the company. In addition, we have moved the operation into a larger location to increase production and expand our service capabilities.” That new location is 2010 Glenn Parkway in Batavia, Ohio, just outside Cincinnati.

Beaumont Machine’s contributions to the aerospace and power generation industries are many and, with this buyback, the company is ready to meet the needs of the changing EDM industry. “We pride ourselves on not only understanding the applications in the various industries we serve but also on building the best machines for the applications we encounter, from small hole to large workpieces,” adds Tanya Beaumont.

From the standard mill style EDM to machining cells with complete robotic operation for large aircraft engine and launch vehicle sections, Beaumont has built machines with an 8’ part rotation, a robotic arm with 10’ reach, and machines as small as 36” in width. A new 7-axis EDM drill has just been developed. All Beaumont machines feature the most advanced CNC technology and user interface.

With customers worldwide, as Ed Beaumont observes, “We are committed to innovation and customer partnerships in various industries, in countries around the globe. It’s a testimony to the fact that the world is still hungry for American technology and ingenuity. We’re very proud of that.”

Ed and Tanya Beaumont founded the company, Beaumont Machine, 30 years ago. Beaumont Machine focuses on building a line of standard EDM’s as well as custom machines plus repairing and retrofitting machine tools of all types. The company started building Fast Hole EDM in 1997 and has been specializing in EDM technology since that time. In 2013, they turned over the ownership of the company to a new owner. With this reacquisition of the company, Ed and Tanya Beaumont are again actively involved in day-to-day operations.

Among its recent successes is a custom robotic EDM work cell for SpaceX, as shown in the below photo.

For more information on these developments, please contact:

Ed Beaumont, President

BEAUMONT MACHINE

2010 Glenn Parkway

Batavia, OH 45103

Phone: 513-701-0421

Zimmermann Milling Solutions, a leading global high-tech supplier of portal milling machines, will virtually show three new gantry machines at their booth. IMTS will be held September 12-17, 2022, in Chicago.

When discussing rigidity, nothing beats mass. Our biggest double bridged gantry sets new standards for dynamic roughing while maintaining high precision. The FZ42 CNC gantry milling machine represents power at its best, combining work areas of different sizes, travels, milling heads and CNC controls. Regardless of weight and size, the milling process is exact. Furthermore, the gantry design is particularly suitable for the entire range of component machining. The structurally rigid center-guiding gantry, cross and Z-Ram, and dynamic milling head enable a consistent, efficient milling process. This combination of high thermal stability and rigidity meets industry-specific requirements in tool and die making, aerospace and automotive industries.

Just as strength and agility make an athlete perform at his/her best, the same is true for the newest high-performance gantry FZ37. Due to its modular system concept, the FZ37 is available in various sizes, custom configuration and CNC controls. The newly designed gantry with center guided Z-Ram in combination with Zimmermann’s dynamic milling heads ensure an efficient and consistent milling process. The high thermal stability and rigidity meet industry-specific requirements in model, tool and die making as well as in the aerospace and automotive industries.

The FZ32 is the high-performance athlete for dynamic machining of aluminum, fiber composites, plastics and tooling board. Its thermosymmetrical design results in high surface quality and accuracy. The rigid center-guiding gantry allows the company to meet the increasing demands in model and mold making as well as aerospace. Additionally, the flexible design of the FZP machine line offers various sizes and configurations through its modular system as well as extensive equipment options and a fully enclosed work area, including effective dust extraction systems and more.

Visit Zimmermann at IMTS 2022 in the South building, Level 3, booth 339336.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Mr. Cornelius Kiesel, President

cornelius@zimmermann-inc.com

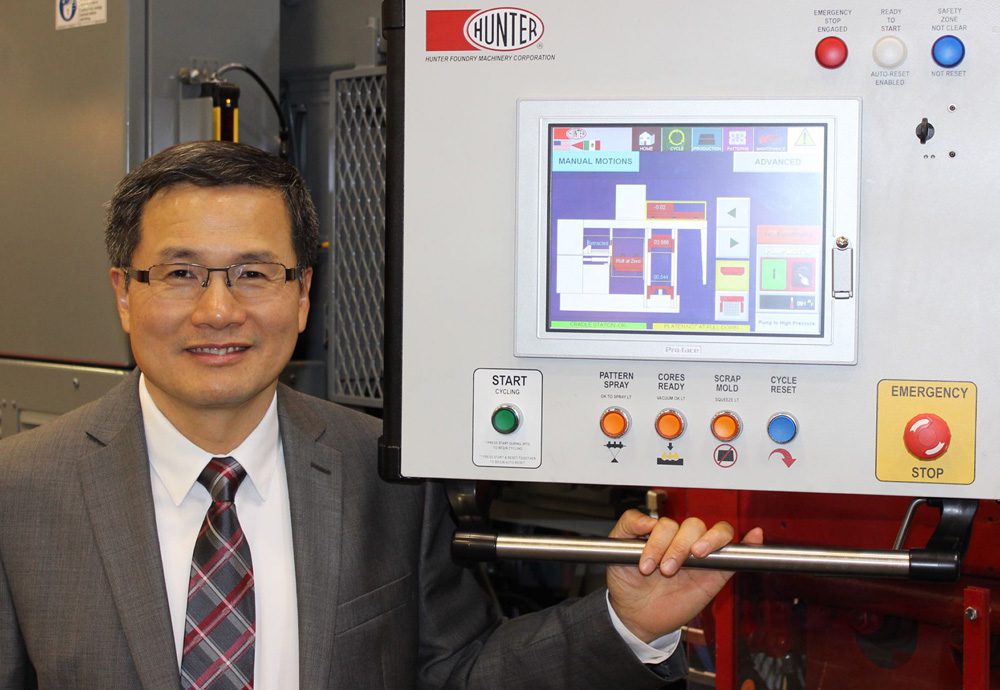

Recently Peter J. Li became the third President in the history of Hunter Foundry Machinery Corporation, a world leader in matchplate molding and sand casting technology. The announcement was made by Chairman of Board Bill Hunter at the company headquarters in Schaumburg, Illinois, near Chicago.

Peter joined Hunter in May, 1996 as a sales engineer. He was promoted to Regional Sales Manager Asia Pacific in 1998. In the year 2000, he became General Manager of Hunter Shanghai; in 2016 he was promoted to Managing Director, International. This history totals 25 years at Hunter, mainly in executive level positions.

Peter graduated from Shanghai Jiaotong University with a B.S. in Foundry Engineering. He then obtained an M.S. in Mechanical Engineering at Oklahoma State University; spent three years in the PhD Metallurgical Program at the University of Alabama, where, by coincidence, the very first Hunter molding machine was donated for that institution’s foundry education programs.

Before joining Hunter, Peter worked for Presto Castings as a metallurgist in Phoenix, Arizona.

Peter comments, “When I first encountered a Hunter machine, I quickly realized it had a unique and very practical labor-saving aspect and this fact was a big reason for its success in the global foundry market.” Li knew the reputation of the company’s founder, Al Hunter, as well as Bill Hunter, the two men who preceded him as President of the company.

Li further observes, “Our challenge for the future is to keep an open mind and remove restrictions on our thinking about the foundry business. The most successful companies in our industry have automated and that bodes well for Hunter matchplate molding machinery, automated mold handling equipment and the advanced software we bring to our customers worldwide.” He also commented that his combination of sales, technical experience and corporate management at Hunter, both in America and at the Shanghai plant the company operates, have given him a perspective on the company and the market that will serve him well in his new role as President of Hunter. “I do consider myself a people person and I believe that remains an important element in our relationship with the foundry business, Li added.”

Hunter is a global force in the foundry business, with an installed base in nearly every industrialized country in the world. In addition to the manufacturing locations in Chicago and Shanghai, Hunter has a worldwide network of sales agents.

The company was founded in 1964 by Al Hunter, who pioneered the automated matchplate molding machine concept and held dozens of patents in the industry. His son Bill, the current Chairman of Board, likewise developed numerous innovations in sand molding machine and mold handling equipment for the global foundry market.

In naming Peter Li the new President of Hunter, Bill commented, “Peter is exceptionally qualified for this position and we know he will lead Hunter into a bright and prosperous future. We have a great team of people at Hunter and, under Peter’s leadership, I am certain the company will move forward in a positive direction.”

For further information on this announcement, interested parties may contact:

HUNTER FOUNDRY MACHINERY CORPORATION

2222 Hammond Drive

Schaumburg, Illinois 60196-1094

USA

Phone: +1 847 397 5110

Email: info@hunterfoundry.com

Web: www.hunterfoundry.com

Attention: Bill Hunter