Contact us today:

Author Archives: Bernard and Company

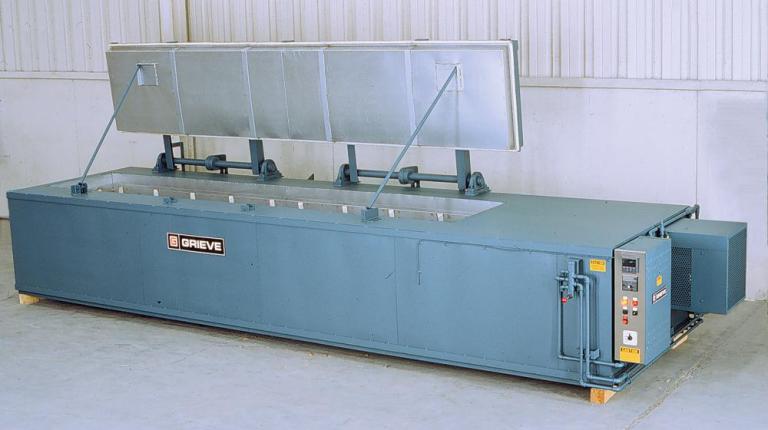

Jumbo Electric Walk-in Oven from Grieve

This Grieve jumbo walk-in oven features 4” thick insulated walls, removable top-mounted heat chamber (shown in the right foreground of the attached photo), aluminized steel interior and exterior, door seals eliminated and doors equipped with drag seals, plus the unit was constructed to split into four sections for shipment to the customer’s location.

Oven controls on No. 976 include a 13,500CFM powered forced exhauster (shown in the left foreground of the attached photo) and other safety equipment required to handle up to two gallons of flammable solvent at 370ºF (~188ºC). Also onboard are a digital programming temperature controller, SCR power controller and motorized dampers on the intake and exhaust for accelerated cooling and rapid purging. This Grieve jumbo walk-in was built to NEMA 12/NFPA 79 electrical standards.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

High-temperature Cabinet Oven from Grieve

This Grieve cabinet oven features 11” thick insulated walls, comprising 2” of 1900ºF (~1038ºC) block and 9” of 10 lb/cf density rockwool insulation, as well as an aluminized steel exterior, Type 304 2B finish stainless steel interior, plus inner and outer door gaskets, with the inner gasket sealing directly against the door plug and the outer gasket sealing directly against the face of the oven for optimum seal integrity.

Oven controls on No. 965 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, 10” diameter circular chart temperature recorder, plus an an SCR power controller and fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Large Capacity 500ºF Top-loading Oven from Grieve

No. 802 is an electrically-heated, large capacity top-loading oven from Grieve, currently in use drying water from spinnerette packs. This unit has a maximum operating temperature of 500°F and workspace dimensions of 13’6” W x 28” L x 24” D.

A 100 KW heat input is installed in Incoloy sheathed tubular heating elements, while a 4,200 CFM, 3 HP recirculating blower provides horizontal front to back airflow across the load.

This large capacity Grieve oven features 4” insulated walls throughout, an air-operated door, reinforced 1/4” steel plate top, wear bars at all sides of the workspace and a reinforced floor for 3000 lb. loading at the removable subway grating.

No. 802 also includes a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and a cycle timer.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500ºF (260ºC) Class 100 Cleanroom Truck Oven from Grieve

This Grieve cleanroom oven features 4” thick insulated walls throughout, aluminized steel exterior, Type 304 2B-finish stainless steel interior with continuously backwelded seams, exterior finished with white epoxy paint, #4 brushed finish stainless steel door and control panel face. The unit includes a 4” insulated floor with removable truck wheel guide tracks.

In addition, No. 970 has a 325CFM stainless steel powered forced exhauster, two 24” x 30” x 12” thick stainless steel high-temperature HEPA recirculating air filters, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and a 10” diameter circular chart recording temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500ºF Electric Top-loading Oven from Grieve

This unique top-loading oven has 4” insulated walls throughout, aluminized steel exterior and interior, a motor-operated rear-hinged door opening the top and front of the oven chamber and a workspace floor reinforced for 7200 lbs. loading onto the 1/4” steel plate surface.

No. 955 features a digital programming temperature controller with two channels providing two independent zones of temperature control. The oven also has onboard two manual reset excess temperature controllers with separate contactors and four recirculating blower airflow safety switches.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Two Zone 650ºF Walk-in Oven from Grieve

A 100 KW heat input is installed in each zone in Incoloy sheathed tubular heating elements, while a 12,500 CFM, 10 HP recirculating blower provides horizontal airflow to the workload in each zone. A top-mounted heat chamber is located above each heating zone, as well, on this Grieve oven.

No. 803 features an aluminized steel interior, motor-operated vertical lift door with foot switch at each end of the oven and a reinforced floor and support stand to raise the oven floor to meet the customer’s conveyor height.

Controls on this Grieve oven include a digital indicating temperature controller and manual reset excess temperature controller for each zone, as well as a two-pen circular chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

1600°F Gas-fired Furnace

This unique Grieve furnace features 5” thick insulated walls throughout, comprising 2” of 2300ºF ceramic fiber and 3” of 1900ºF block insulation. In addition, 6-1/2” floor insulation is made from 4-1/2” of 2300ºF firebrick and 2” of 1900ºF block insulation.

Three air-operated vertical lift doors seal the workspaces, while three independent timers are provided, each with a pilot light, audible alarm and safety door interlock, to individually time the process cycle in each furnace compartment. A tower light is onboard to indicate operational status.

No. 875 is built to JIC/NEMA 12 electrical standards.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

350ºF (177ºC) Gas-fired Walk-in Batch Oven

This large-capacity Grieve walk-in batch oven features 4” insulated walls throughout, aluminized steel interior and exterior, three independent doors for workspace access on the front of the oven, standard double doors on the rear of the oven, 2” insulated floor with three (3) pairs of built-in truck wheel guide tracks and integral 6” I-beam supports to raise the oven above the factory floor level.

All safety equipment required by IRI, FM and National Fire Protection Association Standard 86 for gas-heated equipment are onboard No. 942, including a 325 CFM, 1/3 HP powered forced exhauster for quick purge and cool down, dampers on the intake and exhaust for accelerated cooling, as well as a 10” diameter circular chart recorder and digital programming temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

1250ºF Electric Inert Atmosphere Batch Cabinet Oven from Grieve

Workspace of this unit measures 36” W x 96” D x 36” H. 60KW are installed in Incoloy sheathed tubular elements to heat the oven, while a 4,000 CFM, 3HP recirculating blower provides universal airflow to the workload.

This Grieve cabinet oven has 10” insulated walls throughout, comprising 2” of 1900ºF block and 8” of 10 lb. density rockwool, as well as a 16 ga. stainless steel interior and integral oven leg stand. A 975 CFM blower is onboard to pull air through the air jacket of the inner oven for cooling. The oven is constructed to JIC/NEMA 12 electrical standards.

As an inert atmosphere oven construction, No. 805 also includes a pressure regulator, flow meter, pressure gauge, internal high temperature gasket, bellows type seal in the doorway, 1/2” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations equipped with compression fittings.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

500ºF Electric Walk-in Batch Oven from Grieve

This Grieve walk-in oven has 4” insulated walls throughout, aluminized steel exterior and interior, 2” insulated floor with built-in truck wheel guide tracks, exhaust hood over the oven doors equipped with an 18” diameter tubeaxial fan driven by a 3/4HP motor and an integral door switch to start the hood fan when the doors are opened, then shut down the fan when the doors are closed.

No. 993 also provides many added safety features, including a 325CFM powered forced exhauster, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating airflow safety switch, 10” diameter circular chart recorder and a 30-hour oven shutdown timer.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP