Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Over 100 axes of motion can be engaged on system architecture

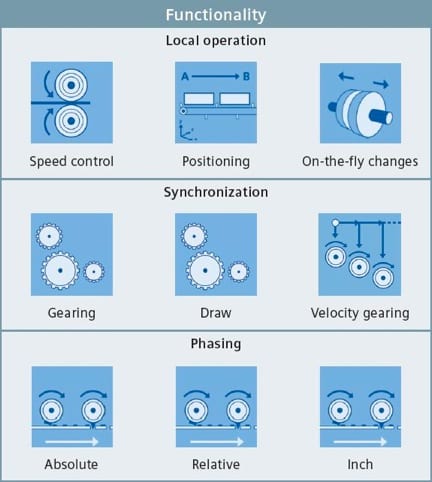

To maximize the make-ready and uptime efficiencies of the line, it is often necessary to electronically decouple line sections for plate changes on the fly. With today’s drives, drive controls and electronic feedback devices, in addition to this Siemens solution suite, it is now possible to synchronize all drive sections to streamline the process.

Synchronized Drive Control is a ready-to-use solution dedicated to the synchronization of all motion functions, whether local or synchronous. It can be implemented in minutes and includes comprehensive documentation. As an open source application, Simotion SDC is immediately customizable for the printing line or converting machine’s specific requirements. Integrated WinCC Flexible HMI is ready-to-use during development, commissioning and operation of the line, as well.

Simotion SDC can synchronize all motion functionality between multiple Simotion motion controllers over a Profinet network, allowing 100+ axes to be engaged on the system architecture simultaneously or grouped, as needed.

This solution can be applied to gravure, offset, flexo and digital printing presses in wide, mid-range and narrow web format, as well as a broad range of finishing equipment including binders, stitchers, inserters, collators, polywraps, conveyors, grippers and stackers. Simotion SDC is further complemented by the Siemens Converting Toolbox for use on a full range of winding, web transport and tension management systems.

For more information about this solution, please visit www.usa.siemens.com/printing

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.