Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

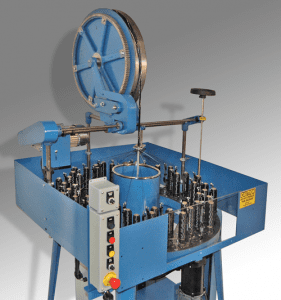

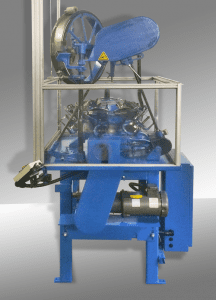

While a machine may look fine on the outside, parts on the inside wear and, eventually, need to be replaced. Wardwell’s braiding machines are suitable candidates for retrofitting with new features such as high-efficiency motors, drives, broken wire detection, empty bobbin detection, core run-out sensors and longitudinal taping systems. The advancements in mechanical and electronic components make retrofit a cost-effective means of improving performance on existing machines.

The management and engineering team at Wardwell has over 100 years of experience in the design, building and maintenance of braiding equipment. Wardwell has all the necessary capabilities to fulfill your retrofitting needs, supporting and maintaining all of its equipment. As the original manufacturer, you’ll never settle for second best or have to wonder about quality. Retrofitting is carried out by Wardwell’s trained technicians, who evaluate the machine’s mechanical components and advise customers on the condition and options available. Electrical and safety systems are replaced with factory-original parts and modernized to comply with current standards. All machine functions are tested and validated after completion. Wardwell guarantees machine retrofits with a factory warranty. Please contact the company for details.

Click photos below to enlarge.

For additional information, please contact Wardwell or visit the company’s website at www.wardwell.com.

WARDWELL BRAIDING CO.

1211 High Street

Central Falls, RI 02863

Phone:. 401-724-8800

Web: www.wardwell.com

Email: sales@wardwell.com

Attention: John Tomaz or Cynthia Chen