Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Powered by the SINUMERIK ONE CNC platform and Ingersoll’s MasterPrint® industrial 3D printer, a new generation of deployable machines is bringing additive and subtractive manufacturing directly to the point of use.

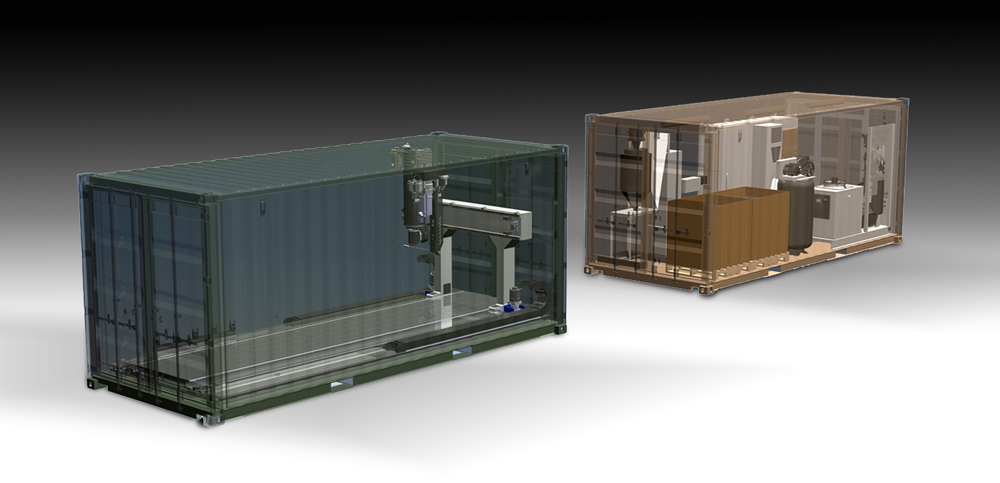

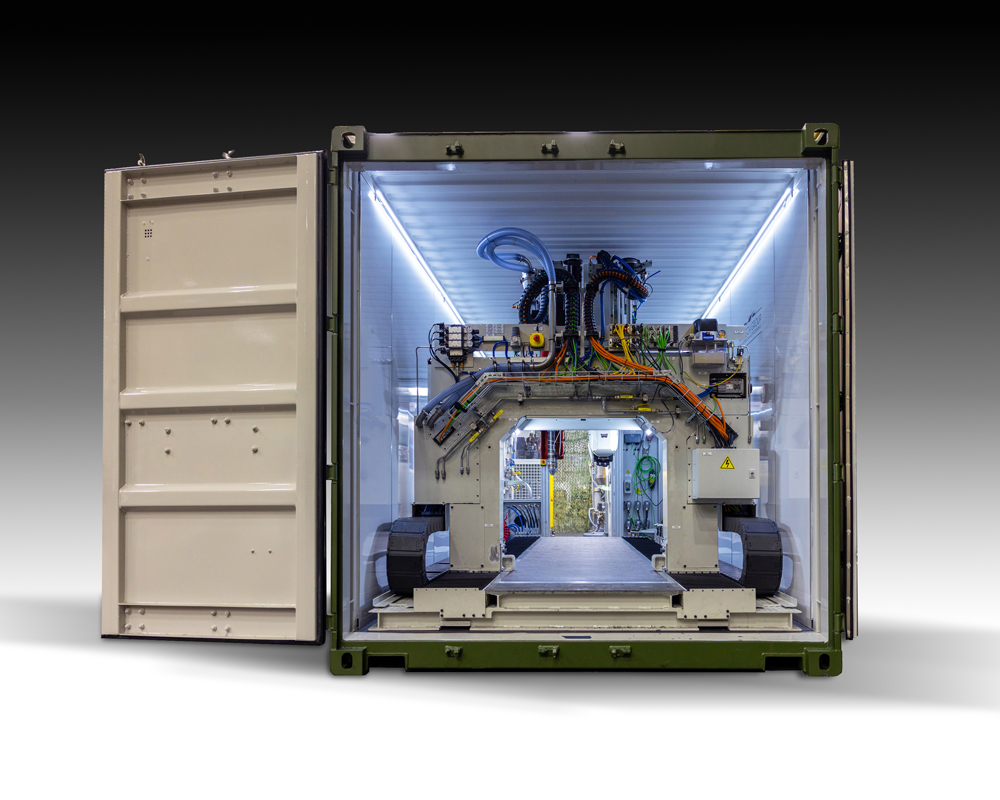

Siemens and Ingersoll, a 133-year-old Rockford, Illinois builder of high-quality, large-format machine tool solutions, have enjoyed a long-standing relationship of business cooperation, engineering dynamism and executed achievements in automated machine technology. That tradition continues today with Ingersoll’s new generation of its “machine in a box” concept, the MasterPrint® Deployable, designed to be an application-specific, portable machine tool, featuring the company’s unique combination of high-speed additive manufacturing and precise 5-axis milling. MasterPrint® Deployable is compactly housed in two 20-foot containers and allows Ingersoll’s customer to send the unit to its point of use as a free-standing manufacturing entity, with all the necessary hardware, software and tools onboard to complete a specific function.

Powered by the digital-native SINUMERIK ONE CNC, MasterPrint® Deployable “opens the possible,” as Zach Gray, Additive Business Development Manager at Siemens, notes. “We were challenged by Ingersoll, as we always are, to think outside the box and yes, that’s a pun, in this case, given the nature of the final machine.” For the initial project, the machine needed to incorporate an additive material extruder, designed by a third party, with full environmental and motion control, plus a gantry and milling head for material removal and finishing, with full capability for onsite adaptation to various conditions and climates.

As Jason Melcher, Vice President and Sales Director of Composite and Additive Technology at Ingersoll, comments, “On the first project, we knew very little about the application, as it was confidential, so we had the empty space of a Conex box as our starting point.” The Conex box is a commercially available item, heavily altered by Ingersoll. The innovation comes with the alterations to make this structure and space a plausible environment capable of carrying a large industrial 3D printer, CNC milling machine, controls and power supply to the point of use. Melcher continues, “Cooperation with our key suppliers was vital on this project and we knew we could rely on our years of experience with Siemens to assist us. As usual, our Siemens partners had less concern about the end-product and put greater emphasis on the process. This gave us confidence that we could journey together in the creation of this unique machine.”

In future applications, the same MasterPrint® Deployable technology might be used with thermoplastic or metal additive materials, applied through cold spray, Directed Energy Deposition (DED), blown powder, Wire Arc Additive Manufacturing (WAAM), friction stir or other technologies, then milled on the same machine to produce the final part. A Deployable Automated Composite solution is also possible. Applications could range from aerospace and defense to energy, R&D and even disaster relief uses in very hostile environments. Also, through the power of the CNC, robotics can also be integrated and controlled. Keeping the machine technically competent under all such circumstances is a challenge for both the Ingersoll and Siemens teams. That’s where the “future ready” technology of SINUMERIK ONE really shine. With its high-fidelity digital twin technology, the entire process can be programmed and visualized with real time operation virtually, before the machine is built. This provides Ingersoll the ability to offer the MasterPrint® Deployable solution for various applications, across a wide range of industries, including the marine industry and residential construction.

Andrew Ramirez, Siemens Account Manager for Ingersoll, adds, “Our relationship with this customer presents us new and exciting challenges all the time, and that’s very rewarding … and fun, because we can leverage our technical knowledge and collaborate with our engineering teams to address the job at hand. When it works as well as it does on MasterPrint® Deployable, that’s very satisfying as an account manager who gets to see innovative solutions come to life.”

Melcher echoes that thought, “We know Siemens has decades of experience in CNC, software development and problem-solving in the machine tool world. They bring a very open-ended attitude to our needs and, together, we produce solutions that benefit our Ingersoll customers in many ways.” In this case, it was necessary to have modifications made to the process and the combination of Ingersoll machine technology and engineering, with the Siemens control environment helps to produce a functional and flexible ecosystem for manufacturing in the field. The Siemens SINUMERIK ONE CNC, Melcher notes, incorporates all the variables and can work up solutions, prove them out virtually, then produce a functioning machine, with the added benefit of accepting variables onsite and adapting the control parameters to manage them.

A further testament to the Siemens value at Ingersoll, is training, according to Jason Melcher. “We’ve worked with all the major CNC control manufacturers and we’ve seen Siemens expand its technology, but also its training mindset. Today, they provide us training both on the operation of the control and the integration of it into the manufacturing process, something we can then share with our customers to get them running more efficiently from the start.”

On the MasterPrint® Deployable application, Zach Gray cites three key concerns.

SINUMERIK ONE plays a central role in the transformation of machine tools in the age of Industry 4.0, outperforming previous generations of controllers in terms of PLC and CNC machine operation, cutting speed, data capture and processing power. With its integrated SIMATIC S7-1500F PLC, the SINUMERIK ONE control offers up to 10 times faster PLC cycle times. Thanks to the PLC, SINUMERIK ONE is now fully integrated into the Siemens TIA Portal engineering framework, enabling standardization of all engineering tasks for operators of larger format machines. This generation of Siemens CNC is fully compatible with the previous SINUMERIK 840D sl controller generation in terms of programming and operation. This made the changeover to SINUMERIK ONE more seamless for Ingersoll and, as Jason Melcher notes, the training supplied by Siemens made the process faster and easier for Ingersoll and its first customer for MasterPrint® Deployable.

With SINUMERIK ONE, Siemens offers CNC technology that easily creates and works with digital twins of machine tools. Work preparation teams and engineering departments can also benefit from the digital twin. Siemens offers a comprehensive user interface for SINUMERIK ONE that enables convenient, flexible and efficient operation of machine tools across all machining technologies, including additive, subtractive and, in this case, both, as well as composites with chopped carbon fibers.

While under development at Ingersoll, the unit was powered by standard factory 480V power. The transformer supplied “in the box” connected to the customer’s on-site generator in the field for immediate startup, according to Jason Melcher.

On the topic of the overall benefits of the relationship with Siemens, Jason Melcher says, “We wanted to produce the largest possible workspace in the footprint provided by our customer. Siemens was very helpful, as they always are, in not letting us overreach the capabilities of the control and its processes. That’s the optimum contribution a partner can make and, combined with their technology and training, we are confident we derived the best solution for the customer’s application and their logistics.”

From the Siemens side, Zach Gray concludes, “This MasterPrint® Deployable application was an exciting challenge for Andrew (Ramirez) and me. With all the other technologies we know we can incorporate into this Ingersoll concept, including robotics, it really does open the possible up for our customer and us.”

Website:

usa.siemens.com/ingersoll