Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Remember this? Star Wars is a great example of maximum creativity in the imagining and depicting of innovative, futuristic gadgets and concepts (meanwhile, creativity for costume design = minimal, pretty sure they all just wore potato sacks and bedsheets)

What’s even more impressive is that THIS IS HAPPENING.

Recently, Watry Industries, LLC exhibited at the AFS 118th Metalcasting Congress and handed out these cards at their booth:

Download the actable™ app for Android, iPhone or iPad and hold the scanner up to the card. Yes – you can even hold it up to a computer screen or the screen of another phone or tablet and scan! Or, if you’re stuck in the dark ages, you can print the card out and scan to play 🙂

See a quick video of the whole thing going down >>HERE<<.

Augmented reality is emerging full force and making big splashes (ex. Pepsi in London and Lego). Computer-generated sensory input (sight, sound, feel) can change and enhance the way we interact with just about anything!

Well done, Watry. We applaud this shiny new toy.

—

Watry is a permanent mold aluminum foundry in Sheboygan, Wisconsin. They take part design and do all of the following, all in-house.

That’s their single-source promise.

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

Wisconsin foundry adding value to parts produced

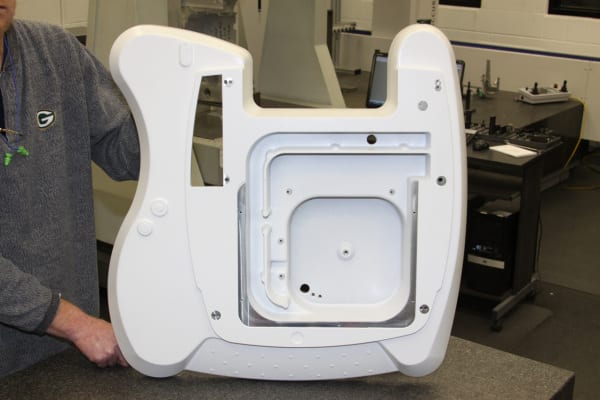

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house.

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house. Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.

Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

Experts at the nuances of powder coating parts produced in all metalcasting processes, as well as powder application on stampings, extrusions, weldments and assemblies, Watry is able to provide their services on castings made by other processes as well as steel, iron and various alloys.

Watry is capable of masking features before painting as well as blowing off un-cured powder in areas where masking is not practical. The Nordson Cyclo-Kinetic reclaim booth, utilizing both manual and automatic guns, is capable of applying the most demanding and high temperature powders, reaching the most difficult areas on any workpiece. In addition, reclaiming the powder that does not adhere to the part during the application process helps control overall costs.

Watry’s roof mounted cure oven, encompassing over 250 feet of conveyor track and operating at temperatures up to 500º F, can cure powder on the largest and heaviest parts at very high line speeds, providing another cost-controlling feature.

Strict quality control systems and procedures include film thickness checks, adhesion testing, color verification and paint hardness testing to ensure compliance to customers’ most demanding requirements.

To watch a video on the Watry powder coating operation, please visit http://www.watry.com/video_library.html

For more information on this release, please contact:

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online: