Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Siemens expands its SINUMERIK Run MyRobot platform with the CNC allowing cost-effective KUKA robot part handling and articulation functions directly on the control screen of a SYIL machine tool

Automation for every shop size

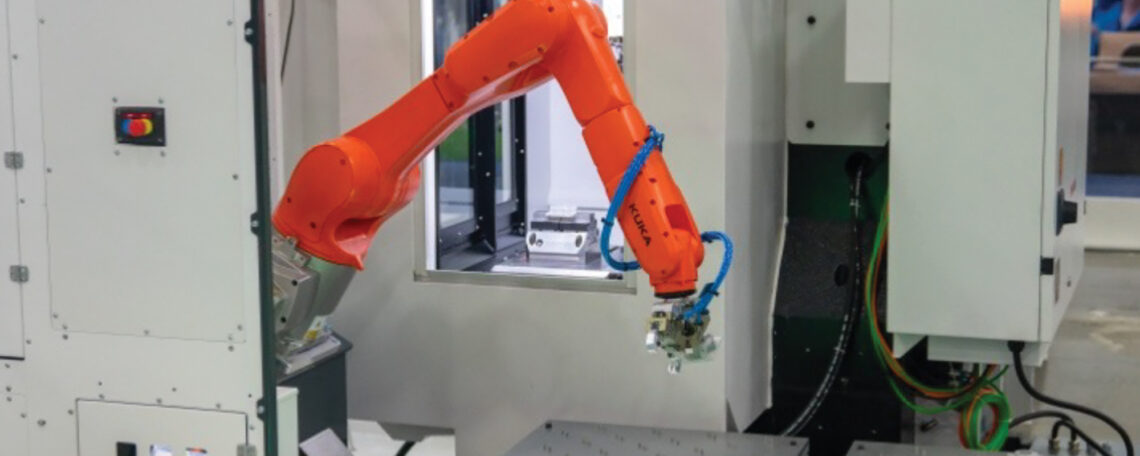

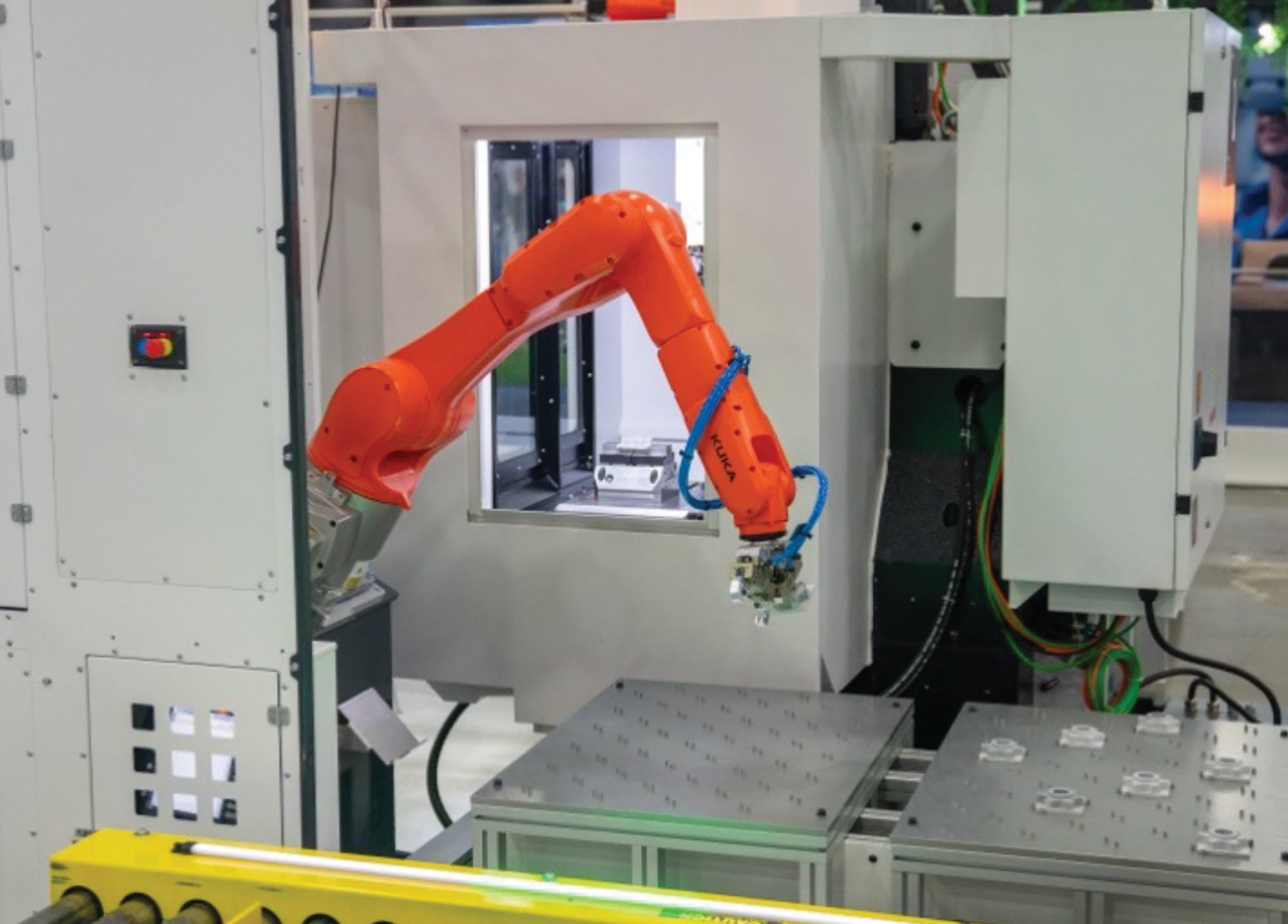

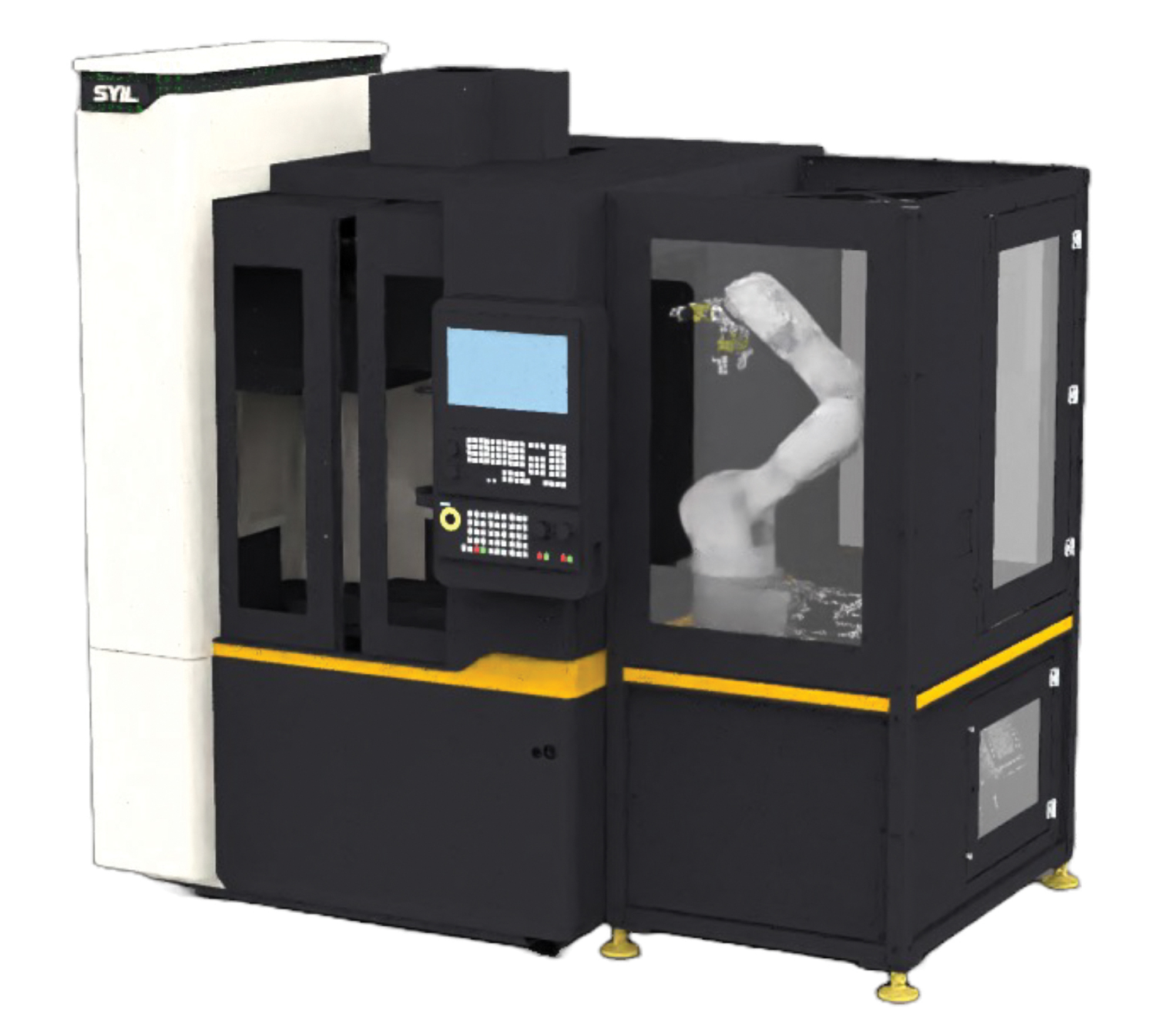

Through a technology partnership that breaks new ground in the machine tool industry, Siemens presents an automation solution for the busy, multi-tasking, small to mid-sized machine shop, as it combines a digital twin of the software and programming of its popular SINUMERIK 828 CNC, working in tandem with a KUKA robot, to simplify the operation and programming in part handling for the machine tool operator. Bringing the concept to life during a recent tradeshow, KUKA Robotics Corporation demonstrated the same control and its robot working in tandem with a SYIL vertical milling machine. The machine featured the SYIL R1 machine-tending automation package, developed with one of KUKA’s System Partners, Waybo, which seamlessly integrates the pick-and-place, part articulation and communications with the CNC onboard, all at a very attractive price point.

The goal of the program, according to Frans Buikema, Chief Marketing Officer at SYIL, is to offer the small and mid-sized shops an entry point into automation without major capital investment. Likewise, as Ron Bergamin, Key Technology Manager for Machine Tool Automation at KUKA, adds, the ROI can be very short, as this automation advancement allows the addition of a lights-out second or third shift at job shops of almost any size. Automation is the key and this cooperative engineering venture has opened a new chapter for small to mid-sized machine shops.

Simplifying robotics through the CNC

A bit of history. Only a decade ago, the integration of a robot with a machine tool required a separate learning curve for the shop, as robotics required special programming and teach-in communications, a separate pendant for operation and other challenges that often required outside consultants to implement. For small and mid-sized machine shops, this barrier, combined with the cost involved, resulted in today’s market condition, where less than a quarter of the smaller job shops in America today utilize automation and especially robotics in their workday.

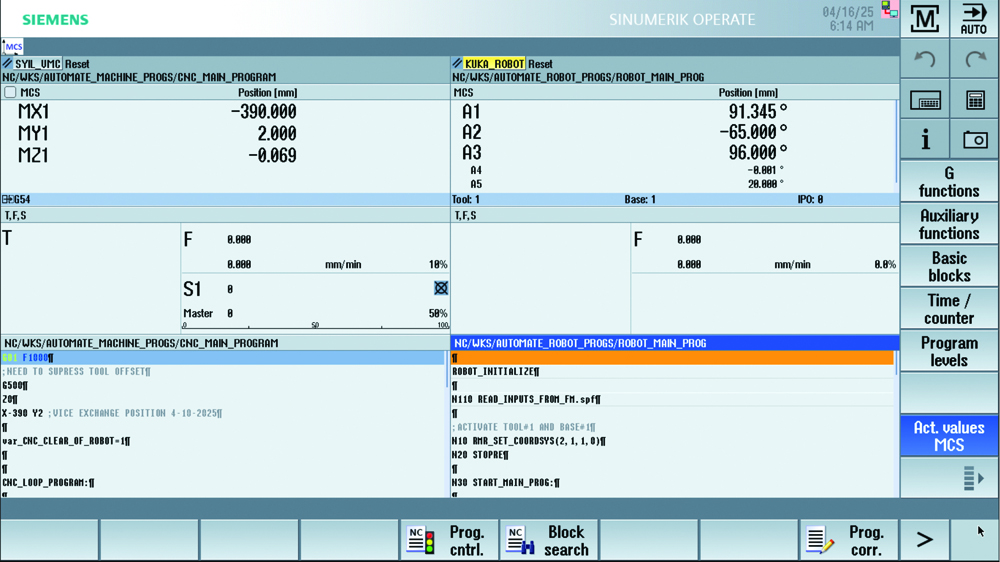

History has advanced. As Tiansu Jing, Product Manager, SINUMERIK CNC systems, explains, “The benefits of this development for the busy job shop are many. Setup, programming, operator interface and diagnostics are all improved with the SINUMERIK Run MyRobot /Handling application, as it easily incorporates the KUKA robot with the SYIL machine tool.” The teach-in functions are implemented through the SINUMERIK Operate HMI system on the control, while the proprietary SINUMERIK Run MyRobot /Handling capability of the CNC seamlessly integrates with the KUKA robot control. Jing further noted that, since there is no need to learn robotic programming, start-up time is reduced and the robot’s separate control pendant is eliminated, simplifying the operator’s task. The SINUMERIK control’s HMI is used to operate both the machine tool and the robot tender, with all commands and operating conditions displayed on a single screen. He also added that the greatest value for the busy job shop comprised the system’s ability to integrate robots on all its machines, while economizing the learning curve for all the operators. This entire cooperative venture between Siemens, KUKA and SYIL made this advancement possible, Jing noted.

From complexity to clarity

The SINUMERIK 828D CNC utilized in this application is designed for the job shop market’s use of turning centers, milling machines and Vertical Machining Centers (VMCs), but it also offers machine builders and end-users the flexibility to enhance the productivity of those machines with this new robotic automation, integrated directly into the control. As Jing points out, “The 828 is scaled to the functionality of the standard machines sold to the smaller job shops. With Run MyRobot /Handling included, programmers can use the same G-code for the robot and the machine tool.”

Designed for the job shop including affordable lights-out manufacturing

As Ron Bergamin of KUKA notes, “Machine builders can now offer robotics from KUKA PLC mxAutomation, a universal PLCopen-certified PLC interface. It allows the user to program and operate all important robot functions directly in a busy shop’s familiar control environment.”

Jing further adds that the Run MyRobot /Handling application allows the machine builder to offer robotics as another option, at a far more affordable price than in the past, as all the engineering effort has been substantially reduced. With the connection of Ethernet and safety cables to the robot, the SYIL customer finds it’s much easier to connect the robot. Bergamin adds that the robot can be up and running in a day, in most cases. “With the addition of a lights-out second or third shift at the shop, the spindles keep turning and the shop makes more money. Plus, the ROI is very fast with this setup.”

Jing concludes, “The machine builder can easily add their own robot specific screens to display the robot tasks and improve the usability. This solves long-time challenges for both the machine builder and end-user alike. Machine tool builders like SYIL can now offer robotic packages to their customers with less price pain and more advantages in the shop.”

Philip Peloso, Business Development Manager for Machine Tool Automation at KUKA, expands, “We saw a resident robotic talent gap as well as price resistance in the smaller machine shop sector and decided we needed to pursue a solution. We turned to our Official System Partner, Waybo, presenting them with the facts. This solution would be an entry-level venture, addressing the 75% of the job shops who currently have no robotic automation on their floors. We sought to present them an easy-to-use, robust system that allowed quick changeover for the busy shop doing multiple jobs or families of parts during the day.”

As KUKA has a longtime relationship with Siemens, their combined support in the field would bring a further benefit to the solution. Once developed, this new system was presented to SYIL, who adopted it as their SYIL R1 solution for the job shop market. Peloso cites the key value proposition. “All meaningful controls and diagnostics were to be displayed on the CNC, thereby reducing or eliminating all the previous roadblocks for the shop personnel.” All the motion control of the grippers, pick-and-place functionality and communications with the CNC on workholding are seamlessly transmitted from an application layer on the KUKA robot, so all commands are configured and programmed to take instructions directly from the CNC.

Ron Bergamin further notes, “Working with Waybo, we developed the automation around the robot. A new interface layer, run through our standard mxAutomation software, allowed the robot control from the Siemens CNC, so a single pendant is all that’s required to run the SYIL machine tool and the robot package. All diagnostics are under the hood,” Bergamin muses.

A new benchmark for machine tool builders

On the tactical business level, Siemens had been providing CNC technology to SYIL globally and brought the concept of robotic integration to KUKA, who worked closely with their partner Waybo to design and implement the package that became SYIL R1 automation.

Frans Buikema of SYIL details this development from the machine builder perspective.

“We’ve long had automation in our company’s vision and road map for the future. As we focus on the small and mid-sized machine shop world, we constantly encounter the lack of skilled labor, the price resistance and the shortage of robotic knowledge in this sector of the machine tool market.”

Wesley Wang, Managing Director for SYIL in North America, adds, “We have recently partnered with Titans of CNC to market our machines here and we feature the SINUMERIK 828D CNC on most of our equipment, as it offers great motion control, monitoring and communications capability, plus the onboard capacity to engage machine tending robotics, which opens the 24/7 running option to our customers in ways they have not imagined in the past.

Real results on the shopfloor

Buikema cites some hard numbers. “We believe we can tell our customers that automation is accessible today in new and exciting ways. It is decidedly not too complicated nor is it a major capital investment. For a $60,000 package, they can be looking at a payback period of a year or less.” Wang adds, “It’s all about knowing your options today and how different they are from the not-too-distant past in the machine tool world.”

Expanding the vision

SYIL currently designs and builds CNC milling machines, CNC turning centers and CNC Swiss type lathes. According to Buikema, “This development with Siemens and KUKA represents our own entry into robotics and we plan to expand the use of such packages onto all our machine offerings very soon.” He calls the implementation of the SINUMERIK 828D CNC with Run MyRobot/Handling “… a real game changer, because it enables us to start creating more automation packages and make them accessible to our audience, the small to mid-sized machine shops.” The SYIL R1 automation package utilizes the same technology integration shown by Siemens and KUKA during recent tradeshows in the industry.

Commenting on the relationship between SYIL and Siemens, Buikema observes, “It grew from supplier to strategic partner very quickly. The engineering support at Siemens collaborates with our own machine tool engineers at SYIL on virtually all new machine developments at our company. This enables us to expand our machine range much faster and better than we could do on our own. That’s true synergy.”

Of equal importance, Buikema cites the support his company gets from Siemens in the North American market. “The help they provide to our dealers in Canada, the United States and Mexico is invaluable. It allows our dealers not only the ability to sell a higher level of machine and automation, but also the software support to fulfill the needs of all our end-users.”

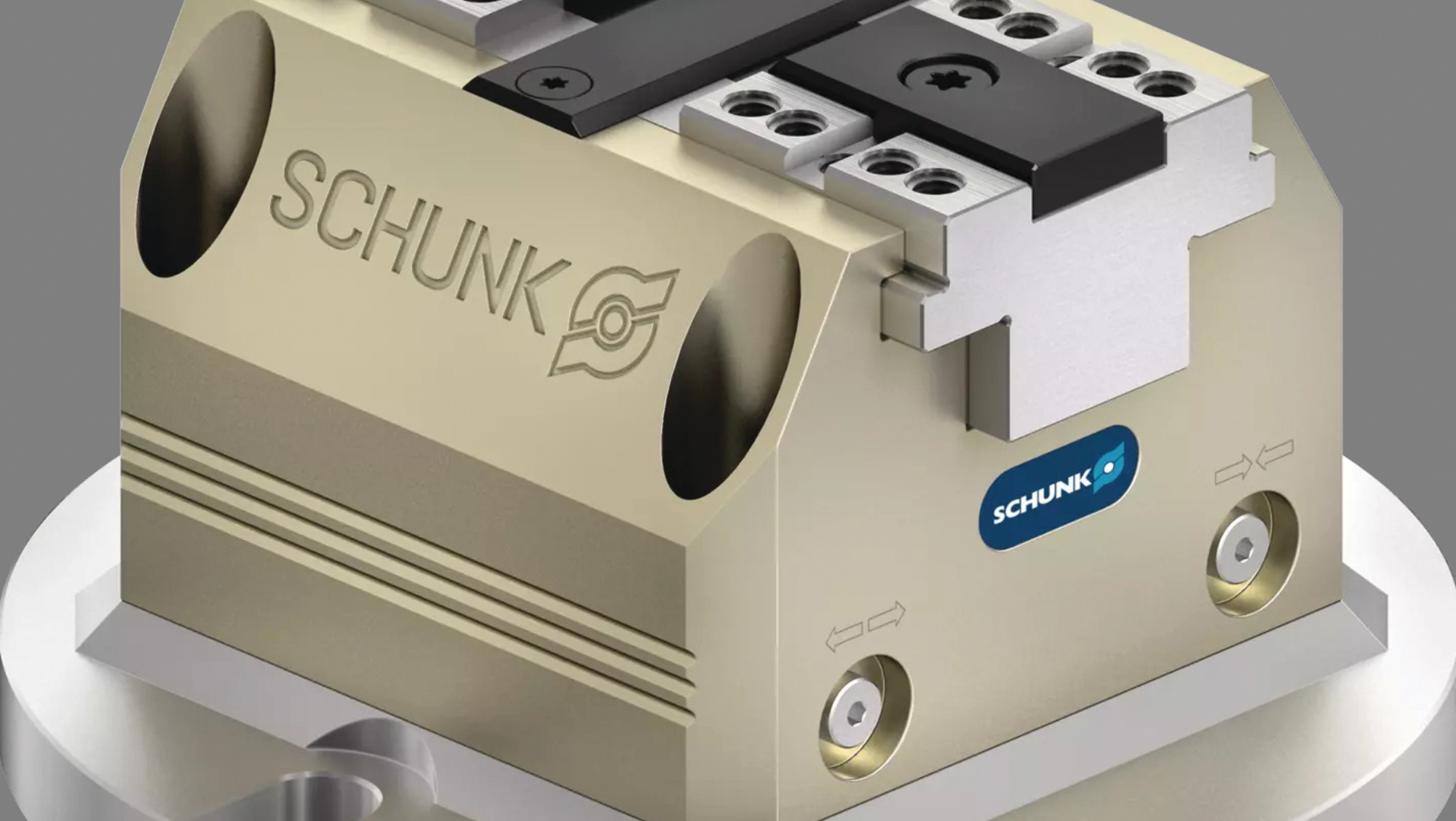

The SYIL R1 machine tending system, incorporating the KUKA robotic technology, is currently offered as a standard package by the machine builder, for parts up to 3kg (6.61 lbs.), a payload of 6.7kg (14.77 lbs.) and a reach of 901 mm (35.47 in). It offers an IP65/67 rating for harsh operating environments. It facilitates the loading and unloading of metal parts from the cutting zone and workholding devices being utilized, plus it is quick to install and easy to operate from the SINUMERIK 828D control. The R1 system from SYIL removes the manual and repetitive tasks for a CNC machine operator by automating the load/unload process. It is an ideal solution for high-mix, low-volume tasks and can be fully integrated with parts conveying systems, bins and pallets. The R1 system is offered with a standard workholding package, featuring pneumatic clamping force block design, as well as a dual gripper option when the finished part has a differing final shape from the blank.

In addition, the SYIL R1 system features an “everything on one screen” format, integrating the robot’s programming and operation in the SINUMERIK 828D control, using NC G-code and robot teach-in function for programming. This makes it very easy for machine tool operators to learn and use. All the robot diagnostic data is shown on the same HMI as the machine, allowing the entire automation cell to be monitored without the need for a second pendant.

According to Buikema, the SYIL R1 automation package can be installed and fully operational in less than one day. The system is expandable with custom solutions and various pallet drawers provided.

The future of shopfloor automation

Increasingly more job shops and machine operators are seeing that automation is an important asset when striving to achieve consistent workpiece quality and more flexibility on the shopfloor. Digitalization facilitates the higher level of automation needed and the networking

of the components involved. With this new development, Siemens is offering a cost-effective solution that incorporates the KUKA robot functionality with a line of affordable machine tools, in this case, the SYIL brand of machining centers and lathes for small to medium job shops.

From the KUKA perspective, Ron Bergamin comments, “KUKA offers machine tool builders and end-users alike the ability to incorporate advanced robotics into their equipment and onto their shopfloors, with the goal of optimizing productivity and reducing operator workload. Our partnership with Siemens has resulted in the synergy that brought this development to life.

It substantially expands the ability of the small and mid-sized shops to utilize robotics in their work environment.”

To watch a video of this system in action, please visit:

http://usa.siemens.com/kuka-syil

For more information on this technology story, please contact:

Siemens

Tiansu Jing or John Meyer

tiansu.jing@siemens.com

john.meyer@siemens.com

KUKA

Ron Bergamin or Philip Peloso

ron.bergamin@kuka.com

philip.peloso@kuka.com

SYIL

Frans Buikema or Wesley Wang

frans@syil.com

wesley@syil.com