Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

This Grieve batch oven features 6” insulated walls throughout, aluminized steel exterior, Type 304 stainless steel interior, a manual, counterweighted rear-hinged door, workspace floor reinforced for 100 lb. loading, access door at each end of the oven, plus swivel casters with swivel locks and wheel brakes for easy in-plant portability.

Controls on No. 988 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve walk-in batch oven features 4” insulated walls throughout, aluminized steel interior and exterior, plus a four-position vacuum manifold, with gauge and hand valve for each position.

Controls and safety equipment on No. 990 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller. An integral five-point thermocouple jack panel is installed through the oven wall.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve furnace features 7” thick insulated walls, comprising 5” of 2300ºF (1260ºC) ceramic fiber and 2” of 1700ºF (927ºC) ceramic fiber, plus 7-1/2” floor insulation, comprising 4-1/2” of 2300ºF (1260ºC) firebrick and 3” of 2300ºF (1260ºC) block insulation. An alloy roller rail is supported by firebrick piers and the alloy loading fixture (shown in photo) with five 200 lb. capacity alloy shelves is provided with an external support roller rack to hold the loading fixture directly in front of the furnace’s workspace for easy loading/unloading. The unit also has an electrically-operated vertical lift door.

Special Grieve inert atmosphere construction includes a continuously welded outer shell, high-temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet and inert atmosphere outlet.

Controls on No. 989 include an inert atmosphere flow meter and pressure regulator, digital programming temperature controller, manual reset excess temperature controller with separate contactors and a strip chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve top-loading oven features 4” thick insulated walls, aluminized steel exterior, Type 430 stainless steel interior, four independently hinged doors to expose the front and back of each loading station, steel plate oven floor and a workspace floor reinforced for 100 lb. loading on 1/4” plate.

Controls on the No. 984 include four special automatic door switches to shut off blower and heat when any door is opened, plus a digital programming temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

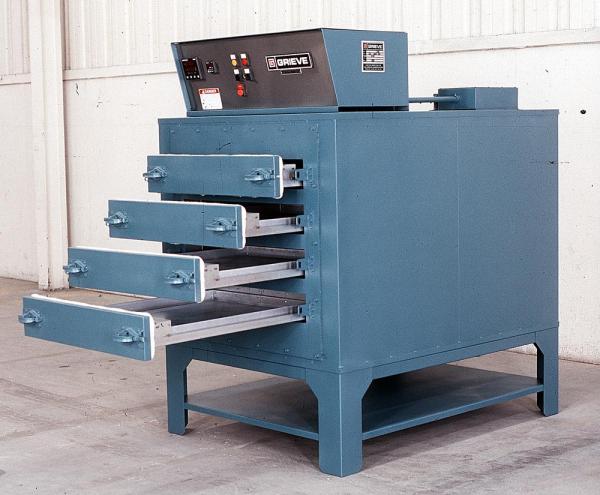

This Grieve oven features 4” thick insulated walls throughout, Type 304, 2B finish stainless steel interior and aluminized steel exterior. The unit is equipped with four drawers, each 24” W x 30” D x 2”H and rated for 50 lbs. loading. The drawers open to extend a full 20” from the front of the oven for easy parts handling. An integral leg stand is also provided on this unit.

Controls on No. 977 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This cleanroom oven features 4” insulated walls, a Type 304, 2B finish stainless steel exterior with 1/2” inside radiused corners and all interior seams are welded, ground and polished. The stainless steel exterior with #4 brushed finish has continuously welded seams. The unit has single access doors, front and rear.

No. 962 from Grieve includes a red pilot light to indicate when the oven’s opposite side door is open, solenoid-operated door locks and 650 CFM intake pressurizing blower. Also onboard are a 24” x 24” x 6” thick HEPA fresh air filter with 2” prefilter, a 24” x 24” x 6” thick stainless steel, high temperature HEPA recirculating filter, plus a minihelic pressure gauge and DOP validation port across each set of filters.

A digital programming and recording temperature controller activates the dampers and locks the access doors during a cycle. A recirculating blower airflow safety switch turns off the blower and heat whenever a door is opened.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

A motorized roller rack is onboard with two levels of 4” dia. driven rollers, each supported by metallized carbon bearings. Each level of rollers holds two 20” dia. stainless steel perforated drums, rotating at 6 RPM, which carry the workload. The rollers are driven via sprockets and a roller chain, exterior to the oven rear, by a 3/4 HP AC motor with inverter variable speed control, gear reducer and torque limiter.

This Grieve walk-in oven features 4” thick insulated walls throughout and an aluminized steel interior and exterior. There’s also a top-mounted heat chamber, single front door and an access door to allow cleaning of the heaters.

Controls on No. 973 include a 10” dia. circular chart recording and programming temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve conveyor oven features 4” thick insulated walls throughout, an aluminized steel exterior, Type 304, 2B finish stainless steel interior with continuously back-welded seams and all wall penetrations fitted with compression fittings. The oven is split into two sections for shipment and reassembly at the customer’s location. Side access doors to the workload and heating chambers are located along the entire length of the unit.

Controls on No. 972 include digital indicating temperature controllers, manual reset excess temperature controllers with separate contactors, recirculating blower airflow safety switches, 10” diameter, two-pen circular chart temperature recorders and SCR power controllers for the heating zones.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

The hearth is driven by a 1/4 HP motor through a gear reducer with torque limiting device, variable from 0.1 to 0.5 revolutions per hour. A loading table is provided in front of the oven to hold extra pin inserts (shown in photo).

This oven features an aluminized steel exterior and interior, an exhaust hood around the openings in the face of the unit with a 130 CFM exhaust fan, plus an integral oven leg stand. The 8” thick wall insulation comprises 2” of 1900ºF block and 6” of 10 lb/cf density rockwool.

Controls on the No. 982 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, fused disconnect switch and a 10” circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve cleanroom oven features 4” thick insulated walls throughout and a Type 304, 2B finish stainless steel interior with 1/2” inside radius corners, all seams welded, ground and polished. The stainless steel exterior has a #4 brushed finish. The unit is equipped with front and rear access doors for pass-through to the cleanroom plus an integral wall sealing flange. A red pilot light onboard the oven signals when the opposite door is open. All door hardware is chrome plated.

For Class 100 cleanroom compliance, this cabinet oven has a 12” x 12” x 6” thick HEPA fresh air filter with 2” prefilter and a 30” x 24” x 6” thick stainless steel high temperature HEPA recirculating filter.

Controls on No. 971 include a minihelic pressure gauge and DOP validation port across each set of filters, digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, 10” diameter circular chart temperature recorder, fused disconnect switch and an SCR power controller.

A stainless steel loading truck with six removable pans and a transfer dolly with oven-to-dolly and dolly-to-truck latches are also furnished with this Grieve oven.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP